Leaderboard

Popular Content

Showing content with the highest reputation on 03/01/24 in all areas

-

Apart from the “picture from the mound” timelapse blog entry, there’s not been much of an update since mid September 2022. So, get your preferred hot drink (maybe a SteamyTea), and settle back for the next instalment. Where were we? SWMBO was still in recovery from her foot infection - you remember? The one that might have killed her? The second floor ICF had been installed, and the concrete poured. I’m still going to spare you any pictures of the foot, but here is a concrete pump truck instead. So, next on the list - a roof please. But before that, the final steel beams had to be installed [FX - thumbs twiddling in the foreground and whistling can be heard as we wait for the steelworker once again], but it wasn’t too long a wait, and by mid October 2022 we had the beams installed. In late October and early November I set to work with the ground worker to do some backfilling, and of course on the days I chose to have the digger onsite, Cornwall delivered some of its traditional autumnal weather so any attempt to properly compact anything was nigh on futile. In the meantime, more joists, endless sheets of T&G OSB, vapour barrier, 160mm deep sheets of PIR insulation, and some of the biggest screws are readied for ordering. The joists arrived in and in early December I had my supervisor and client (SWMBO) back on site 🙂, and she has graduated to being a mountain goat. She now refers to the site as her "happy place", even though we have a strong suspicion that the infection was started by a visit to a local beach. By mid April, with help from some now local family members, we’d installed the roof joists, and in mid May we were ready to start boardin’, vapour barrierin’, and insulatin’. The GRP was installed in mid July 2022 (by others). I’d also been readying the Great West Wall (GWW) to have the triple glazed sliding doors and windows installed (by others), and this took place in mid August, just in time for my significant birthday. There were some fitting errors, but I have to take my hat off to the installation company, they have been back to rectify their work, and have supported me with making the suppliers change some of the sliding door fittings as they were just not correct despite their protestations. In October, we had the mains electric and meter moved from their temporary location to inside the house. Over the ensuing autumn and winter months, we’ve been installing some of the final internal partition walls, running water pipes, installing more insulation around the GWW windows, and recently started on the ventilation ducting following some core drilling being undertaken (Tip: always ask for a hole to be drilled that is about 10mm bigger than you need - expanding foam is your friend. I donate my scar tissue to you all 😂) In December, I got made redundant. No worries, this may actually be a blessing in disguise. Next up on the list: Finish ventilation system Finish insulating the GWW Finish backfilling Electrics Floors Walls ASHP and HWC Kitchen Bathrooms The remaining plumbing Outer wall coverings But, in the meantime, we have the small matter of our daughter’s wedding. DOES SHE NOT KNOW WE’RE TRYING TO BUILD A HOUSE!? (Time to end: 2 years 🙂 )2 points

-

My house (EPC A rated) has done nearly 60 years so far. Stick built. Rgds Damon2 points

-

Or change it to two beams - one for each leaf.2 points

-

I've heard from more than one source that testing them (or having them open due to an over-pressure/temperature event) is the quickest way to cause them to fail.2 points

-

i'm fully aware of this trap and we fell in to it as well. now we're at the tail end of our build i advise you to reconsider. the stress of trying to find the money down the back of a sofa or having to do the work yourself to save money and watching the completion date move further and further in to the future is really hard. and then the extra costs involved in the mortgage payments as time slips and the money you try and save by doing stuff yourself just ends up getting eaten up in more mortgage payments is a bitter pill to swallow.2 points

-

Finished the Kore Passive Raft Foundation this week. Just in time as it's currently sleeting it down out there! Cold enough to make a pour more difficult. they set in a 70mm rebate for the lift & slide door and also cut out the kore to let the concrete out to the edge (up to shuttering) for a steel post to carry the blockwork over the two corner windows. We'll insulate around that later. the Kore went in really fast, then rebar, ductwork for the kitchen island and getting it finished before more cold weather kicked in. It rained just after lunchtime which slowed down the curing. But really pleased with progress and we're ready for the timber frame next!2 points

-

2 points

-

A false trilemma in my opinion, invented to market expensive products. With the right design in the first place, you get the optimum result. The right design requires a knowledge of design and of the construction process (weather and all) from the outset. An integrated process. Not the linear process of client , Architect, Engineer, builder.2 points

-

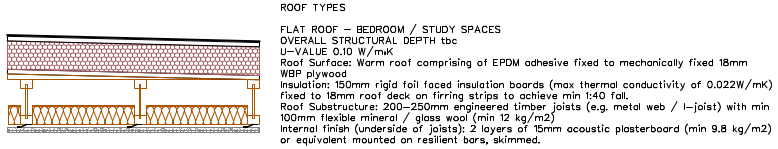

I don't think that the mass loaded vinyl will do a significant amount. 100mm acoustic insulation between the joists will be a better solution paired with resilient bars. However you need to be careful of the risk of interstitial condensation. This was our roof type I got a couple of insulation firms to do a interstitial condensation risk analysis based on my geographical location, which showed no condensation in the lower layers (below the vapour barrier)2 points

-

You can say "Thermal Mass" as many times as you want, it's fine; we all know what we mean / what is meant / time to move (not necessarily swiftly) on.... Becoming energy rich in the summer will allow you to 'bank' for the winter, so a well-performing dwelling will still be manageable in terms of energy / costs aka "green credentials". Solar plus batteries here should be a no-brainer, but even without these a heat-pump based space heating system will make running costs 'acceptable' vs the alternatives. Maybe sacrifice the renewables at the outset to get more spaces with plaster & paint + floor coverings, and just cable for the solar et-al during 1st fix? 10 years is a long time to be looking at very unfinished areas, plus the cost of the renewables buys a lot of m2 of boards etc. Your choice of course, just saying... Airtightness will be of paramount importance with a dwelling this size, but you will need a very good 'team' around you to design out the multiple function living modes of this arrangement (I'll call it that vs a house, if I may ). Having a passive raft or similar long thermal time constant store and 'emitter' will offer huge dividends, so avoid skinny screeds over insulation wherever possible; another place to 'bank' cheap energy. Your architect is a good sort, as ploughing loads of expensive resources into cooling is the anti-energy efficient model you crave. Having a considerable cooling demand is way worse than a massive heating demand, IMHO, as I would much rather be slightly cold than slightly "too warm"; you can get cozy but you cannot escape excess heat. Consider solar-reflective glazing, or even better, solar (external) blinds / shutters. The latter will massively reduce summer overheat issues but will retain maximum solar gain for the winter months. As far as construction method I am a huge fan of Nudura, and it was a no-brainer for the build I am undertaking this year (for a client); 1800m2 over 4 stories (580m2 basement + GF, FF, 2F) and as you say, getting smaller as it rises. You have (again IMHO) chosen well there, for this particular instance. However, with the way it sounds like you're 'arrangement' is set out, do not discount timber frame above ground. MBC's twin-wall frame with blown cellulose is a fantastic solution, with outstanding acoustic deadening / great levels of insulation to boot. I am not a fan of SIP's at all, and would have this as a budget driven, last option. Horribly acoustically transparent. Please avoid this for your roofs wherever possible.1 point

-

The wonderful thing about living in the free world is that it's your money, you earned it, spend it as you please! A fact sadly not celebrated as much in the old world as by our new world cousins. Some plans might help the collective masses gather our brains around the plan. I wish I'd put mine up, lots of good advice I might have received might have saved me lots of hassle!1 point

-

Thanks Glad you are all moved in and happy even if your step count has increased somewhat. The nature of my job means I am quite sedentary so I'm looking forward to the workout. None of us are getting any younger so we could all do with a good bit of exercise! Now where did I leave my phone again .... All joking aside you raise a very valid point, don't forget we are effectively 3 separate families living under 1 roof and we all want garage parking. Divide our square meterage by 3 and you still get a big number (400m2) but not an aggressively big number. In truth I've always been envious of the way our American cousins live particularly their homesteads. That was very much the space goal for us. I know that makes us different to many on here but that's part of the fun of self building right?1 point

-

Welcome to the forum. We moved from a 60m2 cottage to our 180m2 new build and really missed the proximity of everything. Have you done a survey on your daily movements in the house. EG how many times you go walk from the fridge to the TV to the toilet to the bedroom. I think you're going to need bicycle lanes to make it work .1 point

-

Probably best I subtly steer the thread away from what sounds like an old debate. In any case as with any primarily solar powered house the issue is you can only generate when the sun is out and December / January is hard to get through without slurping on the grid (which I'd rather avoid if possible). My goal is to be able to store as much energy as possible. Chemical batteries will only get me so far, storing heat is significantly more efficient. In an ideal world I'd have some sort of inter-seasonal heat storage but the house can perform that role to an extent. Our architect seems significantly more worried about overheating, I'm personally not because if it is sunny enough to overheat it is sunny enough to generate plenty of power for cooling. I'm told no chance of a wind turbine due to nature of the plot but I think attitudes to this will change, particularly with horizontal ridge mount turbines.1 point

-

The calculations are coming out fine, I respect your opinion but you really don't have enough info here to know if this house will be cold or not. Thermal mass is an accepted term? https://en.wikipedia.org/wiki/Thermal_mass Splitting hairs feels like a waste of energy (pardon the pun)1 point

-

Can’t comment on other makes but we have Origin windows and doors (double glazed). Not the best performance on paper but work well and feel like they will stand the test of time.1 point

-

They are definitely concrete, and they aren't apparently aerated (v lightweight), but it is a matter of opinion as to whether those are 'dense'. They are denser than the less dense ones(!) but not as dense, I think, as a foundation block. Think you need to ask SE what they want to see.1 point

-

All the adding mass in the world makes little difference if the ceiling is full of holes. Think of a 1m wide solid stone dividing wall between two rooms with a door opening. You would hear more through it than the most crappy partition wall. You could always put in a couple of layers of plasterboard above a service cavity but you're loosing ceiling height then. These are the trade offs of building.1 point

-

If you look at the below picture, you'll see the knee stud wall fixed to the top of the steel which also supports the glulam beams with the triple studs. This was designed to be the external wall by the architect. As you'll see from the picture, there is an additional stud wall behind. This is my redesign. This new exterior wall sits on my roof joists just behind the steel. Hope that makes sense.1 point

-

1 point

-

I had a design like this for mine. I switched to 2 beams bolted together because they were easier to handle on my own and less cold bridging.1 point

-

But beware of signing off too early and not getting the VAT reclaim on the rest. They only accept a single claim. AND remember the VAT for cashflow if the project is done in stages. The BCO may well be sympathetic and find a way to let you live in a bit of it without giving full sign-off.1 point

-

25mm thick top plate! Bloomin' heck. Switch to two beams, one for each leaf. Put in a row of thermoblocks if you want but it's not a major cold bridge so long as you can get 50mm PIR around it.1 point

-

Well he posted in February, so hopefully he has found a way to progress, though not sure what came of the ICF issue, or can't comment on it if there are legal things going on.1 point

-

1 point

-

Don’t render it. cover the column in insulation and then clad it in an aluminium trim to match the doors. I had a trim custom folded from aluminium and powder coated to match. £120 all done.1 point

-

Perhaps forget the blocks and use XPS? Much warmer. (I would normally say graphite EPS but XPS will give you a bit more impact resistance 'just in case'). Thin-coat reinforced render on top, of course.1 point

-

Don't do it. 20mm insualtion is nothing, you'll be chucking away loads of heat and it'll cost you a fortune to run. Either rads or dig up your existing floor and lay an insulated slab.1 point

-

1 point

-

You can fix the ties to the column with screws or shotfire Hilti nails. You may need 1 every course. https://www.travisperkins.co.uk/wall-and-frame-ties/staifix-spb-frame-cramp-200mm/p/2523091 point

-

Some old tools for carding sheeps wool had very coarse spikes like that.1 point

-

Here's a link to a quick image search : result - possibly for flower arranging. (In Chrome: Google Lens > right click your image> copy the image url > paste into Lens ) https://lens.google.com/search?ep=gisbubu&hl=en-GB&re=df&p=AbrfA8rwK_fYLBGcsvYHT2pF8xGPcHGXNbSsZHfXeAo75ujBOaFTfGNiE3N4EyWNsMUOobSAAa5bi-OvnTvOSybFqzeWYotxXJCoCgGiDWYj6saGGFCb4V3Dv7eSWVGpKHmhg8ddYIlVLn1yaJXMQ8HhT_SSJiHns2RVQR8elpUjcEl-t60m0T9EhlwDHHNqMJu-I_OEha0M7vxlhkDSNxVq8Fr3AVzijdJKhBMWTgDr4RN6P2HLr8gZ1jJc3YmxU4g7ytZWLEAA2LiKEy_guwQoLssaM9cBIA%3D%3D#lns=W251bGwsbnVsbCxudWxsLG51bGwsbnVsbCxudWxsLG51bGwsIkVrY0tKR0V4T1RWaE5URmxMV0l4TldFdE5EUXhOaTFoTWpGakxXUmlZMlkyWlRrMllUWTNZeElmVFY5ZmEyVnZWRE5uTTBWaE5FWXpjRVF5ZGpoaFkzVXRaVU5UV0RONFp3PT0iXQ==1 point

-

Some might argue that point occurs earlier. In our case that was probably becuase we started to fall in love with the place. For so long it was just paper, or a screen image - then it was a 3D animation, then paper / card model, then lines on the ground, then .... etc. There is so much emotion wrapped up in this 'thing' we are all building. In a very real sense it was once a figment of our imagination, then a chat in a pub, then a look from a partner, then a dream ... all the way up to "Where The(expletive deleted)ety(expletive deleted)DoYouWantThisSoddingSocketDarling, please just make a decision and don't change your mind - again." We now have six - yes six - extensions hidden about the house. I lost those "WhereDoYouWantThis?" battles . Not all of them, but most.1 point

-

Funnily on tv recently was an article on weaving with horse hair and they used (bigger) versions of that to de tangle the horse hair like a comb 🤷♂️1 point

-

1 point

-

We have a 6M opening, I had the SE spec vertical fillets at 600 centres that were welded to stich the outler L shaped and internal box section steel. That was can fill the gaps with PIR. Overboarded with 25mm PIR backed plasterboard. Best compromise I could come up with and still guarantee zero flex in the middle to pinch the doors.1 point

-

1 point

-

Data sheet says that's got an RS485 interface to an energy meter and the battery, so you'd be able to use your cat 5 cable to run RS 485 between an energy meter on the incoming supply and an inverter in the shed. With a base voltage of 240vac ish you're not likely to have volt rise issues at your inverter based on your calcs1 point

-

That's a very good point. May be better buying different lengths than 100m or planning the loop layout, so you get to get 3x100m loops. One of my loops does half the hall, main shower room and kitchen diner. Then you only need to 3 port manifold.1 point

-

a bit worried if I tell you I'll find out I bought the wrong ones! 🤣 https://www.aliexpress.com/item/1005004133687443.html the ST8-5DA-N version1 point

-

We are right on the border between Dorset and Devon so possibly even closer to you. If I'm not a divorcee living in a box I'll invite you round when done. This house is being built for 3 generations of both my partners family and my family (5 people, extra on the way) and includes an Annexe, a Flat and what we call the Winter Garden which links the two buildings (building A: house, building B: flat and annexe). Large yes but I believe excusably so (the architect politely disagrees). The workshop, courtyard and the garage are about 200 m2 of that too. The combined building is a rectangle that is 42m long, 10m wide and it gets thinner as it goes up. The basement is 500m2. We have planning and we have gentlemen on site forming the access route. Geotech drilling round 2 is currently ongoing fingers crossed for a good result. Planning required a ratcheting approach that took 3 permission across as many years. I didn't want to leave too much to chance and didn't want a refusal. Why not build something smaller and extend: 1. CIL costs would apply to any extension but not the initial build. This is a not insignificant saving of something like £200,000 for the whole build. 2. The site is beautiful and I want to get it landscaped before completely the entire building beyond first fix (we don't need all the space yet). 3. With inflation nothing is getting cheaper, we had a windfall and we don't want money losing value in the bank. 4. Due to the layout of the building (flat, annexe, winter garden, house, 1st floor house south, 1st floor house north) it is easy to take on piecemeal. 5. My family ran a small building company but this is far beyond our capabilities. Once we are water tight we are back inside our comfort zone. 6. VAT exemptions provide further savings. The goal is to try and get substructure and superstructure finished externally inside of about £1 million to 1.5 million. After that I will be starting to run out of money so need to prioritise carefully and not give up my day job! I really don't mind if I'm still plodding on this project in 10 years time as long as my (extended) family are happy and comfortable.1 point

-

If this is the case, I'd recommend getting a cheap green lazer level, a folding rule and a piece of string/rope with 1m and/or 0.5m markings on it. Set up the level, lay the string on the slope, unfold the folding rule and then walk away from the level and take measurements off the folding rule. Much better for distance work as in some case you might need to walk up to 20meters..1 point

-

https://www.scotlime.org May be of use & they run courses in the skills you wish to learn.1 point

-

interesting, does that mean that there are two vapour barriers, one below the PIR and one below roof joists / rafters above the plasterboard?1 point

-

Our roof is corrugated steel sheets over 150mm thick PIR/composite panels and the rain was quite loud. We've now finished the internal pitched ceiling with 200mm thick rockwool (just standard stuff, not acoustic) behind PB and can't hear anything anymore. Just the slight echo of my empty bank account.1 point

-

Are these 2 points electrically the same point. Do you have a multimeter? If so, is there continuity between the two. And if that is true then it almost certainly doesn't matter.1 point

-

Maybe you can 'train it' a bit by sticking a bit of insulator on the case where you don't want sparking. Try with electrical insulation tape and then use a bit of polycarb sheet if that works? See e.g. https://www.curbellplastics.com/materials/applications/good-electrical-insulation/1 point

-

I would guess that any spark is good, perhaps reassemble and try it out now you have serviced it.1 point

-

I hired a digger driver for £200 a day and hired the plant in. The speed he went was incredible he is so skilled and safe. I saved money by driving the dumper, setting out and holding the laser for him. At times we hit obstacles and I was glad he was there to deal with them. Money well spent and I saved a fortune on the quote I had from a ground worker friend.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.jpg.f9860daaab3b743fa0c27f5c5929df07.jpg)