Leaderboard

Popular Content

Showing content with the highest reputation on 07/18/23 in all areas

-

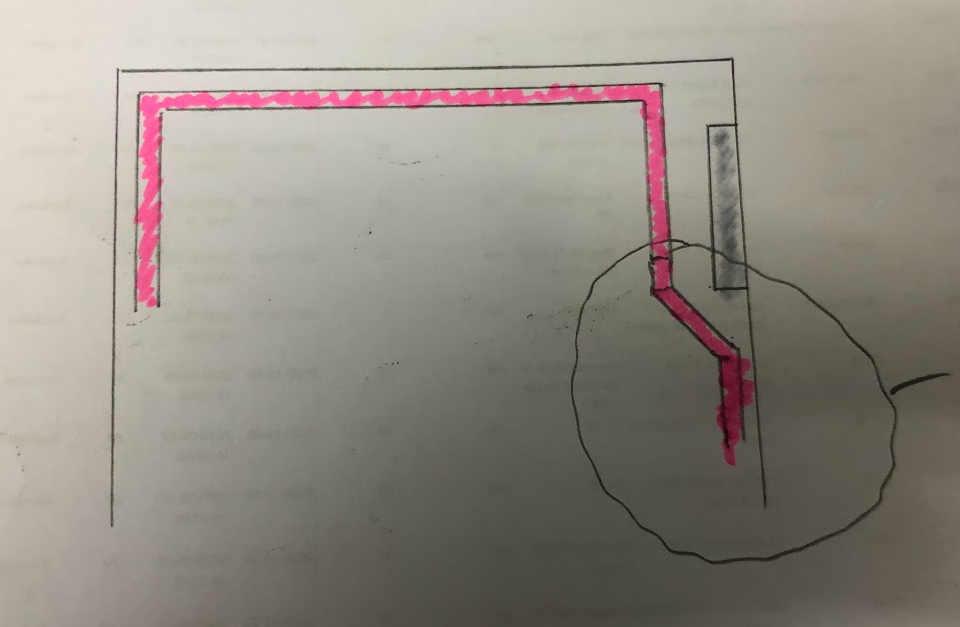

Reckon I've got it! Again more by luck than judgement, but I did change the order of the bends pulled, pulled the bend by the wall first. It's all loose fittings at the minute as I'm trying to do all the prep work ready to be fixed and pressed once that cupboard is skimmed, painted and floor down and cylinder in.2 points

-

If you can build a house, you can certainly take the ten minutes it takes to run a file over a chain. Perfection aint necessary- even if you're just taking the burrs off rather than sharpening as such it'll still improve things...2 points

-

Not ideal but if you put the T in after the trap you shouldn’t get any back noise, odours won’t get back through the washing machine so no problem there2 points

-

Thanks for all your help. I've thought against doing all the door openings like this now. I'll just do the 2 that are needed and the rest will be standard doors. Thanks.2 points

-

So I've been playing with the pipe bender, and probably more by luck than judgement managed to bend 2 22m pipes into a U shape so they go round the back of my cylinder. The pipe work on one side is off from the wall by a small distance as I've got aircon pipework coming down. I need to pull 2 45's to now return the pipework to the wall. I've had 2 goes and measured managed to cock up both times on transferring what I think the offset is to the pipe bender. Anyone got any tips to help please. I know life is too short and I guess I could use fittings, but that'd be no fun and I wont learn anything, so pics below showing what I'm trying to do. I don't like to call on members directly, but I'm going to try and get the genie out of the lamp @Nickfromwales1 point

-

1 point

-

Every house I've had including our selfbuild has suffered from a problem in this area. The plasterboarded ceiling shrinks and the plaster cracks where ceiling meets wall. Unfortunately the crack isn't always right at the junction. If it was it would be easy to fix. Instead its frequently a few inches down the wall in places and a strip of plaster comes away from the wall. For that reason I'm not going to suggest you fit tape over the gaps, or at least if you do I don't recommend lapping it down the wall. Any plasterers out there got a solution for this?1 point

-

Yes, an old neighbour (previous house) had imprinted drive (cobbles) and it looked really good even after about 10 years, my brother in law had it fir around his garden swimming pool (I prepped the shuttering) and he is the most OCD person I know (a nightmare to work for) and he (and I ) were very impressed with the result (and no weeding) 👍 I am seriously considering it for my latest little cottage drive.1 point

-

Hello, I’m a part time care specialist and full time self builder in north Devon. Starting a barn conversion and looking for advice :)1 point

-

Hetas have begrudgingly sent an inspector around....one look and he condemned the install on several points. Next trick is actually getting them to take action against the installer. I was amazed to be told by the Hetas Lead Compliance Officer that an installer does not need to belong to any Competant Person Scheme or even have any qualifications at all, to work on solid fuel installations! Wish I'd known that, would have saved a packet.1 point

-

1 point

-

@Mr Blobby We used the Portman Pocket Door System. They are good but they are not without their issues though. As I said earlier I would only recommend them where they are seldom used (for the potential noise issue) or where they are the only solution and where they won’t need redecorating. Ever.1 point

-

Are you sure? Isn't the gurgling a consequence of syphoning caused by the large volume of water running through the pipes and sucking air behind it through trap? If so, I'd expect an air admittance valve after the trap (may have to be built in the trap if there's limited space) to resolve it as it'd provide a source of air to reduce the vacuum.1 point

-

And don’t forget to file the depth gauge between the teeth otherwise you’re sharp teeth won’t be able to reach the wood 🤷♂️1 point

-

1 point

-

as far as i know the door on the Eclisse system can be fitted later after all the plasterboarding has been done. i'm pretty sure when i read a thread by @pocster that was how he ended up doing it.1 point

-

1 point

-

Take 5 mins to watch a YouTube video on sharpening, buy the correct diameter round file. It takes 5 to 10 mins to sharpen. Depending on what your cutting you should sharpen every tank or second tank of fuel. It makes sharpening easier and quicker. If your chain lasts 2 years you don't use it very often and don't cut much. My wife has a self sharpening Oregon chain on her electric chainsaw. You can get retrofit kits also. Believe Amazon and Screwfix sell them. Most chain makes will be ok. It's the number of links you need to get the same.1 point

-

Oregon always for me, count the links, use a black marker pen to mark where you started. Then get a correct sized file and gauge.1 point

-

No, you just nee d to ensure you compact it in max 100mm layers. Hire a 12" whacker from the likes of Speedy or HSS for a weekend. I think the key here is making sure everything, including the pond in-fill, is really well compacted. How are the existing slabs laid? Directly on to sand? Best to match that method with the new bit. And make sure you figure out the fall on the existing section and match it with the new one, you dont want water ponding between the two areas.1 point

-

Great stuff - thank you all for taking the time to reply. Feel a lot better about it all today.1 point

-

No not paid for it. Everyone I’ve asked can spot it with the naked eye. We’ve had to compromise on so many things that can’t be fixed that when it comes to something that can be I don’t think we should. Having slept on it I’ve decided I want it replaced.1 point

-

I do like a Demo video. This one was put together by my daughter. Last one I promise. Today we move on to excavations. 4a4c26f5-54e6-439f-8e26-4670eb6b9664.mp41 point

-

Yeah, I got 50mm insulation in January, and it took me until around April before I got it all installed and foamed in. Then it took me until the beginning of July before I got the 25mm stuff in (which was date stamped late November last year, so has had time to offgass already, since it seems the majority of it happens directly after manufacture). Haven't seen any evidence of shrinkage while in situ yet. From what I can tell, aside from bad batches, it's UV exposure that kills this stuff. Probably what happened to that stack.1 point

-

Flogging a dead horse comes to mind. Why do you think you are due LDs? Was this a JCT Contract with a pre-determined completion date and was an extension of time requested or granted. As other posters have said - you will need to keep the contractor on side to carry out any remedial works.1 point

-

If they are good, I’d suck it up, as others said, you still might possibly need them back at some point, especially if you can afford it. How about meeting half way?1 point

-

It’s been difficult to get materials in a timely manner, so I feel for both sides of this situation. Juggling labour across multiple sites is just a good way of keeping everyone happy its not easy being a builder!1 point

-

The British Standard is based on research and qualifies as proof to me. I need to see proof, as you say. errrm, that is reversed logic, surely. If the frog is up and filled, then there are no voids. If the frog is down , pushed into mortar, then there are likely to be voids. Between designers and supervisors instructing frog up, and brickies trying to avoid it. this is pretty conclusive too, ans surpisingly forthright. https://www.wienerberger.co.uk/content/dam/wienerberger/united-kingdom/marketing/documents-magazines/technical/brick-technical-guidance-sheets/UK_MKT_DOC_Laying of Frogged Bricks.pdf and another https://www.marshalls.co.uk/commercial/bricks-walling/frogged-facing-bricks QED I feel. I'm not trying to win an argument, I do think this is important, and I hope this is persuasive.1 point

-

I am not sure. There are some allowances, and I think the valuation is set when you rent it out, but other may know better.1 point

-

The 600m of FTTP ducting put in for my property was 54mm grey duct which you can buy online. https://www.drainagepipe.co.uk/bt-duct-54mm-x-3mtr-grey-p-BT54/ They wanted to put a telegraph pole next to the boundary and then on the final install run a cable from the pole to the house but instead they agreed to leave me the 54mm duct and I dug for and buried it myself plus they saved a pole. You also have to install a pull cord (2 is better) for them to pull the fibre through the ducting.1 point

-

I went a year with this issue, the fan was kaput, they even sent a Dimplex engineer out with another fan, but it was another 2nd hand one and that too had issues. Truth is, they didn't and don't make the part anymore, and weren't intending to. The unit model is now no longer on their website. I do worry about other people with this same unit. For many months of the year I was plugging in the water tank to the plug socket and heating my hot water that way. Luckily it wasn't recently when electricity is 3 times as much as I was paying back then. Anyhow, after all said and done, Dimplex actually paid for a new unit - made by Samsung - and sent a third party out to fit it - including a new Samsung control panel. All for free. So I was very lucky, but it took some nagging and emails to the CEO and posts on Twitter etc. Which I felt was justified. Hope this helps someone in the same boat.1 point

-

Big step forward this week. First fix electrics 90% complete. First fix plumbing mostly complete (well the pipes are all in. First fix MVHR mostly complete. I now need to go round repair some of the air tight barrier damage although it’s minor.1 point

-

After 10 years your performance will drop circa 10 to 15%. Paying loads will not see a return on your spend. That's for 1kW installed, so about 3 or 4 panels.1 point

-

I could not operate our 3.6kW PV effectively without a battery as we gather energy during the day and then use it overnight. With a 9.5kWh battery I'm still exporting energy despite having A2A cooling and an EV (which has been running on sunshine for the last couple of months).1 point

-

1 point

-

A few things to consider If you wish to sell the electric generated the whole install needs to be done by a MCS installer. You pay more, but you can sell the electric for 5 to 10p kWh. Not MCS, means you source everything yourself and just about anyone can install. But ideally the electric hook up would be done by an electrician. Plenty of companies are out there that provide full kits. Batteries, if you are installing 3.6kW array, you can self consume everything you produce, so battery benefit in my view is questionable. Roof integrated requires no tiles below the the solar panels, so saving are made there. Pretty straightforward once you get your head around it. Basically the PV panels connect together, go to a DC isolator into an inverter, to an AC isolation switch and then to your consumer unit. It's never plug and play, so don't let anyone convince you otherwise. But it shouldn't be complex. I am in the process of installing a ground mount array of 3.6kW for a total cost under £2000. I have a combination of new and used parts. This is not a MCS install, if it was it would cost 3 to 4 times more.1 point

-

Plus 2 We build block and block land scored similar It’s a myth that solids can’t be airtight I deal with airtightness everyday Mainly commercial But some of our housing sites are taking it far more seriously The testing system for the big companies is open to abuse with so many air test companies chasing the same business1 point

-

I stopped the battens short see image The OSB is attached to the battens. I feels pretty solid. But there is a small bow into the middle, not sure why. The outer perimeter of battens support the inner walls which are now plasterboarded, so there is plenty of weight there. However our main house is 200mm PIR then 100mm concrete, it has a feel that is not as hard as you would think. I fell from a couple of feet on to my bum, and could feel a slight give on the floor, it hurt but as much as I was expecting. The concrete floor is fully floating on the insulation.1 point

-

1 point

-

I would consider some PIR, or even phenolic . As much as you can fit. Then layers of OSB staggered, glued and screwed for the floor. With your proposal and carpet especially it's unfortunately unlightly you would get any heating effect at all from the UFH in colder months. Use large radiator's for the heating instead. Alternatively cut out the block and beam with a concrete saw and put 300mm of EPS and 100mm of fiber reinforced concrete in instead with UFH. That would work well.1 point

-

In view of never wanting to EVER over-complicate things, I only use the installed WC and modulation of the heating source manufacturer ( eg Panasonic for ASHP which comes ready to roll out of the box ). I only ever consult / provide M&E for folk building to very high spec ( lots of insulation / very airtight / PH or near as damnit etc ) so do not often need to 'go mad' with weather comp as these types of dwellings suffer very little effect from what's going on outside. KISS wins every single time.1 point

-

Define your budget and part of this will define your route and kit type. If you want a basic timber frame. Forget MBC they just aren't going to be competitive (where you are) its not what they are good at (good at the kit just not the price). Similarly if its basic...forget scotframe, 25% more expensive in my experience, plus you will pay VAT upfront unless you have a main contractor. Of all the 15 or so initial quotes I got fleming homes were one of the cheapest and very comprehensive. Stephen Scott (sales guy) super helpful and very transparent and from my background checks good reports all round on kit quality and erection team. You need to make a fundamental decision on if you want a basic frame delivered or a high performing kit like val u therm (scotframe) or possibky SIPS etc. Think about you want and go from there. Whilst easier buying a full kit (doors and all) you will pay a premium for this.1 point

-

I had Scotframe, Flemming and MBC on my shortlist. The offerings are quite different and you have to do a deal of probing to get to the bottom of it. Its not just the finish its the spec of the insulation, reliability of the company, confidence in the finished cost, inclination to fix any issues that could arise throughout the project etc. Its a bit of a minefield. I have a spreadsheet which may help if you know what are priorities for you. MBC are one of the few to guarantee the finished cost as per quote. I selected MBC for this reason and also as they provide more of the build, foundation, erection and partnered with a window company at the time (though they no longer do this). I considered it a reduced the risk for me being a first time self build. Though I was very impressed by Scotframe who were incredibly helpful throughout the evaluation. I cant confirm if this is a wise decision as yet as i am waiting for the timber frame to arrive (next Tuesday!!!) Give me a shout if you want me to mail over the spreadie.1 point

-

1 point

-

Ah, 'imprinting' how the racist in society control females in their own societies. Such an unfortunate term. Sorry, very off topic, just the way my wind works sometimes.0 points

-

0 points

-

All i can say is count your lucky chickens that you've been on a fix through the worst of it all. Not an awful lot you can do about the current prices, aside from reducing your usage.0 points

-

More than adequate. I pulled our 1.5 story red brick bungalow down with a 1.6l VW golf and a long chain.0 points