WWilts

Members-

Posts

782 -

Joined

-

Last visited

Recent Profile Visitors

3785 profile views

WWilts's Achievements

Regular Member (4/5)

39

Reputation

-

Slatted screen to be erected around patio. 44mm slats with 16mm gaps to form privacy screen. Surface of patio is concrete patio slabs. Thinking of 4x4 fence posts but need to fix them to the patio. Slatted panels will be 2 x 1800mm (3.6m in one direction) then at right angles 2 x 1800mm. (3.6m at right angles to first). Main challenge is withstanding the occasioinal storm. What would work?

-

Tks Redbeard. I was afraid of someone saying mortar, nothing but mortar. Did consider the cousin of CT1, OB1. Looks like the plasterboard adhesive (construction adhesive) is claimed to be suitable for "All interior and exterior bonding of common building materials." Stone is in the list. Although I have read somewhere that it is water resistant, not waterproof. And not uv resistant. So perhaps it will be a quick solution but with a limited life.

-

Existing old stone steps to be retained. Old mortar gave way. Leaves etc get into cracks. Plants grow there. One stone came loose, could be picked up. How to fix quickly? (Considering eg polyurethane adhesive such as Soudal plasterboard adhesive)

-

I think the builder used a new section of newel post scribed to hang over the top of the stringer. Then a carriage bolt through it all, from under the stairs, into the joist on the far side. Works 80% ok (budges only if a heavy person flings themselves at it, not at serious risk of giving in ... I think). Not a good solution, but working ok. Although nobody knows less than I do about all this - If I were forced to fix wood to steel (as I will have to for some other job) then there are specialist fixings for the purpose, I believe. Please do better than I did. Someone who knows more will hopefully step in & advise.

-

Tks to all. Done the deed in half hour, with 40N readymix after all. Labourer could go on to other tasks, which helps claw back some of the readymix cost. Thin rebar buried without fixing to posts, just to reduce the risk of concrete buttresses cracking. Yes, ducting embedded in concrete to facilitate automation later. Ditched the dpm idea as being further overkill. Will report following gale.

-

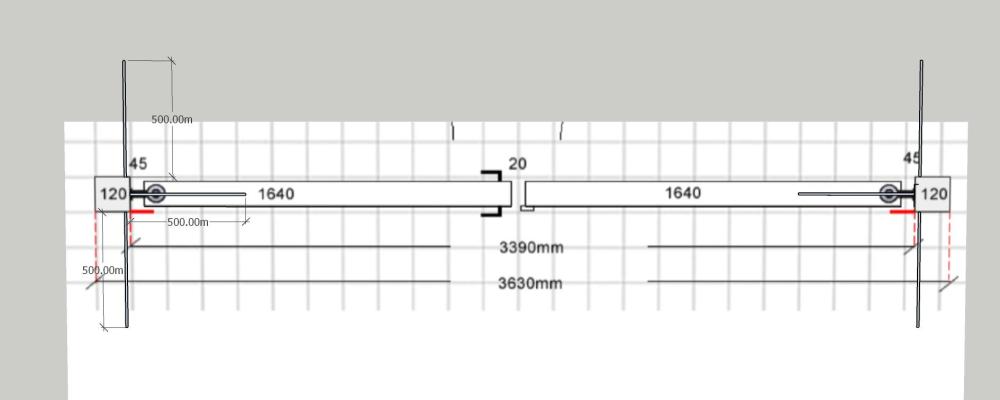

Each steel post will have to withstand the weight of a >50kg heavy driveway gate leaf, 1640mm wide and tongue&groove construction (sail effect in gales). That's why considered strong concrete approx 450 x 500mm & depth 700mm. With additional resistance to deflection of post using buried 500mm rebar rods in tripod configuration, to act as buttresses. (plan view attached) Would something other than 40N concrete do the job better? (approx 0.7 cum concrete for 2 driveway gateposts). And is dpm lining of the hole advisable to reduce rapid drying and shrinkage of the concrete?

-

Steel gate posts 120mm square. Need to be buried 700mm in ground. Concreted in. What concrete to specify (ready mix)? Would 40N be inappropriate?

-

Installing SIPS panels (floor, walls, roof) for 3mx 2.5m garden room. Advice is to allow the SIPS floor to be ventilated underneath. Concrete slab in place already. Height limit overall 2500mm above ground level (which can be altered within reason). Wall panels 2400mm. Q. What is the minimum gap below the floor SIP for ventilation purposes? Would pieces of cement board under the ground frame/sole plates suffice to raise the SIP floor slightly? Is cement board sufficiently waterproof for this use? Detail would be (ground up) Concrete slab DPM Cement board Frame & SIP floor

-

100mm black rigiduct being installed across driveway (occasional lorries). Rainwater drainage. How to reduce risk of crushing? Current plan: dig trench 200mm deep, cover with 100mm backfill of type 1. For bed, would pea shingle or lean mix help? For cover would concrete help?

-

Fence posts for odd angled corners

WWilts replied to WWilts's topic in General Self Build & DIY Discussion

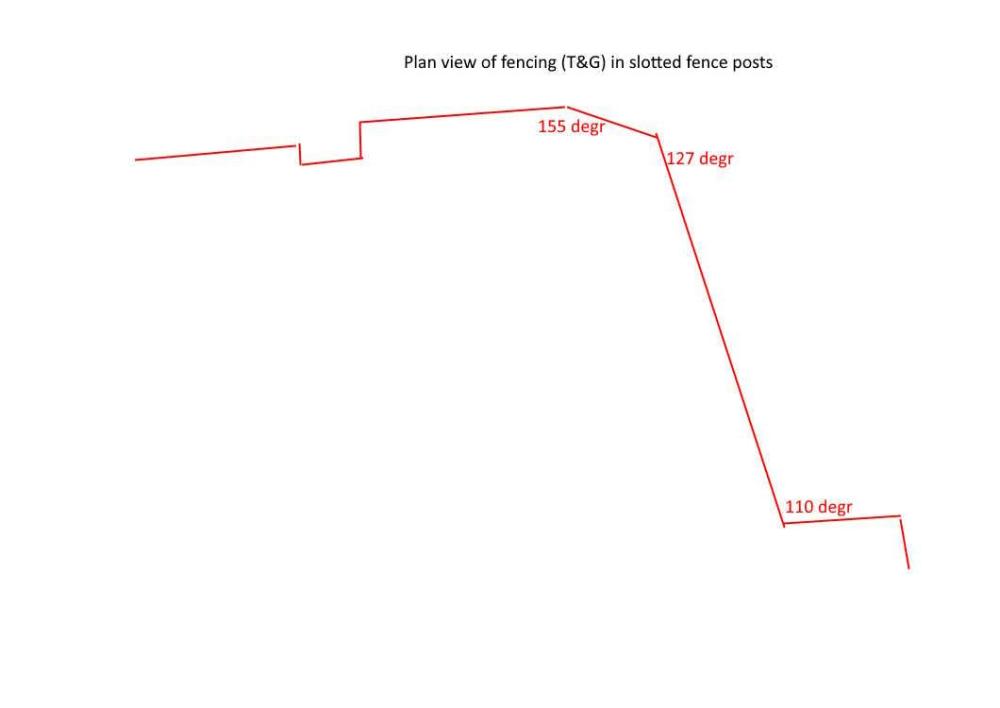

Reporting back. Used galvanised fence clips. Easy to angle any which way. Time will tell how many need replacing how quickly. -

90 degree corners no problem. Slotted fence posts with T&G panels. How to deal with odd angles? How to get/improvise fence posts?

-

One end of the lean-to gable is sufficiently unprotected to receive direct rain on the sapele (dark hardwood) cill. Perceptible water stain already, within weeks. Coverboards are oak, not sapele.

-

Glazed gable, oak cover boards and oak fascia. Q. How to protect vs water damage without sacrificing the natural appearance? So far, front running option is Plastikote clear lacquer spray matt. But I know less than anyone else about this.

-

We built a house in the rear garden. Openreach informed us that the old house at the front can get ultrafast fibre broadband. Checked the address of the new build at the back. Showing as unavailable. Ducting installed to new build from road. With drawstring ready to pull through whatever needs pulling. Q. What should we do in terms of getting Openreach (or anyone else) to provide FTTP to the new build?