Leaderboard

Popular Content

Showing content with the highest reputation on 01/26/22 in all areas

-

Agreed, at least in terms of locations. I always put them in every corner and whilst my wife moans about this during the build she's the one that benefits most when she plugs in her phone/tablet etc all over the place! What I no longer do is put multiple sockets in known locations for AV equipment. In one house I put four doubles and it still wasn't enough - and didn't look particularly neat anyway given the variety of plug types that went into them. Now a single double is all I put in and use multi-way adapter strips plugged into that. It keeps things hidden out of the way (you can nearly always hide such an item even behind the most sparse of equipment rack/cabinet) and can be easily scaled to accommodate additional devices. Given the relatively low power of AV gear there's no safety-related issue that might otherwise have warranted multiple wall sockets.2 points

-

A 2 post in a 3-4m span with the point loads near the edges will be fine on 150mm or less, move to putting it in the middle of what becomes a 7x6 slab and the concrete starts to react differently so you really do need to consider point loads as @Roger440 is eluding to. For any large span over 6x6m with unknown or variable point loads it’s fairly common to up the slab to 150mm with mesh or even 200mm as it means you can put anything anywhere. I’ve put the spare 150mm PIR under the slab in ours and ended up with pretty much 200mm of concrete in the centre and 350mm around the edges but it does hold its temperature well ..!2 points

-

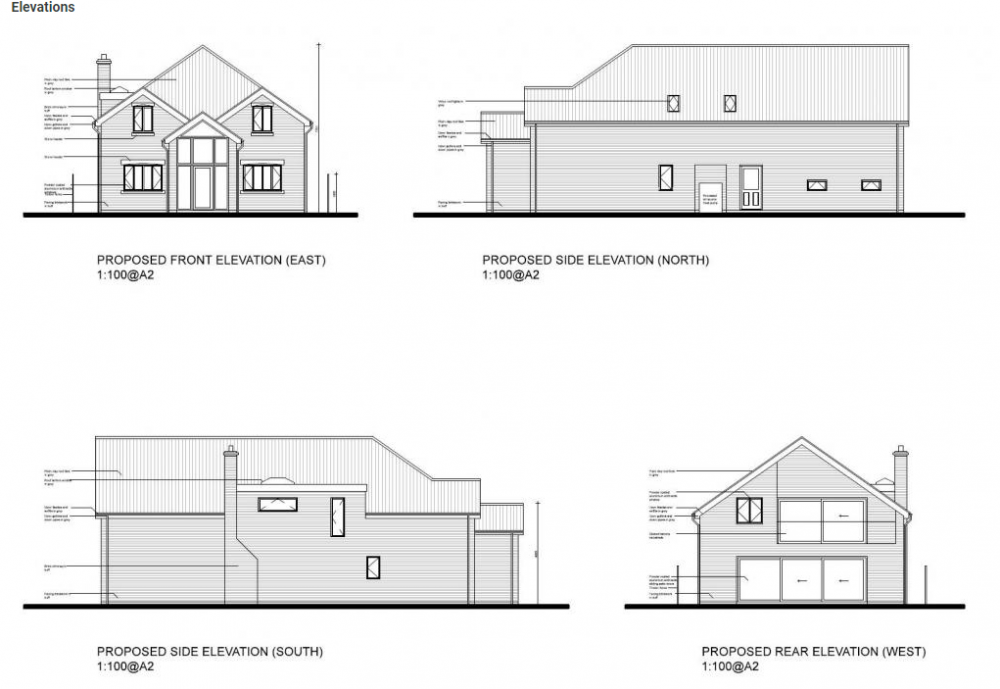

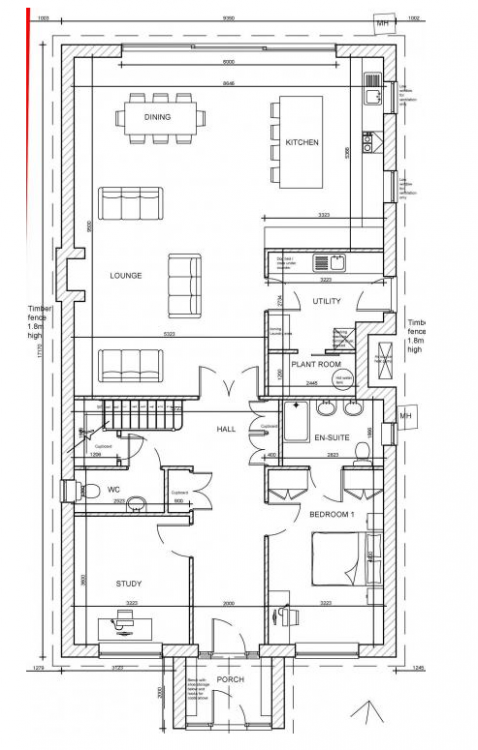

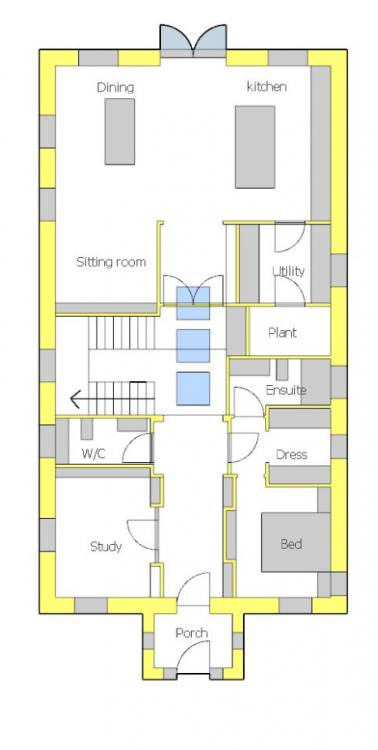

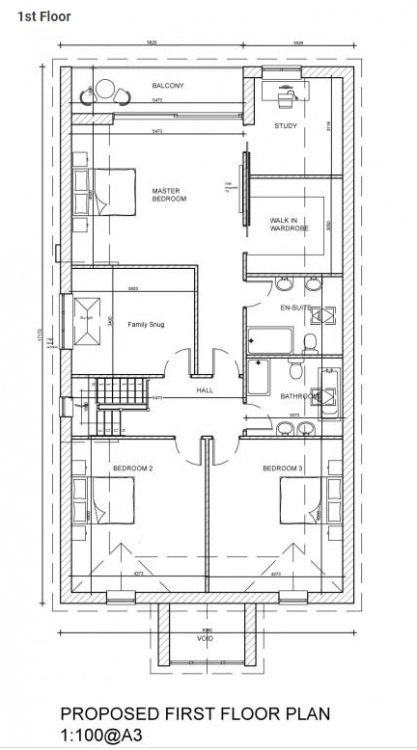

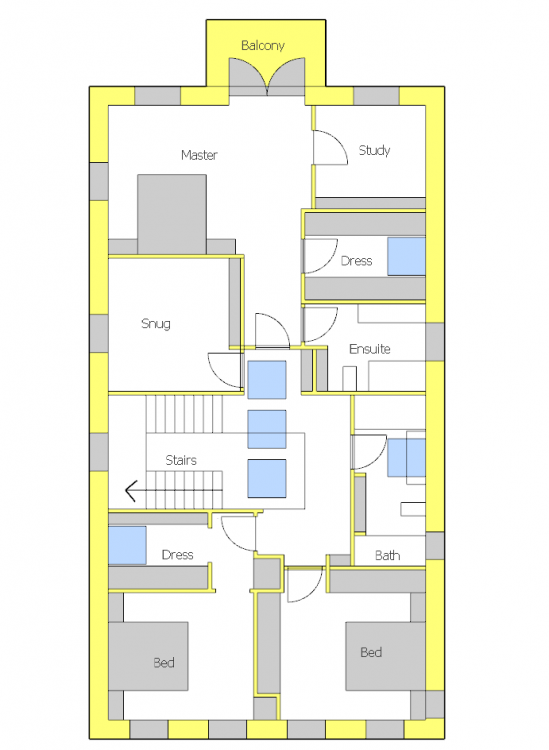

@Indy I've been plugging away at this for a couple of hours on sketchup. First here are the elevations continuing in the style as before. As before I have no idea if the neighbours will be overshadowed or overlooked badly with this design. The council may be dead set against it too. Obvious points to note are. 1. Same footprint as your existing design. 2. Simplified roof. Just a hip roof with a flat GRP rectangle in the centre. 3. Fake chimneys only. 4. Open porch/balcony added to the rear. BEFORE AFTER Now for the floor plans. BEFORE + AFTER The foot print is the same I;ve done my best to keep the positioning and sizes of the rooms as you had them. Changes to note: 1. I've added side windows to the porch. 2. The hallway is more defined and has built in storage. 3. The study has an additional south facing window, built in book shelves and a glazed door with sidelights to brighten the hallway. The Storage opposite is symetrical. 4. The generous sized WC (wheelchair accessible size) has a south facing window and the door into the hall has a fanlight to do the same. Symetrical with the door to the visitors suite opposite. 5. The Visitors suite enters into a large dressing area with a tall window. The bedroom has an extra window and some shelving. It is further removed from the hallway for privacy and noise. 6. The central hallway is the part of which I am most happy! The staircase is much more of an event, fitting of such a larger house. Storage underneath. The South facing tall window will give tremendous light. Above is a surrounding wrap around landing and in the flat roof 3no 1m2 velux flat roof lights. 7. I've removed the niche for the ASHP. it would be more effective in the front garden with a stylish screen. Where it is it's awkward to build around and might be continuously defrosting due to lack of airflow. Also I'm not too enamoured with such a high current device enclosed on all but one side by the house re fire. Domestic bliss calling here............................................ I'll finish when I get a chance!2 points

-

Plot 1 done, my plot done apart from kitchen that was waiting for the worktop template completed today. Plot 2 done in 4 weeks. and externals wrapping up in terrible conditions. 15 months - 3 plots - 7,000 sq. ft at £110 psf to a high (London SW1 spec) in Cambs. Have been self censoring on here as I have been critisised as a bit of a Swearey Mary (in the good times of Viz!) which is fair enough for the community. So this post will pretty much wrap it up for me as coming back from site where every other word consists of 4 letters to post here seems pretty much impossible! All the best lads. Tony1 point

-

Very much so. I would speak to the CIL team at your council and explain what you plan to do and whether they consider it commencing development. Follow it up with an email, and if you have agreement with them of what you plan, then I think you would be safe. It is after all their interpretation that counts.1 point

-

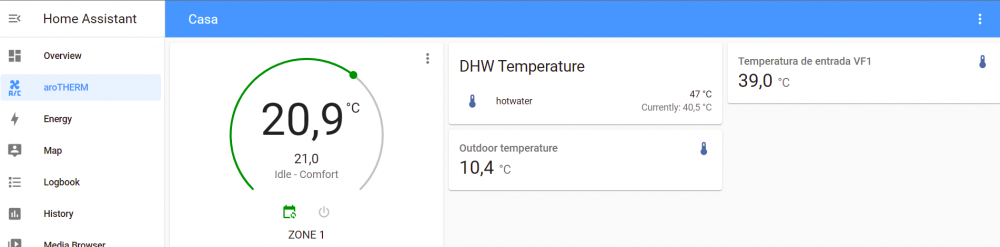

Thank you Further updates: Today I bumped the day timperature to 23º. It was also a bit warmer outside so the flow temperature really didn't change much. The equipment did not cycle often (only 3 times in 8h), but the power consumption was always very low. Setpoint was at 23º, room temperature at 20,5º maximum. It seems clear that the compensation of room temperature is as I read it from the manual. I might get in touch with Vaillant to clarify this. In other news I temporarily set up home assistant in a virtual machine (I want to later move it to a rpi) and sucessfully integrated multimatic. It's really easy and I have have never worked with HA before. It's as slow as the app and fails as often to fetch values ? Unfortunately since I connected the buffer tank sensor I lost the flow temperature in the app, and it seems that in the integration as well. I need to check if there are further values which the API can fetch. And I would need to be able to change my energy meters from emoncms to HA. That will be a problem... While looking for information on how to do this I came across this video Managing heating in Home Assistant - part1 - YouTube In the first 5 minutes the author describes a heating behavior which is precisely like mine - but on a gas boiler. Outside temperature translated to flow temperature. So I guess I'm not alone in this...1 point

-

Back to cables, My spark had a simple solution. He had a double socket, behind where the TV was mounted and next to this put in a blank socket box that was chased out at the bottom. To this he fitted the nylon brush style covers. Vertically below this, behind where the TV table sits, was another run of power, ethernet, RF and another blank box with nylon brush covers. Between these two boxes was just a wall void - you could have duct if required. So TV plugged into wall and RF, ethernet and HDMI cables just ran into the blank box and popped out inside the TV table for termination. Means clean wall between the two. I suppose he could have put ethernet and AV behind the TV also and just used the ducting for HDMI etc..1 point

-

With a sprinkler system who needs fire doors. No one has EVER died from fire in a building fitted with a sprinkler system.1 point

-

There was a young man called Green He invented the wanking machine On the 99th stroke, the bloody thing broke And whipped his balls to cream Keeping that plugged in for your next visit.1 point

-

i've always thought a turbine outside everyones house in the water main would be a good idea1 point

-

I’d let her in unless you have something to hide, do you? If a habitable room is overlooking, that would be a concern and sometimes they condition window openings. Usually internal changes are fine and I’d imagine she’s just being thorough, but then it depends what you’ve done.1 point

-

If they think you may be in breach and you refuse access, they may be able to gain entry with a warrant. I am not sure you are correct when you state that internal changes do not require planning consent. For example, there may be conditions attached to the consent that the building must be built in accordance with the drawings. If the changes involved a different activity or, for example, a change in floor levels or window treatment that could impact a neighbour there could be a case. What have you done that concerns you?1 point

-

1 point

-

I install gate valves at regular / strategic points in my plant room installs, particularly where there’s an ASHP and antifreeze, so when needing to do routine maintenance or repairs, my clients only have to drain the bare minimum of primary water off. ?1 point

-

You can get longer staples too, 60mm iirc. Boom. There goes the dynamite ?1 point

-

You can: House worth £1,350,000 has enough plug sockets for everyone in the street1 point

-

It's difficult to plan for everything - not just needs now but in the future. I put extra cat5 cables in my ceiling spaces. They go back to the unmanaged switch - not wired up or anything but "ready". This also allows for POE. You can never have enough plug sockets. No matter where you put them you always want more. As mentioned ducting or wall cavities - make things a bit easier.1 point

-

1 point

-

Lift out the slotted drain cover under the cylinders and 2M either side and replace with something solid, even treated timber, sealed as you insert it, should do. e.g. I would start by looking at decking planks and see how close they are to the required width and could they be planed or sawn to the correct width to drop in?1 point

-

I personally hate "plastered on the hard" brick walls and chasing cables into them. When I moved to Scotland, where the majority of houses are timber framed, my job became very much easier. I would suggest you consider lining your brick walls with 25 by 50mm battens vertically and fix plasterboard to that thus creating a service void for cables. You could even add an extra 25mm of insulation into this service void as long as you leave a strip clear for the cables. Your electrician who has probably never seen this and is used to bashing grooves in brick walls for cables will be enlightened and will want to move to Scotland for an easier more pleasant life.1 point

-

Hello! My name is Elliot and I happy to be here! Hope to find here a good vibe and communication1 point

-

Make sure ALL the outlets you need, power, aerial, telephone, network etc are on the wall behind where a wall hung tv will be. Think about set top boxes and surround sound etc, where will those go and how will you route cables to them? All the portable stuff most is wifi now so just provision for enough sockets to plug everything in. My favourite recommendation is run socket cables horizontally from socket to socket around the room. As long as there is 1 socket on each wall you have a safe zone all the way round so you can easily add extra sockets later if you find you need more.1 point

-

Nothing to do with planning ..! It’s a building regs issue so don’t even bother including it in any plans. When you get planning, you’ll need to work out where to site a pump station (usually between 12-1600 litres depending on the number of bedrooms/WCs) and then that pumps to a chamber that is above the sewer level and gravity takes over. The tank needs to be minimum 3m from a house IIRC. Where in the UK are you..?1 point

-

It might be OK, but the guidance is, i believe 150mm thick minimum on a slab floor. Deeper if its only a pad. In the workshop i rent the floor was only 100mm thick, so i had to make an H frame to bolt the 2 poster too. Otherwise he wouldnt install it. As its also used for business currently, it needs to be insured, so i had little option.1 point

-

2 post ramps do not need big bases under them (1sq metre at 150mm thick is more than enough) the ones with longitudinal legs will even free stand but that’s not ideal. mine sits on the 100mm thick slab with a couple of bolts to stop it moving if (when) I run into it.1 point

-

2 x 1m3 concrete pads/blocks will be plenty for a 2 post lift, which from a load perspective is the worst you can buy. At least my local ramp guy tells me. He is a stickler and wont install unless he is happy. When i did mine, i did it on a slab, thickened at the edges, reinforced. And frame bolted to it. But, it was expensive. (5.5 x 11) Needed a concrete pump to as couldnt get the trucks to it. It was also laid on 100mm EPS insulation. Along with the sides and walls being insulated, even without heating its a very stable envoronment. Which is great for keeping cars in. Electric undefloor will prob need a 2nd mortgage to pay for it. I still say, put the pipes in. Pipe costs virtually nothing. Its there if you want to use it later. As for planning............................. You might get 4m if its not going to affect anyone. But who knows. It laregly unknowable until you apply. As PeterW says, this is industrial unit territory. Its a problem that i have so far been unable to find a solution too after 5 years. At the risk of boring everyone, and you, i want/need a circa 2000sqft building. I cant do it where i am, so am looking to move so i can. But as you cannot "know" you can get planning, or even "know" you have full PD rights prior to purchasing, effectively that means my only option is to buy a property where that exists already. These are few and far between and only in the much cheaper parts of the country. Q class planning on barns saw to that. Much as id love to do a new build, a new build with a 2000sqft barn is never going to fly from a planning perspective, so an old farm or similar is the only way. Even thats not clear cut from a planning perspective, as the buildings are usually classed as "agricultural" so filling with cars and associated stuff isnt strictly legit, but, without prying eys, who would know. Depends on location. Plus, im budget limited to circa £500k, for both house and barn so i really am looking at wales, the far north of england or scotland. The search for a solution continues..................................... Meanwhile, as you are already there, id be finding a planning consultant and see if he rates your chances of planning sucess. If high, get him to do it. What have you got to lose.?1 point

-

dont look on any of the consumer sites chekatrade etc as if they are on there for a reason. Have a drive round and find a build happening locally and have a chat, expect to wait for decent trades. personally id drop that side extension and start again its a total bodge and a real trade wont want to be polishing a turd.1 point

-

I doubt you’ll get planning for this in a residential area as it is borderline industrial unit size - you may need to start digging down to get the roofline down to begin with. Kroftman do a decent range of buildings that may be of interest but you’ll need to do some work to get them in under budget. Their 7x8 would set you back around £24k delivered, and then it’s a weekend job to build it for a team of 4. Probably talking around 10 cube of concrete for foundations, same for a 150mm slab and then add mesh and thickening for your lifts etc so your £3k isn’t far off. Dig out is half a day for a decent driver and you’ve got space to lose the soil on an acre. By the time you’ve added a mezzanine and walls for that plus electrics etc, you will be at your £35k. Any spare money, I would be putting solar on the roof and using it as a big array.1 point

-

1 point

-

@WWiltswhere is the eave support tray? Re. Your question, the gutter will overflow before the water level breaches the height of the fascia. Remember you are not building Titanic II, so no need for watertight bulkheads.1 point

-

1 point

-

I’ve built a couple of these steel framed workshops 12m by 6m last one. I brought the steel c sections from a steel supplier and then had the angled corners and top sections bent to the angle I wanted. holes drilled on site and bolted together. no need for big pads under the legs, just a floor slab that is thicker in the location of the legs. I cannot see why you can’t build what you want for £20 grand all done.1 point

-

I can't vouch for that exact model, but we have the 8.5kW one, which also uses the FTC6 controller, and that does support cooling. As you suspect, it's a dip-switch flip inside the controller to enable it It depends on the heat emitters. Conventional (non-fan) radiators would really struggle. UFH can work at a very low and slow level of cooling. Fan assisted rads / FCU can work well if all sized correctly. We used a standard schematic, 2 position valve to switch between heating and UVC, nothing stands out as being designed for cooling. We used an electronic motorised mixing valve for the UFH, which allows it to adjust set point for cooling vs heating mode, but this is a standard supported design for the FTC6, recommended when using it for 2 heating zones with differing flow temperatures, regardless of enabling cooling The key thing is ensuring that ALL pipework, valves, pumps, etc are fully insulated/lagged so no condensation can form anyway. Also ensure you have a buffer tank sized for the cooling as well as heating pattern.1 point

-

UK Smart meters use Telefónica / O2 as back haul, so it will depend on their turn down timeline. That said I think UK govt are planning to withdraw the license for 2G spectrum in the not crazy distance future. There's some lightweight analysis of the issues in https://www.stark.co.uk/wp-content/uploads/2020/01/20200801-Response-to-the-2020-consultation.pdf (section 5.4) and https://www.smartme.co.uk/technical.html claims that the meters will be exchanged for 4G versions by 2033. (Why not 5G I ask myself...)1 point

-

Emmisivity without an air gap is next to nothing. So the foil would act as a conductor anyway.1 point

-

I have a bunch of these colour tunable smart bulbs They have a wide range of colour temperatures between 2700K-6500K. If used with Amazon Alexa routines they can be used to start the day with intense blue whites and change to warm whites towards the evening to help settle down for the night. I find it helps with my sleep by keeping circadian rhythms going through the day when the natural light diminishes. I can't speak for their effectiveness in managing SAD but logic suggests it ought to help. The main point, I think, is that lamps like these can be fitted almost everywhere in a house (all popular lamp bases are catered for) so there is a unified lighting regime wherever you happen to be. Alexa routines are easy to create and can be as granular as you like. Cost wise, if not already in the house, you can buy a single Echo Dot for £40 and this will open the gateway to as much control as you like. They are frequently on offer for half that as well. The bulbs also work with Google or Apple smart ecosystems but I have a preference for Amazon who seem happy to sell this stuff at a loss. One thing to note however is that these are WiFi dependent so you need good coverage throughout the house. They can also be a bit finicky to set up on your network if you have 5gHz and 2.4gHz access points sharing the same SSID. This is because you need to use a smartphone to run the app that manages the lamps and have it connected on the same SSID. Smart lamps that use other wireless systems like Zigbee or Z-wave are not dependent on WiFi other than for a single hub but these are generally more expensive. I'm really just giving you the lowest cost approach but the end result can be just as good if not better than the big name brands.1 point

-

Why upgrade to 4mm for a single oven ..? A 2.5mm cable will handle 23-25A, and a number of the Bosch units come with a fixed lead that is only 1.5mm anyway. Up to 4.5kW then you are in the boundaries of a 20A RCBO, 20A isolator and 2.5mm cable1 point

-

The 6mm T&E will be fine for this. The Sparky should make the choices on cable sizing, runs, isolation etc. It is his job to know.1 point

-

A lot of the new ones do have pyrolytic cleaning and/or fast heating modes though, and therefore are up to 3.7kW (16A). If you don't know what oven you are getting yet, you should ensure he allows for 16A. I would personally expect, and insist on, 4mm for anything that may be up to 16A. That is what our electrician has used.1 point

-

rubbish, we have a range cooker and 19kg bottles, no flow problems at all!!,!1 point

-

You could probably generate enough to light a small led lamp similar to the standby LED on the tv https://www.instructables.com/downspout-generator/0 points

-

I wouldn’t recommend timber between insulation and EPDM. It will get damp from condensation and be vulnerable to decay.0 points

-

Don’t be surprised if the electrician asks you if want to take over the installation on his behalf!! The guy will be qualified, working to the spec of the fixed equipment and appliances that YOU have give to him, and will have installed what is correct. 2.5mm2 radial to each oven with its own 20a DP switch is absolutely spot on for anything up to the 16a requirements. Converting now to 4mm is just a waste of time and money. Now we’re getting silly ?. That’s for adverse installations. Never once have I heard any domestic sparky quote or install to that allowance. Cables for domestic ask for an ambient of 20oC to be used, then possibly grouping factors etc may then affect the outcome, but a good sparky will mitigate that simply with segregation. Stick with the 2.5mm and get yourself off to the pub0 points

-

0 points

-

This is something I am wondering too! The thing is, it hasn't been very cold, so if the beast from the east arrived, what would it be like then? Something els is the humidity on Portland is usually around 80%. I read the preferred humidity level should be between 33-50%. Well if the air coming in is at 80% or worse still, it is foggy, which is also common on Portland, then what chance do we have! Back in August, warm weather, the unit basically ran on boost all the time. The summer override lights were initially showing, but when the weather cooled it continued boosting with the summer override lights not showing, which is when I decided something was wrong. I contacted the company, who said either the PCB or humidity sensor could be at fault. They said I could disconnect the humidity sensor, but being blind and my wife not wanting to play with it in case of cutting wrong wire, we left it alone. Then we turned it off for an hour and turned it back on. The unit again ran on boost and was left on to see if it was going to slow down. It didn't and then we turned it off. After a couple of weeks we tried turning it back on and then nothing! Called the company and they said again it could be the PCB or as the motors are supposed to be continuously running, they might have seized! I got them to quote for parts as the unit was out of warranty. We purchased it back in 2016, but weren't able to have final installation and commissioning done until January 2021. This was due to me breaking one ankle after the other. One of them now has three plates and fifteen screws in it! Plus lots of other rubbish getting in the way, resulting in us having to get the builders in to finish. So back in January 2021 the unit was as new and a commissioning certificate issued February 2021. Nothing was said about changing filters earlier than at normal service intervals and so we let it do its thing and here we are! Not happy!0 points

-

For you, yes, yes it is. I know you. Always after the latest gizmo or whatever. In a few years time you'll change your mind again when some other new thing comes along and then wish you'd done it. IIRC it was about £3k for us to go 3ph and I didn't --- mostly because of the extra project risk having to close a main road before works could begin, but I really should have just sucked it up and done it really....0 points

-

0 points

-

Ah... disappointing. I read the title as Design / costs for a shepherd's hut or moveable 'brothel'...0 points

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)