Leaderboard

Popular Content

Showing content with the highest reputation on 01/09/26 in all areas

-

2 possibilities You have a leak somewhere You may have an issue with the expansion vessel (red tank) First check the expansion vessel When the pressure is near zero, like in the first picture, get a tyre pressure gauge and read the pressure in the red cylinder. There should be a valve exactly like a car tyre one on the top. It should be something like 0.7bar, 1 bar or similar. If it has pressure eg 0. 7bar but the gauge on the water reads near zero, it is possible you have a leak somewhere. If it reads near zero your expansion vessel has lost has pressure (you may still ha e a leak but it's a bit less likely) If the latter you can pump it up with a.tyre or bicycle pump. Then top it up with the flexi hose. You need to turn the. Slotted screwdriver thing so it's. Inline withe the pipe, then turn the black handle at the other end. There should be a whooshing sound and the pressure creep up. Once at desired. Level (1 - 1.5bar) turn both valves off and disconnect the pipe (get a saucepan under as some water will come out. Beware just topping up the pressure continuously. The water is going somewhere!2 points

-

I've zero rated jobs in the past there is no form you have to fill in with site details. It would only ever crop up if investigated and I think as long as vat man can see a newbuild has been built at x address which your invoice is for you're good to go. The works could of potentially been done months before its invoiced out.1 point

-

i've already bought the materials so it's only on the labour. i like my plasterer so i'm reluctant to go hunting for a new one now. i'll just take the hit on the VAT then.1 point

-

You are only allowed zero vat when working under planning permission. At sign off of a completion certificate (you are stating you are complete) thereafter you are no longer working under planning permission, as that has been closed. Fudging and using a no longer valid planning number is down to you, but not for me say it's right/wrong on an open forum.1 point

-

OK this is fairly easy, although please take care to give the key relevant info when asking a question, otherwise you're asking us to write very long mostly irrelevant if-then-else replies. The most obvious questions are what is your drainage situation / what soil-type do you have / where will this drain to?. So: Pay 'Freeflush' £100 for the SUDS calc. You need to supply the plan area of your roofs and non-permeable hard standing and your location. Hint: make your hard-standing permeable and draining (using say, MOT3) to vastly reduce that requirement. That gives you your tank volume. Figure out whether you (a) want to use crates, tank, pond, swale, lake or Versailles-like water feature and (b) where it eventually drains to - ditch, culvert, soakaway, drainage field. You will need a soakaway test for the last two. Draw a simple drawing showing the arrangement. Check the levels and drainage fall if you're not sure. Add a short narrative written in the language of a 5-year old for people who don't understand numbers or drawings. Example calc below and no, you can't use those numbers.1 point

-

If the system pressure target is 1.5bar when cold, then your pressure vessel should be at a little bit below (say 1.4bar) when empty. This allows a little water into the vessel when at system pressure and the maximum volume change when hot. So if your water pressure gauge shows 0.2bar your vessel should show 1.4bar. Of it shows lower then the pressure is wrong. You can top it up but the fact the air has been lost points to a failure in either the valve or the internal membrane. If some water comes out of the valve, your membrane is almost certainly shot. Swapping the vessel is the easiest.1 point

-

Your more correct the guy is a kn0b and shouldn't be let through the door.1 point

-

If your checking the pressure of the expansion vessel, you need to depressurise it, otherwise you are just reading system pressure. Ideally it will have an isolation valve and bleed point at the expansion vessel to allow this test. Otherwise it's a pain. Overlapped post with @Nickfromwales1 point

-

What a prick. The whole point of the chuffing “service” is to inspect and top up the expansion, if so required!!!!!! Did he do the G3 inspection for the UVC? That’s the major importance here. I’d not let him back through the door ever again, as he’s gone the easy route and just wandered off with some fast bucks. When you find a replacement, fit one of these to the red expansion vessel. and if you want to make life easier downstream you can fit one to the UVC expansion (usually a white vessel a-la your red one) so the next service chap won’t wince and will be minutes vs hours checking both of these vessels accordingly, per annum.1 point

-

Look on Facebook, normally a few sets on there knocking around for half what your quoting, will sell for same money at end.1 point

-

Buy a 2nd hand Armorgard box. (Yeah, I don’t know why the Americans can’t spell either.) Put your most valuable tools in that or in the house somewhere. All the rest of the xrap - nobody’s going to steal it, in fact you would have to pay someone to take it away - stick it under a tarp and then that’s an incentive to get your new shiny workshop up and running in less than a year.1 point

-

1 point

-

Please don’t do this. As much as I hate conveyancers, a good one is with their fee several times over. You don’t want to make DIY mistakes on what’s likely to be one of the highest value transactions you havre ever entered into.1 point

-

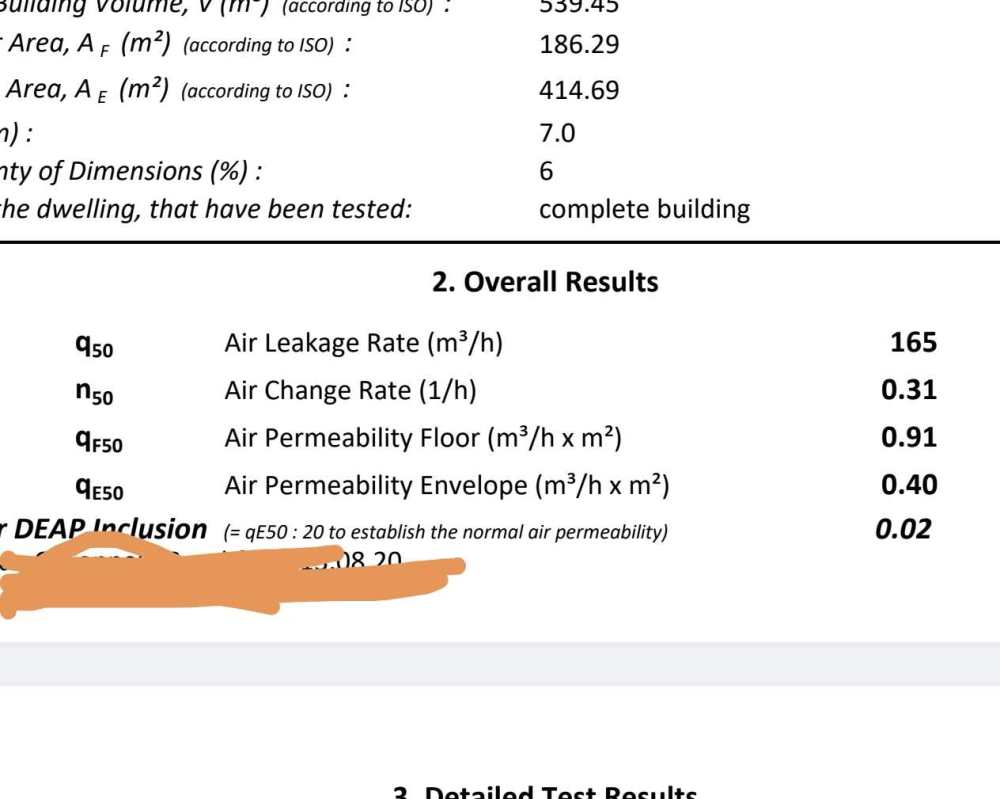

................... sprints to trophy cabinet.........🏃♂️🏃♂️🏃♂️🏃♂️🏃♂️............... .........unpacks golden framed airtightness cert................ ............. Yells "I told you someone would care" at nonplussed family........ .......Tear runs down cheek.......... Tears of joy, tears of pride ..... .......Children roll eyes and crank up some yank making funny with the Minecraft on TV......1 point

-

I think they just said "Oi scrote, make some more muck". There were no pleasantries back then, when I was 171 point

-

1 point

-

We have HS330, triple glazed timber / aluminium lift sliding door. A lot of timber in the doors and no condensation except outside on certain days. No problem with the fixed seals. Not an expert but would say fitting error. Like you the fitters and some parts of manufacturers were poor quality. Disappointing. Add to the list.1 point

-

I taped mine up the walls and the studs. two layers of insulation with staggered overlaps then a thin slip sheet before the UFH. the slip sheet is also taped up the walls my dpm is taped up more so the slip sheet is also taped to this. can you get any insulation in the studs below screed level? Easier to put in first and gives something to tape onto. Then maybe some noggins for the plasterboard later. I presume you’re having UFH, all the layers you tape up the walls and studs should be neat and tight. This gives something for the expansion foam something to stick to in the studs where there would otherwise be nothing.1 point