Leaderboard

Popular Content

Showing content with the highest reputation on 02/27/19 in all areas

-

my lovely kitchen fitter called in to do a tweak yesterday and I got him to reseal that shower screen whilst he was here. Bingo no leak tonight!3 points

-

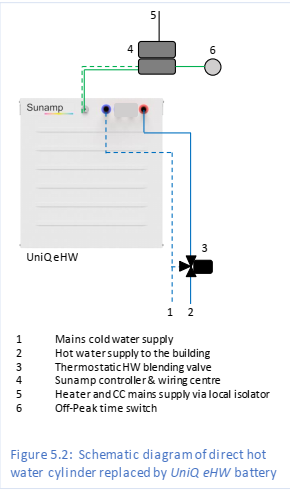

Probably worth restating the circumstances surrounding my acquisition of an early Sunamp PV, and our current Sunamp Uniq 9 eHW, as they are different, and although I think I explained my relationship with Sunamp back in 2015, that was on ebuild, not here, so is now probably lost. I was introduced to Sunamp by Damon Hart-Davis, who told me that Sunamp were looking for "early adopters" for their Sunamp PV. I entered into an agreement with Sunamp which meant we were supplied with an early production/pre-production Sunamp PV, on the understanding that I would report back to them on it's performance, would openly and honestly publish my experiences on eBuild and our build blog and agree to exchange the heat cells for replacements after two years, so that Sunamp could undertake a "post mortem" on them. In return for this our Sunamp PV was supplied at a substantial discount (but it was NOT free, by any stretch of the imagination). As it happens, Sunamp chose not to ask me to exchange the cells in the Sunamp PV when the 2 years was up, so we carried on using it. The Sunamp PV worked very well, and I was more than happy to recommend it. Not long after the Sunamp Uniq range was released last year, I decided that it would be useful to increase our storage capacity. The Sunamp PV, with it's 5 kWh capacity, was perfectly adequate, but, as we can easily generate 20 to 30 kWh/day I felt that it would be useful to be able to store more heat, so that we had a reserve for days when there was little PV generation. The idea was to be able to increase our self-consumption, and reduce out winter reliance on grid boost charging. Sunamp agreed to sell me a Uniq 9 eHW at a discount, in return for me exchanging the Sunamp PV and providing them with a water sample. I'm not able to say what the discount was, but can confirm that I paid well over £1000 for the Sunamp UniQ, plus the exchange of the Sunamp PV that had cost close to the same amount. To sum up, I agreed to be a tester/early adopter when I purchased the Sunamp PV, but not when I purchased the Sunamp UniQ. I'm grateful for the discount from Sunamp, but overall I have paid them a fair bit more than the full purchase price for a Sunamp UniQ.3 points

-

Bang on schedule the raft components arrived on Monday morning. We knew it would be quite a big volume of material on a small site and getting it unloaded and put somewhere it would not get damaged or need moving was s little tricky. JUB insisted on sending the raft on pallets. Our builder was not that impressed with this as unloading the lory requires a folk lift which is something we don't have on site. So we had to hire a set of folks for the digger. With the raft safely stored at the back of the plot the work to prepare the site progressed. The drainage had been marked in the site setting out exercise along with electrical and water ducting. Trying to keep raft punctures to a minimum but also allow for future needs was a concern. In the end we kept it to a minimum with electrical conduit for the rain and foul water pumps and two for water. Along with the raft we received a letter from our neighbours complaining that I had put our water meter box on their garden wall. In retrospect a valid complaint, it was one of those decisions made in expediency without enough thought. Our water supplier Portsmouth Water will now only make new connection when an above ground water meter box is installed. I duly bought the one box they permit (so much for choice), water pipe and water conduit. Not having a house on which to mount the box, I made the required connections and left the box mobile so it could be put in place in due course. At which point I called in the Portsmouth Water, regrettably they said they could not make the connection until the box was in situ. Having explained our situation and the need to get water on the site it was suggested I could mount the box on the wall by our property. At this stage I should have thought about it rather than simply get on with it, my mistake entirely. The wall it outside my boundary, by millimetres true , but still NOT ours. Our neighbours were not impressed so Monday was spent moving the box and apologising to my neighbours. I shuttered and cast concrete into the wall footings and backfilled with type 1 MOT to repair the wall. Having done this I then putting in two concrete posts 200mm inside our boundary and mounting the water meter box on them. This is what I should have done in the first place. Slightly different subject, the Groundbreaker Water box, this is the only box that Portsmouth Water will connect to. At around the £150 mark it's a pretty hideous piece of kit both aesthetically and in product design terms for installation. Given their current monopoly and the fact that all new connections will require one it made me consider looking into producing an alternative. A swift kicking from the boss and I was reminded to get on with the house...maybe later once the house is done. . With the drainage in place the MOT type 1 sub base was spread over the raft area, levelled and compacted. Our builders ICF-homes did this with considerable care and we ended up with a good surface to spread the sand layer which was again compacted before putting down the membrane. Our structural engineers had specified a Radon barrier, we ended up using a standard plastic DPM as Radon is not a problem in our area. The DPM gets glued to the side of the raft sealing it and providing some additional protection for the polystyrene. . With the membrane down the work of setting out the raft. The perimeter is all keyed together It took a while to get the corners located precisely but once this was done the raft slotted together very well with a really solid interlock. The raft was then completed by adding the rebar, four layers around the perimeter. All in all a lot of steel, Pat and I spent most of Saturday morning helping get the rebar in place and wire tying it to make is solid before the concrete pour. Our raft is now complete and this week the surface water drainage will go in. Along with the problem with the water meter box our neighbours also bought up the "Party Wall act". Doing a self build is nothing if not educational. The act came into law following problems with basement excavations in London. It dictates that excavations in close proximity to your neighbours 0-6M have to be notified and agreed. In our case we were within notifiable distance, but fortunately were not excavating to a notifiable depth. Our builders were not familiar with the act and no mention had been made by building controls. The act did effect our other neighbours and I contacted them letting them know what work has been done. Fortunately all the excavations were made and backfilled without incident. Hoping for a less eventful week to allow us to regroup before our first block delivery next Monday. As this is the first build for JUB in the UK the factory are sending someone on site to assist with the build and wall bracing. It's very positive to see the house taking shape, we have our EPC which suggests we should require in the region of 68wats/K to heat the house which is great, but we still only come out as a "B" energy rating! the rating system is bonkers.2 points

-

Having been using this exact product today I can add some absolutely essential information when using this product if you are not wearing gloves and you get a fair bit on your fingers, do not then decide to put your gloves on it does make it a fair bit awkward to remove your gloves later in the day. ??????2 points

-

2 points

-

Suitable for a bulk purchase? (Just saying ... I don't need one, but a small number of people will need a lot of slats, which can be ordered standardised and trimmed to length).2 points

-

2 points

-

Reading this continuing saga makes me glad I fitted a conventional unvented cylinder. SWMBO does not take well to cold showers and if I had spent lots of money on a new high tech piece of kit and it was not working, there would be calls to "get rid of that POS"2 points

-

For those of us contemplating fitting a SunAmp box, should we SNOG, MARRY, AVOID? +++++++++ Last updated 28th Feb, tea time. +++++++++++ THREAD SUMMARY Core issue: given the concerns expressed in this thread , is a SunAmp system a sensible purchase? Whats the concern? The issue is that one person (so far) reports that the system he has won't recharge until either 50% or 90% depleted. So you could run 48% out on day 1, it won't charge overnight and then day 2 you try and use 65% and it will go cold. ( @PeterW ) ? ( @Roz ) If 'charging' with hot water, then charge management problem disappears : ( @JSHarris ) @PeterW suggests '... simple pump and heater on a dedicated circuit with a small expansion vessel and run at 1 bar ...' The main selling point of the Sun Amp is the much lower standing heat losses than a HW tank. That is indisputable. So it comes down to does this advantage outweigh the extra costs and the extra "difficulties"? ( @ProDave ) So a Sun Amp may have an advantage if you are tucking it down down in the eaves where a taller tank might not fit, but otherwise I see little advantage. ( @ProDave ) There are few, if any, significant issues with the non-electrically heated Sunamps, they seem to work very well and provide a reliable, low heat loss, way of storing heat for either hot water or heating. ( @JSHarris ) I'd be reluctant to recommend the electrically heated Sunamp versions at the moment, at least until they come up with a more sensible controller. ( @JSHarris below) ' ... Why are we debating "work arounds"? The product should just do as advertised! It doesn't!! ...' ( @Barney12) @Nickfromwales joined the discussion; he suggests that errors may well have been made in the specification of some installs - that error source is likely to be reduced by SA's policy decision to have approved installers involved in the specification process. He points to the distinction between USEFUL capacity and ABSOLUTE capacity. He also raised an eyebrow at SAs apparently poor communications flow. However, there is some evidence that SA may not be (or have recently started) applying the Installer Only as Specifier policy in every case. ( @paulmb and @newhome) In respect of Sunamp UniQ units, a clear distinction was drawn by @JSHarris between electrically heated models and those heated by water ( from another source) The former appears to be unreliable, the latter reliable. @JSHarris and @Barney12 both argued that the the 'box' should do what it says on the tin. @Nickfromwales argument is that we should leave the installer to specify the size of the tin. He presents clear evidence of multiple successful installs. And hints that the problem under discussion might well be unique: so far it has been reported by only one person. I've read and re-read this thread now many times. The thing that worries me is that - as written - the problem statement (one instance of the electric charge version of Uniq doesn't work as advertised) appears to be based on a very small sample size : 1. So, @Pete, you first?1 point

-

Most of the internal work to date has focused on insulating the suspended timber floor and with this completed our joiners could come back and put down the sub floor. We considered two different materials for the subfloor: 22mm OSB or 22mm Chipboard. We decided to use chipboard as it was 25% cheaper then OSB. Plywood would have been another option but this would have been more expensive than the chipboard as well. To do this job we needed just over hundred sheets of chipboard, 2800 Spax screws and 6 bottles of expanding PU foam glue. Whilst our joiners were on site they also attached some ply and osb boards to the internal load bearing walls. This will provide additional racking strength to the house. As I can walk around all part of the house here are some photos: The porch and utility room The kitchen/dining room Living room which has a part vaulted ceiling and the eventually the French doors will lead onto a decked area. When this is framed it will be a bathroom, hall & stairs Master bedroom and en-suite And upstairs: Two bedrooms on the gable ends. A key feature of these rooms is a PK10 top hung velux. The middle sections between the gable bedrooms will be a wardrobe, WC and a storage cupboard. This area has three PK10 veluxs. Having a floor down feels like a big step forward for us. One of the benefits for me is that I now have space to store materials within the house, as previously it was very awkward as often these had to be shifted around numerous times to complete a single job. The next job is back to insulating, this time in the rafters.1 point

-

1 point

-

Thanks too Jeremy. Still scrambled however. Do sunamp do a product to melt the ice on my windscreen or does it stop working when windscreen is 52% de iced1 point

-

Brill (there are some good un's out there) and I bet he didn't charge you - much less charge you £801 point

-

1 point

-

Thanks, it's deliberately irregular, as it's rough sawn waney edge larch, with the bark on the lower edges (although some of the bark is now beginning to peel off). The trees were grown on Fonthill estate (about 6 miles away from us) and were milled in the local sawmill in Ansty (about 3 miles away from us), so it's a very local product. We went to see the trees before they were felled, and chose (with the invaluable assistance of the sawmill chap) the trees that would provide the wide boards to clad our house (the average board width is around 300mm)1 point

-

I was looking on alibaba - lots of suppliers there, if enough interest that could work out well. I just need to remember to build a hidden mounting in my ICF before we render - I say remember as this is still somewhere in the distance....1 point

-

Get your man to to do it either on a public holiday or after 1600. Will be done in peace and no-one will be any the wiser. Burden of proof would be on the council if anyone there was actually minded to pursue you fixing the road without a permit.... And tell no-one on your street of your intentions.1 point

-

1 point

-

PCM58 for direct production of DHW. What I have in mind is preheat from a buffer tank as @JSHarris does. I did wonder about PCM34 for the buffer tank role up until I heard PCM34 was twice as expensive. Any heat loss from the buffer will be useful space heating, anyway.1 point

-

We had a different situation with a council roads department although there are some similarities. Our plot borders a public road, and had some fairly old, overhanging and in some cases rotten trees along the verge. For quite a while the council had been chasing the previous owner to do something, partly as a result of local complaints. We knew we'd need to do work, so it was factored into our finances. The council couldn't have been more helpful - we needed traffic management for the cutting and didn't need to pay for permits etc and they came out to site to look at things quite promptly. While this is a different situation, perhaps encouraging the neighbours to complain might help? I wonder whether it's worth trying a different roads council officer, or failing that, simply complain or write to the chief exec summarising the ridiculous situation - I reckon council officers have little ability to deviate from standard practice unless directed by someone higher up.1 point

-

My energy meters provide the same sort of values so I'll agree your best guess.1 point

-

1 point

-

Probably a broken flex where it enters the handle. Pretty standard for me to chuck away the orrible short pvc cables on power tools and put a much longer rubber cable on them.1 point

-

I agree, I have bought loads of cheapies in the past but never looked back after buying dewalt.1 point

-

Just a mad thought.... If you put a Steibel Eltron in line water heater into the flow from an ASHP to the Sunamp, would it not then take the output from the ASHP up to recharge temperature..? They are thermostatically controlled and the heat would only be the delta between the ASHP and 58c..? Or should I stop smoking tea bags..?1 point

-

I think, like me, you have a Telford unvented cylinder? I have to say I am impressed with the as supplied thermal insulation, and I have take care to well lag all the connecting pipework. I don't "feel" any heat loss and certainly not enough to cause problems. I am pretty sure the foam lagged copper tanks on common sale are a lot worse from an insulation point of view, and a thermal store more so because of the higher temperature of the stored water.1 point

-

This is true, as if you heat the PCM to a temperature below the phase change temperature then it can only store heat in line with the heat capacity of the solid PCM. Once you heat it to the phase change temperature it can store a lot more heat, over a very small change in temperature around the melting point of the PCM. Heating the PCM above the melting point goes back to just relying on the heat capacity of the liquid PCM for additional heat storage, rather than the latent heat of fusion, but it adds some useful extra capacity, around 1.5 kWh for a 15 K ∆ T (with a guess that there is around 130kg of PCM in a UniQ 9). .1 point

-

So pleased I can only afford Jurassic PV and as a result I will not have to understand this debate.1 point

-

Ta. So it seems reasonable to assume that the “_PV” suffix means that wiring difference plus perhaps some other configuration change on the board. It sounds like they've made an attempt to introduce some, quite sensible, hysteresis but overcooked it. It's difficult to know the state of charge with PCMs but they've got enough temperature headroom between the whole lot becoming liquid (e.g,, I imagine you can be pretty sure of this by the time all the sensors read, say, 65 °C) and cooking the gunk. E.g., stop charging when any sensor gets to 75 °C, start charging when all have reduced to 65 °C would seem to me to be safe but use a much larger proportion of the capacity. You'd still get the behaviour where resetting the controller might cause it to start accepting charge but only over a much narrower band of SoC. And WTF, in 2018, did they build a controller without at least a web interface to allow you to see what's going on?1 point

-

I have used the elastomeric paints in the past. if you let it go off a bit on the brush or the roller it goes a bit rubbery. I think there is defo some stretchability to it, so small hairline cracks would not show through. I can't remember if it has silicon or something in it, but it repells water, and is kind of self cleaning with the rain. It still looked good after about 8 years.1 point

-

Ours has all been plastered and it was also erected and made watertight during the lovely summer last year, it’s now been plastered for around 5 months and we are getting the inevitable cracks here and there, nothing major but I certainly wouldn’t have gone for tape and join which we had in our first house,it’s such a pita years down the line when you’ve wallpapered and go to change it and you inadvertently take the backing off the plasterboard, we ended up having to plaster numerous walls after this happened.1 point

-

It will be a big job to insulate it and to do it so it’s all a tight fit. I’ve just purchased this Festool Insulation saw to make the job a whole lot easier. I will possibly continue building houses afeter my house is complete so thought I would get the use from it again. It’s expesive at £550 but worth it in my opinion.1 point

-

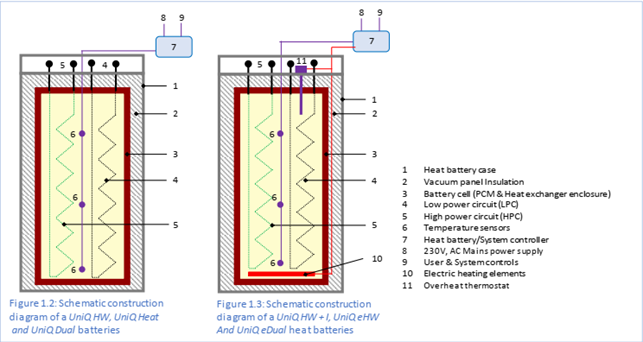

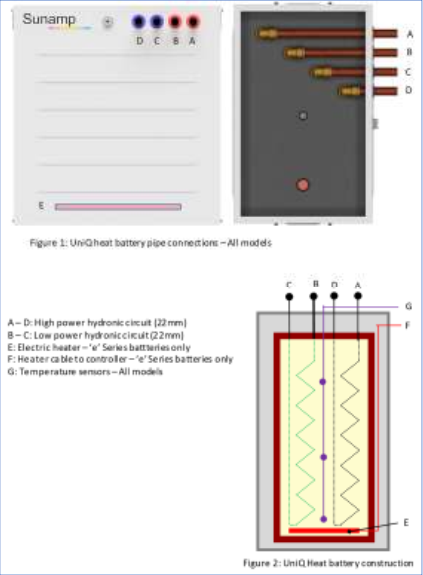

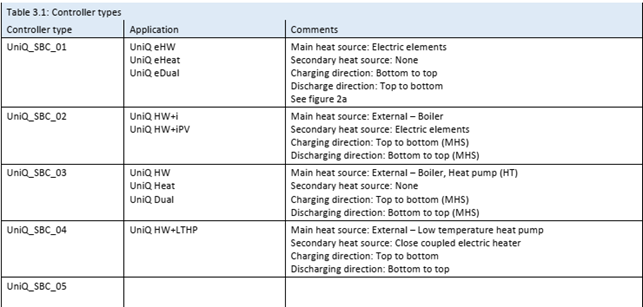

I am shooting from the hip but I suspect that there are basically only two UniQ (physical) models! Agree this should now be a separate thread. They come in five (5) sizes (3, 6, 9, 12, 60) and 3 PCM fillings (34, 58, 73). The two models are with and without the electric heating elements, the Heat 60 is not available with heating elements I believe. Not all combinations are available, the PCM 34 & 73 are not available in size 3 or with heating elements. So, for an example if we take a size 9 in standard PCM 58 there is: UniQ HW 9, UniQ Heat 9, UniQ Dual 9, UniQ HW 9 + I, UniQ eHW 9, UniQ eDual 9 The first 3 don’t have a heater and the second 3 do, so two physical models. I make this assumption for the following reason, design and cost, it is cheaper and simpler to have a fewer physical designs and make changes in software. As detailed in section 1.1 of the design and instillation manual. The only difference is 45mm in height (for all sizes) the electric heater element and it’s connections. The plumbing connections are the same for all models, it is just how you connect them that differs: From section 1 of the reference manual V2.0: A = High Power feeding the top of the heat exchanger. B = Low Power feeding the top of the heat exchanger. C = Low Power feeding the bottom of the heat exchanger. D = High Power feeding the bottom of the heat exchanger. High Power is typically used for the potable water and Low Power for primary Water. The order A – D varies throughout the reference manual! I will stick with this demonination. Controller details from section 3.1 of the reference manual: (there is inconsistency between the two manuals) For all but the e__ units they are designed for an external heat source, so charging direction is top to bottom, therefore Heat source flow goes to B and return to C. Potable water (DCW) feed to D and (DHW) to house to A. This is all detailed in the reference manual and also in the design and install manual. This is what I would consider normal, you pump heat into the top of the cell/tank with the return at the bottom and you feed in cold water to the bottom of the tank an d take out the hot water from the top. For an e___ unit there is confusion, the reference manual shows paralleling the HP and LP circuits (makes sense as all potable) but feeding the cold water into the top of the heat exchanger and taking the hot water out of the bottom, whereas the design and install manual does not parallel the circuits (omission) but does feed the cold water into the bottom and take the HW from the top, so again inconsistencies. I suspect this is down to the thoughts in the previous table that normal units are heated top to bottom but that the e__ units are heated bottom to top (because of the heater element), however that heat will migrate to the top of the tank so it should still be discharged bottom to top (flow) as per normal. The so-what is if you have a standard unit (NO e or I) then it can be used as any HW/Heat/Dual functionality, if you have an e or I unit it can operate as any unit an e only unit a normal unit, just ignore the heater or an I unit, it is just plumbing and wiring. So in theory (at least anyway) Jeremy can wire up his unit as a HW+iPV unit using the correct controller and it should accept charge anytime! It is all just a controller issue. Ready to be shot down in flames!1 point

-

Modern renders are certainly less susceptible to cracking but (and its a big but) if the substrate it’s being applied to isnt stable then it will most definitely crack. Just take a drive around any modern housing estate and you’ll see plenty of cracked modern renders but this largely down to the fact the render is applied before the blockwork has dried out or the render hasn’t been properly decoupled from a (shrinking) timber frame. I assume by “high build” your builder is referring to the silicone based coatings that the render manufacturers sell for rectifying issues? If this is an existing building is some form of renderboard or EWI with a fresh render coat an option? It will almost certainly be cheaper than the incredibly labour intensive route of trying to remove the old render.1 point

-

1 point

-

1 point

-

I have just bought this pair https://www.ebay.co.uk/itm/254026764133 a slip and a normal for £10 I hope they are the right thing, just described as "50mm black poly"1 point

-

1 point

-

for anyone still looking proteck were quoting good prices1 point

-

We have used exterior Osmo oil with the oak stain as we did not want the cedar to silver. We used the clear osmo to start with but found out it doesn't have great UV protection. The cedar started to lose its colour & grey quite quickly. The new stain looks good & is showing no signs of weathering yet. We tried the other colours available but the oak was nearest to the original colour of the cedar. As it is translucent it there is still a variation between the cedar planks. The cedar stain is too orangey red. I would get a sample sachet & try it in a discreet place.1 point