Leaderboard

Popular Content

Showing content with the highest reputation on 01/23/23 in all areas

-

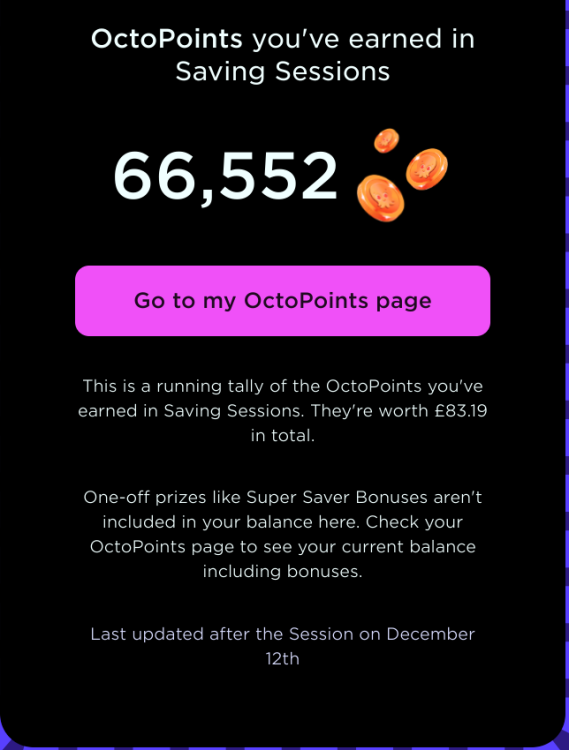

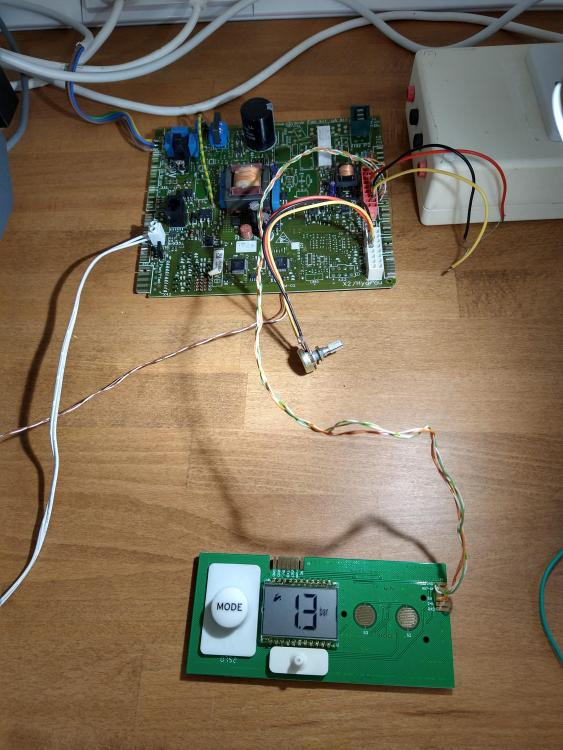

I guess this post doesn't really belong in Boilers & Hot Water Tanks so I'll offload it in this subforum. The central heating system in our house is fired by an ageing Glowworm Flexicom 30HX (heat only) condensing boiler. It's probably on its last legs but while it still works I'm keen to squeeze every drop of life out of it. The main drawback with it is that there's only one flow temperature (set on the front panel display with a couple of pushbuttons) for both heating and HW, with only one demand switch input. Because of this limitation I have to set the flow at around 65oC minimum in order to get anything over 55oC into the HWC so I can't have a lower flow temperature separately for the radiators - which would improve efficiency. Not without investing a few hundred quid in Glowworm's own external control kit that is... this kit talks over a proprietary serial bus called "ebus" and combines a switching unit with inputs for HW cylinder stat and room thermostat(s) for CH temperature and scheduling. Luckily for me, Glowworm were gobbled up by Vaillant before the Flexicoms were released, so under the sheet steel it's pretty much a Vaillant ecoTEC with some budget component choices so while Glowworms don't get much attention, plenty of people like to integrate Vaillant boilers with the HomeAssistant OS. For this reason I set about seeing if I could adjust the flow temperature over ebus using the RaspberryPi that already runs my CH system. If I can make it emulate the external controls, I can set a lower flow for radiators and UFH and implement an X plan scheme. The first step was to pick up a spare main PCB and display panel on ebay to mess around with (too cold to risk messing up the real boiler). Here it is dangling precariously on the bench: It's powered from a 240V isolating transformer so not quite as lethal as it looks. Not quite. The first thing I noticed was that, in its former life, it was a combi boiler (Flexicoms come in three flavours: CX (combi) SX (system) or HX(heat only) like mine). For giggles I stuck some 10K resistors on the NTC sensors and water pressure sensor to see how it would run. It still kept throwing faults until I did some googling and found out that the pump is tested on power-up by looking for a small increase in pressure when running. This was fixed by manually tweaking the pot a bit and kept it happy enough for me to play with the serial interface. That's about as far as it will go without an fan and ignition unit though. But at least I could connect it to an ebus interface and talk to it. There are some PCB's out there to interface ebus to RS232 but it's a simple enough thing to design so I built one on some stripboard that plugs onto the Raspberry Pi header: The two wire link is going off to the main boiler PCB (although the wire magically changes from black to white along the way!) If anyone's the slightest bit interested I can put up the circuit diagram for the interface board but it's just a dual comparator and a couple of opto isolators. Incidentally, this interface and topic in general might be of interest to anyone looking to integrate Vaillant boilers with other control systems as they don't talk Opentherm. The awkward thing about this particular hack is that ebus timing can be quite fussy when doing bus arbitration and the UART in the Pi has a fifo that gets in the way. However someone already fixed this with a kernel module called ttyebus dedicated to reading/writing directly to the UART. Then there's the oh-so-handy daemon for linux called ebusd which can interpret a wide variety of ebus device comms and access it all over TCP, HTTP, MQTT etc. On putting all this together, the automatic scan performed by ebusd instantly identified the boiler and loaded the appropriate configuration files for it resulting in access to a great many parameters: bai AccessoriesOne = extheatingpump bai AccessoriesTwo = storagechargingpump bai ACRoomthermostat = off bai averageIgnitiontime = 1.3 bai BlockTimeHcMax = 18 bai BoilerType = 6 bai ChangesDSN = 0 bai CirPump = off bai CounterStartattempts1 = 3 bai CounterStartattempts2 = 0 bai CounterStartAttempts3 = 0 bai CounterStartAttempts4 = 0 bai currenterror = 75;-;-;-;- bai DateTime = nosignal;00:00:00;-.-.-;- bai dcfState = nosignal bai DCFTimeDate = (ERR: invalid position for 3108b509030de500 / 072b080101010150) bai DCRoomthermostat = off bai DeactivationsIFC = 0 bai DeactivationsTemplimiter = 0 bai DeltaFlowReturnMax = 22.69 bai DisplayMode = 2 bai DSN = 8193 bai DSNOffset = 1 bai DSNStart = 8192 bai EBusHeatcontrol = yes bai EbusSourceOn = on bai EbusVoltage = on bai errorhistory = no data stored bai expertlevel_ReturnTemp = -1.81;cutoff bai ExternalFaultmessage = on bai externalFlowTempDesired = 90.00 bai externalHwcSwitch = off bai ExternGasvalve = 240 bai ExtFlowTempDesiredMin = 0.00 bai ExtStorageModulCon = no bai extWP = off bai FanHours = 1250 bai FanMaxSpeedOperation = 5780 bai FanMinSpeedOperation = 1500 bai FanPWMSum = 58260 bai FanPWMTest = - bai FanSpeed = 0 bai FanSpeedOffsetMax = -580 bai FanSpeedOffsetMin = 210 bai FanStarts = 30964 bai Flame = off bai FlameSensingASIC = 709 bai FloorHeatingContact = off bai FlowsetHcMax = 82.00 bai FlowsetHwcMax = 80.00 bai FlowSetPotmeter = 45.00 bai FlowTemp = 25.88;ok bai FlowTempDesired = 45.00 bai FlowTempMax = 116.06 bai Fluegasvalve = off bai FluegasvalveOpen = on bai Gasvalve3UC = off bai Gasvalve = off bai GasvalveASICFeedback = off bai GasvalveUC = off bai GasvalveUCFeedback = off bai HcHours = 901 bai HcPumpMode = permanent bai HcPumpStarts = 29164 bai HcStarts = 4500 bai HcUnderHundredStarts = 0 bai HeatingSwitch = on bai HoursTillService = 3100 bai HwcDemand = no bai HwcHours = 263 bai HwcImpellorSwitch = no bai HwcPostrunTime = 80 bai HwcSetPotmeter = 62.00 bai HwcStarts = 22600 bai HwcSwitch = on bai HwcTemp = 116.06;circuit bai HwcTempDesired = 0.00 bai HwcTempMax = 62.00 bai HwcTypes = 0 bai HwcUnderHundredStarts = 0 bai HwcWaterflow = 0.19 bai HwcWaterflowMax = 11.57 bai Ignitor = no data stored bai InitialisationEEPROM = no bai IonisationVoltageLevel = 72.2 bai maintenancedata_HwcTempMax = 116.06 bai maxIgnitiontime = 2.1 bai minIgnitiontime = 0.2 bai ModulationTempDesired = 33.0 bai OutdoorstempSensor = -60.44;cutoff bai OverflowCounter = yes bai ParamToken = 3 bai PartloadHcKW = 19 bai PartloadHwcKW = 30 bai PartnumberBox = 20 00 46 39 50 bai PositionValveSet = 0 bai PowerValue = 21 0a 50 18 64 1e bai PrAPSCounter = 0 bai PrAPSSum = 0 bai PrEnergyCountHc1 = 3291922 bai PrEnergyCountHc2 = 0 bai PrEnergyCountHc3 = 0 bai PrEnergyCountHwc1 = 994043 bai PrEnergyCountHwc2 = 0 bai PrEnergyCountHwc3 = 0 bai PrEnergySumHc1 = 776243897 bai PrEnergySumHc2 = 0 bai PrEnergySumHc3 = 0 bai PrEnergySumHwc1 = 383284736 bai PrEnergySumHwc2 = 0 bai PrEnergySumHwc3 = 0 bai ProductionByte = no data stored bai PrVortexFlowSensorValue = 0 bai PumpHours = 2157 bai PumpHwcFlowNumber = 0 bai PumpHwcFlowSum = 0 bai RemainingBoilerblocktime = 0 bai ReturnRegulation = off bai ReturnTemp = 25.75;65123;ok bai ReturnTempMax = 0.00 bai SecondPumpMode = 2 bai SerialNumber = 42 30 36 30 33 34 35 33 bai SetFactoryValues = no bai SetMode = auto;69.0;68.0;-;1;0;1;0;0;0 bai SHEMaxDeltaHwcFlow = 27.81 bai SHEMaxFlowTemp = 83.31 bai SolPostHeat = (ERR: invalid position for 3108b509030d7304 / 00) bai Statenumber = 98 bai Status01 = 25.0;25.0;-;-;-;off bai Status02 = disabled;76;38.0;80;62.0 bai Status16 = (ERR: invalid position for 3108b5040116 / 00) bai Status = (ERR: invalid position for 3108b5110103 / 00) bai StatusCirPump = no data stored bai Storageloadpump = 0 bai StorageLoadPumpHours = 630 bai StorageloadPumpStarts = 21447 bai StorageLoadTimeMax = 45 bai StoragereleaseClock = yes bai StorageTemp = -14.94;cutoff bai StorageTempDesired = 62.00 bai StorageTempMax = 0.00 bai TargetFanSpeed = 0 bai TargetFanSpeedOutput = 0 bai TempDiffBlock = 0 bai TempDiffFailure = 0 bai TempGradientFailure = 0 bai Templimiter = off bai TemplimiterWithNTC = yes bai TempMaxDiffExtTFT = 0.00 bai Testbyte = 3 bai TimerInputHc = on bai ValveMode = 0 bai ValveStarts = 12893 bai VolatileLockout = no bai VolatileLockoutIFCGV = no bai VortexFlowSensor = 0 bai WarmstartDemand = no bai WarmstartOffset = 0.00 bai WaterHcFlowMax = 0 bai WaterPressure = 0.974;ok bai WaterpressureBranchControlOff = off bai WaterpressureMeasureCounter = 231 bai WaterpressureVariantSum = 65534 bai WP = off bai WPPostrunTime = 5 bai WPSecondStage = off broadcast datetime = no data stored broadcast error = BAI broadcast hwcStatus = no data stored broadcast id = no data stored broadcast id = no data stored broadcast load = no data stored broadcast outsidetemp = no data stored broadcast signoflife = no data stored broadcast vdatetime = no data stored general valuerange = no data stored memory eeprom = no data stored memory ram = no data stored scan id = no data stored scan.08 = Vaillant;BAI00;0202;8001 scan.08 id = 21;10;31;0010005484;1300;021068;N6 So far, so good. But the fact this PCB was obviously out of a combi was bothering me so I went about finding how to change the ID. This turned out to be a simple matter of searching around for the correct button presses - which kind folk had already posted details of how to do it. Now it has a new personality, the same as my current boiler! Then things get a bit more hazy. Some people were looking at the ebus traffic coming from Vaillant controllers with the objective of emulating them but nobody was doing the same for Glowworm controls. It's an open question whether or not Vaillant controls could be used with Glowworms but I'd be surprised if they could. However, after adding an extra configuration for the Vaillant external controls I seem to be able to affect some of the registers relevant to flow temperature. For example, sending: ebusctl write -c bai SetModeOverride '0;50;70;-;-;1;0;1;-;0;0;0' results in being able to read back the following from the board: ebusctl read -f -c bai FlowTempDesired 50 ebusctl read -f -c bai StorageTempDesired 70 The first parameter for SetModeOverride is listed as 0=auto, 1=off, 2=water but the pump relay actually responds differently 0=off 1=on 2=on so I'm not sure what's going on. The second parameter seems to be all I need to set in order to adjust the flow temperature maximum and also shows up when using the diagnostics menu on the LCD in addition to being read back over ebus. I have no idea of the significance of the third parameter (listed as StorageTempDesired in the configuration file) but it seems only relevant to HW in the combi models. Maybe someone familiar with the Vaillant room controls might shed some light? CXdump.txt2 points

-

Looks like the external sensor on pins 5 & 6 has failed, shorted or become disconnected. From the manual:2 points

-

I'm a recent convert. Nothing else quite delivers on-demand heat with a potential for COP 4 or higher. The closest would be ASHP with radiators but low flow temperatures limit the response time. Forget UFH unless you are prepared to have it running pretty much all of the time. Our A/C units are Daikin and they have a "Powerful" mode which, once activated, heats at full power for 20 minutes - but usually it gets too hot by then so we cancel it. This is one way to use it (when you only want heat intermittently) and works well with the scheduler which lets you set a minimum level for other times. Or you run the schedule as you would with any other space heating regime - i.e. timed for comfort at certain times of day and a setback for others. It really is incredibly flexible. And voice activated. The downside of course is that it blows (warm or cool) air around the place and makes some noise to do that. Modern domestic oriented units are much better at this compared to the office style A/C of yesteryear. Occupancy sensors and directional vanes on some models will attempt to vector any breeze away from people. And noise levels can be controlled down to remarkably low levels. What you would be advised to do is look at how you might site the indoor unit(s). The best arrangement is if they can be wall hung somewhere distant from where people sit. I have an 8.5m long room with a unit at one end and the most comfortable spot is at the opposite end. Not by a huge margin but noticeable. I think they suit open-plan layouts much better than individual rooms but with multi-split systems available, you can certainly use one per room.2 points

-

2 points

-

As I promised I have created a first-cut model of weather compensation, attached. Its based on the Mitsubishi PUZ-WM112 performance data, which is pretty comprehensive. I have modelled the CoP with 5 different W/C schemes and none, estimating the CoP as a function of flow temperature and ambient by linear interpolation. Weather data is average daily temperature for 2022 from the Met Office Central England database. The average daily temperatures are collected into bins 1 degree wide, the number of days in each bin counted, and then the load and consumption for the conditions calculated and multiplied up to get the total annual for that 'bin' according to the w/c scheme selected. The totals for all temperature 'bins' give the total consumption over the year. This is compared with the total demand calculated the same way to get an average CoP, and the total for any particular w/c scheme compared with scheme 'none' (ie no weather compensation) to estimate how much w/c saves. The 'ideal' W/C curve is based on adjusting flow temperature to precisely match demand at ambient temps other than the design temp, using the heat output curve of a typical radiator (which varies as (flow temp-room temp)^n where n=1.3). If someone can tell me how UFH output behaves as a function of flow temp I can model that. Other curves are variants of this, Simply put, it suggests that the various weather compensation schemes I modelled save between 11% and 15% over no compensation at all, which is, frankly, disappointingly small (so I am a little nervous a mistake has been made - but I cant find it). The model takes no account of inefficiencies due to cycling, only the improvement in CoP. This might be significant, if anyone has any figures it might be possible to add them in. I will write it up in more detail over the next few days and - health warning - there may still be errors so, until its been peer reviewed or checked against real results, treat with extreme caution. If anyone wants to critique, contribute suggestions, discussion or actual results of comparing the effects of weather comp, I suggest to do so here so as not to hijack other threads. WC Simulation.xls1 point

-

Comparable, I'd say, to the real cost of installing a fossil fuel boiler and multiple radiators - especially if not on mains gas. There are two main issues that I can think of. Obviously if there's only one outdoor compressor unit, then the indoor units can only cool or heat together. Less obvious perhaps is that the simultaneous heating/cooling capacity will be lower and all indoor units will go idle during defrosting mode. Neither of these is a show stopper but having one-to-one indoor outdoor units doesn't add a huge premium when most of the cost is in the indoor units. Here's the two outdoor units that provide us with a total of 7kW of heating for around 1.5kW of electricity. Quite a bit smaller than an ASHP and more practical to hang on a wall.1 point

-

We are a slightly higher building reg self build on Skye. Nothing fancy, just a modest three bedroom 138m2 completed in 2020. Our installation consists of three extraction points in our en-suite, bathroom and utility this goes into a metal ducting into a mini air source heat pump on top of a cylinder. It takes that air and heats our domestic water (not heating) and blows cold air outside. It also extracts moisture through a pipe to the outside to help with humidity. It was quite cheap to install and is cheap to run. It's very consistent in the energy usage as it's not trying to take cold winter air outside like an external heat pump therefore always achieves a very higher cop. Points to consider: sound proofing - our sits in a cupboard in the utility room. No noise in the house, but when working its slightly louder than a fridge freezer. We have it on anti vibration mat. We also used flexible ducting just before it goes into the unit. Get one with a good quality tank, some have anodes which require maintenance. A better quality one, such as a Joule cylinder does not. Mostly importantly, as its sucking internal air into the system and this will pull cold air from outside. We manage this by having lots of south facing glazing which heats the house for about six months of the year and allows for a bit of this free energy to be sucked up into the system. In the winter we rely on a centrally placed wood burner. Having access to free wood means that I can heat the house, with a few sticks and also the heat from the stove goes into the system. I am in an unique situation and if I did not have endless wood it might not be so attractive. That's not say it can't work efficiently in other circumstances. With the £400 rebate and further expected £200 rebate as a non gas customer, we will have no energy bills for ten months. I don't have any solar panels at the moment, but might get some fitted in the future. Here's my blog if you want to see pictures of the set-up.1 point

-

Yes, ducted just means the warm/cool air is delivered to the room via pipework and is sent into the room by grills or circular diffusers in the ceiling (normally), rather than physical units sat on the floor, high up, or ceiling mounted. The bits that do the work are suspended in the loft. Can be a multisplit, or non multisplit depending on how you want the system. In my case I have a multisplit going in Costing about 5,500 all in, which I think is in the right sort of ballpark, not cheap, but I'm doing this once and if it means the build takes a couple of months longer then so be it.1 point

-

1 point

-

Yes, it is an unvented system so will require a pressure vessel too. Check your current plumbing is capable of mains pressure. You can dispense with this as you'll have mains pressure hot water, a vastly superior experience. Disclaimer, I've never used one, rather learned here about them. I like the theory however. A search of the term "ESHP" should point you in the right direction. You might fall in to G3 regs which technically require an annual check AFAIK. Stand alone systems. No interdependence. It depends, a multi split is one external to many internal. A simple split unit is one for one. More knowledgeable folk than me could point to the advantages/disadvantages of siteing close to the indoor unit. A warm location for an external unit is a bit mute given the enormous volume of air they move, so long as the fan isn't constantly fighting the prevailing wind or in a tiny alcove that will become refrigerated by the external unit you'll be ok.1 point

-

Option 1. DPC for DPC sake makes no sense to me. You already have a continuous barrier under all the house.1 point

-

Ceramic tiles looking like concrete appear to be fashionable. Too realistic for my liking esp where there is 'damage'. Repeat patterns bother me so check for that. But then so does any material that is deliberately allowed to look temporary or deteriorating. Any flammable material would need treatment which would alter it. Cement boards come in many finishes so there is rough to ultra smooth. You might need to visit different merchants to see. I assume you would glue it to avoid screws.1 point

-

Also have a look at wood wool boards, which will also give some acoustic benefit too, recently saw a house with the entire ceiling done in them and it did look really nice1 point

-

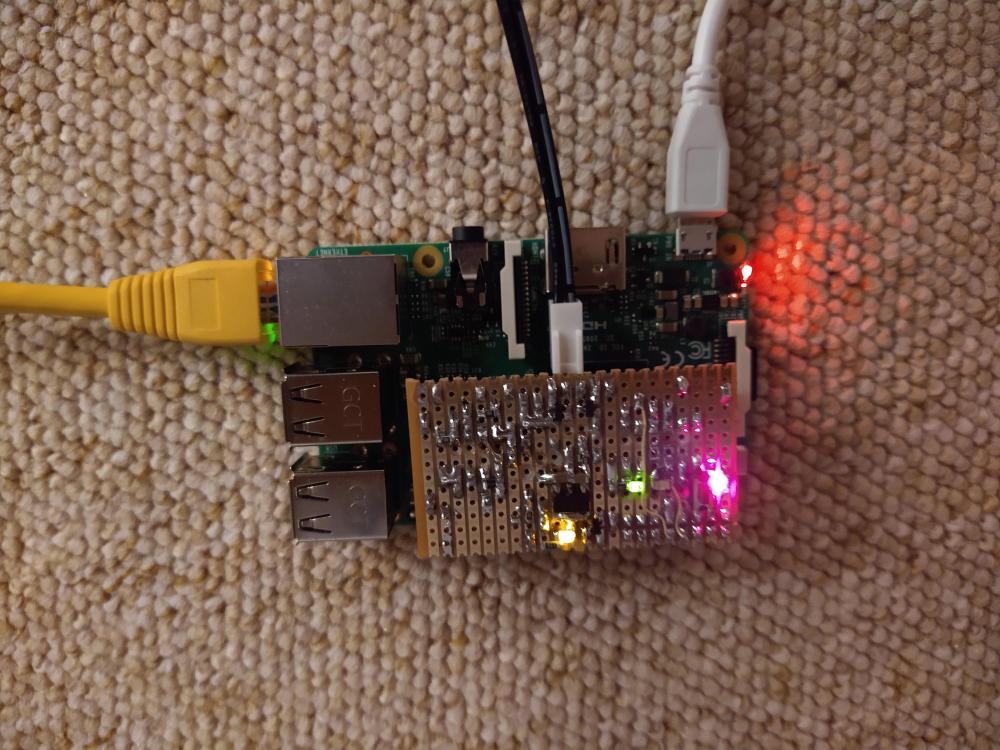

Turning stuff off is easy, I have a button in Loxone for price surges. Made no difference though as the battery still at 40% from good PV around midday so not importing anyway. Given the news I could have put the battery into export, if there was a financial incentive rather than penalty for doing so!1 point

-

Welcome to BuildHub. No reason it can't work. We had the same thought when we saw what the cement board we have in a few places looked like (before it was tiled). You could buy a piece and experiment with different finishes. I'm sure you could make it look more interesting with a waxed or lacquered finish, or even ragging or coarsely thinly/randomly trowelling on some tinted plaster or cement. Even some offcuts that we left outside developed an interesting patina after a few rain and drying cycles.1 point

-

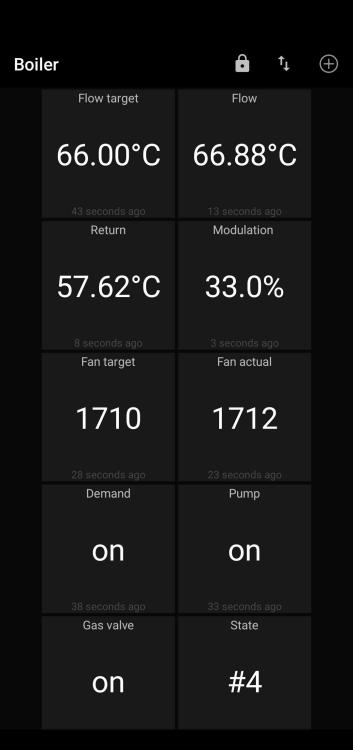

Progress: 😎 Now I've just got to squirt the above MQTT data into a database so I can graph it up. But it's already obvious to me that despite my novel HW cylinder buffering scheme for a small UFH zone , the boiler is still suffering with too high a return temperature (33% is the lowest it will modulate down too - nice of them to actually present this figure though). This screenshot was taken just as the boiler was about to shut off and go into anti-cycling mode as the demand was still present with a HW cylinder setpoint of 55oC in buffer mode.1 point

-

I think part of the problem is that people treat it like old fashioned gas heating. Turn it on for a couple of hours at full power, turn it off, then hours later, pull power again till bedtime. Going to be hard for people to realise that has never been a good way to heat a house, but 50 years if it being the norm is going to take some changing. I could drain my car fuel tank in less than 2 hours at maximum speed, and only go about 180 miles, or I can run it for 12 hours and do over 700 miles. Start and end points have not moved.1 point

-

Congratulations on the newborn. It's a special time, and the house. Also having ones own home is something to celebrate, even when it needs improvement. I have been studying this and making assumptions...…. 1. You like the house and the area. 2. It is sufficient in size and layout for your needs. 3. A budget for a knock and rebuild is completely off the table? 4. It suffers from poor ventilation. 5. You have lots of drafts, lots of outside doors, lots of sliding patio doors. (Notoriously draughty) 6. The house has awful thermal bridging, especially the extension with all the steelwork etc. 7. You are relatively confident regarding DIY etc 8. You need to live in the house whilst any work is ongoing. 9. The house swallows heat like there is no tomorrow given it's large outside surface area vs internal area. (form factor) 10. You need to live in the house whilst any work is ongoing. 11. You will be able to afford over a few years to get it to a good standard. Just not in one go. 12. You're off the mains gas network? I don't know much about Bregs, especially in Scotland. However in practice it's unlightly anybody will stop you. Tell the neighbours how bad it is, with the baby etc and they'll be lightly to support you rather than call the council. Here is my proposed list of actions. 1. That flat roof has to go. Take it down and scrap the lead. Erect a proper pitched roof integrated into the original house. Assuming you have at least 10 deg pitch you can use roof tiles which are cheap and durable. Leave at least 600mm overhang at the gables/eves. Insulate it all with 400mm+ of insulation. Rolls of mineral wool are cheapest but a blown one like cellulose or Glass Mineral Blowing Wool will be easier to fit and re settle when you put in ducting, pipes and wires at a later date. 2. When budget allows strip the original roof and with a bell cast extend the eaves and gables at least 600mm also. 3. When the money allows for new windows and external insulation go ahead and do this, You can do one wall at a time if budget is constrained. Take the insulation around the outside of the steel poles and existing stone walls. You can continue living in the house while this goes on. Install the new windows in the insulation layer. Good quality PVC are fine, compression seals are vastly superior to brush seals so avoid patio doors, bifolds and sash windows. 4. Install some kind of ventilation system that draws air out of all wet rooms continuously and vents it outside. This can be done now, a decent inline fan, a silencer and some ducting would be enough to get you started for a few £100. The only really disruptive part of this is taking the roof off. Everything else can be done bit by bit and without upsetting the apple cart inside. Important with a family there. You could even use the opportunity of external insulation to really spruce up the outside, metal wood cladding etc.1 point

-

1 point

-

A customer of mine many years ago asked me to create a cat tunnel, only one flap tho, from her kitchen worktop through a wall with a dustbin outside for the cat to jump on 🤷♂️. It worked great.1 point

-

>>> Were you at the blue parrot Friday ? I usually do one of my other rough looks when I go.1 point

-

This summer-time exercise worked for us. Feed them outside for a week. Then - with the cats inside the house - put their feed outside at the tunnel entrance with both flaps up. Then one flap down .... Then do the same with both down.1 point

-

Power of and took off the top of the unit and one of the wires was indeed lose. Tightened up the screw that clamps it. Shower running for 5 minutes without any tripping. Hopefully that's it sorted for the time being. Thank everyone for chipping in with suggestions. Far more comprehensive list than my googling gave me.1 point

-

Well at the other end of the spectrum, our ASHP consumes about 1200kWh per year heating our 150 square metre house in the Highlands and another 1030kWh heating DHW so a total heating bill about £624 per year. I do wonder why some with what should be well insulated houses have such high usage. I often wonder just how low our bills would be if we had built the identical house somewhere less cold that the Highlands.? There are plenty of people with lower heating bills than ours.1 point

-

James May did an interesting thing about his Porche A/C lights, think it showed red when it was on, and nothing when it was off. If it was the RCD, which is a device that trips if there is an 'earth leakage fault' which basically means that a wire is loose or damp, causing a mismatch between what is going in and what is going out, then turn off power and look at ALL the wired connects. If the fuse has blown this shows 'over current' and the fuse blows to stop anything catching fire. The RCD and the fuse/MCB (mini circuit breaker) do different things, though there are combined units that can do both. There are many things that can cause an RCD to trip, one is damp, and shower pumps can easily get damp.1 point

-

Also GSHPs are very expensive to install and probably similar running costs to an ASHP. In theory they ought to be more reliable over their lifetime than an ASHP. I briefly looked into it and it was going to cost circa £28,000 to fit one. There is little doubt that a poorly designed/installed ASHP that isn’t setup correctly is expensive and your average punter has no chance to understand any of what’s needed to fix it.1 point

-

To many variables to comment on, the house may be huge, the heat pump huge, setting everything at high temps, loads of zones, heat pump cycling, poorly commissioned. Do the same with gshp you would get a similar outcome. PV in winter output is the just about zero anyway, so will have little or bearing on monthly heating bills. Many on here get excellent cost effective heating from an ASHP. Mostly down to how you set things up and operate, keeping flow temps as low as practical.1 point

-

Your local council is responsible for this. https://www.warwickshire.gov.uk/directory-record/1190/street-lighting Councils tend to list a cost of around £1500-2500 to move a light up to 3m. Costs rise substantially if it has to be moved further.1 point

-

A quick google https://www.mepa-shop.de/en/window-sills/aluminum-window-sill-accessories/anti-drumming-strips-for-window-sills/anti-drumming-strips-for-window-sills1 point

-

Don't use 35mm battens, just double up 25mm ones so you have 50mm. Also cheaper as you can order a big job lot of 25x50 and not risk running out and have less wastage.1 point

-

Make it a condition of the offer that the plot comes with planning permission. then contact the council to see if they believe the development has "started" If they do, the good. If not, then you re apply for exactly the same plans and the vendor waits.1 point

-

Yup. I always spec a rising cold main at the kitchen sink, if the primary one rises in the plant room, so there’s no wait for raw, cold water. My main concern was, if there were to be any hot returns they’d need insulating.1 point

-

We have alu cills with our Norrsken windows - the only noisy ones when raining are the small GF windows in the gable end; the FF windows in the same gable (including the one in our bedroom) are not affected, presumably they get enough protection from the roof eaves.1 point

-

Then a harder hit with a larger tool. Well at least your are happy to get the tools out and give it a go. We like that.1 point

-

Plug a desk lamp in the socket the pump's plugged in to to make sure power is there? Also give the housing a sharp hit with the handle of your screwdriver to see if you can unstick the flow switch.1 point

-

1 point

-

May be the RCD and a mini circuit breaker is in the consumer unit. Is anything 'tripped' in there?1 point

-

1 point

-

1 point

-

Much better one here for £112. LINK Plumber will charge more to come out and condemn the existing one. Time to put good money after good, especially if you've been having trouble before.1 point

-

1 point

-

1 point

-

That's a tremendous amount of info. Well done. Will go through it later.1 point

-

Ouch? In the context I was talking about the general benefits to the world/society. I don't think it's too contentious that an ASHP will produce a unit of heat for less CO2 than a fossil burner. And I don't think it's wrong to consider that a benefit. But, no, that's not my situation. I don't have an ASHP. In fact I first started asking questions on forums when I was considering getting one. The advice I was given was completely sound. Don't, until you've done as much insulating as you can do. That was a few years ago and since then "operation insulation" has been in play. I work full time and my budget is not huge, so I'm doing most of the work and learning as I go, whilst living in the house, and life is busy, so the pace is slow, and there is loads to do... And lots of unexpected issues... but I'm pleased that our gas consumption has already decreased from approx 24000 kWh/year to about 10000 kWh/year. Of course I'm pleased for both the cost benefit and the environmental one. I know in the grand context of things such a saving is a drop in the ocean, but it's the drop that I have control over!1 point

-

Rope in the ducting is the best way. I have a few long lengths of ducting with rope buried around the plot in readiness. Getting the rope through a long bit of ducting can be a challenge though. In my case I used the slope, gravity, and a socket. Tie it off at either end to a bit of wood. I used the cut up plastic advertising board that was advertising our plot for sale which was oddly satisfying. That combined data and power cable looks good. You could always phone an installer and ask them what they’d need. When it comes to electrical ducting my view is to put in more than you think you’ll need. Much harder to do it afterwards.1 point

-

1 point

-

In a previous house I owned, the gap was sealed with linseed oil putty. In just a few weeks after it was fitted, the local birds had removed all the putty from the upstairs windows. I assume they felt downstairs was just too exposed to danger for them to do the same. Could yours be the same, it was sealed originally but has been removed by local wildlife?1 point

-

1. Almost certainly 2. No. 3. Yes. And perhaps ask them why they thought it was reasonable to leave the job unfinished. Was there no damp *whatsoever* before the window swap? If that is the case you may wish to get a quote for remedial work and forward that to the window co. I am not au fait with attaching pics on this site but probably shrinking them as much as poss will help. Edit: Just realised this was 3 years ago. Had you not noticed the gaps till now? The installer could (a) say 'too late', (b) argue that had they been informed immediately after the installation the damage you may now ask them to repair would either not have occurred or would be less severe1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)