DonGillies

Members-

Posts

19 -

Joined

-

Last visited

DonGillies's Achievements

Member (3/5)

8

Reputation

-

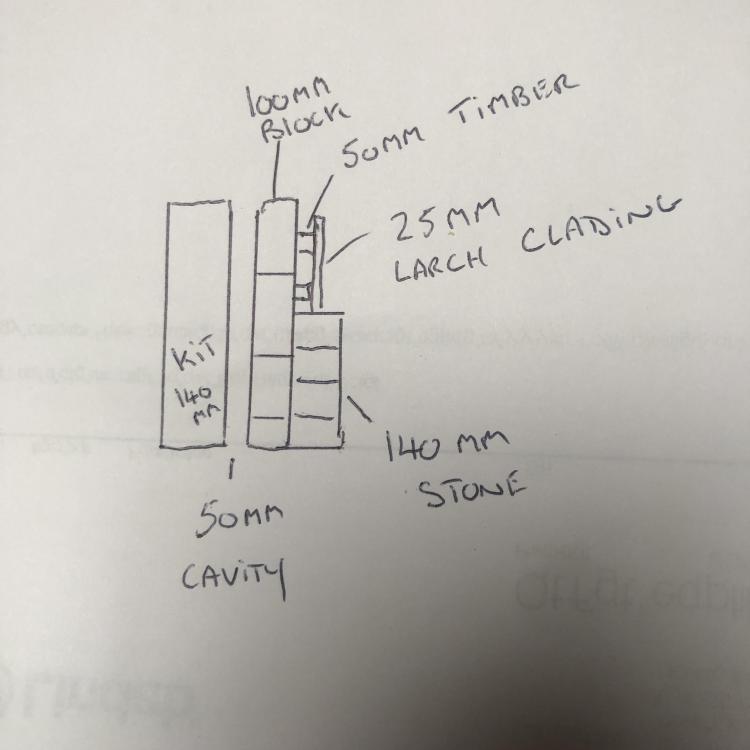

Hello all, I was wondering what peoples thoughts are on having a block skin around the whole of the timber frame kit. The way my house has been designed is that we have a 140mm Timber frame - 50mm Cavity - 100mm Block Skin - 140mm Stone at low level - 25mm larch mounted to 50mm battens that are fixed to the block work. I'm wondering if i do actually need the block work or if i can fit cladding and stone work to the kit providing i still leave a cavity.

-

Hello all, I have my Architect saying that I should not be plastering my timberframe kit as it’s likely to crack due to the movement in the timber. has anyone got any experience with this? I’m not really wanting to tape and joint. I have a young family and know that it’s easy to damage the walls that have not had a skim of plaster on them.

-

It will be a big job to insulate it and to do it so it’s all a tight fit. I’ve just purchased this Festool Insulation saw to make the job a whole lot easier. I will possibly continue building houses afeter my house is complete so thought I would get the use from it again. It’s expesive at £550 but worth it in my opinion.

-

I have just used Fleming Homes on a kit in Dunkeld, I've been very happy with the service and the kit. I had them supply and install the Velux windows and the windows and doors, this way its all zero rated for VAT. One thing I will say is to ask them to get a like for like the quote from Alan Bros for the windows. They tend to push the Rational windows but the Alan brothers windows are top quality and in my opinion better than the Rational (We had Tripple glazed ali clad) I managed to save £4k by changing to Alan Bros. I'm just starting a second project now and going to use Flemings again, this time I will be getting the uninsulated kit and will be doing the insulating my self. Think the price from Fleming was reduced by around £10k if i do that myself (fit 120mm Celotex in the kit panel then 50mm on the inside) and materials are about £4k. Means i should save £6k as my labour is free.

-

What size house is it for?

-

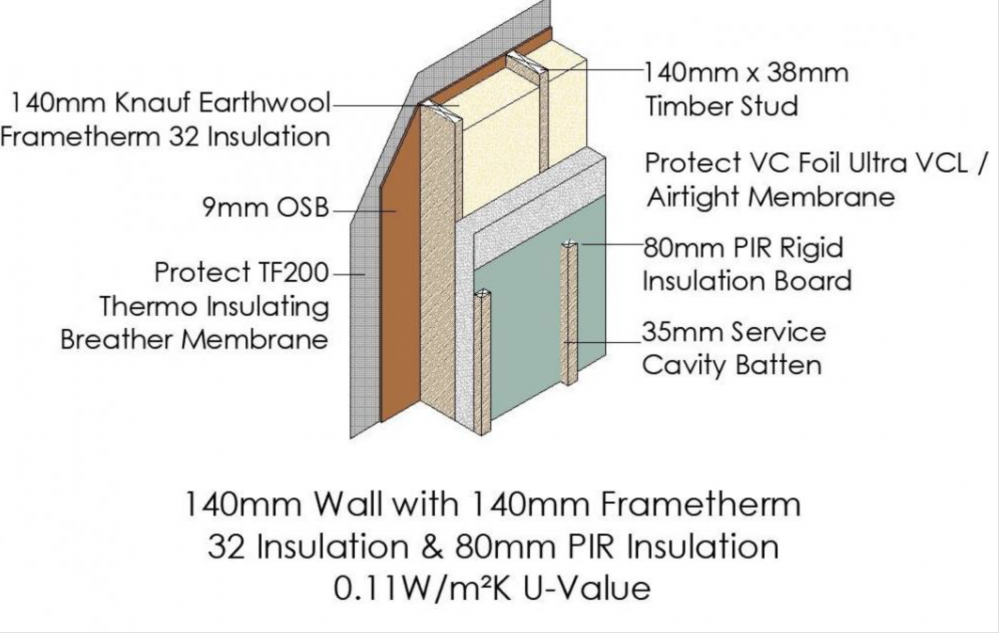

Hello all, I'm looking at ways to reduce the cost of my kit house, one big saving is to get the kit uninsulated and installing the insulation myself. I wanted to hear some opinions on using the 140mm Knauf Frametherm Insulation inside the 140mm Kit Frame, then using rigid Celotex type board on the inside face of the kit with a foil barrier. I've seen some kit manufacturers offer this option but my Architect is advising that its not good to mix the insulation types in the wall (wool and celotex). Is this correct? The U Values look to be the same and I imagine its a lot easier using the frametherm than trying to cut 120mm celotex boards neatly to fit in the verticle studs. The kit I'm looking at has 120mm Celotex in the kit frame and 50mm celotex on the inside face. If I get the kit without the insulation it's £9800 cheaper. Picture below shows what I'm looking at doing.

-

I also worried about removal in the future, although the Project Manager on the job said they should last at least 20 years so can worry about it then.

- 12 replies

-

- timber frame

- timber kit

-

(and 2 more)

Tagged with:

-

We have fire stop material around the outside and i think it will be expanding foam around any gaps. what would you recommend for air sealing? The windows are triple glazed Ali Clad from a company called Alan Bros. Been pleased with them and price was good in comparison to others.

- 12 replies

-

- timber frame

- timber kit

-

(and 2 more)

Tagged with:

-

I just done some on a project and I was surprised at how easy it was. We had 50x50 battens that are cut to the fit around the windows, they are then screwed onto the outside edge of window frame (so like a frame around the window) You then push the windows into the recess and the battens leave it sticking out by 50mm. You then screw through the battens to the outside of the timber frame. If you zoom in on the picture you will see what I mean. This will I’ll have a block skin on the outside of the kit so the windows will be recessed once the blockwork goes up

- 12 replies

-

- 1

-

-

- timber frame

- timber kit

-

(and 2 more)

Tagged with:

-

I think if the drawing is detailed enough from Cullen then I would consider building them onsite myself with the help from a labourer. I have already forked out a good deal of money on tools for the job, would just need to add a nail gun and make a large bench to work on. I would need to get the joiners in when it comes to the roof trusses i guess, but again these will be supplied direct from the truss manufacturer.

-

Hello all, I'm looking for some advice on cost benefits of stick building instead of ordering a timber frame kit. I have received my first quote back for a timber frame package, cost has come back higher than I was expecting and I am now looking into stick building options so I can build the kit on site. The kit will be 145mm External Stud walls, lined externally with OSB and VC Foil, we will then have 120mm Rigid insulation inside the kit frame, then a further 50 Rigid insulation on the inside face of the kit. I have read some good reviews of Cullen Timber Design on here so have emailed them today for an idea on what they charge for their service. Does anyone have any real life comparisons on what they managed to build a kit for in comparison to what they had been quoted for a kit from a kit manufacturer?

-

I have a grounds work contractor lined up, same with block work, slaters and most other trades. I am midway through the project management of a build for my brother in Dunkeld, this has proved valuable in learning the sequence of a build, and also meeting some reliable trades people. Pic below of the project I'm doing for my brother.

-

Hi Neil, Internal size is 256 Sq M I'm aiming to build it for around £280k so will be a bit tight.

-

Dons-Final-Draft.pdfDons-Final-Draft.pdf

-

I'm not 100% sure at the moment, I'm waiting for the engineers to do their bit and advise of the best detail.