Leaderboard

Popular Content

Showing content with the highest reputation on 09/25/22 in all areas

-

3 points

-

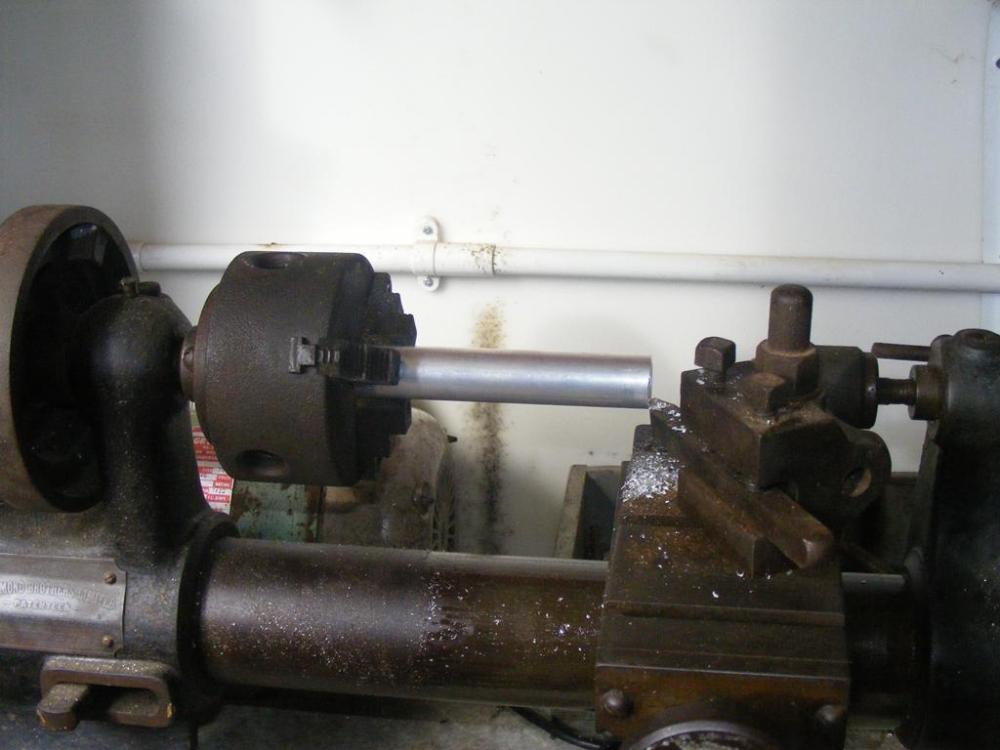

More progress today. Attaching the frame to the wall. Drill a hole in the wall, drilling through the wood fibre EWI until the solid ring beam is reached. Insert an aluminium spacer and a long coach screw will then fix the timber to the wall. On final assembly that gets lots and lots and lots of sealant in and around that hole. The very good news is the wood fibre I was drilling into is completely bone dry. First time I have done such an exploration since it was put up something like 5 years ago. The spacers were made from aluminium tube, cut to length roughly with a hacksaw and then faced off on my vintage lathe. I needed to drill a pilot hole for the coach screws into the solid wood. The drill bit is a lot smaller than the bore of the spacers and I wanted the hole somewhere close to the middle. Time to improvise, a "jig" made from a spare sealant tube nozzle and duck tape. And here is the basic start of the frame now attached to the wall, the outer edge is supported on packing blocks from the scaffold at the moment. Next thing needed is the posts, and for that I am awaiting post feet. I think my neighbour who runs a steel cladding business is going to make them for me. Meanwhile back to painting the last bits of the frame.......3 points

-

I’ve been meaning to provide an update on the progress of this build for a while, and I find myself with a spare couple of work hours 🙂 At the end of December 2021, we left you with 95% of the lower floor walls complete, and looking forward to getting the first set of steels installed. Of course, last winter’s weather, including some furious storms, had a thing or two to say about that, which included me going down at short notice and staying in the local Travelodge (other chains are available) ready for the inevitable turmoil that would greet me after the 90mph storm. It turned out not to be too bad, with only limited damage to the caravan awning, and some items moved around the plot. In early March we decided to make our first visit since that storm, and were greeted by a lovely surprise - the first set of steels were in place. I am still amazed at the lack of communication from some building industry people, but as I am told by the locals “its Cornwall”. It was time to order the next set of materials to get to the upper floor stage, which we wanted to get done by the end of June/mid July (it’s always good to have a target even though you won’t meet it 🙂 ). This included joists, flooring, the next set of Nudura and wood to create partition walls. In the meantime, we got started with applying the over-specced, and over-engineeed waterproofing scheme that our “professional” had stated we needed after deciding that their first spec was not up to the mustard. Can I just say at this point - there is an awful lot of discrepancy with what we self-builders are being told is required, and even after asking a lot of dumb questions, it’s almost impossible to get a straight and consistent answer, even from the same person sometimes. This is where having some common sense mixed with an engineering/technical background does come in extremely handy. Suffice it to say, that I have ditched some of the “uprated” waterproofing spec on the basis that logically it was overkill for the build type and soil conditions. Some will question “what about building warranty/guarantee” which is fair, but on the basis that we are not intending to sell and to live there for many decades to come, we are prepared to take what is a very small risk on this. Come early May, and with careful planning and scheduling I had 3 major deliveries lined up for the same day. The careful scheduling went South of course, and everything turned up within an hour of each other. 3.5 non-stop hours of handballing Nudura ICF, webjoists and floorboards, a 150kg, 6m long glulam beam (more of which later) and enough wood to build an ark (at least that what is seemed like at the time), I was a gibbering wreck, only fit to nurse a mug of tea and a heavily bruised thigh (did I mention a glulam beam?). For 5 weeks between the end of May and the beginning of July, supporting partition walls were created and installed, joists hangers and joists put up and some flooring. This work also included the installation of that 6m glulam beam which was a one day job on its own. So finally, at the beginning of July we were ready to miss our end of June/mid July target date but roped in some family members to help get us cracking on doing the second floor Nudura walling (the pic of the family is from July 10). . We were still on for an end of July concrete pour, until …… I would insert some pictures, but cannot take responsibility for any impact they have on the squeamish and faint of heart. Neither we, or any of the medical staff who have been involved with the treatment, can put our finger on where the infection came from but shortly after that July 10th picture of the family, the wife was struck down with Cellulitis that turned into necrotising fasciitis, which could have led to sepsis. If you read the link, you will realise that building a house suddenly becomes the least important thing on your mind. However, I am happy to report that the first operation saved her foot, and quite possibly her life, and the subsequent 3 operations to clean and repair the foot have been traumatic and very worrying. She is now on the mend but ….. I AM DOWN A LABOURER. Thanks to the NHS, however, and the enforced hospitalisations, and visiting being taken care of by other family and friends, the wife was able to send me to Cornwall (rather than Coventry) and I managed to get the walls finished and the concrete pour took place on September 9th. Now to wait for the second set of steels to go in, and I can order the roof joists. We might be semi weathertight for the winger 🙂2 points

-

Too right. I am not going to push a car a mile for 50p. A human needs around 2 kWh a day, that is a a fifth of a litre of diesel (ish, would not matter if it was a quarter). My local Tesco is charging £1.80 for a litre. So 2 kWh is 30p (and some clubcard points). The best value for calories food that is easily available is lentils, my local Tesco sells a kg of them for £1.80. They have around 4 kWh of energy in a kg bag (about the same energy content as timber or other biomasses). So to get 2 kWh cost 90p, 3 times as much as pump diesel. That is before processing costs i.e. boiling. To cook half a bag will take take around 10 minutes boiling (for the split red ones). On my induction hob that will be around 0.1 kWh of electricity, or 3p (ish). Washing up about the same. So close to 4 times the price of pump diesel. Now my favourite curry is, just by chance, a dhansac, a lentil based dish. For £8 I get about a half kilo of it. OK, it has some ghee, very high energy content, and some meat, also high, and a lot of flavour. But I can get all the ingredients for less than a £1 (I can if I want also spend £10 on ingredients at the artisan shops, but it tastes the same and I have to wash the dirt off). So as tonight is my night off, I am going to fill the car up, get a curry and tomorrow, fart the lentils out in a satisfying manner. Ok, probably going to cost me 90 quid in all today, once I add in a drink and a packet of fags. But at least I know what terrific value filling my car up (the major cost, I will drive it about 450 miles next week) is compared to the rest (except the fags, they are calories free).2 points

-

Nope .. but .. That means your septic tank isn’t working properly as they shouldn’t smell. When was it pumped out last, and also do you use bleach etc as you’re probably killing the good bacteria in the septic tank. They are a lot more sensitive than packaged treatment plants2 points

-

Pylontech has some newer generation batteries out. Most people probably know the 'U' series batteries, but there is also the slightly newer 'Force' series batteries. See e.g. here https://www.zerohomebills.com/product/pylontech-force-l2-7kw-lithium-solar-panel-battery-storage/ It looks to me like the Force series is internally the same as the 'U' series... but they come in a more attractive stackable housing. But then there is also the Pylontech 'Pelio' series. https://www.pv-magazine.com/2022/05/11/smarter-e-products-new-residential-battery-from-pylontech/ I can't find all that much info, but it seems Pelio isn't just a re-packaging of the U series... there's an (overlong, corny) launch video from China on Youtube that says energy density is 60% up from the Force (U-in-disguise) series. Anyone know more? I wonder when the Pelios will start hitting the UK market. Hope they keep on being good value.1 point

-

Imagine you live in a terrace, a 3 doors away they are on the same electrical phase. So your PV us generating nicely and your load sensor sends the spare to your 3 kW immersion heater. All good, little goes out if the house. Then your same phase neighbour turns on a big load, say 6 kW. Will this force your diverter to get confused and make you export to your neighbours? Or are the local wires fat enough to not cause enough of a local voltage drop? What happens if you don't have a diverter and just use a timer to get the most probable times of greatest generation to top up your cylinder?1 point

-

1 point

-

I would seriously consider selling up and buying something newer that isn’t going to affect your health. I’m not sure I buy the “it’s the local microclimate” thing, because a good house should be built to deal with it’s climate. If you had a fully airtight and water tight well insulated new build with MVHR you just wouldn’t have mould anywhere, whatever the local climate.1 point

-

You bought an old stone cottage that will have no damp proof course and was built to standards of the era. I could have told you it would likely be a cold and damp building to live in. Unless you hermetically sealed the extension from the rest of the house then the damp air will circulate. I very much doubt it is your location. Put a modern house like the ones many on here have built in that location and I bet you would not have any problem.1 point

-

ok, ok. you all win. I will disregard the crush resistance and run both the SWA 6mm 3-core and the PE sheathed Cat6a U/FTP cable in a 63mm duct and be dammed about the cost and the ramifications that might ensue! (can you tell that my funds are running out?)1 point

-

Hallways and corridors and stairs are part of the ventilated floor space, you may not supply air directly to these areas, but they have to be included.1 point

-

1 point

-

If it says suitable for direct burying it will be. What ducting will do for you, is enable you to replace it for a different type of cable when the "next thing" comes along.1 point

-

If you re silicone you could use Forever White. Has anti mould stuff in it and works.1 point

-

I didn't want to over dramatise 😂 but yes, the first of the 4 ops she has had has been marked up by the medical staff as a life saver1 point

-

Or decentralised control, where the mains cycles are individually tagged for consumption and gobbled-up by anything 'listening' that can make use of them on a one-by-one basis 😉1 point

-

We're direct electric here for everything. From my calcs/experience any space heating is better off done by a heat pump unless your annual demand is less than about 1MWh. (Electricity price dependant) @Spacey73you are already there with your A2A units. DHW is much more marginal given the lower COP achieved once you get to tap water temps. If you've already got an ASHP for space heating it's the cheapest solution. However the ASHP capital for DHW alone will take decades to pay back. Then it's much of a muchness between adding PV and a divert to the UVC or an ESHP. It really depends on where you are beginning from. For us I plan to add PV at some stage to the garage as the UVC has years of life left hopefully. If we needed to replace the UVC anyway an ESHP would be best. The Sunamp argument is separate. They're good for high temp heat sources, if you're really tight on space and need to avoid G3 servicing requirements and need to minimise heat loss requirements. I think an ideal application may be as a replacement to an electrical boiler or conbi in a tight cupboard to self use PV. For most situations a Combi, or an UVC or thermal store will be cheaper. However, who really cares, it's your money after all. This perpetual accountancy would have us all taking cold showers and eating spam direct from the tin.1 point

-

' ... the wife was struck down with Cellulitis that turned into necrotising fasciitis, which could have led to sepsis....' And what you don't say is that she could therefore easily have died. I really deeply , from bitter personal experience, hope she is on the mend. Really. deeply .... In my case, a cat bit me. A favourite, much loved playful cat. Cant take a joke? Dont keep a cat1 point

-

No. It was Chancellor Alistair Darling's 2009 Budget for introduction from April 2010. https://en.wikipedia.org/wiki/2009_United_Kingdom_budge It means we have a 60% tax rate between £100k and £100k + 2x the personal allowance, as the allowance is tapered out at £1 for every £2 of income over £100k. (Though I had to go and check!). I remember the political cynicism of New Labour as it passed into history. Were i in that tax bracket, that's a good reason for doing charity donations for income over £100k, since the Govt will give £1.50 for every £1 donated. (I think) There was a similar thing with the 50% top rate of tax being announced in 2009 and introduced in 2010, despite the lower top rate having existed throughout their 13 years in power. One way to look at that is a political time bomb to allow Conservatives to be branded as pandering to the rich at some point in the future - you saw the coverage over Kwasi Kwarteng doing just that. (Unfortunately I'm no fan of Krazy Kwarteng either. They should not have walked away from stabilising the housing market and levelling up imo.) F1 point

-

The air stops pumping or the wheel stops turning, but the microbes carry on munching and gravity makes the liquid flow. Then the power comes on again. Nothing to worry about. I think human waste and the air contain plenty of microbes and the additives should not be necessary , but wont do any harm. Just avoid the first deposit being after a curry night.1 point

-

Thank you, maybe I should have given it a wee house warming dose when we finished the build but better late than never!1 point

-

Maybe worth trying this. https://septictank-shop.co.uk/category/septic-tank-bacteria/1 point

-

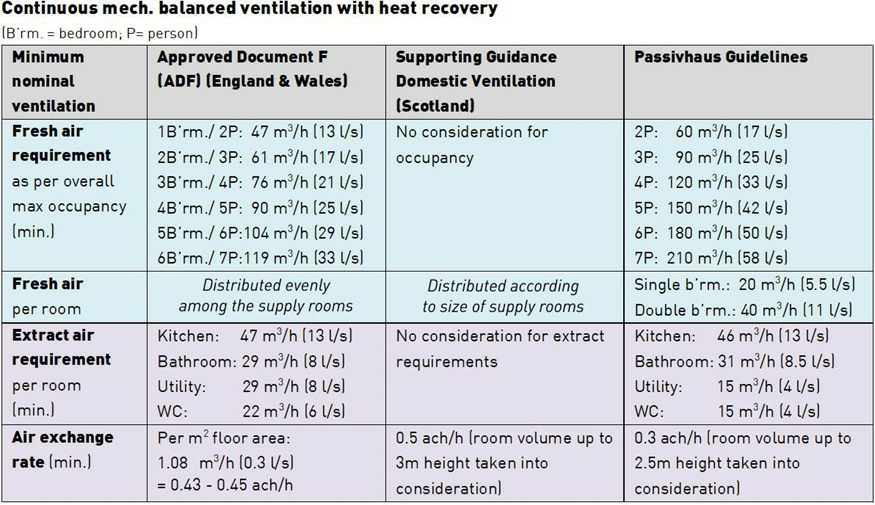

Use the attached will give you good starter for ten. You need your floor area in m2 for a start. Your flow into the house has to match the flow going out. Your inlets and outlets are already in place, so an easy reference for number of inlets and outlets. Inlet in dry rooms extract in wet rooms. Boost rate at 20% above normal flow. Humidity sensors are ok, but you end having to change the settings for summer and winter. So boost switch in wet rooms and kitchen are ok. Size MVHR unit at 50-100% bigger than your flow required, so unit is running almost silently. I have Titon MVHR units which seem ok.1 point

-

Ok so that must be a treatment plant not a septic tank - Chuck one of these in and it will start up properly https://septictank-shop.co.uk/product/starter-kit-home-sewage-treatment-system/1 point

-

As @PeterW says it should not smell. As it is new, it may not have "started" yet? The local advice here is drop a dead rabbit in the tank to get it going. You can buy some stuff to put in to provide it all it needs to get going and start digesting, someone on another thread posted a link. Our treatment plant does not smell at all, even if you lift a drain cover for any reason, no smell, and if you are in the garden right by the discharge point into the burn, no smell. On the other hand our neigbour still has an old septic tank discharging to the burn and that smells a lot at times.1 point

-

UFH wiring hubs can have a dry contact for each channel and you can do nifty linking of the inputs and outputs to give different combos. I've one of these (Hetta branded, but they don't sell them any more) https://www.aliexpress.com/item/4000221789143.html with four thermostats. Multiple stats can be assigned to a channel, and channels can be paralleled also. Plus an additional dry, and a live mains contact.1 point

-

Building regs have two measures, one for ‘wet’ rooms and one for whole house. Do the sums and see what comes out. As a guide, my place is 280m2 and I have installed a 350m3/hr unit but not tested or signed of yet!1 point

-

You can do it either way Sometimes it may be that planning permission for the extension hasn’t come through and it saves time to get on with The inside whilst waiting for PP Q 2 Extending or adding a heavier longer steel won’t be an issue1 point

-

Go for it - I'm 4kW array on a WSW roof - it means we only generate decent amounts around lunchtime but right into the evening. In June-Aug when you get the long evenings to 8-9pm its generating and offsetting house load all the time. Peak I have seen is around 3.6kW from the 4kW array - usually its more like 2.5 with clean sun. That charged the battery to 90% yesterday and even now is offsetting the house daily base load of around 500W Not enough to divert to the immersion heater since last month though. Don't expect any miracles re getting the max theoretical output from the panels. Think of it more like an investment in the building - roof/windows etc - (My opinion only) All this 'pays for itself' stuff is a little odd - gas and oil boilers never pay for themselves - indeed they consume even more money after install to run!1 point

-

Fair enough: not his shout on fire risk. Good point. I was thinking attic with insulation over, and shouldn't have.1 point

-

This kind l kind of thing? 😉 https://www.linkedin.com/posts/markocosic_too-many-people-think-that-gas-boilers-cost-activity-6970379299598045184-i81G?utm_source=share&utm_medium=member_android There are still two sets of three of those heat meters available for those interested in monitoring the actual performance of boilers or ashps feeding cylinders. Viewing the summer daily gas use on octopus also works just fine. Boiler Cost.xlsx1 point

-

So tangible progress today. First assembly of the deck frame. this has been a work in progress for a couple of weeks. As soon as I got the timber I cut it all to length so I could get it in the dry, in the static caravan. And then I have been painting, and painting and painting. Each joist will be getting 2 coats. It takes several hours to dry, so all I can do is one coat in the morning, and then later in the day turn it over to paint the other side. And there is room only to do 2 joists at a time. So that's a throughput of 1 painted joist per day. Today there was finally enough painted joists to put most of it together to see if it all fits. That's the first time it has all been put together. Phew, i got the measurements right. The 2 missing long joists are still in the paint shop. The two end joists and most of the remaining dwangs (nogins) are still to start being painted. I have now dismantled it again and re assembled up on the scaffold, jacked it all up into position on packers got it into the exact position above the post support pads and then marked the holes through to the wall ready for drilling and trying my spacer idea. TIP: I am fixing to the wall with M12 long coach screws. I have drilled 13mm holes through the wall joist for this. I find a standard sharpie marker pen is a perfect snug fit in a 13mm hole, perfect to mark through all the hole positions onto the wall.1 point

-

Can you not use a relay connected to the lamp output to give you a volt free contact?1 point

-

That's an interesting statement. Something like that, if it failed, I would expect it to be repairable for a reasonable price. e,g it is easy to change the immersion heater in a normal HW cylinder. If it failed and was not repairable, that would be a big put off for me and I would be wanting to replace it with something else.1 point

-

I was thinking you could run three core & earth to each PIR. So you have power to the PIR and switched live coming back to a box in the house. Then run switched live to the light(s) from there. Put the relay or onto isolators in another box in the house. I 3D printed a box for the Arduino with a wall for isolation but it could do with improving.1 point

-

Yes, an opto board like that would work instead of a relay and get around @joth's clicky noise problem, but it's all a bit exposed at the lethal end. With care though it could be a solution that might fit inside the PIR casing.1 point

-

This is more or less what I did. Mains PIR driving a 240V primary relay with 24V on the secondary in a cabinet. Problem was the relays were dreadfully noisy and banged away all night whenever wildlife passed by So I replaced them with cheap mains to 5V switched mode power supply (i.e. any old usb charger) which is silent. But still too many false triggers, so now all driven by Frigate image recognition running off the CCTV cameras 🙂1 point

-

I used one of these to interface mains to an Arduino. It's used to detect when my boiler pump is running. https://www.ebay.co.uk/itm/-1-Channel-Bit-AC-220V-Optocoupler-Isolation-Module-Board-Adaptive-For-PLC-/154400482521?pageci=204718bc-c2f2-4557-a2dd-49ea4e2a55af&redirect=mobile1 point

-

Such a good job, well done, so sorry to hear about your wife and hope she is on the mend. It’s times like those that puts life into perspective.1 point

-

Wow, well done and OMG re the necrotising fasciitis. I hope she's well on the mend now.1 point

-

The concrete fill in the icf looks very neat and the walls look nice and straight. No grout runs or bursts. Do you build studwork against the walls for services and plasterboard?1 point

-

A bit of a long back story this, sorry. Recently had a Vortex 9 installed for our Devon farmhouse. At the same time, I had a separate septic tank installed for a planned shepherds hut. To get PHE to agree to the planning request (for change of use of land, as we want to rent out the hut) we had to change our plans from a composting toilet to a standard WC. After quite a few visits from various companies, I went for the proposal where the liquor (if that's the right terminology?) from the septic tank is pumped along a 32mm pipe into the new Vortex for final treatment before discharge to a watercourse at bottom of garden. I'm sorry, but I don't have the make or model of the septic tank yet, still awaiting the final paperwork, but it was the smallest available and hopefully is identifiable in the accompanying photo. When discussing the project with the company representative, the venting of the septic tank was mentioned and we decided the best solution was to run a subsurface pipe about 5 meters to a wooded border and then install (cable tie to a tree) a vent pipe. This was to remove any chance of smell from the vicinity of the hut itself. Unfortunately, I was not on site for the last day of installation. On return I see that there is no vent fitted and now everything is underground apart from the two access covers and a capped inlet pipe. The vent pipe is not individually mentioned on the quote. It just says installation of septic tank and pump. I've asked the question of course, and been told that the vent should go in on the inlet pipe side, after the shepherds hut has been put in place. My question is, should the tank have it's own vent, presumably coming off one of the knock outs that were visible on top and should this have been part of the installation process to make the tank safe to use, or will a vent running off the inlet pipe serve to both vent the inside plumbing system and the tank? Apologies for any mistakes in terminology. Thanks!1 point

-

0 points

-

Anecdotal evidence these sorts of mould spores can lead to dementia like illnesses. https://www.alzdiscovery.org/cognitive-vitality/blog/can-mold-harm-your-brain Could explain a lot.....0 points

-

0 points

-

We do eat a lot of chillies...0 points

-

0 points

This leaderboard is set to London/GMT+01:00