Leaderboard

Popular Content

Showing content with the highest reputation on 12/31/21 in all areas

-

Another one from me. After the digger and dumper finished assaulting my concrete paving slabs I had to replace the path and patio entirely. This left me with a plentiful supply of hardcore plus nearly one hundred usable riven slabs to hide somewhere. The handiest option was to use them to back the stone retaining wall I was building:3 points

-

In these times of rising costs and shortages of supplies, I though it would be great to find out what people have achieved by recycling materials. I can kick-off with our storeroom floor made from the original roof trusses demolished to make way for the new attic trusses above our garage. It used up nearly all of it which struck me as being very jammy indeed ?2 points

-

2 points

-

Another vote for a proper tractor. Get an old Ford or Massey. They're reliable, cheap to run and go forever. Also you can absolutely abuse them and they just take it and take it. Our Ford 3000 is almost 50 years old, has had little love and I still use it on the farm for all the job's that aren't too big for it. As far as i can tell it need's to be refuelled about once a year! They're probably cheaper to own than a compact utility type and certainly cheaper for parts. Also I'd like to see a baby kubota try and pull a 3 furrow plough!2 points

-

2 points

-

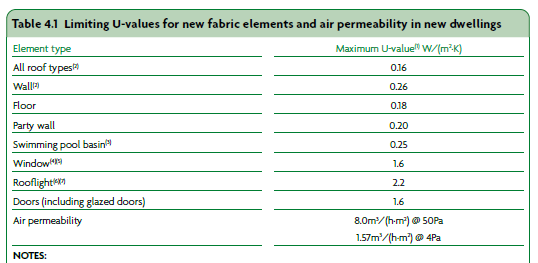

Decided I need a longer than average trash picker befitting someone of my stature. This after a spot of civic duty earlier. I took it upon myself to collect the recyclables along the 1/2 mile stretch outside my house. AONB my arse! ? There were plenty of cans just out of reach in the hedgerows. Found a business end, claw thing on Yeggi that uses a 10 or 15mm dia tube as the main shaft. Printed both options but it'll be based around 15mm copper pipe: There was no design for a handle though so I came up with this. Just a render here, being printed at the moment. My lad did the chequering on the model I did:2 points

-

I repaired a large single garage roof built by a builder in 1919 on his own house, the roof has a nice fall, 1:40, on big joists nine by two and a half with inch x seven inch boards. what he next did was remarkable, a single layer of bitumen felt laid dry no tar, no clout nails with three inch overlaps turned down into a cast iron gutter clout nailed in the face. There was an ornate zinc trim nailed 3/4” back retaining a two inch thick layer of pea shingle over the whole roof, by then full of moss and sedum, the trim was designed to allow water to drain out into the gutter I replaced the roof in 1999, eighty years after it had been installed !2 points

-

I've been naively scrabbling around this topic for a while and already have the envelope of a building mostly built, but the other day came across a new source of info with some surprises in, which made me wonder a) what else I've missed, b) how much of what I think I know about the topic is either wrong, outdated, or at least not the full story. Clearly buildhub is useful, but what are additional sources of moderately detailed information, up to date with recent building science? E.g. Building science corp https://www.buildingscience.com/ great stuff Green building forum http://greenbuildingforum.co.uk/newforum/ GBA https://www.greenbuildingadvisor.com/ Partly paywalled, but interesting insight into the US market - which is mainly timber frame and very experienced with it UK PH trust https://passivhaustrust.org.uk/guidance.php The technical guidance is especially useful, but doesn't cover everything. Passipedia & iPHA https://passipedia.org/start Limited info for non-members. Is anyone on the forum? Any good? ACEB knowledge base https://aecb.net/knowledgebase-archive/ (Membership required for most resources, never looked TBH) Country-specific passivhaus orgs: NZ https://passivehouse.nz/hpcd-handbook/ (This handbook is good) North US https://naphnetwork.org/ (never looked) Canada https://www.passivehousecanada.com/ (found a couple of things) Suppliers I'm wary of info from suppliers but a couple of recent US timber frame ones with seemingly good info: Hammer & hand https://hammerandhand.com/best-practices/manual/ 475 https://foursevenfive.com/1 point

-

If I were you I'd be wondering whether or not to tile at all and use wall panels instead!1 point

-

Generally plastered or boarded But it’s really not an issue tiling into flat block or concrete Just more adhesive1 point

-

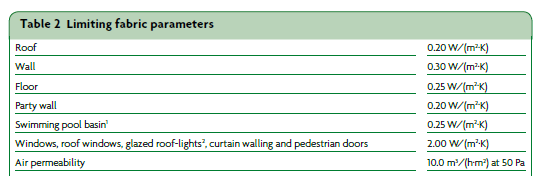

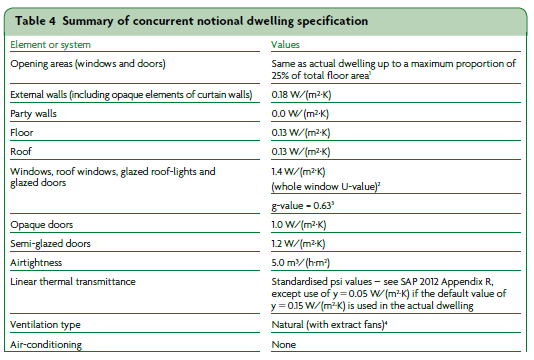

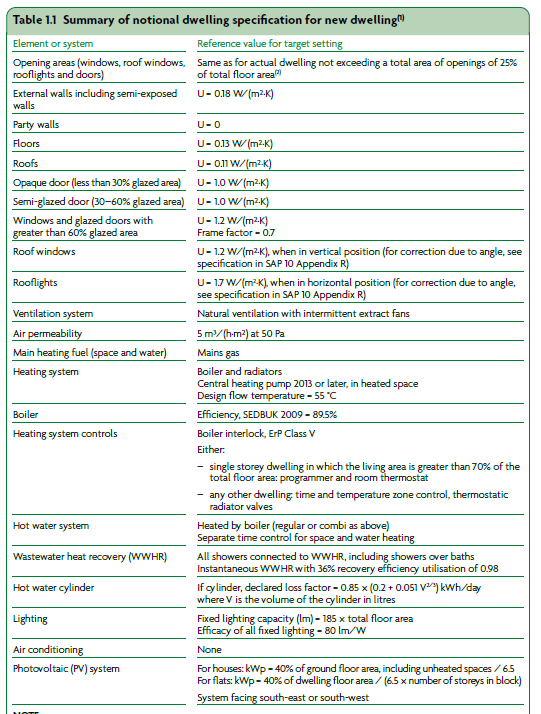

All On 15 Dec Govt issued the new Approved Doc L for England. https://www.gov.uk/government/publications/conservation-of-fuel-and-power-approved-document-l Also new version of SAP, Part F (Ventilation) & Part O (Overheating). All becoming effective in June 2022. Does not look to be a big change in U-values apart from tightening of worst case values. Air tightness tightened and use of solar PV used in Notional Dwelling. I am waiting for the new software from Elmhurst to assess the impact in more detail. One good point is plenty of practical guidance - not read it all so not sure how relevant. One big change is information gathering - documentary and photographic evidence required of almost all construction stages (insulation being fitted, junctions, windows, boilers, controls etc, etc....... ). These will be required by Building Control and the SAP energy assessor to assess the 'as built' dwelling. I can see this increase in red tape increasing the cost of assessments considerably. Personally I do want to spend the majority of my time chasing this data knowing its probably not available (I tend to deal with self builders and small developers) so will cease to be a SAP assessor for the new version of the Regs. I'll switch to 2D thermal modelling of junctions for bespoke psi-values. Plenty to read in the new ADs and SAP - perhaps 500 pages! Get your Building Reg application in before next June!1 point

-

Thermal Conductivity k or λ = W.m-1.K-1 To convert to R-Value, divide thickness [L] by λ R-Value = m2.K.W-1 Take the reciprocal to get the U-Value U-Value = W.m-2.K-1 So k = 0.042 L = 0.15 [m] R = 0.15 / 0.042 R = 3.57 m2.K.W-1 U = 1 / 3.57 U = 0.28 W.m-2.K-11 point

-

Tbh my girlfriend is the one that does the painting so I’m just going off what she says. She’s only used F&B and Dulux paint and I think it’s only the Dulux she needs to dilute ever so slightly. But she does wash it out between every coat so maybe that helps to minimise any blockages.1 point

-

Hi, you should aim for as large an overlap as as possible, but as long as the joint don't coincide with each other you should fine with a small overlap. The main reason for the staggered joints is to limit the thermal bridge, if you have gaps at joints.1 point

-

1 point

-

1 point

-

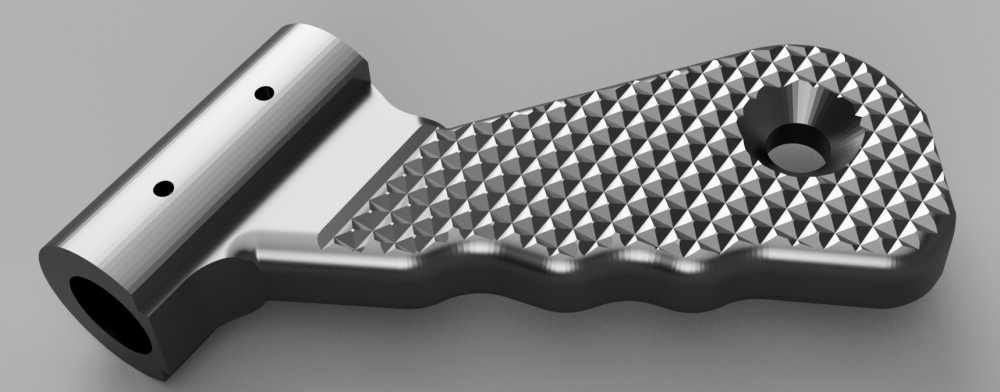

The new standards v the 2016 ones are very similar. I think you are confusing the standards for the Notional Dwelling and the Limiting Standards, which are far more lax but can only be practically used for very small areas.1 point

-

Stand the glass on 2 or 3 5mm spacers and tape the floor and the glass - then put clear CT1 between the spacers, tool it and let it cure for 24 hours. Pull the spacers and then fill the gaps, tool it and then take the tape off.1 point

-

1 point

-

You don’t mention if you own any land with the house. I presume your figures are fictitious but if you purchased the original house with over 1.25 acres then you don’t have PRR so CGT is then due. Note that what counts as garden\grounds is best researched with a tax accountant as it depends on how the land is used eg is it farmed for profit, self sufficient home produce or extended garden. A good accountant will advise you but tax rules are always changing e.g. CGT is now due 30 days after selling rather than your annual self assessment. Could you keep the property at a furnished holiday let, then it’s a business with no CGT and instead business asset relief. I would decided what you want long term then seek advice from accountant but also remember that if your plans are for in x years then tax implications can change.1 point

-

I've the opposite issue with my system- *too much* flow from the manifold to the ASHP. Thankfully the pump set has a bypass and a restrictor, so you can throttle back the return flow even if the thermo valve is wide open; I'm playing with that currently to control the DeltaT at the ASHP.1 point

-

Yes I think the manifolds with a 3 port mixer are better at "drawing" the hot water in. At our old house, the heating is UFH upstairs and down and UVC for HW. I was called by the tenant to fix no heating upstairs. That fault was the useless 2 port valve head had failed, for about the third time. i replaced the head but I also observed the circulating pump was not working. But no other fault had been reported and the heating worked again with the new 2 port valve head even before I replaced the pump. So i concluded both UFH manifolds were circulating the water in on their own and the HW tank must have been working on gravity flow. P.S. replacing the pump was a mare as the the cheap pump isolating valves both leaked after changing the pump requiring a drain down to replace the isolating valves.1 point

-

I wonder if adding a restrictor (disc with hole in) at the joint between return rail and the bottom pump manifold might upset the flows enough to force more return out and back to the buffer?1 point

-

@vfrdave I picked up an AGS Gardencare hydrostatic machine for good money and - you know how rough our site is yet- it cuts perfectly well at the fully-raised "travelling height" setting. /for info the AGS machines are the same as Starjet and made by Seco in the Czech republic. The same factory produces for a number of the bigger names too...1 point

-

Yes. They are essential really, not so much for personal safety as when used in static power tools like table saws, but to protect the mixer gearbox should the drum contain a full load when the power was lost. And for the fix, now I have some spare time to document it for anyone sufficiently interested... To fix it I first looked at the way it was made and figured out why it might fail. The on button has no mechanical latch so would spring back were it not for a solenoid energised along with the motor. This effectively keeps the on button held in just as if you were stood there holding it yourself. The off switch has no latch either and just momentarily interrupts the power to the solenoid which releases the on switch - as if you finally took your finger off it. So much for how they're meant to work. The clue as to why they fail is in the buzz you sometimes hear when you use them. This buzz is from the 50Hz 240/120VAC mains supply (60Hz in some countries). The solenoid is energised by this alternating current therefore so is the magnetic attraction developed by the coil. But the magnetisation of the materials used in the solenoid can't keep up with the rate of change of the magnetic field so smooth it out into a constant force that keeps the switch held in. My guess is that over time the constant vibration and temperature swings endured on building sites knock the magnetisation out of the materials so reducing the force available to keep the switch held in the on position. My solution is to convert the AC supplying the solenoid coil into DC having the equivalent power. This loses the reliance on the material properties that degrade over time and finally put this issue to bed for anyone that wants to implement it.1 point

-

1 point

-

I have a different make of manifold that uses a three port TRV. I originally questioned the need for a store to manifold pump. Supplier said one was needed because they couldn't guarantee the manifold loop pump would draw water from the store when the TRV was half open. I was surprised as obviously the resistance in the floor loops should be a lot higher than in the short 22mm run from store to manifold. PS My concern about fitting a pump was that it would stir the store when the TRV were recirculating. To make matters worse my electrician wired this pump on permanantly! I've two manifolds and ended up making an OR gate from relay so that it was only turned on when one was calling for heat. PPS May need a bypass as well. In case rooms call for heat turning on the pump but both TRV are shut/recycling.1 point

-

We are a in a similar position to you Two houses in principle One of the two neighbors thinks she can dictate the location of the houses and talked about engaging a planning consultant As Temp pointed out They have no right to appeal There comments have been noted But ignored by planners Daves one and a half floors looks really smart Which would keep planners happy Neighbors are never happy so you might want to push for two floors Neighbors will have hardly any input from this point1 point

-

They have no right of appeal.1 point

-

Why did you knock the old house down before embarking on this journey?1 point

-

They don’t want three stories or future possibilities thereof ?1 point

-

Some Architects are basically artists who prefer shape and form and novelty to any thought of structure and keeping the weather out. I know that universities encourage novelty and even teach the students to 'not worry about how it is built. Leave that to the Engineers', which is not only ignorant but also arrogant. Fortunately a decent proportion of those that come out the other end are already, or become, practical and valuable professionals. If I had to find an architect or Architect then I would depend on references, both in looking for a shortlist and checking up on them after interview. Tough questions about what is included and very tough questions on keeping to budget. Insist on some previous clients who you can speak to. Of course they will push the happy ones, so somehow you need to find any others: perhaps a list from which you choose who to contact. Did it go alright, and did it come in on budget?1 point

-

Just to clarify here, the Riba is an expensive London old boys club, you can be a registered architect who doesn't pay a few hundred quid a year to use their signboard... What you want check is if they are registered with the ARB1 point

-

1 point

-

Thank heavens for that. If the flow temperature is 45 C then typically the return temperature might be 40 C (heat pumps usually use a higher water flow rate than conventional boilers so the temperature differential across the radiators is less). So if your room temperature is 21 C and your average radiator temperature is 42.5 C that means Δ21.5! It's hugely important to get this right or you won't be able to get your dwelling warm enough in winter.1 point

-

I think it relies on the hot feed to the manifold being driven by a circulating pump of it's own, so the hot water arrives under slight pressure and the return is relatively under slight vacuum. The position of the manifold circulating pump means it is pulling water into the bottom of the pump so it will be a blend of fresh hot and recirculated cold going through the manifold pump. Assuming it was working but has stopped, I would suspect either the manifold pump, or the main circulating pump has failed with my bet being the manifold pump has failed. If it's not on it's full speed setting already, try increasing it?1 point

-

@Olly P @Onoff I have a 0.75 acre field/paddock and have been mulching it once a year this last few years. Have looked at many countax/Westwood mowers potentially to tend a bit more to the field. What height of grass can they cope with? Can they stick a bit of abuse? Alternative is a tow behind atv flail mower, don't have an atv though.1 point

-

I hear what you are saying velox is diffferent in that the woodcrete does not penetrate the concrete core( basically its woodcrete shuttering) -so not to looked at the same as durisol and isotex and again needs very little if any bracing as braces are built into the wall construction before concrete pour1 point

-

Took it all out. Trying to "blend" the plaster afterwards seems to generally be considered a bad idea. The lime is significantly thicker, and it will crack along the join. Also then allows you to use one of the lime based insulating products. Ours isnt listed which obviously makes things easier. Pics below as it stands today. As you can see, its had a chemical injection applied at some point. ABOVE the floor level. Which stopped precisely nothing.1 point

-

I only have 0.5 acre (but it’s fun to own), also have saw bench, carry all and made a crane for it. Over 60 years old and still goes well, all parts available and mendable with a few spanners .0 points

-

0 points

-

0 points

-

0 points

-

0 points

-

0 points