Leaderboard

Popular Content

Showing content with the highest reputation on 12/12/23 in all areas

-

It’s been two years almost to the day since the water borehole was drilled and we now finally have a water supply into the house. It’s the oldest outstanding action on my action log which I can now change to green! I have two supplies into the house, softened and unsoftened (for drinking) the unsoftened is yet to be connected. It’s slightly complicated by the fact that for it to bypass the softener it also bypasses the final water filter and UV light before it comes to the house so I’ll need to add that back in to the plant room before it goes to the kitchen. ASHP and HWC get delivered on Friday and it will be installed the following week which means we’ll also have heating in the house other than the oil filled rads.3 points

-

3 points

-

Mathematicians discover shape that can tile a wall and never repeat Aperiodic tiling, in which shapes can fit together to create infinite patterns that never repeat, has fascinated mathematicians for decades, but until now no one knew if it could be done with just one shape By Matthew Sparkes 21 March 2023 This single shape produces a pattern that never repeats David Smith, Joseph Myers, Chaim Goodman-Strauss and Craig S. Kaplan Mathematicians have discovered a single shape that can be used to cover a surface completely without ever creating a repeating pattern. The long-sought shape is surprisingly simple but has taken decades to uncover – and could find uses in everything from material science to decorating. Simple shapes such as squares and equilateral triangles can tile, or snugly cover a surface without gaps, in a repeating pattern that will be familiar to anyone who has stared at a bathroom wall. Mathematicians are interested in a more complex version of tiling, known as aperiodic tiling, which involves using shapes that don’t ever form a repeating pattern. The most famous aperiodic tiles were created by mathematician Roger Penrose, who in the 1970s discovered that two shapes could be combined to create an infinite, never-repeating tiling. Now, Chaim Goodman-Strauss at the University of Arkansas and his colleagues have found a single tile shape – which they have called “the hat” – that does the same job. Goodman-Strauss says that both finding and proving the tile to be aperiodic involved the use of powerful computers and human ingenuity. The team used computers to eliminate large numbers of options, then applied their experience to finding a shape and developing a proof. “You’re literally looking for like a one in a million thing. You filter out the 999,999 of the boring ones, then you’ve got something that’s weird, and then that’s worth further exploration,” he says Goodman-Strauss. “And then by hand you start examining them and try to understand them, and start to pull out the structure. That’s where a computer would be worthless as a human had to be involved in constructing a proof that a human could understand.” Until now, it wasn’t even clear whether such a single shape, known as an einstein (from the German “ein stein” or “one stone”), could even exist. Sarah Hart at Birkbeck, University of London, who wasn’t involved with the research, says that until now she thought it would be impossible. “There are infinitely many possible candidate tiles, and even the existence of a solution feels quite counterintuitive,” she says. Despite evading mathematicians for decades, the newly discovered einstein isn’t a convoluted or complex shape. It features just 13 sides. The shape also retains its aperiodic qualities when varying the lengths of the sides, meaning that the solution is actually a continuum of similar shapes. Much of the difficulty in finding an einstein is proving that it really can tile aperiodically, without throwing up unusual counterexamples. The team discovered two proofs for the tile, with one being based on computer code that has been publicly released. Hart says that knowledge of aperiodic tile shapes could help us design materials that are stronger or have other useful properties. Repeating patterns like tiles are also seen in crystal structures, where they can lead to fault lines along which material tends to break. Another example of “the hat” David Smith, Joseph Samuel Myers, Craig S. Kaplan, and Chaim Goodman-Strauss “Certain strange and wonderful types of crystalline structures called quasicrystals exhibit aperiodicity,” she says. “It may be that this new tiling may have applications to our understanding of the possible structures in quasicrystals.” Colin Adams at Williams College in Massachusetts says he was shocked at the simplicity of the solution, and that this was a problem that “does not easily yield to brute force” computation. He is also keen to put it to practical use. “You’re going to see people putting these in a bathroom because it’s just cool. I would put it in my bathroom if I were tiling it right now,” he says.3 points

-

2 points

-

Isn't this how the position of breaks, and shorts, in cable runs are detected? The time and magnitude of the reflected signal shows where, and what, the problem is.2 points

-

All my lighting circuits will come into the Loxone cabinet with a single isolation point in the CU. Electrician didn’t have an issue with this. It seemed the most logical and neater way to do it.2 points

-

2 points

-

This is just an altogether rather depressing thread, especially given the implications for lifetime C02 associated with the build. As several people have pointed out nothing is going to change until home buyers become aware of the real cost of not building airtight structures. It may help if buyers started demanding airtightness tests as part of their surveys. The test cost next to nothing in real terms and tell you so much about the cost to heat a structure. Certainly U values are important but nothing like as easy to verify as airtightness. I don't believe the big building firms will do a darn thing until buyers start holding them to account and to do this airtightness needs to be part of sales contract.2 points

-

I don’t get this. Just open the (expletive deleted) window if you want it open! 🤷♂️ as @ProDave said having MVHR doesn’t mean you can’t open a window.2 points

-

When the house was built, I asked the builders to put some shelves in the hall cupboard. They put in some unpainted MDF and we have always felt it looked a bit cheap compared to the rest of the house. Having watched how easily a DIY-Kitchens Kitchen went into my brother's flat I decided that I would order up similar for the cloak cupboard. DIY-Kitchens did not offer enough customisation options, but they are very good value. I priced it up with a company called Lark and Lark who offer more options for carcas colours and custom sizes, but they wanted £400 extra on top of their normal delivery charge to deliver to Scotland. I then went to DIYHomefit who supplied our dressing room which was installed by the builders. I measured, measured and measured again, then ordered the stuff. Came in at £1700 including VAT and delivery which was more than I was planning to spend. Probably saved a good £1000 by installing it myself. I started ripping out the old stuff at 10am yesterday and finished installing all the cupboards this evening. I have filled the holes and will paint and install hanging rails tomorrow. I was really surprised how smoothly it all went. I had installed a utility room years ago, but it was very simple with no infil panels to cut. That was the scariest bit, but it went pretty smoothly. I now have plans to do cabinets around our home cinema screen in the new year.1 point

-

Tighten the cams in the windows until they were virtually unusable (pushes the sashes firmly onto the baffle). Use the shittiest fitting door as the one you replace with the air-tightness fan. (in the end we used the best-fitting window). Ensure all shower traps etc are filled, or tape them over. (Fair enough. Except we later found one shallow trap actually wasn't full but nvmd got 0.5 anyway) But I think the most negotiable one is to be 'generous' with the calculation on treated floor area and volume of the building, especially relating to noncuboidal shapes (vaulted ceilings etc)1 point

-

I refer you to my earlier post. So what if its law? If no one enforces it, it will be ignore with impunity. Just like all the current regs. There is no one to enforce such a law.1 point

-

Not often. I had issues with cheap DMX dimmers for a while so I did need to switch it all off to make changes. I wouldn't bother just for the convenience of having fewer switches to isolate, but I do like the idea of less wiring coming into the Loxone cabinet. As with so many things, there's a lot I'd change if I were doing it all again!1 point

-

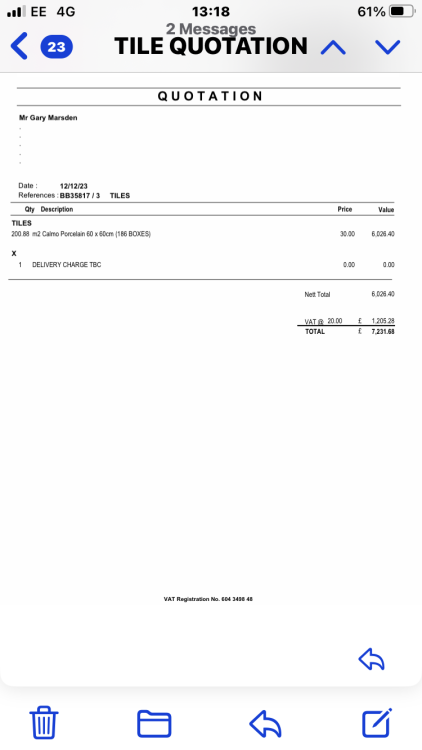

It will take me about four days once the heat is on The original ticket price was £97 Whilst they are good quality Italian porcelain I wouldn’t want to pay much more than 30 for a floor tile Tge markup is incredible on tiles1 point

-

1 point

-

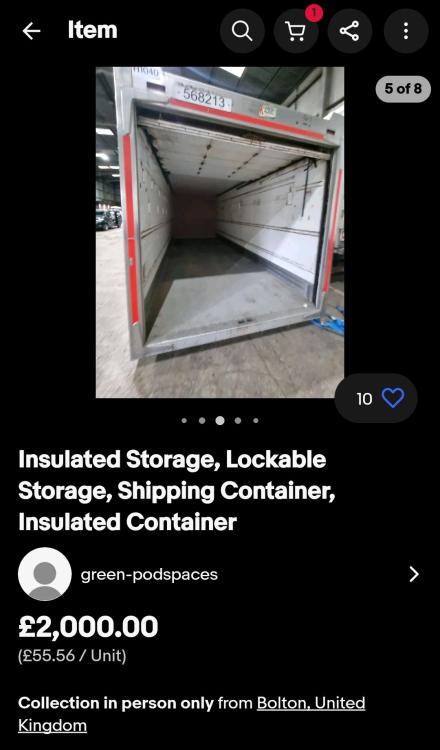

By default it fits on a flatbed. So it's just the cost! Perhaps find if your local haulier can fit in a delivery the other direction.1 point

-

Tiny bit niche for us yokels. But why dont you review a good few online PP submissions online and see whose signature is on a range of them. Select three, ask for a fee proposal and you are in business.1 point

-

Perhaps we should follow the Germans and make it law. https://www.renewable-ei.org/en/activities/column/REupdate/20220721.php Having no experience of house building, with the aid of the folks of on this forum have managed to build a very low energy house, so it's not rocket science. I had the choice of multiple build methods all of which could deliver a low energy solution. I also don't believe it costs appreciably more that traditional methods. We all know the story of the motor manufactures who pushed back against the cost of fitting seat belts....the same is true of the building industry today. The consequences of not fixing this is bad for the planet and bad for the economy.1 point

-

In which case nothing will change and the UK will continue to build sub-standard houses. Commercial buildings are typically built to a higher standard so the building industry is capable of doing it. If you can’t test every house or substantially enough of them randomly with no notice then the regulations mean nothing which is exactly where we are today and why we have the example that started this thread. The culture change can only come from the boards of the big building companies. Like I said they need to think about their ‘just cause’ and configure their businesses to meet it. Here’s the Taylor Wimpey why choose us page, match that to the opening post. I doubt it’s a one off example of that particular set of TW houses. They will all be the same or similar. https://www.taylorwimpey.co.uk/why-choose-us/why-taylor-wimpey Knowing what I now know about building I’d advise no one to ever buy a new build as you can be reasonably certain they are mostly all poorly built.1 point

-

if it stops radon gas coming through it’ll definitely stop any water vapour passing through it. in what situation are you using this barrier? I’ve used radon barrier as above underneath oversite concrete, and everywhere else used a combined air and vapour control layer such as this https://www.roofingsuperstore.co.uk/product/barriair-vapour-control-layer-air-barrier-by-protect-15m-x-50m.html?gad_source=1&gclid=CjwKCAiApuCrBhAuEiwA8VJ6JjllfP_hI4URp9992b8XIkJ_q9BRbxq9iNkRywsDBMsJ5qNL4jbmPxoCjLoQAvD_BwE also seen this product in stock - https://insulationwholesale.co.uk/polythene-vapour-control-layer-1200g-4m-x-25m-green/ but definitely depends where it’s to be located1 point

-

Yep. I’ve done my best to make it as easy for them as possible. I tried to split the plant room in three so MVHR on the external wall, electrical, networking, Loxone in the middle leaving the other end for all the wet stuff.1 point

-

I don’t really have the room for all that either. My cables all come down from the ceiling and through the plywood so it’s mostly all hidden.1 point

-

I'd get a commitment from them that they'd do that for your build in that case - huge difference in being a client with a regular stream of work (like a big contractor/developer) and a one-off house builder with little prospect of repeat work. Chances are you'll be very much viewed as the latter and you'll need to accept that in most cases subbies will go where the money is and you'll not always be at the front of the queue. Do that, keep healthy communications with your trades with a bit of come and go, and have a ready supply of caffeine and some decent biscuits and you'll generally be fine - but you'll never complete in two months. Or get a main contractor in and have penalty clauses in your contract if you're wedded to that timetable.1 point

-

1 point

-

1 point

-

Downside of this is an earth leak (especially likely on an outdoor circuit, but easy when changing a lightbulb indoors too) will trip all lights in the house. Sparky on my current project wants 2 RCBOs per floor to ensure everywhere still has some lighting even in the case of nuisance trips. I think we're up to 12 RCBOs in the Loxone cab, and about 30 more in the main 3ph DB1 point

-

So each sparky has a different take on this, but the common view is the place that contains the isolation and earth leak protection is the thing that has to confirm to 18th edition IET cu rules. By putting all isolation and rcd in the main CU you may relieve the Loxone cabinet from having to comply as a CU, effectively it's just another custom-built appliance. (Or, collection of CE marked appliances assembled in one box for convenience). Note the CU regs are more than just the enclosure having the 18th ed mark, it also includes correctly sealing all openings with grommets and so on. Of course it's a good idea to try and comply with as much as you can of that anyway, regardless of technically whether or not it "is" a CU. The point here more is about the scope and ownership of paperwork involved for signing it off. I've built cabinets both ways. In each case led by site sparky preference and also by having site sparky terminate the cables into the Loxone cabinet it's their ballcourt to seal openings into it as required and sign it off too1 point

-

I found a surprisingly accessible illustration of the effects of wave reflections and wire branches in this video. Despite having a masters in the subject I'd never really considered the interaction of potential voltage and current in this dynamic sort of way.1 point

-

I have to flip several RCBOs in our CU to isolate the Loxone panel. It's been over 8 years since we did our installation, but I vaguely recall having a conversation about this with the electrician, and seem to recall that he was uncomfortable with moving a lot of what would usually be in a CU into the Loxone cabinet. I don't remember whether it was regs or a lack of panel space that led us to the decision in the end!1 point

-

If the system was not balanced (unintentionally) then if the Boost upped the extract, outside air would be pulled in via leaks and hence by-pass the Heat Exchanger. In the winter (or colder months) this would reduce the efficiency of the system overall. Some MVHRs allow differential settings, I assume to either achieve room flow rates (as pipework will vary) or intentionally - I have read on here that recommendations from Finland and Germany vary for either radon or damp.1 point

-

I agree. The general public have no objective standards when purchasing the most expensive thing they will ever buy. Contrast this to a car purchase, or even a toaster. Very few of those tout period features or 1900s technology as a selling feature. Because no one would buy them if they did.1 point

-

32A I think. Then in the cabinet, everything is 6A apart from UFH which I think is 16A. We used c-curve RCBOs for the chunky PSUs otherwise, they trip due to in-rush current. The Meanwell datasheet says how many are recommended on a B-curve vs a C-curve etc.1 point

-

1 point

-

I DIY fitted a MVHR. It works really, really well, however do not under estimate the work in installing. We went from a house that had mould in the bathrooms (no extractor fans) to much better air quality. Running the ducts in the loft was the easiest, for a given value of easy in the loft. Running ducts down to the ground floor took a while as hiding ducting in cupboards and also ensuring the loft end worked was more effort. Fitting the intake/extract vents in the roof was straightforward for a roofer! It took five weekends; One for the intake/extract/condensate drain/unit setup. One for the upstairs rooms (two bathrooms, three bedrooms). Another for an extension bedroom (should have hired a core drill for going through an outside wall that is now internal). Another for downstairs ducts to kitchen and lounge. Another for a downstairs loo that involved dropping part of the ceiling to fit the ceiling duct as I could not access above it. I think I could do it in half the time or less as now more confident. All my parts came from ebay, isells, BPC, Screwfix. I did the design myself with a spreadsheet of room volumes and flow rates. I went slightly below the suggested flow rates for "Normal" rates and over for Boost. I overspeced the ducting to reduce noise (ie twin ducts to all rooms as running these is not much work relatively). I fitted noise silencers. I would go higher for boost, to clear damp air quickly, however above 90% flow rate it is noticeable noisy. We have virtually zero condensation. The odd, tiny bit behind some plantation shutters on some cold nights. Some condensation on a door lock that is a cold bridge in a yet to be vented room (its the hardest to get to) and sometimes on the letterbox flap (needs more insulation!). If you have reasonable loft access and only need to do runs in the loft this will help reduce install effort allot. I assume you could have the intake/exhaust through a gable end which should be quite easy (given value of easy). Think of the condensate drain and where that goes (I suggest a soil vent spigot to keep it warmish). It is great, but allot of work. I would have a strong think of doing it again, but on balance would do it again. I did consider four individual room MVHR as these would be quite allot of work to install (core drilling, running electrical feeds) and these are expensive units. I think this would be cost neutral compared to my MVHR. Maybe slightly less work, but not much. Running costs would be more due to more fans. It would not have improved the air in non-vented rooms compared to MVHR. Your air leaks might be an issue although depending on units you can set them to run intake fans faster than extract to positively pressure the house which will help with internal air quality. This would be slightly less efficient as you are losing air that is not going via the heat exchanger. On either method consider the filters the units have. Mine goes upto M5 (A "Pollen filter" ie 50% of Pm10). Newer models have HEPA level filters. You could DIY a HEPA filter on the intake from BPC/Isells bits. Sorry that turned into an essay...1 point

-

"As the OP we have always slept with bedroom window open and are at the beginning of the design stage of our self-build. I think the 'air quality of MVHR', 'you will get used to it' etc. comments won't wash with us." This is not hearsay, a myth or a legend - the air quality, and in particular CO2 levels, are always far more important than temperature1 point

-

If you work on 7 boards per bag 20m2 You won’t be far off Most decent plasters will do at least 3x30m2 each day1 point

-

my plasterer was labour only. I bought materials as and when required. I bought a load at the beginning and when that started to get low he told me how much more to buy and my local BM could deliver within a couple of days at the most so it worked well and we didn't have to have all the materials on site in one go.1 point

-

1 point

-

Energy usage comparison based on real energy consumption. During the last 48hrs no other heating sources have been used just the heat pump. Garden room was averaging around 7kWh per day for heating, using direct electric heating. This has reduced to zero for the keeping warm (via direct heating), when in use I will still use direct heating for now. Last 48hrs has averaged 18kWh a day (between 3 and 8 degrees, wet and overcast), for house heating at a continuous 20.5, garden room heating was at 14-15 degrees and providing all DHW. Almost all energy is coming from cheap rate (15.16p per kWh), via E7 overnight and a battery in the daytime. Calculated heat loads at an average 5 degrees OAT House 56kWh day (found similar gas usage last year) Garden room 7kWh (based on previous direct electric consumption) DHW 7 kWh - (based on previous usage patterns) total 70kWh heating demand, electricity consumed by heat pump is 18kWh, overall CoP of 3.88. Gas price 6.489p assuming 100% efficiency 70x0.06489 would be £4.54 per day, would cost more if less efficient E7 Electric with battery 18 x 0.1516 is £2.73. 40% cost saving.1 point

-

Unless there is a planning condition requiring a wall, a cheaper way is replace it with a fence.1 point

-

I'm using the Open Energy Monitor heat pump monitor. https://shop.openenergymonitor.com/level-3-heat-pump-monitoring-bundle-emonhp/ The full kit is expensive, but I like to know what's going on and I'm not too sure that the readings given by the heat pump are accurate. It is very helpful when setting the system up. If you want to look at other systems there are quite a few online at https://heatpumpmonitor.org/1 point

-

It really annoys me that heat pumps are singled out whilst noisy oil or gas boilers are unconstrained, except possibly by a complaint to Environmental Health. What is really needed is a unified standard.1 point

-

This is just what we are doing at the moment. Not sure we are going the cheapest route mind you but pleased with how its turning out....... Top tip - you need the correct membrane at the back designed for open cladding. In the pro clima range its this one - https://www.ecologicalbuildingsystems.com/product/solitex-fronta-quattro1 point

-

Get it designed by someone, lots of easy control panels, sounders detectors on the market all depends why you need https://www.firedetectionshop.co.uk/shop-by-brand/c-tec/?gclid=CjwKCAjw6p-oBhAYEiwAgg2Pgq0qqPw78tGJpOJeHTmRc4kAsd0SvrLOGnvAgjEJALaU8A3aEWY6KxoC2ZAQAvD_BwE1 point

-

For anyone looking, I used this one and adapted it. https://digital.flintshire.gov.uk/FCC_Planning/Home/NewDocView/165043#:~:text=1.,be taken down in stages%3A&text=Any persons working on site,safety boots and hard hats.1 point

-

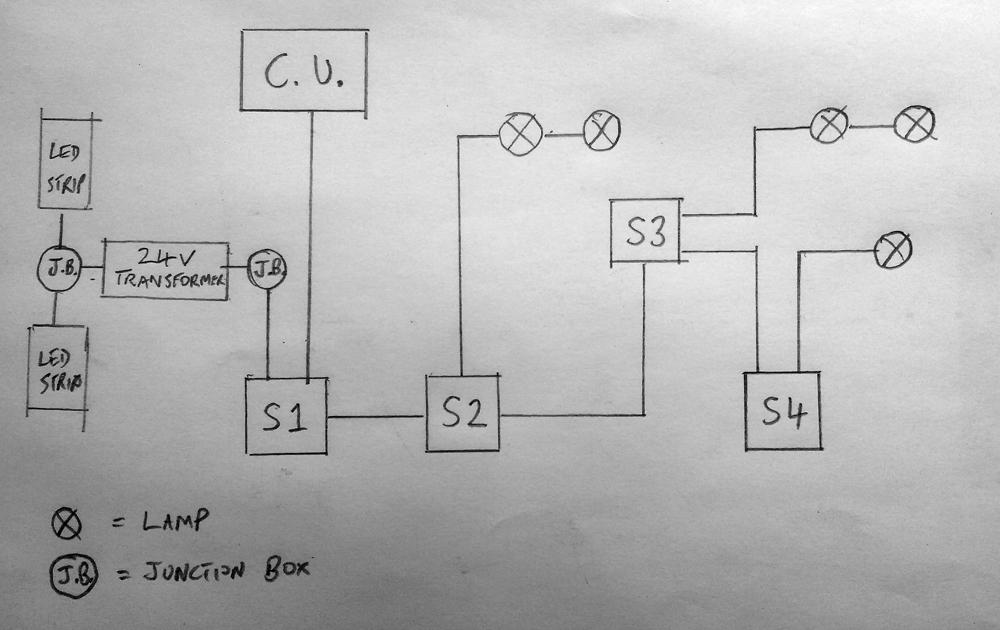

I am ready for first fix electrics in a very small barn/office with mezzanine bunk bed and shower room and would welcome any advice on the lighting plan. I have an electrician on board but he is currently out of action/contact with covid symptoms. S1 – switch for 24v LED strip lighting under the mezzanine bed S2 – main switch for lighting S3 – positioned at mezzanine/bed level it is a 2 gang switch – one switch as 2 way with S2 and other switch for bed reading lights S4 – switch for lighting in shower/toilet room positioned outside the room Avoiding any ceiling roses with circuit wires being brought into the switch. All wiring 1.5mm 2 core except wire from S2 to S3 in 1.5mm 3 core. Questions: Anything wrong with the layout? (especially the 2 way switch S2/S3 and then going on to S4) Could I use 1mm 2 core for all wires from switches to lamps? (most lighting would be from S2 – 4 small lamps on the purlins with overall length under 10m) Would 35mm back boxes be sufficient? 25mm? Minimum distance of wiring from EPS insulation? (only couple of sections where this is relevant)1 point

-

I guess that's what he means cos reflections in the main line will be common to all and loop means, IIRCC, take the main cable right up to the transducer and out again.1 point

-

Running 3 1-Wire sensors is just a case of wiring them in parallel and putting the right resistor at the RPi end. So yes, use a bit of CAT for it. If you get the right resistor value (it all depends on the number of sensors and cable resistance), they are pretty robust. DHT22's (which are cheap and do RH and Temp) do need to be on separate RPI IO pins and need their own resistor.1 point

-

Air tightness tester: you don't want a house that is too airtight, it'll get stuffy and if the MVHR unit breaks down you won't be able to breathe, that's why trickle vents are better and way cheaper than MVHR. Me: (deep breath, count to 5, censor self) If the MVHR breaks down I'll just open a window. True story !0 points

-

Oh please come round Gary, and shout that really loud for the rest of the family to hear. They'll believe you. But, wimmin; - They will do what they do do. Phhhhhhhhhh.......0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)