Leaderboard

Popular Content

Showing content with the highest reputation on 04/06/24 in all areas

-

The height is the issue here. Part A building regulations says wall below 2.5m can be 90mm but with piers. So reverting to the general rules H/16 = 2.7/16 = 170mm thickness.2 points

-

Put up a 2M fence, 1M in from your existing low fence. That should meet the argument of not being adjacent to the highway. That won't enclose all your garden, but most of it. Then in that gap between the tall fence and low fence plant a nice hedge (NOT Leylandii) and when the hedge should reach maturity about the same time as the 2M fence is ready to fall down. I have a relative in a similar layout estate and his entire garden is surrounded by a nice mature Beech hedge.2 points

-

While a fire engineered solution may be acceptable to BC having the kitchen open to the floors above is - in my opinion - dangerous. Consider a scenario where smoke from a fire on the ground floor rises - the parents are in their bedroom and the children are in theirs. All rooms have fire escape windows but a parent will always want to get to their children in an emergency and this could mean entering a smoke filled hallway.1 point

-

Unfortunately, that's the main downside to mains dimming. If you want the ability to dim very low you really need constant current dimmers rather than mains dimmers. Constant voltage dimming is also fine but is generally used for LED strips.1 point

-

Most decent cladding fitted correctly will last decades even unpainted/stained.1 point

-

If you clad a house in unpainted treated softwood it will last about 10-15 years. Clad it in untreated imported Western Red Cedar and it will be good for 50+.1 point

-

The linked article is referring to the "crisis in the volumetric house-building sector", so I took the OP to refer to the common meaning of modular build, ie. Pre-built "modular" boxes, assembled on site. And you can build panellised kits in much smaller, grottier factories, or handle and store (waiting for delivery) more panellised house kits in the same space.1 point

-

Maybe. Maybe not. https://www.visitnorway.com/listings/stålekleivloftet-one-of-the-oldest-wooden-buildings-in-the-world/207516/1 point

-

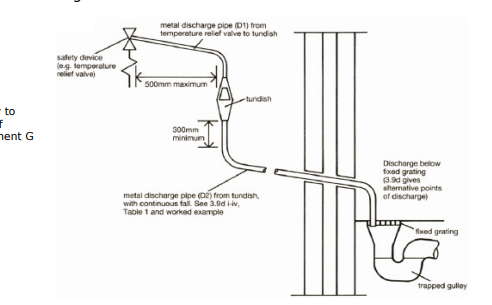

I would say no Picture from here (first google link that found the picture I wanted) https://www.e-lindsey.gov.uk/media/4257/050-Unvented-hot-water-storage-systems/pdf/050Unventedhotwaterstoragesystems.pdf You are supposed to have 500mm of straight pipe below the tundish. Yours appears to go straight into what I think is a waterless trap. Whether that will cause a problem I could not say. You could try manually operating the over pressure or over temperature relief valve and see how the water flows?1 point

-

If you're worried about getting planning permission, first speak to or get your Architect to consider working with Aurora Planning https://auroraplanning.co.uk when putting in your planning application. One of the consultants was head of Aberdeen city planning dept. for 10 years before leaving to set up Aurora planning.1 point

-

1 point

-

Bed time reading……https://www.gov.scot/publications/householder-permitted-development-rights-guidance-updated-2021/pages/6/1 point

-

Yes but heading for robots and all kinds. The ones I have seen in UK and Germany have robots assembly cells, CNC wood cutting etc. Old shed won't cut it, pardon the pun. going forward. We need to invest in automation so fewer people can get more done - for the mass market. I am the robots on our build.1 point

-

You will be OK with thermalites. You can't rest the roof joists on them though.1 point

-

There are plenty of timber frame houses with wood siding, plywood sheet roofs with cedar shingles in Canada and the US which are more than 100 years old. There's nothing wrong with this method of construction if it's done properly and maintained, which is true for any building system.1 point

-

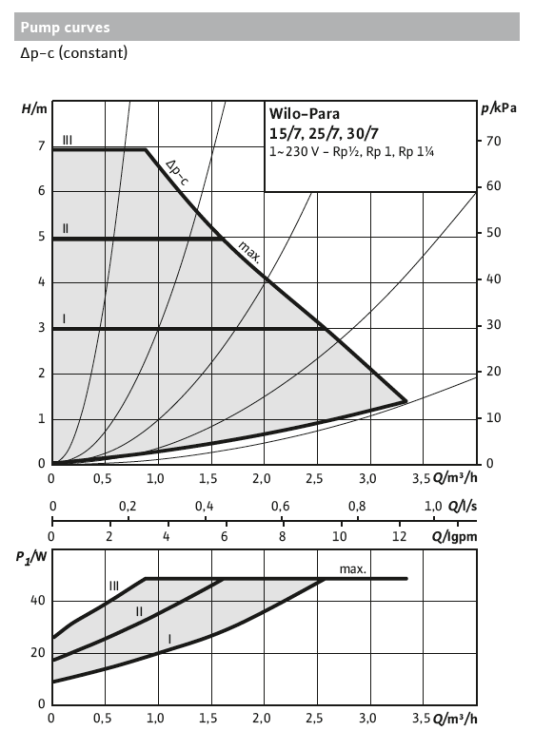

Whatever about the thermal mix. would suggest CPi setting at 3M initially, 3M (2.8) should be sufficient to circulate 3.0LPM through each 100M loop, total 12.0LPM, 0.72m3/hr, as long as there is a bit of adjustment left in the (max) flow loop regulator then its fine, if not, go to CPii, 5M setting. In practice, the flow requirement will probably be less than 3.0LPM/loop. "4 loops, 2 zones, 400m, 16mm Pex-al-Pex, biscuit mix between joist, Wilo Para pump as in the picture. Pipes tested at 5bar."1 point

-

“UK legislation defines the permitted height of fencing that is "adjacent" to a footpath or highway, but doesn't define "adjacent". However, it's generally accepted that fences at least one metre from the road are limited to one meter in height, and fences more than 1 metre from the road can be up to two metres ”1 point

-

Stopping generation due to faulty peripheral kit doesn't seem such a good idea! We have an HD wave inverter with an unused integrated EV charger that had the comms disconnected so the inverter saw the charger as faulty but the inverter continued to run as normal, other than showing the charger fault. Shame they weren't more open about the reasons for the lockout and the fix for it1 point

-

I know them well. My BIL used to live in one, until they were forced out when they were all being dismantled (he ended up buying his AERE house in Wantage) They were very cold, and no doubt contained a lot of asbestos in their construction. I often said, and I believe the residents committee argued for selling them to the tenants as individual building plots, but the authority had other ideas. Half the Diamond project sits on one of the prefab sites now.1 point

-

Thx Saveasteading Slab poured last is something I hadn't considered, great plan. Stone sub is fine just didn't detail it. Walls will be lined internally with firecheck. Will also have 60 min fire door to access utility at rear. Neighbour is away abroad for 8 months of the year and the house is empty, so we haven't met him yet. Hope this won't be a problem though as we have similar interests - at least that's what I understand from the other neighbours. I very much doubt he has recd the letter from planning tbh! Thx for your input1 point

-

Planning departments make stuff up as they go along so this might not be useful to you. There have however been cases where it was held that "adjacent to the highway" means you have to be able to touch the fence when standing on the road. In this case because of the pavement you could argue that your fence is not adjacent to the highway. Unfortunately we had no pavement so we couldn't rely on that. (Edit: sorry after looking it up that would only apply to a grass verge / hedge, the footpath is considered to be part of the highway) You might need to be persuasive / appeal. I lived in a corner plot, did something similar and rubbed a council enforcement officer up the wrong way in the process. Took me the best part of a year to finally get him to leave us alone. He even tried pursuing us when we reduced the fence to 1m high claiming a change of use had occurred (he was unable to evidence this so eventually gave up after haunting us for a few more months) You will also want to check your deed for covenants, your house looks the perfect age to have a whole laundry list of them. Some are likely to refer to the fence and garden / what you can do with it. Don't panic though as you may be able to argue they no longer apply.1 point

-

Agreed number 2. So much easier to build and also means that the slab can poured last, and in the dry. You need a stone sub base beneath the eps. Again that is a good working surface while you build it. I'd use "stick build", esp with your skills. You should line the walls internally to be fire resistant, being on the boundary. Is the neighbour OK that you will be working in their garden?1 point

-

While I appreciate it is only a workshop, thermal bridging is still important for longevity for sips, which are only OSB and PU foam, both of which absorb moisture. So in my opinion, the middle image is heading in the correct direct. I think the KORE foundation system puts the thermal break on the outside and the panels would be sitting on the fully insulated slab, but it is a while since I looked at the details.1 point

-

Not according to Bernoulli. https://sciencing.com/fluid-dynamics-overview-basics-terminology-equations-13723386.html1 point

-

@Carly Lawson there’s nothing to apologise for, I just think you are jumping to decisions after talking to someone selling a product. it’s like the saying, don’t ask a barber if you need a haircut. I would say do more research, and then base your answers on sound evidence. you have mentioned wall thickness a couple of times, unless your land is only a few metres wide then 50mm wider or thinner is not going to matter. the crane comment was in regards to a timberframe house, like saying timberframe was cheaper, but forgetting you needed a crane to put it up. I think we’re hijacking the original post here, so maybe start your one about your journey and hopefully we can point you in the right direction there.1 point

-

If they have half a commercial brain they will have an encrypted connection you can't break without enormous effort so when they want to monetise it they will hold all the cards.1 point

-

I'd be very surprised if it wasn't possible to "unlock" directly on the device - maybe it was easier for them to do remote access than talk the customer through it? What was the actual fault/fault code? I have a solax inverter, it does connect to the internet to email me stats, but other than that it functions fine without connectivity1 point

-

1 point

-

Steamy Tea will tell you that might well not be enough insulation under the ufh. A lot of people here have put an electric Willis heater or two as a back up to a ASHP, rather than a boiler.1 point

-

the quote we got wasn't cheap but you get what you pay for I guess. in the end we decided to just use a standard TF and fitted the insulation ourselves to save money. it took well over a year to do it all and was horrible work. if I was to do another self-build I would get the TF company to install the insulation. I keep thinking that if I'd spent the extra money we'd be living in the house by now enjoying it. and we'd be off our self-build mortgage and I wonder if the extra payments on that have amounted to more than we saved fitting the insulation ourselves? sometimes a saving isn't really a saving when you consider the time and other costs involved. the MBC twin wall system is 300mm thick walls. I thought they were thick when I first started looking at it but our standard TF 140mm walls with 80mm internal insulation means that our walls are only 80mm thinner which is nothing in the grand scheme of things. I don't understand what you have against thick walls though.1 point

-

You have to define what you mean by 'eco friendly'. When I was at university doing my environmental science degree, most of the course was made up of ecologists, then there were 4 surf science students, one marine management student and 3 of us from the renewable energy course. The surfers have had the biggest impact in cleaning up the environment.1 point

-

1 point

-

Yes DC over the long run, just use normal armoured cable of the correct size. The more vertical the panels the more even the production is over the year. You get a slight lower yield overall but more when you need it. Mine are vertical and more like a fence. I took the 9m2 as floor area it takes up. 40mm thick is a lot of panels1 point

-

Hello. I am an MVHR Designer and I thought I would weigh in on some of the posts made, as I think they are a bit misleading. This is incorrect. Where i-joists are used, rigid ducting is the norm. The major advantage being the ease of cutting holes in i-joists, and the amount of holes that can be made (following guidelines on the data sheets). People often think of semi-rigid (flexi) ducting as space saving, but clearly with this type of joist you would require far more holes because there are far more ducts. A good designer will ensure the guidelines for holes are not breached. It is straightforward to cut duct with a hand-held grinder, even with a 1mm cutting blade. See my post above, rigid ducting is the norm where i-joists are used for the floor structure. 28m3/hr down a 75mm duct is fairly standard for a lot of companies, however, an optimal design will use two ducts for this flow rate (or higher). Bearing in mind that lower air velocity = lower pressure = lower sound. Most people would rather spend a bit more, have more ducting etc to have an inaudible system, over saving a few quid but having a system they can constantly hear. This is generally true. Rigid steel ducting tends to be lower pressure/sound. Semi-rigid does get unnecessarily harshly judged in my opinion. I have designed perfectly good systems for Passivhauses. In my experience it is due to many early systems being in semi-rigid, and were poorly designed and/or poorly installed. Even though it is straightforward to make connections airtight, I see more often semi-rigid systems with leaks due to improperly connected ducts to manifolds, plenums, etc. With rigid steel duct you just push it together once and it is airtight. And lastly the high volume of air many companies design for each duct. When I design I aim to put less than 26m3/hr down a 75mm (ID) duct, and less than 18m3/hr down a 63mm (ID) duct. To the OP, it looks like a nice system.1 point

-

I use mlcp extensively, I’ll measure fittings bore for you this weekend. p.s. Unless you’ve got naff all water pressure, the reduction from the fittings won’t make any noticeable difference. your issue is 100% the incoming supply. Your plumber should have advised a new 25mm mlcp into the house.1 point

-

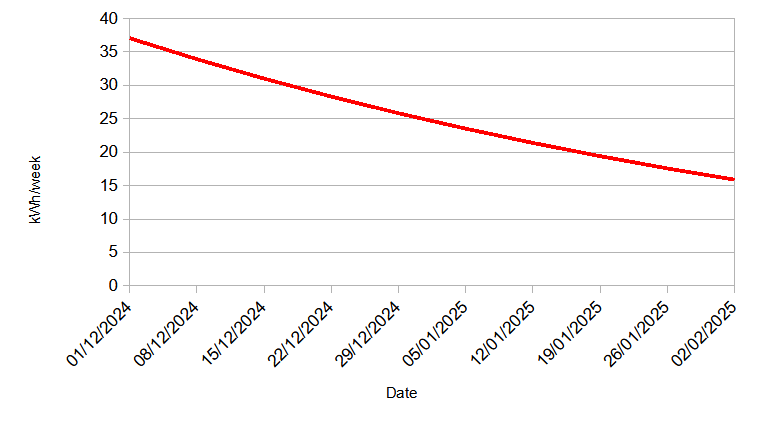

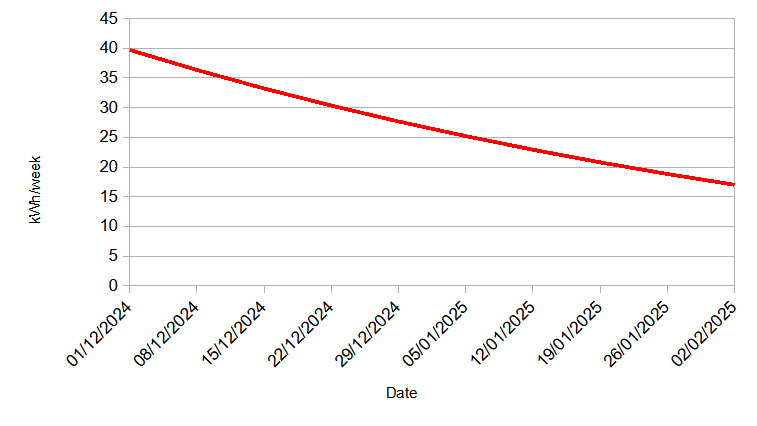

I use about 300 kWh/month in the winter to keep my house warm. So approximately 10 kWh/day. Initially I shall assume that there is no added input in December and January, so I need to store 600 kWh. Water would be the most cost effective medium to store energy in as it is cheap and easily transportable. Water stores about 0.00116 kWh.kg-1.K-1. So I would need, if I could get a ΔT of 40K (40°C up to 80°C as anything below 40°C would not really be useful) to store approximately 6,500 litres. If they were stored in rectangular vessels, I would need 7 m3, so quite a big hole. That is before adding insulation. Realistically PIR with a k-value 0.025 W.m-1K-1 is the most practical. So how much would I need. Assuming that my ground is at 10°C once deeper than 1 meter, the vessel is 7 metres long, by 1 metre wide and 1 metre tall, I would have a surface area of 30m2 to insulate. If I added 1 metre of insulation onto each side, then that is 9m by 3m by 3m hole I would need to dig, 81m3, the surface area would be 126m2, that is about half the volume of my house and nearly the same surface area (house is 184m2). So what would the heat losses be. R-Value = 1 [m] / 0.025 [k-value] = 40 U-Value = 1 / 40 [R-Value] = 0.025 W.m-2.K-1 Power [W] = 0.025 [W.m-2.K-1] x 126 [m2] x 70 [ΔT] = 220 W or 5.3 kWh/day. Knocking up a quick mathematical model, the losses, before any usage, look like this: So that is 254 kWh of useful energy lost. So what to do. Two options really (well 3). Add more insulation, which is expensive. Doubling the thickness will give a surface area of 270 m2 and a volume of 275m3. That is now much larger than my house, but no matter, lets work out the losses as I am full of hope. 2 metre thickness of insulation works out as a U-Value of 0.0125 W.m-2.K-1. Now this throws up a strange result, the losses are actually greater, 272 kWh total, because the total surface area has increased by 144 m2. Now there is some dispute as to where the thermal losses should me measured. I always use the outside area as this is larger. Just for a laugh, and I had a good snooze this afternoon, let us see what the losses are when using the surface area of just the water container, the 7m x 1m x 1m, 30m2. At a U-Value of 0.025, it is 60 kWh total, and at 0.0125 30 kWh. Now the truth is it will be somewhere between the two and without a much more detailed model, which allows for the corner affects i.e. effectively thicker insulation. So shall we settle on 155 kWh total losses. The second way is to increase the volume of storage by an extra cubic meter, that would store an extra 45 kWh but loose some of that to losses, about 7 kWh total. So we would actually have to add another 4m3, so a total storage of 11m3 of water. Now we could change the geometry to get the smallest surface area to insulate. This may need a custom container that is cube 2.25m on each side. Adding a metre thickness of insulation would expand that to 4.25m on each side, so a volume of 77m3 and an area of 108m2. The losses would now be 208 kWh total out of the original capacity of 510 kWh. Still not enough. Let us for a cube 3m on each side, that is easy as you can buy 1m by 1m by 1m vessels easy enough, and stack them in a cube. So that would have a storage capacity of 1254 kWh initially (at Δ40) and losses with 1m of insulation of 301 kWh, leaving a possible useful amount of 950 kWh. Big hole in the ground though, 5m on each side, 125m3 which is only 35m3 less than my house volume. Now I have only worked this out for a laugh, but I did it a few years back when @DamonHD and myself discussed it before, I think I came to the same conclusion, which is my third option, don't (expletive deleted)ing bother.1 point

-

I do 127mm cores fairly often, but by hand and without a rig. Just be patient, and like with metal, run the drill at a slow speed and let the diamonds do the cutting. Depending on how thick the slab is, bring the bit out every now and again to clear the dust. Just double check if the bits you're supplied with the drill or which you buy yourself are for wet, dry or suitable for either. I buy the Marcrist ones and they last pretty well. Oh, and make sure your unit has a good clutch!1 point

-

make sure access is all sorted and safe. keep a very close eye on them and dont let them leave until you are happy. Good to have your main builder on site. We had ot get our installers back multiple times. Last issue was resolved a couple weeks ago - three years later!!!1 point

-

FFS. so glad I've moved to the Highlands where no one can see what's going on. This country is doomed1 point

-

When I signed the contract for our timber kit I hadn’t fully appreciated the financial exposure we’d let ourselves in for. It wasn’t clear in the contract that for several months the timber kit company would have 80% of the total kit price. I tried to get them to put some kind of financial protection in place in case they went bust and despite them saying they would look into it they never did. Fortunately it turned out fine and the kit turned up etc. However during that period three companies went bust with clients losing significant sums of money (some documented on here) so my fears about it were real enough. There are a few kit companies that put your money in Escrow so you have protection and I’d only do it that way in future or stick build on-site as I’d at least own the materials regardless.1 point

-

You can calculate and design it pretty easily. 75mm rigid ducting is ok for 2.5m/s flow speed so 28m3/HR. Assuming normal ceiling heights and a desired ACH of 0.3 then each pair of 75mm ducts will supply 37m2 floor area. So if you have a floor area of say 35m2 that'll be ok with one 75mm supply and one extract. If you have a floor area of 300m2. Then you'll need 8.1 pairs of supply's and extracts. Manifolds only come in 8 or 10. I would be happy with 8 in this instance as it's pretty close. Then sketch out on your plans one duct to each supply and extract room. Double up extracts for the kitchen and then for the dampest/furthest room until all the ducts are used up. Similar process on the supply side. Easy. Keep sketching until you can draw it without any ducts over lapping. That'll make it easy to install. As for materials, It's all much the same stuff. I would buy the cheapest. About £113/50m roll at a quick Google. Leave space for two of these between the mvhr unit and the manifolds. Install your supply plenums opposite the room door, usually over a window. Install the extracts close but not directly over the source of steam. Say 1-2m away and again opposite a door if possible. These ones are cheap and work fine. For the larger ducting to outside I like the rigid insulated stuff. Nice and tidy and doesn't leak as much heat as the metal. Finally site the MVHR unit inside the heated envelope, with short runs to outside for the inlet and exhaust, where it won't cause noise or vibration issues and can be serviced easily . I wouldn't skimp in the unit or buy something too obscure as you'll need parts in future. Aim to have one with a headline M3/HR of about your house volume. That way at normal rates the fans run at about 30-40%. Bargains can be had. This one is ok for about 120m² floor area. If you post your plans I'm sure we could collectively design it for you in about 15 mins.1 point

-

Have recently had this garden office built. I bought the cedar cladding but wondering if builder's installed it correctly. When it rains, water seems to absorb up the bottom of the cladding. Should I worry about this? Maybe water isn't an issue with cedar but might this lead to the wood rotting? Should there have been a gap between the limestone paving and the cladding - like an expansion gap? Or a gap to stop the water soaking directly into the wood? I've also noted some black spots on the brise-soleil slats (Siberian larch) - is this an issue? Many thanks for any help/advice.1 point

-

There have been quite a few variations of the 100-W over the years so probably worth being more specific when discussing them and referencing their model code (e.g. BK1F).1 point

-

0 points

-

A huge chunk of it I imagine. I suppose if you were able to install a subway train in your house that would account for a significant amount of the annual heat demand. It'd be irritating though.0 points

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)