Leaderboard

Popular Content

Showing content with the highest reputation on 08/23/22 in all areas

-

It is indeed. @pocster.. thanks for the response.. it took me a bit of time to write that while trying not to sound too much like an.. @pocstercan fill in the expletives.. I maybe failed as concrete lintels are not that sexy.. The thing I like is that there are folk here on BH that have forgotten more than I know an don't mind sharing their knowledge and experience.4 points

-

Hi pocster. That looks like a typical lintel that may be produced by say Robslee, they call it a type A lintel which is what we call a composite lintel. It has the rod in the middle. For all they are two types of generic lintels, one is called a composite lintel, the other a non composite lintel. They are two different animals. The composite lintels tend to have the rod in the middle and a bit of prestress in the rod to keep the concrete in compression, also helps it not to fall apart while you are laying the bricks above. Long composite lintels need to be propped until the brickwork cures so read the manufacturer's instructions. If you have a good height of brickwork above they can span quite a long way if you are careful. If you think about a reinforced concrete beam. It has steel in the bottom with a bit of cover to the steel to prevent corrosion (plus often fire protection) and provide bond between the concrete and the steel rod / wire. Concrete is good in compression, steel good in tension so when you load up the beam from the top the bottom goes into tension (resisted by the steel) and the top into compression (resisted by the concrete). Now for a composite lintel you can mix up materials. You can have a rod encased in a bit of concrete, like your's pocster. If you make sure the top of the lintel is clean and put say 5 -7 plus courses of brick (see manufacture's spec) on top then you now have a deep beam.. (the top 80 odd % is of brick if you have 5 courses or more of brick) .. the depth of the lintel plus the brickwork above and that works quite well in places. In fact surprising well.. What happens here is the courses of brick above acts in compression and the rod in the lintel is in tension. The concrete in the lintel is not doing that much. In other words the brickwork acts compositly with the steel rod / wire in the lintel.. like say a SIPS panel where the sheeting and internal timbers act together and to make this work the sheeting has to be well fixed to the internal timbers.. thus the brick work has to be well bonded to the top of the lintel and the perpendicular ends of the bricks fully filled with mortar. In summary the lintel per say does not act to resist the majority of the bending effects.. the concrete around the rod / wire just acts arguably as a medium to transfer the horizontal shear forces (tension) in the bottom side of the brick to the rod in the lintel, which happens to be encased in concrete. A big mistake folk make is to put a DPC (cavity tray) between the top of a composite lintel and the brickwork above. Here you create a slip plane and the whole system stops working.. please don't do this. Now a non composite lintel acts much more like a reinforced concrete beam. The major difference is that it does not rely on having masonry above. This lets you introduce say cavity trays and put floor joists on it for example... maybe a bit of point load. The rods are more heavily prestressed and are in the bottom. They are marked top. If you can't see the mark, (sometimes the lintel may have been cut down) then look for the rods and put them at the bottom.. unless your SE tells you otherwise. Sometimes you can use a lintel upside down to create a cantilever / corbel but this is not that common. Prestressing? An ordinary precast reinforced concrete beam has say steel in the bottom, a rebar cage is made and the concrete poured round about it. It all cures and you load it up. Now steel is quite a stretchy material so when you load up the beam it drops (deflects) a bit before the steel really starts to work. The concrete is also a bit elastic so it has to "shorten" on the top of the beam and this gives rise to more deflection. Also concrete shrinks so that relaxation has to be taken up and that can manifest as more deflection. When they make lintels they don't make them one at a time. Commonly they have a very long mould and run a long wire near the bottom. The wire is put under tension and the concrete poured and cured. Then they release the tension blocks at each end of the wire and saw up the long prestressed beam into common lintel sizes. Once they release the tension blocks the wire in each section of lintel it wants to shrink, but it can't as it's bonded to the concrete in the bottom of the lintel. What happens here is that the wire compresses the concrete in the bottom of the lintel and this makes it bow up a bit.. which is good as when you build it into your house it bows back down. the idea is that the bottom of the lintel ends up about flat... in an ideal world.. just like us on BH! If you are curious if you take a longish non composite lintel.. say a 145 high x 100mm wide (type C that look like a concrete beam higher than it is wider) and lay it flat with the rods near the bottom you should see a bit of a bow upwards. But @nod some non composite lintels do have the rod in the middle!! and !!! The explanation for this is very lengthy but so have left it out. These tend to be wider and flatter. There you go.. hope this helps to give you a flavour of how the different type of lintels work and hopefully this will help you select the right lintel and use them in the right way. For me I tend to stay away from composite lintels on longer spans even if I have a good few courses of brick above as the workmanship / site supervision is often so poor these days. Yes I know the heavier non composite lintels cost a bit more but they are more "idiot proof" to some extent. Also, on self builds we often make late changes so non composite lintels give you a bit more flexibility here.3 points

-

Joe has 10p and Fred has 20p. So Fred is twice as rich as Joe. But if you give them both £5, Joe has £5.10 and Fred has £5.20 which is almost the same.3 points

-

2 points

-

I guess it was always that high as it’s just been resurfaced but what a state. The flashing looks diabolical along with everything else.2 points

-

One of the interesting aspects of Octopus Agile is the ability to integrate it with other ‘smart’ devices. This could allow you to set devices up to look ahead at the cheapest rate window for the next day and automatically run the appliance then. It has a lot of potential for the kind of people that are engaged with this sort of stuff. Most aren’t though.2 points

-

Hi, New here and looking for advice on adding new things to the house such as wood burning stove, solar panels and other ways to be more efficient given current energy crisis. Looking forward to all the advice. thanks1 point

-

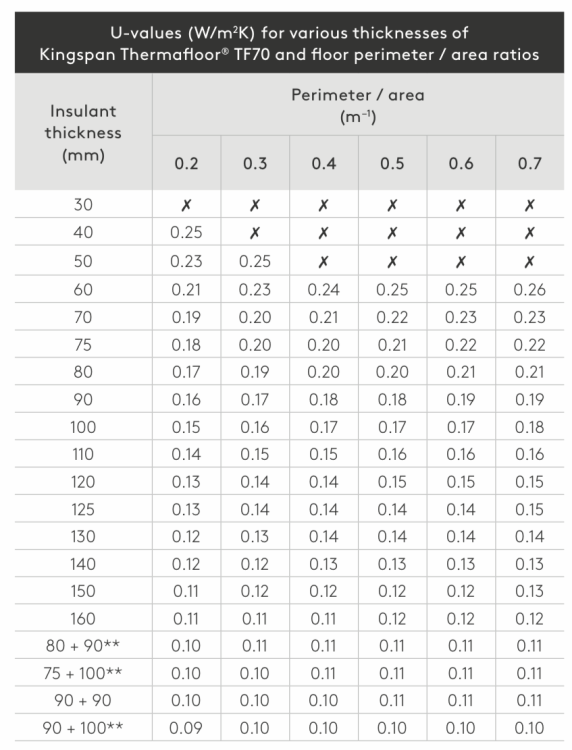

Not a recommendation, this was just the quickest PIR board U-value I could find. https://www.kingspan.com/gb/en/products/insulation-boards/floor-insulation-boards/ Table from Kingspan Thermafloor brochure. Need 175mm for 0.10. That is their standard PIR board. They have two other products with better resistance to thermal conductivity, Kooltherm is a phenolic board and Optim-R which is a VIP board. These can be much thinner. Optim-R only needs to be 70mm thick to hit 0.10 u-value. Here is a calculator for another product, EcoTherm board, it only needed 140mm to hit 0.10. https://uvaluecalculator.ecotherm.co.uk/calculator/1 point

-

Concrete lintels are fine either way The reinforcement bar runs through the middle1 point

-

1 point

-

No. Just divide the thickness (in metres) by thermal resistance. Then you will have the R value, to get the U you need the inverse, so 1/R equals U. 0.022 is PIR thermal resistance 125mm thick. 0.125 / 0.022 = 5.68 1/5.68=0.17=U value.1 point

-

My other thoughts were: 1 - That's a lady's hand. 2 - He's showing off the only finger that isn't chewed to the quick.1 point

-

So what is super-distinctive about that leaf that is the same as all the other leaves?1 point

-

It could be a good precedent to set if they stopped asking for the MCS certs. It would open things up a bit and as long as approved equipment was being used, which it should be if sold in the UK for UK use (I know some will not) then it could encourage others to get solar without feeling railroaded into a MCS approved contractor. That would perhaps reduce costs for all. I did know that payments were possible without MCS cert, but it was more difficult. Maybe finally they are coming round to the whole thing and being more sensible.1 point

-

Is that the only paperwork they have asked for? Or have they also asked for am MCS certificate?1 point

-

1 point

-

No. I just gave that as an example. If you wanted to know the U-value of say 125mm insulation you multiply the Thermal Conductivity by 1000/125.1 point

-

yeah. cheers. plant room is in the basement so it's surrounded by concrete. I think I'll be ok with the cheapest option there. thanks for your help on this thread. it's really appreciated.1 point

-

When it was about double the cost, if I am honest, probably not, but I see the difference is £13 for 2.5mm² PVC vs. LSF, so yes at that price difference I would. Even if I only did all my 1.5mm and 2.5mm and say had 1 x 6-10mm PVC cable, it would be better in a fire having most of my cable LSF. If your house is on fire and the cable is burning, you would hope in a modern house you would be long out of it before it got bad enough, however, if something happened, and I did not get out of it, me and my family, pets too, would have a much higher chance of survival. So even if I needed a good few drums, I would probably use T&E LSF. As for your SWA, how much of it is in the house/outbuilding, if 95% of it is in the ground then, maybe I'd take that risk.1 point

-

I wondered the same, brickie looked at them it and said, "that's the top" after rolling them a bit, all I could see that he used to differentiate it was that the top was a vibrated, or simply a naturally settled finish but the bottom and sides were smooth from being in formwork. From what I can remember, the prestressed wire/rod is biased towards the bottom, so when loaded that steel is in tension and gives the strength, however, you also get plain ones... I think if the steel is mid, then its plain and can indeed go anyway. I have been left scratching my head looking at them too. Where is @Gus Potter - he will know for sure!1 point

-

Even electric vehicles have a bog standard battery to drive the 12v stuff. Leisure board, caravans etc are ok with big lead based batteries, no real justification to have a light energy dense battery, that isn't normally managed well and is cheap enough to replace every few years. So normal batteries will be around for decades.1 point

-

I’ll need a pint in my hand before replying to this later. In the interim, is there 100% defo just the one header tank servicing the copper cylinder and Rayburn? Looks like it from the images, which send a shiver down the spine…….1 point

-

No. It is based on the thickness you specify. If the k is 1W.m-1.K-1 changing the m, thickness in metres, or the K, temperature difference, will change the 1W figure.1 point

-

1 point

-

Like that's ever stopped you... Anyhow, weren't you planning a 'Green wall'? Did you find a solution?1 point

-

Basically low smoke, zero halogen and various variants are used in every commercial building and indeed most new residential developments it is not in BS7671 but is spec'ed as a standard now and oddly seems to be one of the things that everyone just accepts and rarely value engineer out (also because I think contractors buy so much is is cheap enough anyway), they now sell more of the low smoke variants than normal PVC, I also think the time will come grey T&E will go and we will just have low smoke variants as it will become more of a hindrance to make the normal PVC version. They always kept the low smoke variants more expensive because it was a premium product and it was on every spec up and down the country, but a shift may see this change soon. So on your costings, the price difference will be driven by the market. I have terminated both types of SWA cable and in all honestly I cannot see the big difference, knife to ring the sheath, slice it down the length, that pulls off, normal hacksaw or armour tool for the armours, internal bedding is fine too. Commercial boys have no choice really anymore and they get on with it.1 point

-

Neem oil seems to be the thing for shield bugs which we do have in the garden. Wonder if it's any use to deter the lower hanging, bottom dwelling pocsteris bug that's plaguing this thread?1 point

-

Thanks @SteamyTea I wasn't sure whats a figure worth caring about and what's insignificant and just looks better on paper. 0.17 vs 0.18 vs 0.19 @Temp I missed the surface effect from the calculation both sides and see you have reduced the dab gap to 10mm from 15. Boffin of the night award for you tonight 🏆. I'll keep my dunce hat on, brains cooked for the night. Hopefully now I have enough figures to input everything as rockwool provided the partition walls, loft and intermediate floors values. I did look at the examples again & used the formula you provided and now understand how close it makes it. Thanks again both of you.1 point

-

I know, everyone seems to make a big deal about slimline frames. But sometimes there's also an aesthetic or practical reason to go with wider ones. we had a pre-existing theme of black posts to a loggia porch and corner posts forming our pavilion-style extensions so we reflected that in the choice of slider frames.1 point

-

For a sandwich of materials you add up the R value... R = R1 + R2 + R3 Or the reciprocal of the U values.. 1/U = 1/U1 + 1/U2 + 1/U3 or.. U = 1 / {1/U1 + 1/U2 + 1/U3}1 point

-

Yes, get on with it! Main thing here is compaction to prevent settlement later on. hire a wacker plate go over it a few times, spread the type1, plenty more wacker ing and you are sorted1 point

-

The depth isn't important as much as how compacted everything is. 100mm would be the default as it allows you to get away with an uneven ground below, e.g. if you are on stoney ground you don't have to worry about picking out every protrusion. We dad did ours 20 years ago, we just put 50mm of quarry dust on the (rock hard) ground, and it still hasn't moved. Hire a vibrating plate compactor and make sure everything is firm.1 point

-

I have done 50mm MOT on chalk for a patio and 300mm hardcore, terram and 100mm MOT on clay for a driveway. It really depends on ground conditions.1 point

-

I've used the Paving Expert website for many years for stuff like that. https://www.pavingexpert.com/1 point

-

You can easily do this yourself. This will show if it is feasible at no cost. Then you may have to get your professional to watch you do it again and confirm. It is not normally in SE or Architect skillset if it is a full assessment. But simple proof may be enough. As I said, contamination isn't the issue.... It is reasonable however for the BCO to ask how you are disposing of the rainwater. To a soakaway, any exceptional rain held back by a swale. None to burn if you can. All my comments have to be related back to the reality of the site of course. This will be on the surface. The test is dug beneath the soil, in the ground which has to allow the percolation. perhaps the same clay, but 18m is a long way down and maybe a different stratum there. Which brings us back to a pond. The fish and frogs will drink the water.1 point

-

The advice above is good. In a trench of round gravel, a third is air and the rest is stone. Anything less than round and the volume of air (hence water) decreases. Therefore your trench of 25m3 will only hold about 8m3 of water at best. Perhaps that is enough. The calculation depends on location, rainfall intensity and duration, and is rather hard work, hence computer programmes are used as standard. You haven't said much about the site: permeability, slopes, area. This can be increased by using expensive crates instead of gravel, or by adding empty pipes to the trench, although that can be as expensive. As Gus says, the trench will perform as a soakaway, depending on your ground permeability. This can be increased by changing the shape to provide more edge area, if space allows. Also you may be able to use the drain pipes as temporary storage, and soakaway area, if they are shallow slopes. It is good practice, even if not enforced, to avoid any water at all running straight to the burn. I don't think pollutants are an issue in your case, but it is good to do your bit to avoid increasing flooding downstream. What happens to the water after your storage trench? Is it to soak away, or is there a controlled outlet to the watercourse? Bottom line. Designers sometimes forget that rain has been falling on your site before your project. Your responsibility is to not make it worse for the environment. Soakaways, ponds and swales can be worked with to achieve this. The latter have the benefit of surface evaporation as well as soakage.1 point

-

So 25 cubic meters full of stone can probably hold what 10% of that? or 2.5 cubic meters of water. Would some sort of surge attenuation tank be an option?1 point

-

Good point. My assumption is that with the outgoing Agile Octopus you also get the agility and smart device integration benefits. I’ve not read the FAQ for a while.1 point

-

Or abolish it to keep costs down. Not sure how much CT the domestic supply companies have paid, they all claim to loose money on supplying homes.1 point

-

1 point

-

Probably all of the above. All those 'challenger' suppliers had crap business plans, just Del Boy market traders. I suspect that Octopus are hoping to get huge grants from the government to keep the lights on. That is probably the best way to reduce the price, no mucking about with tax rebate, grants, price capping. Just agree on a price i.e. 30p kWh for electric and 10p for gas. 30p a day for standing charge. Then the government can top up the difference.1 point

-

With the original FiTs, all income was tax free. That may not be the case if you sell to Octopus. I would wait to see if Octopus buys Bulb. Lots of debt to recover.1 point

-

It used to be that you had to be on the Agile Incoming Tariff to get the ‘Outgoing’ tariff. Has that changed? The half hourly changing Incoming Tariff can be brutal, I was on it over the last winter (when, of course, there was very little ‘outgoing’)1 point

-

Interesting. I think this offering has changed since I looked into it a while back. My recollection is that you couldn't previously sign up for this if you received the feed-in tariff. Withdrawing from the feed-in tariff concerns me slightly. Do they say anywhere whether you can re-join in the future. If that's not possible, there's a bit of a risk if Octopus stops offering this or changes the payments so they're less than the feed-in tariff.1 point

-

Oops sorry wrong thread. Are you printing from CAD op? you need to print them to scale from there, not ‘fit to page’.1 point

-

buy a powder puffer and the wasp powder -shove the nozzle in a gap 0ne or 2 good puffs and they will die in a day -where the powder lands -any bug that walks in it from ants to wasp are dead1 point

-

0 points

-

I thought it was only me that only opened their mouth to change feet 🤣0 points

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)