Leaderboard

Popular Content

Showing content with the highest reputation since 01/02/26 in all areas

-

Ufh pipes will cost a grand to buy, if you don’t put them in you need a serious word with yourself. I don’t understand the figures like some on here, but I know I’m sitting in the most comfortable house I’ve been in for a long time, just a gentle warmth in the tiles emits to every point of the house. it’s just an absolute pleasure.7 points

-

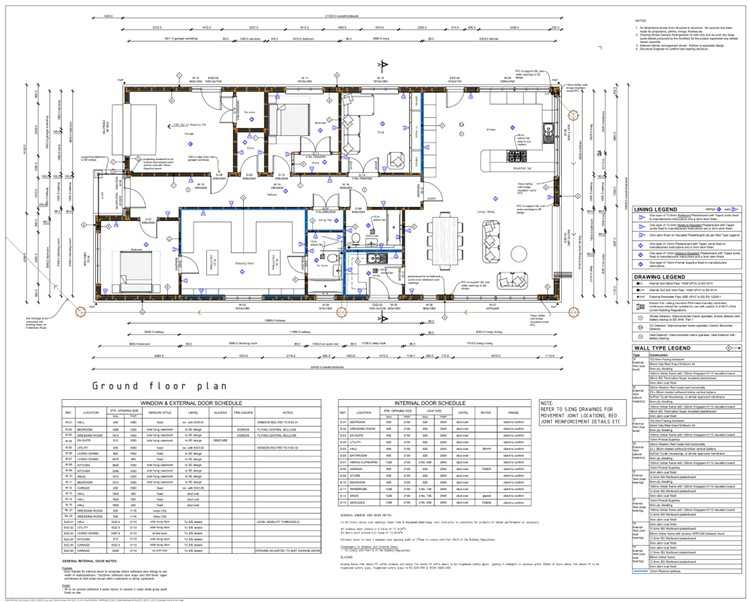

Hi all. I've been on here a while on and off and posted about 3½ years ago for advice on potential plots. We ended up getting a lovely plot in a nice village in Norfolk not long after that but was held up for 3 years because of neutrient neutrality and natural England stopping all new planning permissions being granted. We got full planning 4 months ago and have made a start, in the winter🫣. Foundation blocks are nearly laid to ground level. Me and my husband with a little help from others are running and building ourselves. My husband's a carpenter and was a site/contracts manager for a building company. We are building a single storey timber frame home with a brick skin up to window height then black cladding. A slightly unusual roof will top it off. We're both really excited and frightened especially regarding budget. We will have to stop the build throughout to earn more money to finish it but will be determined to get there in the end. If anyone has any words of wisdom or suggestions regarding internal layout we'd welcome your input. Also we're stuck with our heating and hot water system in terms of best and most efficient way to do it. It will just be 2 adults+a dog living in the house. We have no gas here and don't want oil so will be all electric. We'd love to have solar and batteries one day but it'll have to wait a while. The back of the house is south facing so will need to organise some shading but again budget may determine what we have. Thank you all in advance and I look forward to being part of your amazing community4 points

-

Yes, already proven here. Very early on in the build I confirmed the heat loss calculation was correct by leaving a single electric convector heater of known power on and plotting internal vs external temperature for several days. That gave me the Dt for a given power input, which tied exactly with the calculations. In any event I bought a 5kW ASHP to satisfy a max demand of just over 2kW. For me the only leap of faith was no heating in the bedrooms. SWMBO likes a cool bedroom about 18 degrees. Usually we have to keep the bedroom door shut to keep it down to that. In this cold spell we had to open the bedroom door occasionally to let a little bit of heat in, and still achieved the required temperature with no actual heating there.3 points

-

If you want to do as much as possible yourself then I think there’s a few options. icf you can do everything yourself timber kit, get that put up and then finish it yourself timber built on site, you will probably need a couple of carpenters to help brick block cavity you will need a bricklaying gang. will also depend if you have a large chunk of cash up front, timber frame erected on site will probably be the heaviest up front cost. icf has a large up front cost, but probably 20% of a timberframe then you can drip feed cash into it. brick n block lowest up front cost but large weekly payments for labour.3 points

-

Full planning it is. Prepare yourselves for more questions. 🤠3 points

-

Triple glazed lift n slide from norrsken here. the back wall of my place is 90% glass, I can’t recommend them enough -3 outside here and the doors on the inside feel warm, open them up and the outside feel is freezing. a strange thing you notice with this quality is the outside door handles are freezing cold, the inner handle is warm, there is no heat transfer through the door via any lock mechanism.3 points

-

The mix is not important, getting your bricklaying team to mix it the same every time is the important thing. when you get the colour you want you need to discuss it with the bricky and get it in writing that they will use a gauge box to get it the same every time. any not up to standard gets taken down at their cost. you will need to buy sand in bulk and cement to get the same batch every time. DO NOT USE any form of mortar dye.3 points

-

Hi everyone 👋 I’m new here and thought I’d introduce myself as we’re about to embark on what feels like a fairly sizeable (and exciting!) project. We’re currently in the process of purchasing an old farm property that’s seen better days and is very much in need of some care and attention. The house itself has been a rental for a long time and, as you’d expect, has suffered from a fair bit of neglect. Phase one for us will be getting the main house brought up to modern standards – sorting the basics, improving comfort and efficiency, and generally making it a solid, future-proofed home again. Once that’s complete, phase two will be the big one: converting the existing barn into residential use. The long-term goal is to create a spacious five-bedroom family home, making the most of the character of the original buildings while blending in plenty of modern comforts – hopefully lots of underfloor heating and well-thought-out modern electrics along the way. I’ve already spent far too many hours reading through the forum and it’s clear there’s a huge amount of knowledge here, so I’m really looking forward to learning from others, sharing progress, and no doubt asking plenty of questions as we go. luckily we gutted/renovated a nice 3 storey property in Whitby over lockdown which has given us confidence to attack another project. Thanks in advance – I’m sure you’ll be hearing more from me soon!3 points

-

Once upon a time a deluded wrinkly, his much less wrinkly wife and their noisy little dog left their almost fairy tale rural retreat to live in a freezing rented bungalow while they buggered about trying to build a new semi-urban retreat nearby. (How clever am I avoiding the word suburban!). Everything would have gone swimmingly but for the fact that the head of the wrinkly was just too full. It sort of still is I think. In the four months since the last post (stop thinking of a bugler at sunset even though some days that feels appropriate) much has been done: We’ve built a garage and the front of site is much less of a moonscape. All our blockwork is in, much of it rendered. We’ve now got one flat roof and two slated rooves, one with loads of solar panels. All our windows and some of our doors are in. We’ve got 240mm of underfloor insulation and a circa 100mm sand and cement screed with lots of buried pipes, of both the heating and soil varieties. The screed alone changed things to more house than warehouse - fabulous. Almost all the internal wall skeletons are back up - so now we get a much better feel for the layout which is a very good thing. (We built some downstairs walls earlier but took them down to make the DPM and insulation easier.) Most of the frame insulation is in. There’s even loft insulation in the loft - ok it’s still in its rolls ready to be fitted but it’s still there, patiently waiting. And there’s some VCL in place and we’ve made a start on the inner skin - some battens and yet more mineral wool to form what is really an insulated service void to give us a half decent wall U value. The man cave has its insulated metal panel roof and is usefully storing tons of stuff. All the service pipes and wires are buried in a trench ready for connection to said man cave which meant yet more depressing hours on a digger, and now the back garden is a moonscape. A humongous insulated twin pipe monster conger eel of a thing is buried, surfacing at the concrete plinth for the heat pump at one end and in the under stairs cupboard at the other. We have surface water drainage pipes installed at the back. Phew. No wonder we are worn out. And I’ve probably left lots of things out too - when you are on site every day it’s so easy to forget what has been done and focus instead on the rather elongated to do list that keeps me awake at night. Not every night mind, some nights are a lot better than others and I am getting a vaguely sensible amount of sleep more nights than not now, thanks to constantly talking stuff through with J. But there is an essential difference in the build. Before we sold Bramble we knew we were running out of money so we weren’t going at full hurtle. I had a twenty minute drive to and fro and a soak in the bath, all of which helped me keep my head in the game. It felt like there was time to think. Now I have a twenty second walk (if I dawdle) to and from site. Despite the ice box (aka rented bungalow) having a really powerful gas combi boiler it has a low power electric shower that dribbles just enough water to get clean but not get warm. And we’ve the money we need to complete, so it’s warp factor 8 Mr Sulu. Now if I was doing this on my own I’d have no choice but to slow right down, and try and get my head together, and feel in control again. Thankfully we are totally in this together, so we aren’t slowing down. Not that it’s without tensions. J and I talk everything through and she keeps track of tons of things that I can’t (hopefully everything that I can’t, which is an unfair burden but that’s how it is). We identify short term priorities and I focus on them, with me tacitly accepting that I am not personally in control of everything as for me to be so would mean a lot slower progress: neither of us want to stay in the ice box a day longer than strictly necessary. So the tightrope act is to balance keeping the pedal down as hard as possible without us actually losing control or allowing any major cock ups to occur. Simples. It gets harder when there is anyone else on site but ourselves and Rolly, our chippy. Peeps are incredibly (and I believe unconsciously) attention hungry especially when their needs are coupled with my need to monitor all work and limit disturbance to the neighbourhood. It’s so frustrating that when a contractor is on site my own productivity declines enormously. And then there’s the gargantuan mess, especially in one particular case - the thoughtless dumping of spare stuff; the treading of material up and down the road without a care for the frozen moron still sweeping and hosing down the road in the dark hours after they’ve finished their second pint; the drifting flocks of discarded paper bags mixed in with fast food packaging. Sigh. At least everyone we’ve had on site so far has done excellent work, so that does compensate. The feeling of a lack of control is not helped by the fact that I’m completely useless at estimating the time needed for tasks - though as J frequently mentions we’ve not done lots of this stuff before so we should accept that we can’t know. The DPM and underfloor insulation took me many, many times what I imagined and I’ve a black belt in beating myself up. I enjoyed doing the lower polystyrene layer, so nice to work with, but hated the PIR layer. The polystyrene has spring in it and one can cut pieces a little oversize, lever them in and get a really nice, tight fit. It’s messy in that little baubles of white stuff get everywhere but they don’t get down your throat. PIR however is sooooo different. The dust it creates is truly horrible, it lingers in the throat many hours later even if a mask is worn, which it mostly was. It almost appears to shrink away from it’s neighbours - when cut to precise size and shape, wrestled into place shooting showers of nasty dust up as the air trapped underneath is expelled through the tiny gaps at the side - it still sits there showing a small but definite gap between the sheets. Not at all satisfying. Thank heavens we ignored the architect and chose not to put PIR in the walls. So it turns out that there is a job worse than moving tons and tons of crush. But thats now done, thank heavens. As an aside I’d planned just polystyrene, but the reinforced slab came up a bit more than planned so I switched to part PIR to get the insulation level I’d targetted. Note to self: get quotes for different thicknesses of stuff before deciding. Buying stuff that local suppliers have on hand saves tons, which accidentally benefitted us on the underfloor insulation - had things gone to plan it would have cost us rather more for the same insulation performance due to me designing in theoretically available sizes. Odd world, innit. The need to book contractors is a real source of pressure. An example: We have been recommended a plasterer who everyone says is brill and so is v busy and we don’t want to lose him, but that means guessing a timescale and thence sticking to it. I’m an ex-project manager. I know that to manage the project requires knowledge of the timescales for each task in the train, and as above - I really don’t have a scooby. Well, I do, but Skooby the Skoda probably doesn’t count in that regard. So, in summary we’ve got tons done, but tons still to do. Xmas has annoyingly punctuated the project but that’s probably a mental godsend - at least I’ve a popped ballon to enjoy putting in my empty honey jar. We’re working really well and closely together as a couple and I will get used to the feeling of panic just below the surface that not feeling personally in control causes; the foreboding that I cannot be confident that I haven’t missed something important; the relying on J that will deliver much faster progress. You never know, my next post might even be a bit about the build…3 points

-

Passive class house here, not certified, no UFH. An actual measured heat usage of 3200kWh or 17kWh/m2/annum. Supplied by an electric plug in heater. It worked fine so long as you plugged it in anywhere downstairs and allowed it to gently input heat for 18hrs/day. Expecting it to batch heat on TOU tariff overnight wasn't as successful as i had hoped. it needed to be turned on at about 17:00 in winter to keep the living rooms warm enough(21deg). I added some electric heaters in the bathrooms for comfort as 21deg isn't quite toasty enough. Fan heaters are better than 2 Bar quartz heaters. The house is very comfortable. I replaced the electric radiator with an A2A HP for 2025. It's dropped our heating consumption to very close to 1000kWh or 5.5kWh/m2/annum. It works fine so long as you give it long enough run times for the heat to disperse around the house. It won't be quite as cheap as an A2W HP as you can't batch heat a slab on TOU tarriffs and a COP of 3 to 3.5 won't match a top end A2WHP. However it only cost €1500 installed so there isn't much in it. Add DHW demand or solar and the sums would change again. (FWIW an A2W + UFH was quoted at €14k in 2020) TLDR: 1. Anything will heat a passive house comfortably if you're prepared to give it a fair chance. Short run times and quick runups won't work with localised heat sources. 2. A2W HP's are best for comfort and running costs. However they only have the best long term costs if you can get a well priced install.3 points

-

2 possibilities You have a leak somewhere You may have an issue with the expansion vessel (red tank) First check the expansion vessel When the pressure is near zero, like in the first picture, get a tyre pressure gauge and read the pressure in the red cylinder. There should be a valve exactly like a car tyre one on the top. It should be something like 0.7bar, 1 bar or similar. If it has pressure eg 0. 7bar but the gauge on the water reads near zero, it is possible you have a leak somewhere. If it reads near zero your expansion vessel has lost has pressure (you may still ha e a leak but it's a bit less likely) If the latter you can pump it up with a.tyre or bicycle pump. Then top it up with the flexi hose. You need to turn the. Slotted screwdriver thing so it's. Inline withe the pipe, then turn the black handle at the other end. There should be a whooshing sound and the pressure creep up. Once at desired. Level (1 - 1.5bar) turn both valves off and disconnect the pipe (get a saucepan under as some water will come out. Beware just topping up the pressure continuously. The water is going somewhere!2 points

-

Please don’t do this. As much as I hate conveyancers, a good one is with their fee several times over. You don’t want to make DIY mistakes on what’s likely to be one of the highest value transactions you havre ever entered into.2 points

-

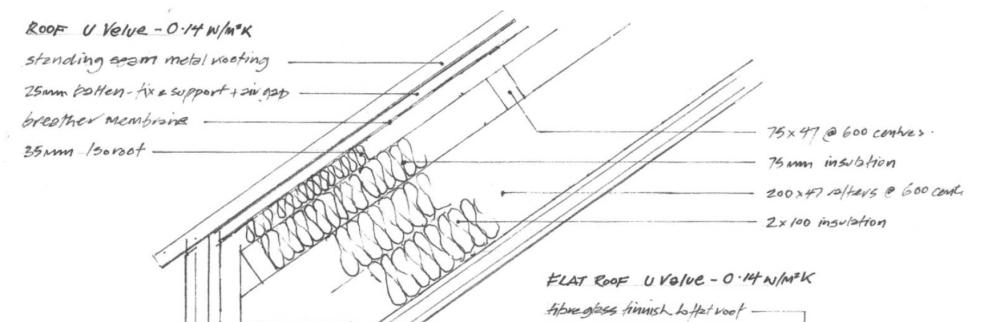

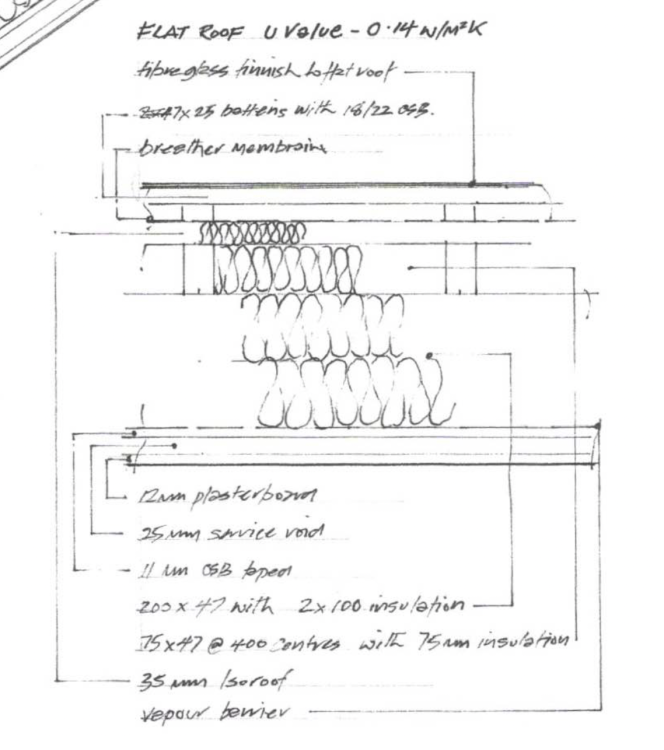

@Iceverge I do like this roof build up, similar approach to our roof, I have included drawings including my fibreglass flat roof. The drawings were all done by hand using Rotring pen! These are screen grabs. 200mm Rafters with Rockwool 75mm counter batten with Rockwool 35mm Isotherm T&G Breather membrane 25mm Batten for air gap Standing seam metal roof On the inside of rafters Vapour. barrier 11mm OSB 25mm Batten Plasterboard2 points

-

Here's an excerpt from the email that came with a quote I received in August 2025, if that's any help: "Pleased to provide a quotation for the airtightness works in your project - to view in full, please click the Quotation link above. For the supply and installation of the AeroBarrier system in your 190m2 project in [my postcode], your installation would be £2,538.40 (ex VAT but zero rated on new builds). This price is inclusive of travel, labour and materials and we do not charge a premium or any added fees for you end airtightness target (even to high performance levels)."2 points

-

An excellent improvement. That corner seal in the window is a bit gash though. I'd be having a word with the window man. Having gone to the hassle of manually doing this it's like climbing Snowdon and seeing there was a blasted train to the top when you arrived.2 points

-

Had some very minor domestic renovation experience but achieved possibly 90% of our self build. Paid professionals for electrics, plaster skimming, ASHP, window installation and screed. It is doable, time, money, quality consideration. 3 years before we moved in and 6 years later fitting final architrave ready for repainting!! Has been an amazing experience, learnt so much and the amazing contributions from Buildhub. My Dad, 75 years at the time helped me with the stick build. Would look at other build methods in the future.2 points

-

Not me, but G, and not finished, but have a look at our blog......demolished bungalow and timber frame build2 points

-

Neither! It's a good room-by-room heat loss calculation that must come first which you then use to size the heat source, followed by the emitter design. Then you look at flow rate, velocity and pressure loss through your pipework.2 points

-

I can assure you, they absolutely hate having to do it and will charge to apply it. I prefer to source it direct, that way I know the install is with products I have discussed. They would rather not apply it, they'll try and offer alternative solutions but compriband, airtight pu foam, airtight membrane is the way to go.2 points

-

Good day for a test. (Did this about 95min ago) Outside temp according to the ASHP is 2°C. House Internal air temp is 18.4°C Here is a photo from my thermal imaging camera. The window pane glass is at 12°C, look at the heat outline of my body showing the reflected heat, which is 15.1°C. The frame is at 9.1°C.2 points

-

What @Russell griffiths says. This will take a bit of research and a lot of management. And you will have to pay a bit more for the materials and a very professional bricklayer. The typical bricklayer will engage a ' trowel' (another bricky) or two, and a labourer. He may understand your requirements but not convey that properly, or they don't understand or don't care. The labourer especially is unlikely to make much effort and will be under constant pressure for 'more bricks, or more pug/muck/mortar ' acc to region. Then next day it is a different labourer. Most just shovel in sand and cement and add some water. The same shovel holds different volumes of cement / dry sand/ damp sand. I have never witnessed the use of a gauge box. Even getting them to use buckets rather than shovels is a pain. Explaining is likely to be met with a smirk implying 'what do you know?' they dont know what they dont know. And then you must only use one brand of cement...fairly easy. And one source of sand. This week's big bags may be completely different from last week's as they come from a different sand pit or a different layer of the same one. The BM has little to no control over this. Some sand is remarkably orange and will never look like your pics. But I don't want to discourage you as the right mortar makes the wall right too. Perhaps you have to be cheeky and knock on the door of a house that has achieved what you want. a few compliments will excuse the intrusion and you might get the info you need. To me the answer is a professional and proud bricklayer or builder who knows how to achieve this, and will want an extra 20%. They exist. You will choose your sand and get it all delivered in one hit. Why's this? Again because of getting the mix exactly the same for every single mixer load. No chance really other than black.2 points

-

Very inconsistent results, it takes only a small mistake in measuring to alter the colour which might not be noticeable until properly dry, I’ve had some horrible results using dark browns which looked brilliant while wet but dried very inconsistent they also tend to not like being wetted after they have dried and tend to look patchy.2 points

-

We had 3g windows throughout our last house except for the patio doors which were 2g slide and folders. They were definitely cold. This time we have gone for 3g throughout (from Norrsken) including some 4m lift and sliders. Too soon to say how they feel because we aren't in yet but early indications are good - running the house at just 18deg for the 2nd fix trades it feels amazingly comfortable and those sliders are not giving any impression of feeling cold. I'd go for it if you can.2 points

-

Really appreciate the input @Nickfromwales, @Russdl and @BotusBuild - we are sticking with ONE BIG DOOR 🎉2 points

-

As you would on the sides and top, you should retain packers all around the frame and not install without any. The compriband should be on the outside aspect of the frame, packers every 150mm from corners and then every 300/400mm and I also recommend under every mullion if possible, as it helps the frame from dropping/twisting.2 points

-

Past experience. LED themselves are pretty reliable. Drivers on the other hand tend to be crammed into a little box with minimal cooling. Some types of capacitor are particularly sensitive to temperature with their expected life halving by every 10C rise above about 40C.2 points

-

Not clear where your boundaries are with neighbours etc from those drawings. Personally I find all this 'permitted development' stuff a bit unnecessary. If you are going to build something reasonable with due consideration for your neighbours and the local context and setting, why be trying to use permitted development ? The cost and timeline involved with getting planning permission is not excessive compared with the costs, timelines amd risks involved with a building project. I don't think LA planning are going to have spurious objections. You don't say whether you are engaging with neighbours regarding your plans - which is the recommended approach by all good architects and the planning office. Going through planning permission will at least ensure immediate neighbours are informed even if you want to shaft them. You never know, LA planning might have something helpful to say about your plans, and having planning permission can only be a positive when it comes to the sales value of the property, and dealing with neighbour relations during the build itself.2 points

-

The shoulder months are also problematic for us (!) we are in a well Insulated house (miles off passive though... 2.7 airtight, 0.11 floor, 0.22 walls, p. 14 roof). We also have a huge amount of glass & very high ceilings of 3.2 to 4.2m, and regularly during shoulder months the house isn't cool enough to trigger the heating (21 - 22 degrees) , but the tiles feel cold under foot and you can actually feel quite chilly... Maybe due to the large glass? As a result we actually need to force the heating to come in (set thermostats to 24 degrees) for a couple of hours to warm the tiles up. We are also heavily zoned, which works well for us, as we have a very complicated design, so can fine tune the boost to rooms that need it, and leave the bedrooms etc2 points

-

Think the bend radius for getting pipes through is way to small, firstly. Why run pipes through floor at all. Take them from outside direct in to house.2 points

-

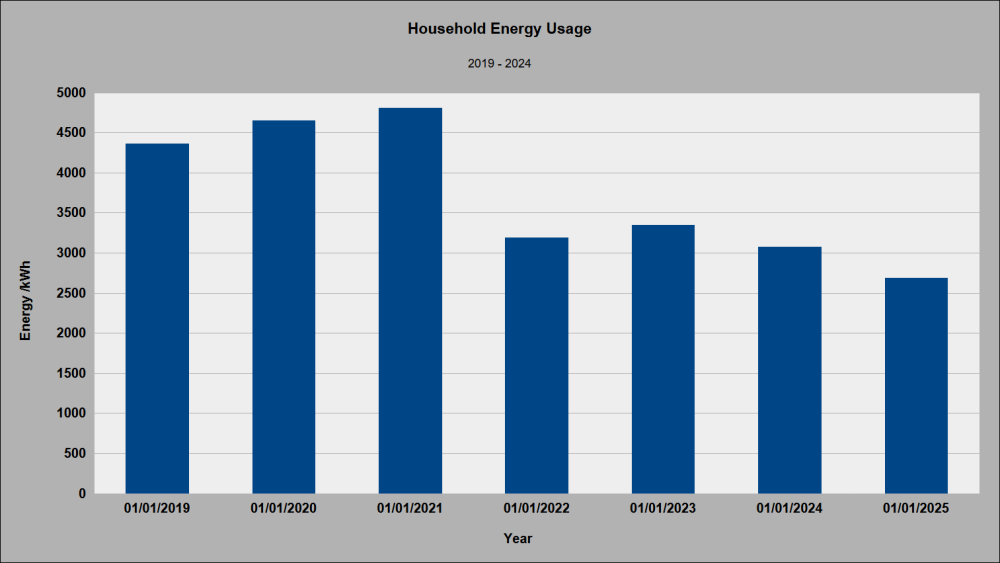

Take me 20 years, but very little cash to to reduce my household energy use to below 3MWh.year-1. When I first moved in, it was around 11 MWh. This last year, I used 2,780 kWh. That is 335 kg of CO2. Feeling pretty chuffed about that as I have been warm, but never too hot, fed and bathed. If you are wondering why there was a big drop from 2022, that is because I fitted my home made secondary glazing (making my windows triple glazed).2 points

-

Also trying to sell a house (who knows what the future will bring?) without any heating may be problematic. That was one of the reasons we opted for UFH. The lived experience is that if we were living without UFH during these cold spells there would more than likely be a bit of grief with ‘er indoors. As an aside, our downstairs north facing toilet has two short loops of UFH pipes going in and out. The UFH is never on for more than 6hr (cheap rate electric) and it can feel cooler than the rest of the house during these cold spells. One or two tea lights is all it takes to keep that room snug and warm.2 points

-

Neither. For simple white switches, I don't think you will beat Click Mode for quality, value and reliability. But Screweys don't sell them. Toolstation do. https://www.toolstation.com/click-mode-10a-switch/p73508 A little "quirk" of these switches is the switch mechanism can be removed from the plate, enabling you to mix normal and intermediate switches on the one plate. Almost like a grid switch.2 points

-

A point people miss with airtightness is the role it plays in keeping damp air out of your walls and ceilings with the knock on effects of interstatial condensation etc. If you want a durable building you must control the air leakage through the structure. This is of course in addition to it's comfort benefits and energy savings. Regarding ventilation theres essentially only two types. 1. Holes in the wall and hope for the best. Be prepared to be overventilated in gale and underventilate otherwise. 2. Continuous mechanical ventilation, with or without heat recovery. MVHR is the most comfortable, uses least energy. It's not cheaper than other forms once you take filters and servicing into account. PIV,dMEV,MEV,DCV are all the same thing with little nuances. Just sucking or blowing air in/out. All will give you adequate quality air if set it up correctly. Unfortunately unlike MVHR you still need holes in the wall which may be drafty on windy days. @Eastfield have a look on search for @Thedreamer who heats their house with a stove and uses an ESHP for DHW and ventilation. An elegant solution I thought.2 points

-

2 points

-

I would say have the wood away from the ground, I use hot dip galvanised metal plates concreted into the ground and built the structure from there. Build heavy duty, not lightweight, I have perimeter structure in doubled up 10x2, infill is all 6x2 on 400mm centres. It's super solid under foot I used composite boards.1 point

-

Topdon have this on sale on amazon right now: https://www.amazon.co.uk/dp/B0DJQ91653/ref=sspa_dk_detail_2?psc=1&pd_rd_i=B0DJQ91653&pd_rd_w=WtqBx&content-id=amzn1.sym.9a64fe05-cdee-4d53-a27b-f3614d726545&pf_rd_p=9a64fe05-cdee-4d53-a27b-f3614d726545&pf_rd_r=DCY5A3JDRDX0B55FQ81X&pd_rd_wg=8KGNE&pd_rd_r=c53ae250-2421-4060-948f-40fb46782dd4&aref=UNy5aGjL5p&sp_csd=d2lkZ2V0TmFtZT1zcF9kZXRhaWxfdGhlbWF0aWM I have their version that attaches to the phone, which is great but I don't think I paid anything close to what they're asking for now: https://www.amazon.co.uk/dp/B0FFMHNDXM/?_encoding=UTF8&aref=FCWnrz47ke&pd_rd_i=B0FFMHNDXM&ref_=sbx_be_s_sparkle_ssd_img&qid=1767798926&pd_rd_w=6ua5j&content-id=amzn1.sym.7d8787df-7d4c-460d-ab31-21b0ba272b2f%3Aamzn1.sym.7d8787df-7d4c-460d-ab31-21b0ba272b2f&pf_rd_p=7d8787df-7d4c-460d-ab31-21b0ba272b2f&pf_rd_r=9B0GAABG10RHT7HCD0VE&pd_rd_wg=vOgfl&pd_rd_r=9e2b9072-7eae-4a6b-b97c-9d1b70393079&pd_rd_plhdr=t1 point

-

Go full plans, at present the rear extension is greater than 3.0m deep and more than one storey as well as being a side extension to the existing rear single storey part and is more than half the width of the original house. I'd rather not risk building that without a certificate of lawfulness to confirm it's PD and if you're doing that (and I think you would fail) you might as well go for full planning.1 point

-

Did they demonstrate how long the 2 loops would each be? For this amount of m2 I would be looking elsewhere as the loop lengths would be crazy long, and the effectiveness of the loop pretty dire; energy disrupted into the slab would soon sap the heat out of the pipe long before it had returned to the manifold. Thos installer needs to be binned off afaic.1 point

-

1 point

-

I have no doubt you are reputable and have a proven solution. I've had badly used foam cause extensive damage and leave a bodge behind.1 point

-

Standard window and door frames are solid material, wood or alu, or PVC etc. A thermally broken frame will have a layer of something (cork often used in wooden windows) as a means of separating the exterior and interior halves of the frame. Pull out the compriband and set it to one side. Use kitchen roll etc to remove any obvious moisture. Get some Illbruck 330FM foam and seal up under the threshold. Have you used a foam gun before? On amazon you can buy disposable tips which give you a means of getting the foam much deeper into the cavity, LINK, which you fix onto the gun by pushing them on and then tape in place with a good few turns of pvc electrical tape so that it doesn't fall off 'mid squirt'. Any residual moisture will be absorbed and dissipated over the following few days, so don't worry about 'trapped' moisture, it'll find it's way outta there by itself.1 point

-

People generally do it to get to a plant room in the middle of the house. I would just run pipe along wall and cover in 25mm external insulation. Does that give any fire protection?1 point

-

Mainly the challenge and CO2. The grid intensity CO2 is outside of my control, but then I started it was around 0.7kg.kWh-1. Initially I saved 30% by just managing my usage better. That was a no cost option. Changed to LED lighting (less than £30). I then started by spending some money, mainly £60 on some digital timers to limit my E7 window better (heat up in the last 4 hours rather than the first 4 hour). Then extra loft insulation (still got some more to add). Then I started the miserable job of draughtproofing, cheap to do, but time consuming. Then the secondary glazing (less than £200 for all but 2 windows, so 12 windows in all. Left 2 windows for escape routes). I also reduced parasite loads. This really involved making sure any standby loads were very low. Getting rid of a desktop PC and using laptops has made the biggest difference. There were setbacks, mainly my lodger who, until I beat her with a pointy stick, would stand under the shower till the water went cold. Eventually she learnt her lesson. If it was not more the orientation and the small roof, and having to spend my spare cash on bi-monthly visits to see my Mother, I would put some PV on the roof. As my DHW usage is about 4 kWh.day-1, I could probably get 80% of my DHW for nothing (I could also reduce usage, but I love my morning baths). To celebrate, I heated up the room I am in to 24°C this morning. Hansom it was.1 point

-

This is getting into science fiction. I need a lie down. What is the cube root of time anyway? Or is it a way of proving that that entropy isn't what it used to be?1 point

-

EDF FreePhase. We have averaged ~16p/kWh over the last month: 7kW Vaillant ASHP, no solar or battery, maintaining 21.5C indoor temp 24/7, no setback at all. We ignore the 4-7pm peak except for load-shifting the dishwasher & washer/dryer overnight.1 point

-

If youve got a near new working system then your primary motivation for change is likely only for environmental reasons?? If your boiler is still running perfectly in 20 years time that would be an awful lot of carbon emitted that you could have avoided if you'd made the change now. I'd bin the boiler now but my measure of ROI isn't just £££. Only you know your measure of ROI.1 point

-

But you also need to buy the correct grade for appropriate compression strength. Not all are equal. Not sure I get that, why is it a pain? I have cut PIR and EPS,both are equally a pain or easy.1 point

-

Thank you. Keep bays as square as possible, ideally 1:1 to 1:1.5 and no worse than 1:2. UFH pipes stapled to insulation are common and fine, but they do not control cracking. Saw-cut joints to about one-third depth and cut early so the slab cracks where you want it to. Avoid adding water on site, over-trowelling or closing the surface too early, delaying saw cuts, skipping curing, or pouring long thin bays. Get the joint layout, timing, and curing right and the UFH will cope with normal movement without issue. You could use a macro fibre but it will not fix the basics. Used correctly, they are a support measure, not a solution.1 point

-

Marvellous. The most important thing when renovating an old bungalow is to immediately bulldoze it.1 point

-

I (J) hesitate to enter the fray here as this appears to be an emotive subject (including, at some points, within our own household!) but here goes We bought a run down bungalow, with a good size garden for an urban area, in our ideal location. We had a good idea of how we wanted to remodel it (add an upstairs) and did our own preapp during the period the sale was going through. Once we got a positive pre app we did a beauty parade with a couple of local architects " we are VERY hands on, have quite clear ideas of how we want to live, have a a couple of "difficult" experiences before (in truth the latter was partly because we were't clear enough in defining the ground rules/expectations) and we want to spend £ " The practice we chose was a good match, values wise, and the first key intervention "knock it down". G was well along that route as a possibility, but the reasoning and experience the architect offered both in terms of end results, as well as costs, of trying to upgrade the existing was really helpful to me (J). As we had spent a lot of time laying out floorplans ourselves the stage pricing was adjusted accordingly (less for the initial survey/design phase) they were also really clear to set out additional costs eg fees, SE, BC etc. and the potential cost of the build if we went the main contractor route. Very much along the lines of @Gus Potter They prepared and submitted planning (they "know") the area, and the planners and planning was approved first time almost within the "given" timescales The building control drawings were more £ but boy did they earn their money. There was a good degree of to-ing and fro-ing regards how the wall build ups would be, what materials would be specified etc as we were hoping to do something outside their "norm" (learning from here) They suggested a couple of local options for BC, and for the SAP requirements, both of which, so far 🤞, have been "sensible and pragmatic". The fact that we had the architect drawings also helped in the warranty/insurance process, and it would seem that based on discussion here, we've paid "reasonable" premiums We chose to have a frame built off site, due partly to the nature of our plot, but the frame company commented that the BC drawing were amongst the better ones they see from architects in terms of actual buildability. As we are building (including constructing the frame kit), the design "works" ....where for example blocks have needed cutting it's because we've "tweaked" something So yes it seemed a large £ upfront, but in reality its probably going to be less than 5% of our final spend; it set us off on the correct path (demolish and rebuild), it minimised the planning angst, and finally it furnished us with something we could use to build in a way that we could undertake the project management/oversight which has and will bring savings as per @saveasteading So yes, there is an element of a leap of faith and when budgets are tight you "wonder", but at the end of the day, depending on experience (we're not all @nod) it would seem that you "pays your money and takes your choice" somewhere along the line.... There, light the blue touch paper and retire...... Ps. It' also fair to add that G is still not "quite as fond"...1 point