Leaderboard

Popular Content

Showing content with the highest reputation on 04/14/22 in all areas

-

As far as I'm aware because it's not an alarm and does not need to be linked you need to get something like this https://scotlandhomesafe.co.uk/collections/carbon-dioxide/products/domestic-carbon-dioxide-monitor These seem to be what most people have around here and I have the same one, wall mounted so you can see the screen.2 points

-

Are you sure you are correct stating that. You need CO for any combustible appliances, gas boiler wood stove etc. It is also mandatory to have a CO2 if your airtightness is better than 15. This is a stand alone monitor mains powered. https://www.gov.scot/publications/building-standards-2017-domestic/3-environment/314-ventilation/ Section 3.14.2 applies2 points

-

In Scotland, (not sure about rest of UK, if you have a high airtightness, below 3ACPH (IIRC) you do need to monitor Carbon 'Di'oxide.2 points

-

A**hole abusive threatening n'bors' Onoff, unfortunately. But thankfully that tiny sliver up there is their backward/ farthermost bit. And the bank immediately below that ladder/ scruffy top bit, actually is not theirs. Almost vertical steep to stream. We're uncomfortably close unfortunately, but, they have a mass of overgrown bamboo & a general established bigh "forest" of xyz plants hiding them from me 90%. Prior owners gardening experts you see, these two (since 2 yrs) not a clue so its all going haywire ott.. helping privacy a bit. zoot.1 point

-

Bit of a worthless and obnoxious comment. I certainly had no issues with the product or the company.1 point

-

New build in progress. Carpenter asking how much gap to leave off floor for door frame (if I understood correctly). Plan is to use underlay & carpets. He suggested 20mm. Is that good advice?1 point

-

1 point

-

Worth checking that two of these can be joined together. You might need a short length if pipe between the two?1 point

-

Hi, My name is Lori,thank you for accepting me on building hub. Can anyone give me any advice on how to take bitumen paint of a victorian gable end Or am I better just leaving it and point the gable end with lime ?1 point

-

Use the 135/45° bends but make sure you joint them using something like CT1 especially onto that horizontal outlet as they will leak otherwise.1 point

-

1 point

-

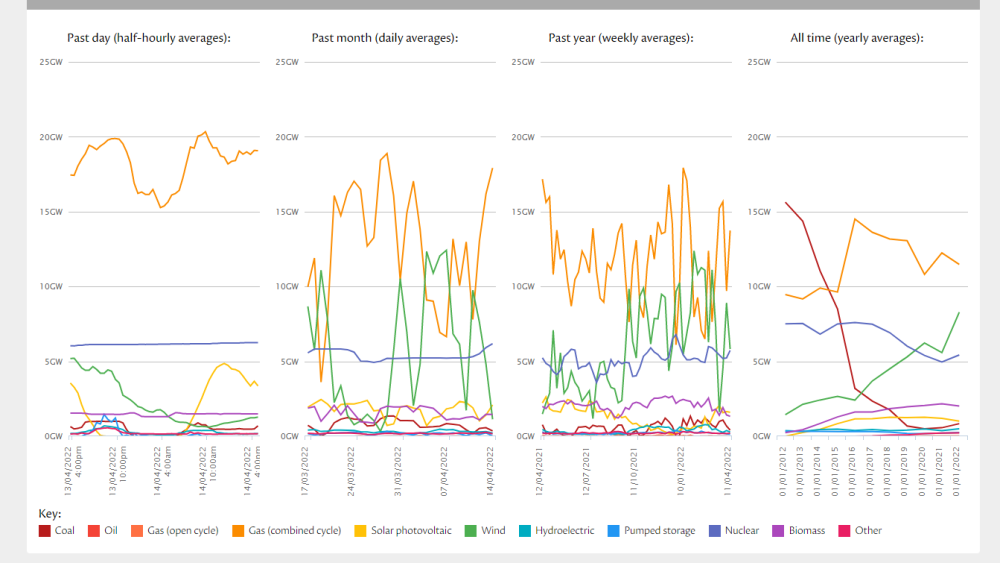

Another pretty picture from the usual source. You can multiply zero (left graph) by a 1000, but you will still get... not much. Unless a conversation/text about GW, renewables etc. starts with "we recognise we can't even talk about not using FF anytime soon" I personally won't listen as the speaker simply lies to me.1 point

-

The door only opens on one of them!!!, decent threshold strip to join them (and make sure the threshold strip is exactly under the door or it looks crap 🤔)1 point

-

Timber alu clad, generally speaking no, the water is allowed to drain behind the cladding and the window cill sits further back (always refer to manufacturer or supplier for clarity on product you're looking at).1 point

-

Have the video camera and at least you might get £250 if it all goes t!ts up!1 point

-

Something like..... .....strap a couple of 4.8m scaffold boards atop the Genie arms, parallel to the roofs. You need to get the load dead centre. Lay 3 decent ratchet straps across the boards. Handball the roll onto the boards so if 5.5m you'll only have 350mm overhanging each end. The ratchet straps will be under the roll. Lift to height. Ideally a tad higher than the roof. Next strap 3 more boards from the "Genie" boards, to the roof. Ladder job to get up there. Roll off down the slope and watch it go straight across the roof and off the opposite edge! 😂1 point

-

Agreed but are you having MVHR? As then you will need more. My pet hate is doors that “scrub” carpets. I used to put a 2” strip of hardboard between frame uprights to kick the carpet up to the door when closed but allows the door to swing missing the carpet (just).1 point

-

It really comes down to what the building inspector will let slide on the day. The regs specifies mains and a visual display, no mention of it being integrated and no problem with it being on the ceiling. That certainly looks nicer, no mention of being able to record data over the past 24 hours but I would seriously doubt any one is going to care.1 point

-

No, to be fair it is right. Common to have a CO2 in master bedroom in Scotland, it does not need to be on the interlinked fire alarm system though as it's not a fire alarm. CO for combustion appliances, usually done with a combined CO/optical head.1 point

-

The CO2 alarm doesn't need to be part of the fire alarm, it is just a monitor/warning alarm if the CO2 ppm gets too high, you get staged alerts then a danger level. Maybe if houses were built with proper ventilation rather than stupid sealed boxes. I have just finished a residential development of 36 flats just outside of Glasgow, we omitted the CO2's a design stage because we could prove the MVHR system would provide suitability fresh air.1 point

-

The levelling spacers are typically removed by hitting them side on with a mallet (or kicking them if on the floor)1 point

-

Could be gap for door itself or he may mean the frame to allow wood or tiles to slot underneath. I have just done some frames with 15mm underneath and wish I had left more … it was a pig of a job slotting the 8mm click fit planks under with 5mm underlay. 20mm under a door for underlay and carpet sounds pretty good1 point

-

It still needs to be mains operated, have a visual display and be capable of logging C02 data for the last 24 hour period. That would rule out the Aico Temperature, Humidity and CO2 Environmental Sensor. unless it can connect to a visual display. It looks like that would mean getting the Ei1000G SmartLINK Gateway and connecting it to a laptop. I'm not sure that would meet the easy to use and understand part of the requirements, it's also more expensive than just getting the standalone monitor and having it wired in somewhere on a wall.1 point

-

Yep . Seen detached and yet I’d struggle to walk down it . Best one was my brother many years ago bought a new build with a garage . He had an average size car . It would fit in the garage but you couldn’t open the doors to get out!. Absolute joke these ‘ developers’ . Yet try and do a single self build and all those ‘ignored’ rules are suddenly applied and enforced .1 point

-

Thanks everybody. I've found long radius 22.5 and 45 bends and my local builders yard. Because of the distance I need a chamber regardless (need one every 20m) so I think I'll put in the bend just downstream of a standard chamber. I'll skip the chamber for the second bend as it's right before the last MH anyway. Seems to be the best value and fastest option... Only got the digger for the weekend so don't want to spend half a day benching and building chambers!1 point

-

I think you can do either. I used both of the following: 1. 45 deg bends at the entry and exit of the straight through run of a 3 or 5 way to make a 90 bend. 2. A long rad 45 bend with no chamber at it. The theory being a long rad bend should rod through from the closest chamber. Where I did it nearest chamber was about 6m away. BC were happy with all I did. Give them a call for confirmation.1 point

-

Our LA required a minimum of 22 metres separation on upstairs facing windows between our new build and an existing property on adjacent plot. And yet the same LA has permitted national house builders to erect new builds in the same Borough with upstairs facing windows less than 9 metres apart. Go figure 🤔1 point

-

Yes it does. However, there are now several lime products to go on woodfibre IWI, for example, that are very easy to apply, so much so that a typical plasterer will find it easy, possibly easier, to work with than gypsum - nicely workable and long set time. An example is Lime Green Solo as part of the IWI system - https://www.lime-green.co.uk/warmshell/warmshell-interior. Baumit also sell products well regarded in this area. This piece does highlight that local climate is very important, and that driving rain can have a significant effect on the performance of the wall. You're going to find variations in suggested buildups. I would personally like to see an update of this as it's from 2010. The Bristolians guide to insulation suggest 0.60. https://sdfoundation.org.uk/wp-content/uploads/2018/01/2015_bristolsolidwallinsulationguidance.pdf. There are lots of other links in some recent posts that go into a lot more detail about approaches to IWI.1 point

-

Yes that’s fine or you can do it the old way with benched bends in brick built chambers.1 point

-

The post 8 hours states CO2, you then said the spec was wrong without further explanation. Scottish Building regs require a CO2 monitor not CO2 alarm. So the word alarm is incorrect. Also in Scottish Building regs the use of combined heat and smoke alarms are not allowed, as only a heat alarm is allowed in a kitchen. It even makes a comment about combined units in a kitchen will not comply with the regulations.1 point

-

yes - Cramer / Fugi tools come with plastic runners that stop the tool dropping into the gaps and following the tile profile.1 point

-

yes pencil round but it is quite deep radius to about half the thickness of the upstand. You can hide it by reversing it1 point

-

Sorry, just read up on the 10yr rule; I now understand that hmrc view 'conversion' and '10 Yr rule' renovation as effectively the same thing. Every day's a school day!1 point

-

Will try the LithofinPower-Clean as recommended by @PeterW Reluctant to use acid unless I really have to and equally the same with bleach .1 point

-

We used to get rest bends and cut the top out and sit a small size chamber over it notched and concreted in with a lid1 point

-

1 point

-

This is a response from a company that does insulated raft slabs, about @Iceverge's idea about a timber insulated raft foundation:1 point

-

Ours hob extracts to the outside and is pretty powerful. If it over powers our MVHR it hasn't complained 🙂 It clearly bypasses the heat exchanger in the MVHR so must reduce efficiency but its probably only used a few hours a week so the effect would be small.1 point

-

You can also see the reclaim form here. Search it for "10 years". It asks you to provide evidence its been empty. Try council tax dept? https://www.gov.uk/government/publications/vat-refunds-for-diy-housebuilders-claim-form-and-notes-for-conversions-vat431c Some other things to think about... VAT: I know you plan to live in it but if circumstances change, do not rent it out without seeking tax advice. If you let out the property you may have to repay any VAT you saved under the scheme. This is because letting income is VAT exempt not zero rated. The difference may seem trivial but if something is exempt it means you can't reclaim so called "input vat" on your costs. House sales are zero rated so you can. Its not clear if this also applies to something like a property let via AirBnB. CIL: You mentioned a loft conversion. If this is big (close to or over 100sqm) you should check out the CIL rules. If they apply you might be exempt but only if you claim the exemption before work starts. The 100sqm rule is the total increase in floor area so it might apply if a small extension and loft conversion together add more than 100sqm.1 point

-

In short.. If you buy materials from a builders merchant you pay 20% and reclaim 20%. If a tradesman supplies and fits materials then they charge you 5% on both labor AND materials and you reclaim 5% on both. In detail.. The important thing is to pay any trades you hire the correct 5% rate. If you pay 20% VAT on labor you can't reclaim it later as HMRC won't refund VAT paid in error. So when you get quotes make sure they say VAT at 5%. If not ask for them to be amended before you accept them. Some trades may question this if they aren't familiar with the rules. It may help if you give them a "certificate". This is essentially a letter from you stating that the work they are to carry out is on a property being reinstated after 10 years empty. Include your contact details, the site address and any planning permission reference numbers. There might be a template in VAT 708 or someone here can probably post one they wrote. If someone quotes to "supply and fit" then both their labour and materials should be 5% rated. Some trades may not like this as they pay 20% when they buy them. This should be sorted out when they make their VAT return but some trades still worry about it. If any refuse to 5% rate your only option is to buy materials yourself paying 20% and reclaiming 20% later. You can then "free issue" the materials to the trade to fit. The downside is the trade might get a better discount than you. Under no circumstances must anyone live in the building before work starts as that resets the 10 year clock. However i believe you can move in a few days after work starts if necessary. T1 point

-

Possibly worth looking at something like Lithofin Power-Clean which is very good at ingrained dirt on stone. It’s alkaline so doesn’t dissolve like an acid will.1 point

-

Getting there slowly. The bond pattern is working out ok. Main issue I'm having is that the stone isn't a constant thickness. The difference between thick ones and thin ones is 3mm. Overall I don't think its great quality stone but it will look ok when done. Lucky I have so many to cut I can cut off defects. Any tips for removing these levelling spacers?1 point

-

You've got to be a bit careful with reading these documents as the reference note in paragraph 48 points to this: You really need someone who can run it through a proper analysis like with WUFI before arriving at a buildup for yourself. You still have the challenge of how to create and maintain a fully sealed and effective vapour control layer throughout the building if using PIR. The detailing thus being imperative. I personally don't understand the popularity of PIR in these circumstances because of the detailing and added risks, particularly when you have a preferred option of moisture open solutions available to you. The alternatives will not only reduce your risks but also tend to provide a nicer indoor air environment because of their breathability. This can in turn reduce the demands on additional ventilation requirements.1 point

-

Ha, I did no modelling, no calculations just pure logic, and it worked 👍1 point

-

I built my own silencer. worked very well. Next time i would combine and build my own manifold/silencer like @joe90 did. I would consider building a soundproof cupboard for the MVHR UNIT too. You can hear it when the door to the utility is open.1 point

-

It's been a while since we obtained planning permission and my last blog entry but we've not been idle. it seems that the last 3 months or so have been a constant stream of decisions that need to be made to get this project started. It's also been a period where money seems to be going out but we don't have much to show for it! The majority of the decisions have stemmed from the architects needing to get the detailed BC drawings finished. here's a nice summary of our decisions so far (although I've probably missed and forgotten a few) Timber Frame Company This was a one of the biggest decisions for us (windows and doors was the other) and was the one that had to happen as soon as possible after getting planning permission so that we could get the timber frame designed and the BC drawings created. We previously had quotes from 9 on the original plans before we had to make changes to get through planning. Of these one was discounted as they never got back to me about changing their set specifications, one because they wouldn't use metal web joists insisting that they only used I-joists, another due to extortionate costs and one more because of costs although not as excessive the ones that made the shortlist but just enough for us to make an easy decision not to include them. That left 5 for us to get updated quotes on the approved planning documents. We are going for an open panel system and I will be fitting the insulation to help reduce costs; even though this will extend the build time the savings are substantial enough to justify it. With those quotes we discounted another due to their location and narrowed it down to 3 local companies and MBC. MBC were by far the most expensive for an open-panel TF but they get such good reviews on here and we have friends that are using them we couldn't discount them out of hand, but in the end we couldn't justify the extra cost when we weren't getting from them what they excel at, i.e. factory fitted insulation and promised air tightness levels. to give them credit they were completely upfront about it and completely understood the decision. So that left just 3 local-ish companies to choose from. We visited sites from each company to see their work and after that, although it wasn't easy, there was one clear winner and that was Flight Timber (https://flighttimber.com) based in Essex. We were very impressed with the quality of the build we visited and are very happy with how they've conducted themselves during the negotiations. So we signed the contract and paid a deposit. Since then they've been doing great work in getting the TF design done and liaising with the architects to finalise everything. That has now been completed and it's all with the structural engineer to do the basement/foundation calculations and drawings. Structural Engineer For the structural engineer we had 3 quotes from firms that the architects use, one from a friend of a friend and 2 from recommendations from the buildhub hive mind. We are having a basement and so this was a consideration and needed someone who could provide us what we needed. One of those requirements was an insulated slab foundation under the basement and the arms of the house. There was quite a discrepancy on costs between the 6 quotes and a couple were easy to discount as they were so much more than the others. So from the remaining 4 and after much consideration and communication we decided to go with TSD as they have a great reputation for insulated slabs, are highly recommended by many on here and their price was very competitive! So far, they've only been working on the design since the start of the week, I've been very impressed with the communications and their open-mindedness to my ideas and requirements. I made a decision (doesn't really require it's own heading) to ditch the idea of using block and beam for the lid of the basement and will be using hollow core precast slabs. Sadly though, after the SE spoke to a supplier it was obvious that they wouldn't span our basement at a reasonable thickness without internal structural walls (which we were trying to do without) and so we've resigned ourselves to having load bearing walls in the basement, otherwise costs could easily have gotten out of hand by going for thicker precast slabs, thicker foundations and thicker external basement walls to all accommodate the extra weight of the thicker slabs. so be it, I'm sure it's not the last concession we'll need to make to save money. Civil Engineer we are creating a new entrance to our plot from the road that will go over a ditch and so requires a culvert. so we decided to hire a civil engineer to plan and manage that, the drainage, driveway levels and water course discharge. we only got 3 quotes (it's my magic number for quotes) all from companies that the architects deal with and simply chose the one that wrote the best proposal and the costs were reasonable trusting that the architect's recommendation for each company was good enough for us. Windows and Doors This was a huge decision for us and caused a lot of brain power to try and work out who best to go for with spreadsheets being created to compare the various companies. We have a lot of glazing (about 120m2) and we want triple glazed alu-clad units. We approached 7 companies initially, visited lots of self-build shows to get a feel of the windows to help us to decide. We did consider IdealCombi for full alu windows but in the end our desire to have timber internally won and we didn't proceed with them. We discounted a few others due to costs and in the end it came down to Internorm and Norrsken. Internorm windows are so nice but they are so expensive; despite this we thought we could potentially justify the extra cost but the reviews of the supplier on here put a dampener on them as the last thing we wanted was to pay a load of extra money for windows that we didn't get any sort of support for when things go wrong. We visited the Norrsken showroom in Poole and were very impressed with the windows, doors and sliders and I couldn't find any bad reviews on here for them. The price was very good and so we signed on the dotted line and paid our deposit. We are very happy with our decision and the money we saved over going with Internorm will pretty much pay for our kitchen! External Blinds With all the windows we are having I was worried about overheating, especially after reading some of the issues other forum members have had with solar gain. We needed to make a decision on these before the TF design was completed so that they could be built in to the frame and are then hidden from view. So, external blinds were on the cards and needed to be researched and a decision made posthaste. I've posted elsewhere about my experiences with Roma blinds so I won't repeat that here. In the end I came across Warema blinds which look good and seem to do what we would need them to and found 2 London based Warema suppliers to get quotes from. Both were so similar in price it was hard to choose between them. In the end, after my company house checks (which I do on all people I wish to do business with) it looked like one of the companies had grown their business really well over the last 5 years when looking at their accounts that I decided to take a punt on the smaller guy and went with Corner Star Aluminium. Only time will tell if I made the right decision on that one. MVHR This is a subject that I have done a ton of reading on here in the forums and also posted a few times on the subject. the whole 1 or 2 unit debate is real but I really would like a single unit solution. I got 5 quotes (one through the architect and 4 off my own research). BPC wouldn't do a single unit saying that the largest unit they do is for a 350m2 house but our house is 450m2 and so we need 2 units. I felt that they're just sizing on Part F calculations and the manufacturers own statements regarding house size for unit size and didn't take running at Passivhaus levels that most on here feel that running their MVHR units at is fine. Also, they do sell bigger units, e.g. the Airflow DV245, so they could do a single unit but I just got the feeling that they couldn't be bothered to consider another option. so they're not getting my business. CVC were just too expensive and I didn't trust the company the architects asked to quote as they didn't give any details as to the ducting etc that they'd use (and also were selling a 2 unit solution). so it came down to PAUL Scotland and Enhabit, both of which were offering a single unit solution (Zehnder Q600 with 90mm ducting). Pricing was very similar so in the end it came down to location again (although a price reduction did help!) and Enhabit won. the deposit will be going over today and then they can crack on with the design. Others I'm sure there are loads of other smaller decisions we've made, like external finishes for the discharge of planning conditions etc, and I know there will be hundreds more to come as we move forward with the build including ASHP, Solar PV, UFH, DHW, RWH, floor coverings, tiles, lighting, home automation and so on. The next big decision will be the groundworks company to do the culvert, driveway, foundations and basement. Once I have the SE plans and designs I can approach the companies I've shortlisted to get detailed quotes and can carry on with the decision making. I have ended up having to make a list of decisions to be made there are so many. that way I can tick them off when they get done as it was getting to the point that it seemed they were never ending. at least this way I can see what has already been done and can see the list getting smaller as we progress. thanks for reading. ?1 point

-

0 points

-

Ask 100 architects for an eco solution, you get 100 wrong answers, at least.0 points

-

Interesting subject... large isolated conductive structure. Might be able to harvest a small amount of power from local radio transmitters. Or make it into a radio telescope if no transmitters nearby. If it were mine I'd definitely want to be able to make a connection to it.0 points

-

0 points

This leaderboard is set to London/GMT+01:00