Leaderboard

Popular Content

Showing content with the highest reputation on 07/23/22 in all areas

-

Robin Emley put up this video showing what his meter does: Very helpful for me. I wish I'd gone through all his videos like this before I started 🙄2 points

-

Generally a single skin liner will be ok in an old brick flue that is not totally wrecked. Go for a good quality one. Make sure you install the liner the right way up, see manufacturer's instructions at all times. Have a look at the flue exit height. If you live in a town then other things may have been built round about later (taller buildings within say 200m distance, if near the Shard say in London then the vortices will extend much further) that will cause down drafts, if in the country you may have large trees that were not there when the house was built. For the cowl have a look at an "OH" cowl.. more expensive but they do work and are great for counteracting down drafts and promoting a more stable draw in the flue. If the flue is going to be long then to keep a good draw at low burn rates you can often put a single skin liner in an old brick chimney and pour in vermiculite. It keeps the flue warm so you don't cool the gases on their way up the flue. Important when you are just letting the thing tick over. Just make sure you have another baffle or rockwool above the register plate so when you service the stove the vermiculite does not all fall out. Again, ask your stove installer and find out what you think you will mostly burn in the stove and how you will be using it.. full blast occasionally or for mostly regular background heat.. big difference so choice range of stove performance is important. Best thing to do is to take advice from a registered stove installer then feed back the info to the roofer.2 points

-

The Vaillant controlls have dew-point monitoring, not sure about the Daikin Altherma (google doesn't throw anything up). If you ASHP doesn't have this then yes, you do need to be careful with condensation by limiting the temperature your floor surface gets too. The UFH flow temperature can be slightly lower, but should insulate exposed pipework in this case (could be an issue if it goes withing any walls). Have a play around with dew point calculator to get an idea. 18C floor with 24C room temperare and 60% RH is a non-issue, but if RH or temp is much higher than this then condensation can be an issue. https://www.calculator.net/dew-point-calculator.html2 points

-

Number of alternative options, aside from the Partel product. - https://www.ecologicalbuildingsystems.com/product/phonotherm-200 - https://www.phstore.co.uk/foamglas-perinsul-hl - https://www.cfsfixings.com/products/purenit - https://www.greenbuildingstore.co.uk/product/compacfoam-200/ We used perinsul foamglass blocks for some sliders and then used purenit (recommended by @craig) elsewhere. The purenit I think was available in a lot of different thicknesses and came in a 2.4x1.2m sheet which was easy to cut down, so might be worth looking at.2 points

-

I've ordered the blue plug (VAI0020266328) for the aerotherm+. Will confirm if it works or not.2 points

-

1 point

-

We’ve discussed this before and I quoted what Wavin told me back then. You also need to remember that your central heating will be running at a higher temperature for longer, a circulation system will be fine. he’s guessing ..! PEX and the likes are guaranteed for a minimum 50 years, mostly it’s lifetime.1 point

-

You could put it on Google Storage, and allow access whilst talking about it, and then remove the access at the end of the chat - just leaving some reflections to keep the thread useful.1 point

-

What about 1 network cable to upstairs to a switch, and then first floor cabling from this switch?1 point

-

My plumber said the same (about my DIY JG speedfit secondary return pipework) explaining it's because it can't survive being at a permanent 24/7 high temperature, the plastic breaks down much faster. Take it or leave it but that was his explanation Doesn't worry me much as my secondary return (if I ever get around to commissioning it) will be time and motion controlled so the pipework generally spend most the time at/near room temperature. Just the same as a heating pipe run, which it is rated for.1 point

-

May be worth reading the specification. Look at the intermittent and long term max temperatures. Our circulation pump lets us set times and temperature of the hot water circulation, we only have it on for an hour or so morning and evening at around 40 degrees. So would see any issue with any pipe material suitable for domestic plumbing.1 point

-

How deep did you excavate? Assuming you plan to hardcore before block paving anyway I'd backfill with soil whacking it at intervals of 100mm.1 point

-

After following others journeys into the self build world for years, it looks like I'm finally about to embark on my own after several soft starts. The first major work is to realign the driveway and I've opted for paved over other styles and to do most of it myself. I got a driver & digger to take up the concrete driveway and grass and pile it up and hired a grab truck to take it all away. Less than two days later I was left with a barren front garden! Since then I've been figuring out a few details and grading the site to prepare for the required level of MoT. There was some damage done during excavation to be repaired which is underway. The current list of problems are: Get Earth Rod reinstated and connect house ground to it - Electrician Buy another wavin universal gully 110mm as the first was to replace one cracked during digging, this one is to replace the old one which doesn't have a swivel head and its at the wrong angle to the house and will make the paving cuts a lot harder to achieve and look wierd. The new ones let you turn the gully to different angles to run parallel to the house. Buy adjustable connector for linear drainage channel to connect to inlet of universal gully as they are nearly level but not quite. Trace broadband cable from house to a point where I can create an access point and run a pipe from there to my site next door (I tried digging to find it on the other side of the site to only find a gas main where it's not meant to be!). To dig this alternative position out tomorrow and see if it's viable. Decide if I'll keep the loose soil in the original broadband excavation hole or remove and replace with hardcore (I've asked this question under the driveways topic on this site) Hire concrete / kango hammer to remove concrete surround of manhole cover and replace with a recessed unit and gain access to drain on other side of house for linear drainage channel over there - the side of this drain has a mass of concrete beside it for an unknown reason. Dig out holes for more concrete posts to form new front boundary but mind electrical cable heading in same direction Assess how much MoT I'll need to build up 2 x 75mm levels on far side of site which was grass and will take the most vehicular traffic. The old concrete driveway sub base is still there and its nearly at the right level, won't need to do much to it except whack it a few times and it'll be good to go. Risks: We found the water pipe near the far side of the house but I didn't take a photo before covering it back over. Now I can't find it again. The builders dumped a load of concrete beside a drain that I need to plumb a linear drain into and I'm concerned I might hit it. I have to chance breaking that concrete. Concrete fence post holes vs main electrical cable to house Finding broadband line - it's a 1 inch black cable but so are the electrical and gas lines! I'll have to excavate the whole route of the broadband pipe to ensure I'm looking at the right one. There is tape to show which is which eventually but nearer the house they don't bother with this. Marking on pipe aren't clear what it's for either. Site Safety: I've Heras fencing up & warning signs and put a temporary post box and wireless doorbell on it to avoid people coming onto site unnecessarily and twisting an ankle. Dust is a big problem. We had some rain last night which helped. The new side gate is up and the back is secured again. Today I was replacing the cracked drain gulley and nosing around a few builders providers trying to find what I was after. I'm back to work next week so things will slow down. If I can get that broadband junction sorted out tomorrow that would be great, otherwise I might have to try dig more holes again! This is definitely the biggest project I've taken on to date. Bits of civil engineering, drains, electrical, using a digger, compactor, line levels and more skills besides! The head is definitely taking a bit of a beating but I've had some great answers to my questions on this forum which has been a BIG help! At night my brain is going 90 mph though so need to balance things. At least going back to work will be a distraction. I'm past the point of no return but do wonder am I mad and should I have gotten someone else to do this for me!?! But the budget wasn't there and I'm learning a lot. Expect the unexpected. What lurks under the ground level for decades can't be put into words...strange cables with no purpose, concrete and gas lines where they shouldn't be, aching arms and head! Would I go it again? Ask me when it's over! Hopefully my next post will be it completed but until then, good luck with all your summer projects and I am VERY sympathetic to anyone taking on a house, I'm aghast at just a driveway!!1 point

-

This is Robin's video where is uses an old wheel meter to show how his box works. What it also shows that using calibration changes the wheel can drift forwards or backwards when the diverter is dumping load.1 point

-

Other than the smallest ones, new stoves in Scotland now must have a fresh air feed. At first I resisted but can now see the reasons. ie I was going to put a closable grille nearby, for use only when needed. But of course this is subject to user knowledge, and ability. A few stoves now have a dedicated air inlet at the back, but they are much more expensive. This is what we have shown on our Building Warrant application, so must shop around or hope that prices drop as it becomes standard. I didn't know until recently, and don't expect most builders to know either.1 point

-

Yeah that can happen also . Especially true for my bathroom . Pir turns lights on but if you are in the shower can’t detect you ! - so lights go off eventually. I did suggest to SWMBO a camera would solve it ; but she wasn’t sold on the idea ….1 point

-

Difficult to advise without knowing your layout, I would look to locate your network stuff in a central location - under the stairs maybe? Then look to terminate all your CAT cables there I'm not sure I'm going to bother with COAX other than at the main TV location as everyone is now streaming, but obviously it is a lot easier to run cables during construction than afterwards. If your build allows I would recommend running some kind of coduit / ducting to allow pulling new cables easier1 point

-

Yes, but when RH does increase it will accommodate and adjust a few degrees. In going to have to dable with Vaillant ebus protocol to control cooling as no dry contract or interface for this 😞1 point

-

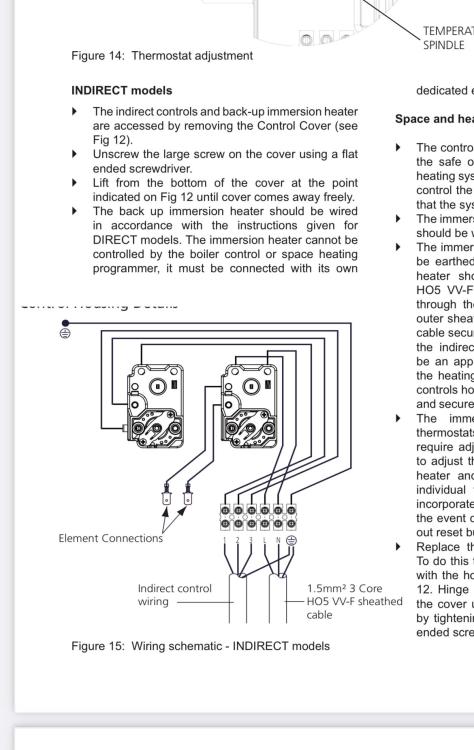

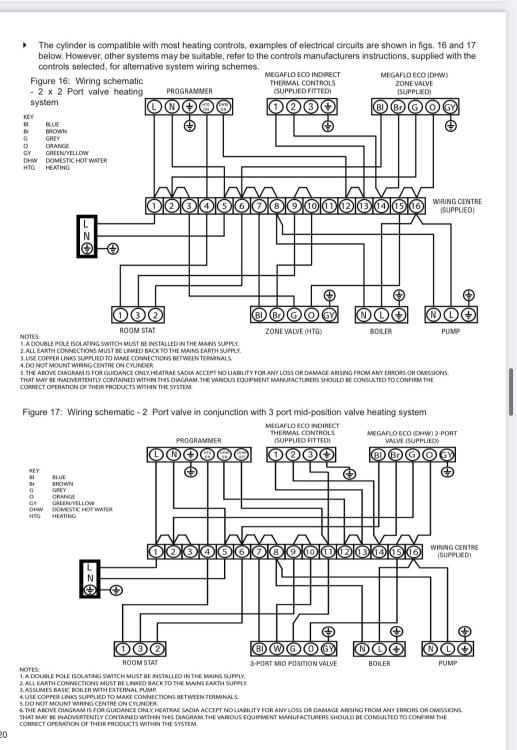

Right so looking at this pic he has a pair of wires heading into the Megaflo control panel (the lower one) and that should be wired as per page 19 of the installation manual. But from there, the wires marked 1-2-3 should go to the wiring centre and the zone valve controller for the cylinder as per wiring on page 19/20 of the manual If he has followed this correctly then the supplied zone valve (that has a micro switch in it) will trigger the boiler to fire when it’s needed using the live switched terminal 16. If the boiler needs a NV connection then it’s a bit more complicated but it’s all done with the valves. Tank temp / cutout is then driven by the correct thermostats on the tank ..! All of this is in the installation manual if he read it ….1 point

-

they may be talking about commercial ringmains, that often run at far higher temperatures.1 point

-

1 point

-

I made one for mine, used off some vapour control fabric/foil, some left over mineral wool and double sided tape. Made a load of pillow/cushions, shaped to go around the cylinder. Two layers of vapour control fabric (back to back), double sided tape on 3 sides, fill with mineral wool seal with double sided tape. They can be easily removed if I needed access. Heat exchanger is wrapped in 25mm PIR. Took about an hour.1 point

-

If the stove is going outside the chimney then some planning needed for the bottom end. Typically would be a register/adaptor plate then cast iron pipe to the stove. The register plate may need a door in it for sweeping if not one in the cast iron pipe or it can't be swept through the stove. Bends would normally be 45 degree max. Should really be installed by a Hetas registered installer unless Building Control already involved. Builder shouldn't really have to ask you for the spec as he should know.1 point

-

Yes it's essential. As we are introducing lots of insulation into buildings we need think carefully about trying to stop air with a high water gas content getting into places where it will later condense into a liquid and not be able to get back out easily. A VCL is essential.. Alutrix is one of the products you can research.1 point

-

Most plumbers can’t wire up an S plan, so they come up with all sorts of incentive ways to dodge those mystical 5 wires of the zone valve….. For G3 you need fail safe on the controls. That is via the cylinder stat. An UVC is a potentially explosive device, and relying on just the boiler stat is a defo no-go. He’s not only careless, but he’s dangerous, and clearly doesn’t know the requirements of G3. Get him gone and get the system made safe plz!!1 point

-

1 point

-

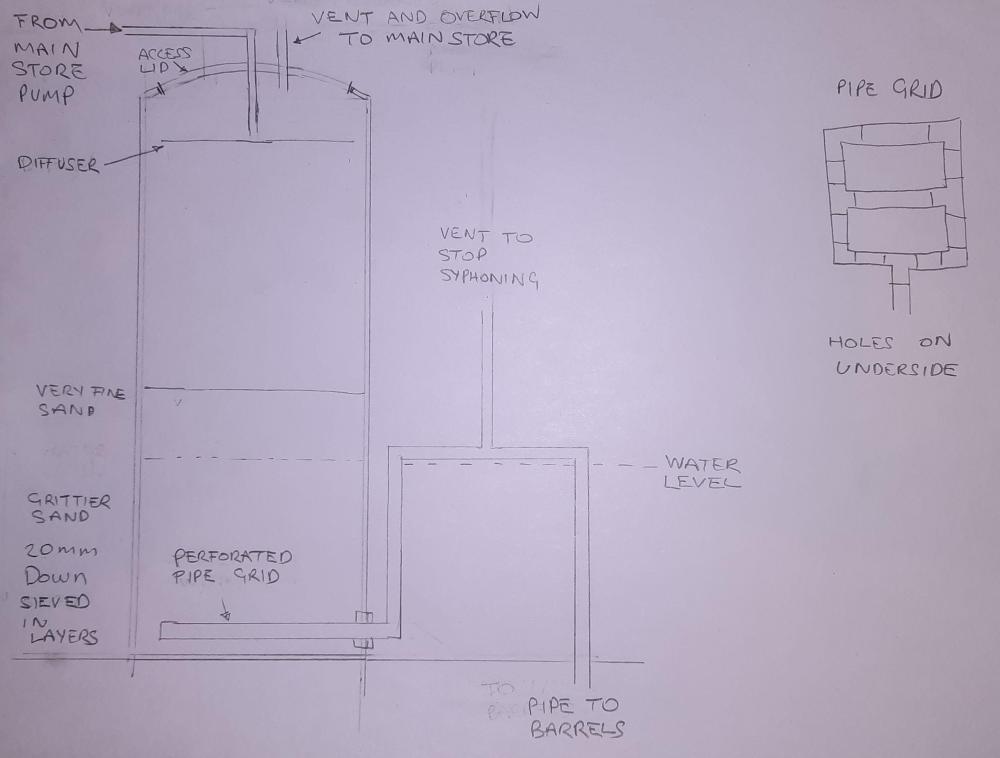

Fine filtering basics: https://www.cdc.gov/healthywater/global/household-water-treatment/sand-filtration.html Here is my adaption: So the pump pumps up to the top of the filter. The water drips through the diffuser (The bottom inch of a bucket with holes in it in my case) and runs through the barrel to the bottom pipe grid. The filling is a graded very fine sand (I used block kiln dried paving sand, then sharp sand, then grit, then sieved 20mm down stone into bigger and bigger layers until starting around the pipe grid with 20mm stones. The levels of all of the pipes in relation to the power of the main store pump, how fast it flows, and how fast the water passes through the filter bed is all critical. If the main store pump pumps the water in quicker than the filter will let it pass it will travel out the vent at the top. As it rises up the vent pipe more pressure is put on the filter to let the water pass and this may resolve the problem. However high up I installed a Tee which allows any excess to return to the main store via the overflows from the barrels. I brought the water level low so it was in the sand to try and stop the plastic barrel from splitting in a frost. The bottom pipe needs to rise so water is held in the sand. Most of the pipework I used is actually overflow pipe including the pipe grid, but the delivery pipe from the main store pump is plastic pipe. The barrel I used: https://www.diy.com/departments/ward-100l-slimline-water-butt/679230_BQ.prd?ds_rl=1272379&ds_rl=1272409&ds_rl=1272379&gclid=Cj0KCQjwlemWBhDUARIsAFp1rLUXvi2blwts9pdQr41OGdw5rsl3w2dI2rdvcebgBOq0ri9rHPDhGhEaAj82EALw_wcB&gclsrc=aw.ds&storeId=1163 Pipes all over the place... In order to get the pipes right I played with the levels by putting a really tall pipe as a vent and looked to see how high the water went. Secondly I reduced the amount of sand used which had no adverse effects. Once started the first water was brown but after about a week it went clear. My filter is also connected at the top to a water butt overflow so during the winter the excess water flows through the sand filter over fills the barrels and overflows into the main store to run into the soakaway when too much. I think this constant trickle through the winter is what has kept the system so well. Good luck. M1 point

-

+1 That earth rod is not there just to earth the gas pipe, it is there to earth the whole house so fix it ASAP.1 point

-

1 point

-

I scratched using my siberian larch on walls aesthetically because we went a different route and fitted black cedral which is very nice. But still used siberian larch on soffits and canopy which is lovely, but no help to you. If you like scottish larch go for it....you won't regret it and if you have the right details for ventilation and water it'll all blend eventually and look good. They can all get a wee bit of mould and wee spots due to natural sugars. My siberian larch has only a couple which I was surprised at butnthey go away. Few pics for reference....1 point

-

Incoming gas is a galv pipe above ground by the looks of it, and the supply to the house looks like copper. The requisite is to have the gas earth bond within the first 600mm of the outgoing gas pipe from the meter. For aesthetics, you could put this just inside the meter box to not have it 'on display'. If you are living in the house and have damaged the earth rod, this is a matter of immediate concern and should be fixed and checked asap.1 point

-

A good argument for being all electric and one standing charge. Or Oil or LPG for heating with no standing charge.1 point

-

Hi Jilly. Have they referenced the clause in the regs. They should have, but if not ask them to ref the clause on which their request for information is based on... as this will "help you" answer their query in a direct manner. Next examine said response and the regs. Is there a reference to say "as far as reasonably practicable" on the point they are focusing on. Post more info on what their actual response / query is. It could be a officer on a fishing expedition so you don't want complicate things by providing extra info that opens other doors you may not wish to open. The as "far as reasonable practicable" is a grey area. If you have time on you side and can't lift the phone to BC (almost impossible these days) then ask them what they would consider to be "as far as reasonably practicable", if it could be sensitive then hold back a bit, but give them some info like you are engaging and let them make the next move.1 point

-

I’ve been competent with complex 1ph and 3ph electrical design and installation projects, in both the domestic and the marine environment, and am taking delivery of my own panels imminently. I’ll be completely honest, even MY arse is twitching over the DC-related-death likelihood. I’ve had more AC shocks than I can remember ( memory loss probably caused by these lol ) and only one got me worried, but DC is a different beast altogether. As an aside; It would be such a shame to die now, as my children are 11, 13, 15 and 18 years of age now, and over the last few months I’ve started to become quite fond of them…….1 point

-

Use 25mm MDPE and sleeve it with 28x19 armaflex pushed over the top of it without splitting it. Fits easily inside 110mm UPVC1 point

-

Thanks everybody. 10mm hot and cold pipes to all WCs and basins 15mm to showers/baths and kitchen sink. Tee off in kitchen and utility for appliances, boiling water tap etc. 22mm supplies to the manifolds / UVC. At a quick count that means approx 30 individual pipes. I've not seen anything bigger than a 4 port manifold. Do you have to make your own from 22x15mm / 22x10mm tees?!1 point

-

Having finished mine off recently, I would definitely: 22mm hot and cold manifold. Isolated feed to all outlets from there - I went 22mm to 1 shower and bath and 15mm to everything else but that was cos I didn't have 10mm, probably makes sense to where flow not needed. Armaflex lagged everything - I used the self-sealing split stuff, really good but does need taping too where you go round corners. Probably overkill and took ages but hey, it's done now Continuous runs of Hep2O from manifold to outlet (or very close) - no way I would do anything different or use any other pipe. Absolute no brainer I feel here. Long 28mm runs to/from ASHP - due to circumstances these were needed but hell to work with, definitely design out if possible in future... Think that's the main bits from my recent adventures in plumbing.1 point

-

Silicon grease is better If I have to squeeze a straight joint in I knock the lugs off the fitting and slide it over one of the pipes Then slide it back when the pipes are together1 point

This leaderboard is set to London/GMT+01:00