Leaderboard

Popular Content

Showing content with the highest reputation on 05/27/23 in all areas

-

Possibly just taken out of context / worded 'poorly'? Some written comms here are difficult to decipherer with some folk opening mouths seemingly just to change feet, (I think I actually invented Foot & Mouth tbh because of doing so "more than once") but things aren't very often meant in a bad way on here. Seems we have a reasonably decent bunch in residence.4 points

-

Hmm. There follows a short essay which I hope is helpful. I'm avoiding being angry, and taking this as an opportunity to correct a misunderstanding. It is a common one too, supported by excellent self promotion by Architects and less so by Engineers ( who tend to be immersed in the job). Journalists encourage this because they generally recognise "pretty" but don't understand science, especially physics. So, who designed the wobbly Thames bridge? The Architect was all over the press until it wobbled, then disappeared while the Engineer sorted it. Arup gained a lot from that. Who do you think designs, then manages motorways, bridges, dams? No Architect involved in any way. It's not Surveyors either, it is entirely an Engineering project, with various other professions involved. What profession do you think organised the Channel Tunnel? Then the main man also organised the London Olympics. Other names to the fore of course. I would say they involved management. Look at suspension bridges. Occasionally an architect tweaks details, then pushes themselves, but good engineering results in elegant design.....then the small matter of building the thing. Teamwork in construction is essential of course. Is the gherkin architecture of engineering? Which matters more.. the appearance or it not falling down? Now of course it takes all types. The Engineer designing a beam in an hour from information supplied to them is probably not the same character as the head of an international contractor. Also there is a career change after degree when you have to decide to stick with Civil or specialise in Structural Engineering. The latter suits academics more, and the former suits hands-on and management types more. I've nothing against Architects by the way. I hope that clarifies somewhat. Discuss.3 points

-

I have a pet theory that a good few self builders (if not most of us) are tipping the scales at this end of the spectrum 😉2 points

-

2 points

-

You don't need a passive house engineer. There's very little relationship between calculating the loadings of a building and insualtion. It's your architect that needs to be on the ball with things like efficient form, cold bridging etc.2 points

-

2 points

-

Coolio. Get the order of events clear, post your 'plan of attack' here, and "we" can offer support and critique before you push the button. For a bit of respite, there are many folk far worse off, and this is recoverable. Time goes, that's a given, but the effort here and now will produce dividends for sure. 👊1 point

-

Indeed. Be pragmatic, and be firm. Keep the threat of legal action back as a last resort. Hopefully you won't need to show that card, let alone go the route of legal recourse. If you do then I think you'd be successful in this instance, but don't assume you will be. Consider costs before lighting any fires. CAB will be a great sounding board, as will BH.1 point

-

He gave me 2 options : 203X203X71 UC with steel bearing plates on the sides 305X165X54 UB.1 point

-

1 point

-

1 point

-

They can’t be arsed so want the easy option. some timber wedged in the web of the beam. Fine for the national housebuilders….1 point

-

1 point

-

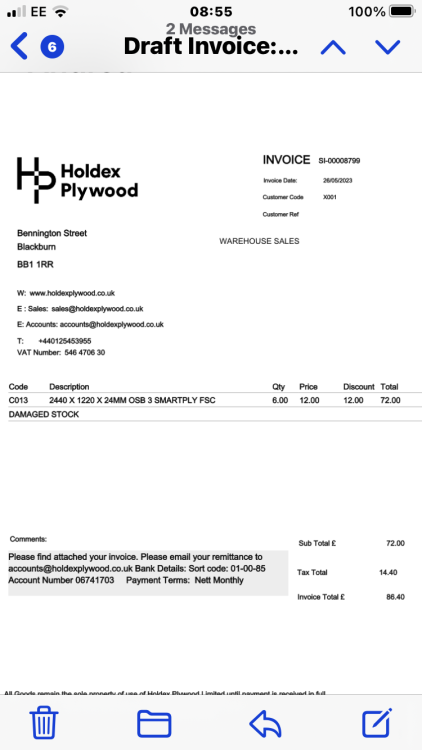

Yeah I know how you feel, having been caught by insulhub I was very nervous of paying by bank transfer, the boss at Beco let me pay a deposit with the balance on delivery so that was a little more comfortable.1 point

-

1 point

-

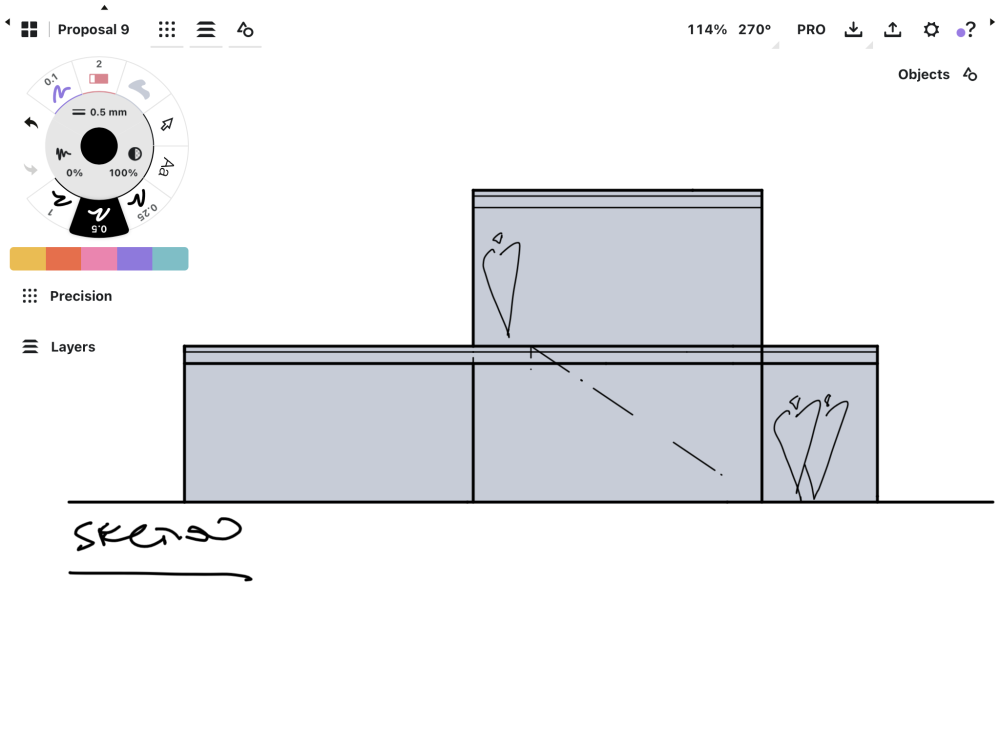

A good point about building a very expensive basement then using up floorspace. That will work especially if you like plain walled brutalism.1 point

-

I’ve had the MKM man visit my site 3 times this week flogging me kitchens, bathrooms, and doors. He also mentioned prices for materials coming down.1 point

-

Far better option AFAIC and saves on precious GIA. I thought closer to 13o? I would not want the entirety of the basement concrete to be at exactly that temp and then to have to try to mitigate retrospectively / internally. Seems a no-brainer to dig a bit wider and drop 200/300mm of EPS around / underneath. At depths of 2m and more, the ground temperature does not deviate very much from the average summer/winter surface temperatures (around 8° to 12°C [46ºF to 54ºF] in the UK depending on location). At this depth, there is an enormous store of heat that can be usefully tapped for heating in the winter.1 point

-

1 point

-

1 point

-

The arithmetic and science, once reduced to the SI system is very similar. They all tend to use kg, metres, seconds and temperature.1 point

-

A little rant. Are you sitting comfortably? Then I'll begin. This particular design of Geberit flush plate uses levers - not buttons. It's round - so it's a button isn't it ? No it's not. The visual lie is the roundness of the lever. How do I know? One of the two Geberit flush plates we installed broke. So I had to take the flushplate assembly off the wall. The lever is made of a very thin, springy piece of stainless steel, it's stuck to the back of the so-called button. In normal use, pressing the 'button' means people press the middle of the circle. So less than half of the potential power of the lever is used - and the resultant water flush weak. With obvious results - or lack of result if you like. The only way to make the flush work as it should is to press and hold the bottom of the lever while the flush takes place. For the priviledge of being allowed to buy two flush plates, I spent £160. And the ones we bought were the cheapest available at the time. "Oh, yes, they have been known to fail " said the Geberit Tech support guy. And promptly sent me another flush pate assembly of exactly the same design. One word for it ..... Shite.1 point

-

1 point

-

@pocster we do refer to it as the ‘Upstairs Basement’. I guess it’s a sign of my sheltered upbringing that ‘Hidden Pleasure Dungeon’ didn’t spring to mind when it came to the naming ceremony.1 point

-

We had a condition to our planning requiring an "archaeology" report. I sighed thinking that's another £xxxx to find. So I asked what they wanted and it turned out it was a combo of detailed photos of our old house pre-demolition and a narration of the history of the plot etc. So I asked if we could prepare such a report ourselves and the City Archaeologist agreed. My partner takes an interest in local history so had already done most of the research. I have a good quality camera and tripod. We made our own surveyor's ranging rod by painting a broomstick red and white and set to work. It took a lot of work and hours collating but we were commended for our work by the CA and it was satisfying to save a shedload of cash that would otherwise have gone down the drain.1 point

-

Is this a windup? Consider it successful. The majority of Civil Engineers end up in general management, many outside of construction. SE is a subset of CE. Perhaps you have only met the ones who are proposed by architects. The likelihood in this case is that the SE had a very limited brief and low fee....as set by client or their agent.1 point

-

Yes sure The way they were talking it sounds like the reductions will be across the board No pun intended They where packed to the rafters with sheet materials Nice to be talking about reductions I buy a lot of insulated plasterboard I think that will be next The insulation stockist that I use is running stock down As the increases are not sustainable good news for all on here1 point

-

Centre of the frame, bead of decent sealant on the lip of the cill only, then screw down but not so much that you distort the cill base.1 point

-

1 point

-

Well done @Adsibob. I know that this is not your trade. You will get a lot of satisfaction from doing that.1 point

-

Just a quick update as not much has happened. Still waiting for confirmation of "commencement" from BCO. Have just paid diggerman - £560 which I think is reasonable for 2 trial holes, one 8 m trench 1.2 m deep, and exposing massive roots of conifer. Two visits in all. Grinder coming to deal with conifer stump on 30 June so will post photos.1 point

-

I think this is an oversight. An SE is only expert in structural engineering. He has no appreciation of aesthetics, convenience or even client management. This is why they are traditionally employed by, or in conjunction with, an architect. There are of course exceptions to this general rule, but in the same way you wouldn’t ask your kitchen fitter to design your kitchen, or your tiler to give you tips on interior design, you don’t leave key dimensions that impact the design of your extension to an engineer.1 point

-

Dig down 250mm and shutter the edges to the correct size with OSB then put 150mm of EPS in the middle of it up to 250mm from the edges, DPM over the lot and then pour fibre reinforced concrete - you’ve got a pretty well insulated slab along with a ring beam that is never going anywhere ..! Just remember to duct in for the power and water !1 point

-

Can you make 1220mm doors work as that is the width of a sheet of MDF, at 1250+ there will be lots of waste and more expense I suspect. A thin strip across the top of the doors of 30-40mm would let 1220mm doors work and may give a neater finish.1 point

-

Exactly, one group is ignorant of science, the other isn't. It is how to educate the vast majority. The science and theory behind heat pumps is talk at secondary school but not reinforced often and then forgotten. Madcap ideas that skip the science and theory are reinforced ever day, even within the heating industry.1 point

-

As soon as you can’t score it with your heel This weather you wouldn’t get it up with a pick after 24 hours1 point

-

I let a hose slowly run over mine in the daytime for at least the 1st day . You want it to cure slowly . Keep it damp1 point

-

7N is actually 7.5... https://www.mannokbuild.com/aircrete-thermal-blocks/1 point

-

When a cat walks over it and you can't see the paw prints....1 point

-

1 point

-

Builder will say tomorrow or the architect will say a week. Monday would be a good compromise1 point

-

Floorboards above the joists. Spray the bottoms white. LED strip lights (the equivalent of florescent tubes) in the "bays" between the joists. Sockets on the sides on the joists. That'll give useful spread out diffused light (unlike downlights that bounce off what you're working on and blind you) and sockets in places such that you don't need to run extensions everywhere. Plus you can put lightweight bulky crap on top of the floorboards.1 point

-

If using only 6mm I would make sure ply edges between joists were supported (I.e. scrap wood screwed to both edges).1 point

-

I think you need to define gubbins in a bit more detail to work out how much room you may need. My plant room (cupboard) is 1.2*1.2, will house the cylinder which is about 600mm diameter. Expansion vessels will be wall mounted, and the hot and cold water manifolds will be wall mounted high up too. Pipework will run round the perimeter. The UFH manifold are located under the stairs (centrally in the house) so just a supply and return pipe to this. MVHR is in the insulated attic space. there will be 1 Consumer unit too. The challenge is placing everything so that access and maintenance isn't too much of a challenge.1 point

-

If you are going to buy scaffold, then buy one of the system scaffolds like Kwikstsge or Cuplock. Whatever is available. They are really a scaffold tower system where you can join as many towers together and build whatever height you are likely to need for a self build. Very simple to erect and change about. For inside use you can build a single tower and put it on wheels just like a scaffold tower and move it about. It is so useful that at the end of the build, I did not sell it all, I kept enough to scaffold one wall of the house. It is just so handy to have when you need it.1 point

-

I bought mine, but it's not something to do lightly - you do need to know the rules to buy, erect and maintain it. You also need to be prepared for when it turns up, with people to help unload (especially if it arrives loose) and somewhere to put it (scaffolders would erect it direct from the lorry, you'll need to unload it all). Potentially a good idea. You'd probably need them to specify what to buy too. There is also a requirement to inspect and record the state of the scaffolding at least weekly - more frequently if there has been adverse weather or if the scaffold has been modified - and to remedy any problems. I'd suggest getting yourself onto a scaffold inspection course if you want to pursue this.1 point

-

I think you put too much emphasis on being 'neurodiverse' you have written it in almost every post of yours. There are plenty of self builders with autism and adhd and a host of other things, you shouldn't let that define you and hold you back and it's not as big of a deal as you think. Neurodiverse people will have advantages when it comes to some things the others do not.1 point

-

I've just taken delivery of my PolySteel ICF, they would not / do not take card due to costs. Had to pay by bank transfer 😕. Was a twitchy 8 days. Not a great sum, but would have sunk us if they went bump.1 point

-

The business case for self-build scaffolding (like Cuplok - other brnads available) is compelling. I've had mine for eight years now. While we're getting rid of building kit slowly, I'm loathe to sell our scaffolding. We have two indispensable stillages made out of the stuff. And its in use today because we are at last rendering. Read @Conor's last paragraph immediately above. If you've mastered the trick of lining everyone up and you are ready to go - fine - hire. But if not, put a few thousand aside.1 point

-

A 3.5m alloy tower was one of my best build purchases. Can see it being used for odd jobs for years to come. The big advantage of hiring is that you've somebody that will pick up the phone and get that extra lift done or an extra bay. Ours put up a two lift bay in our stairwell for £50. No extra hire charge. If you have bought your own that kind of thing can be a pita to do if you don't have a fitting team at your beck and call. BUT .. you will need the scaffolding for rendering, roofing etc. You'll need it for many months unless you have managed to get everybody lined up and ready to go. We waited two months for roofer, three more for the renders. Think our total scaff bill was £9k.1 point