Leaderboard

Popular Content

Showing content with the highest reputation on 03/09/20 in all areas

-

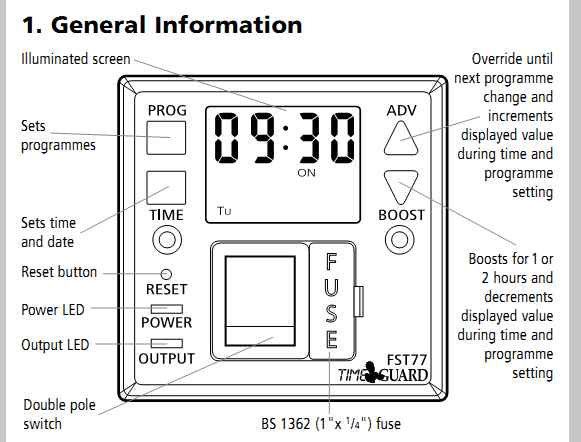

I have one of these fused spur timers on the wall outside the bathroom doors. https://www.tlc-direct.co.uk/Products/SMFST77.html I have these on the electric towel rails. https://www.geyser.co.uk/terma-moa-chrome-thermostatic-element-for-radiator-or-towel-rail You can hide the wiring with these. https://www.geyser.co.uk/geyser-chrome-cable-masking-cover-for-sim-elements4 points

-

I have used i joists for a small section of upper floor as they came free when I ordered all my roof timbers i have considered cutting them out and throwing them on the fire, the trouble I’m having trying to get all my services running through them is untrue, by the time I’ve finished with ducts for mvhr pipes for water and cables for electric yhey will look like Swiss cheese. If you will have lots of services I would go with the metal web joists.2 points

-

2 points

-

I'd put it in a bit of 20mm pvc conduit. Always a good idea especially if a cavity where it can get wet, chewed or damaged by debris. Have it point slightly downhill if ending up external. Similarly it can allow gas/fumes from the cavity into the room. Just good practice anyway for mechanical protection, cavity or not.2 points

-

Friday was a near perfect day for concrete pouring. A little cold at first, but by the time the concrete lorries arrived it was warming up nicely. The pile caps are all tied together nicely. The first lorry arrives. Disapointingly they didn't pump the concrete because of equipment availability. One of the snags of living on an island! The concrete was poured into the dumper, then the digger used to bucket it in to the beam. Half the long run done. Plenty of "watchers" on hand to use the poker to get the air out. The Driveway will take a bit of cleaning up now! The finished ring beam. Order says the house is a postage stamp and thinks the kitchen is way too small. Another view of our tiny new house. And now the start of the celebration for completing stage 1. Only three more to go.2 points

-

@vivienz it’s quite interesting really, the house has no heating but has never felt cold over the winter even though it’s been down to 10 degrees inside, now that we’ve added gallons of water 14 degrees feels cold. @Dreadnaught We’ll use what we have left to finish of the bathrooms and toilet where it will be tiled over, so much easier to use. Onwards and upwards...2 points

-

I think that is ultimately where I am regarding Fermacell. I found myself putting noggins in today, never considered that when I was using the Fermacell.1 point

-

We used these they were quick and provided a thorough report for our predicted assessment. Cost £120.00 inc JSP SUSTAINABILITY LIMITED York Science Park Innovation Centre, Innovation Way Heslington, York North Yorkshire YO10, 5DG Tel : +44(0)1904 435 325 Email : info@jspsustainability.co.uk VAT Reg No: 1419945911 point

-

I find the box cutouts to be a piece of cake with the right tools. 10mm steel drill bit for the corners and a jigsaw with the right bit does the job well. The issue is it eats impact drivers and wrists. Technique is critical to get a good quality install. Also, need at least two people to make the job viable, even with one-man boards. It is a viable product, but not certain it is worth it for the extra cost and effort.1 point

-

No reason, as long as the pipes go downwards and air can come upwards. Why not just fit one large combined manifold to serve both floors.1 point

-

One got into our house when I was fitting a velux window and left it unsealed for over a day (we had previously heard it on the roof between the roof tiles and sarking board) After about 2 weeks of the cat not getting it, and it fully exploring all the service voids and scratching about just about anywhere you could mention, I put poison down for it. It has gone now, but no smell at all. It can't have got out, it will have died somewhere but no smell.1 point

-

I did one, using simplifying assumptions such as the whole thing being one room per floor with just the outside walls, and it was within a point or two of the number at the end of the project. F1 point

-

We didn't have any problems using metal web joists and as you say they are much easier for first fix.1 point

-

It takes a few days for them to die after ingesting the poison, so hopefully they'll pop back next door to expire!1 point

-

just a little light reading, hey? ? I'll crack on with that. I know people on here have used I-beams and others have used Posi Joists. I like the idea of Posi Joists for the ease of first fixing but if there are potential issues using them then why do people? would this simply be a companies preference or (with my cynical hat on) a product they make a higher margin on?1 point

-

1 point

-

Any SAP assessor will surely be able to do a design SAP from Plans. Like @Bitpipe I needed one for ecology and did it myself but it would have been under £200 to get someone else to do it. When I got my mortgage Ecology wanted over 100, wich was perfectly manageable with a BMC build and 5.5kw solar pv.1 point

-

As a previous Ecology customer (rate them very highly BTW) I had to provide a SAP assessment of the predicted build - obviously as it's not built yet. I used @Jeremy Harris Stroma model and the free PC s/w to do this and it was accepted. You can only really get an official SAP assessment once the house is built, although I suppose some assessors could do one from plans and proposed windows, heating system etc. My completed build came in at 90% so just squeaked a SAP A rating, even though it would also have qualified as a passive standard house so some quirks in the SAP rating system.1 point

-

It's all male into female going downhill so even if the push fit seal failed it'd all have to back up seriously to leak at the Geberit to "other" push fit joint. There's TAP Poly Weld 2-part epoxy that is supposed to stick HDPE to PVC. Tbh I think I'd just push the Geberit in then CT1 around the whole joint after cleaning it if that worried.1 point

-

Personally I would use two 45’ bends if it’s possible to get them in, if not 90’ (ish!) ones will do but maybe more prone to blockages ?1 point

-

Try cutting in a few electrical sockets. I will be very interested to hear your take.1 point

-

1 point

-

1 point

-

If you make a straight cut across the pipe, in a couple of places either side of the damage, you should be able to lift the damaged part away and then lift the bit that's fitted to the bend away. You can then fit a slip coupler over the new bit of pipe, slide it into the bend and then line it up with the good section of remaining pipe and slide the slip coupler over the joint. I had to do something just like this a while ago, and as long as the pipe ends are chamfered well, and lubricated, it isn't too hard to do.1 point

-

Definitely cut out the damaged section of pipe and fit a new section in, rather than bodging it with a patch. The last thing you want is to have the pipe fail later and need digging out to fix properly. If you can't get the whole run of damaged pipe out easily, then you could fit a section of new pipe, joined to the old with a coupler. In order to get the new section in you may need to use a slip coupler, so that it can be slid over the pipe completely, then slid back over the joint when the pipe's in place.1 point

-

1 point

-

So a cable straight through the wall is ok ? I think it looks neater than a plate in the bathroom1 point

-

pull out strip of PB fill behind with foam or what ever --refit PB when it still sof-pb should stick to it -trim off foam as required ?1 point

-

This is good for small areas. https://www.wilko.com/en-uk/unibond-whiteteq-expanding-foam-500ml/p/04575751 point

-

I suggest you chew toilet roll (admittedly can be hard to find these days but worth a look) and insert it in the gaps. The saliva acts as a harding agent but retains flexibility.1 point

-

That’s a great point. They will need “breathing space” as the can’t be boxed in. Ours needed a minimum 600mm around the back and sides and nothing blocking it in front so that the cold air could be blown away.1 point

-

Buildhubbers think we’ll be dead before the summer so probably no point in buying too much.1 point

-

Have you sorted that you have space to put the ASHPs outside, and where they will go?1 point

-

That’s it. Make sure you tie the laps well, in case they pop up as somebody stands in the middle.1 point

-

FCU = Fused connection Unit. SFCU = Switched, Fused Connection Unit. If the towel rail is too close to a bath or shower it's normal to just have a Flex Outlet Plate in the bathroom and a switch outside the bathroom to control it.1 point

-

I couldn't immediately think where you would do that? I mean if you have a pipe run that descends vertically, then goes horizontally (with a fall), then descends vertically again you need two 92.5 degree bends not one of each. Perhaps if you were going around three sides of a building?1 point

-

Suspended floors here, cavity walls, footings with gaps in allowing God knows what into said cavities. Do they smell when they make nests near badly positioned hot water pipes and you poison them...oh YES! ? Then there's the flies.....0 points

-

I just read an apt description of fuel prices at the pumps, and the reason they always seem to go up within hours of the oil price increasing, but take weeks to go down. It's because the pump price contains hydrogen, so being lighter than air it floats up, but needs to be physically hauled down . . .0 points

-

Yeah I did think that also i.e. downhill away from the push joint, but you know. When I post 5 years from now about this brown stain on my ceiling......?0 points

-

The waste only has about 300mm to travel at 2.5 degrees ..... but that would tend to be noisier than a couple of 45s wouldn't it? And knowing my luck if it has a tendency to block more easily, it will. Merde, Scheisse, Poo, Merda.? 'Nother steep shitty learning curve innit? Bugger. Thanks @joe90 : its obvious, you are right. Coffe and then the SDS. Damn! Cant take a joke? Don't start a self-build.0 points

-

Who knows: your last thought might be a vary warm feeling inside? (I think the lasers were fairly feeble and diffuse.) Rgds Damon0 points