Leaderboard

Popular Content

Showing content with the highest reputation on 11/04/19 in all areas

-

I'll have a look at that link when I get home (Son number 2 just passed his driving test 10 mins ago).2 points

-

I think it would be better to have the final ICs on your own land. Gutter outlet will be OK if all properly sized. Run all the drainage fairly shallow and just dive down where you are connecting into the main drain.2 points

-

Not at all. I have a 10mm cable to our island, currently fed from a 16A MCB just feeding a 3 gang pop up socket. The large cable is there in case we change the gas hob for an induction hob.1 point

-

Fit 10mm from CU to isolator to Cooker Connection Unit. You can then use a 6mm tail from there to hob and oven with 32A mcb. the purpose of the thicker cable is "in case"1 point

-

Yes I will organise some photos, Liz I have been following your build you fantastic build and location1 point

-

Picking and choosing definatly has merits, as does a bit of DIY creativity, just made a few 100mm vertical terminal housings for about £2.50 each, mainly because it was something I couldn't get easily ( @joe90 would be proud...). While a duct radius of 150mm might be quoted by blauberg, it'd kink in the corrugations I'd think - but not collapse, I've used it and have a load of off-cuts if you want me to post you a metre?1 point

-

1 point

-

You need a series of weep holes above the cavity tray to eject the water1 point

-

90 degrees into an IC is standard - all the side entries are either 90’or 45 to the main channel flow.1 point

-

If that’s on ply, I would smash the be,Jesus out of it and lay down new ply. It will be a ball ache trying to get that adhesive off rip it all out and start a fresh will give you a better option to fix the ply down better instead of trying to get a few more fixings in without knowing where pipes are.1 point

-

We once had to fit Kidde in a hurry, as a last minute thing when Aico weren't available (that afternoon). They were alright.1 point

-

Hi, yes I'm cherry picking from different suppliers, I've been checking out minimum bend radii for various semi rigids, it seems the blaufast and the quiet vent red versions both specify a min rad of 150mm, the quietvent blue is 250. the re is no spec shown on the BPC site for the green basic duct. Restrictors- thanks for the info, I'd assumed incorrectly that the restrictors would not fit the quietvent manifold. I will comission the system then see if significant throttling is required at specific vents where I require low noise, and use restrictors if necessary. If anybody is currently purchasing items, I've found that external bull nose vents are available at better prices on ebay, as is flexible insulated ducting, also on ebay.1 point

-

I only fit Aico. Just about the only manufacturer with proper terminations for a flush mounting system. I like the fact Aico do a combined heat and CO detector. I wish they would pull their finger out and also do a combined smoke and CO.1 point

-

1 point

-

https://www.tlc-direct.co.uk/Products/EI1529RC.html - Switch https://www.tlc-direct.co.uk/Products/EI146RC.html - Optical https://www.tlc-direct.co.uk/Products/EI144RC.html - Heat1 point

-

Pretty sure @Temp referenced a program earlier in the thread that allows you to slice STL files? I'm NOT looking forward to learning a new package(s) I can tell you now. AutoCAD till I die! Too old & jaundiced! (I will though).1 point

-

Born in Lancashire, post code now is LA so say no more (just dont check on a map!!)1 point

-

Sorry I can't help with a specific contractor recommendation for you, @Visti. My impression was that any drywall contractor could do it but that they will inevitably grumble. I have heard of some bodge jobs so, like you, I'd be certainly be looking for someone who'd had some experience with it. Generally. I am interested in your decision, I am seriously considering Fermacell myself, because of the lack of the need for any plastering, but in my case I am tempted to try and DIY it as I have the time.1 point

-

+1 and when I buy my next house an en suite and dressing room is on the list of essentials.1 point

-

These will have a specific profile - usually to the manufacturer. Quickest way would be to template one and use a plane and router to create something that’s a near match and the “hide”it where it won’t show up as much.1 point

-

Mainly for the print quality, but also because of the low price. However, the small build volume is an issue, especially the maximum width (fore and aft, looking at the printer). The resin smell and messiness are also a nuisance; I run mine in the garage because of this. I can get around some of the build volume limitations by printing things in sections, then glueing them together later (superglue seems to work very well for this). This can also speed up prints, as print time is determined only by the height of the object above the bed, not any other dimension. It very much depends on what you want to print as to what type of printer you get. If you want to print fairly large things, and surface finish isn't that important, then an FDM printer might be the one to go for. If print size isn't that important, but surface finish is, then a DLP resin printer might be the best bet. If the printer is to be used indoors, though, then a resin printer really needs a workspace where parts can be washed free from resin residue with IPA, and that has good ventilation, because of the smell.1 point

-

1 point

-

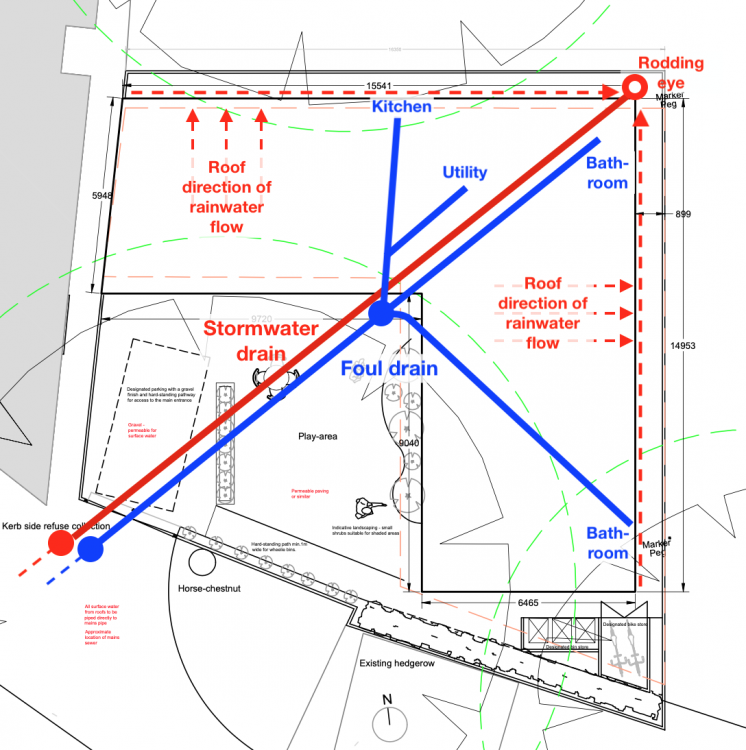

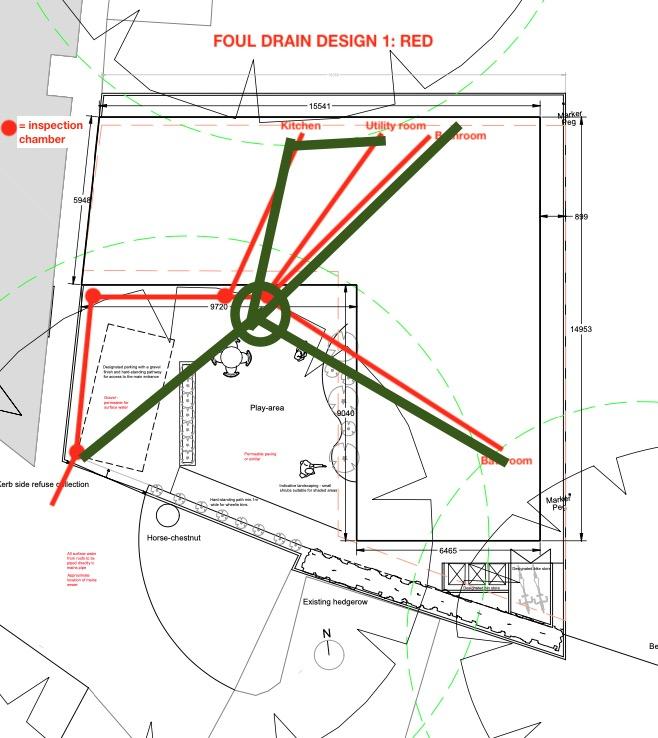

Thanks everyone! Superbly helpful. Here's the new plan based on all your comments. Got it down to just 3x ICs (from 8x in the plan by the engineer). What does everyone think? Is it OK to have the ICs just outside my gate? Nobody owns the road. Would help to keep the IC's off my paving. The road is concrete. The gutters (shown as red dotted) are long, about 15m each. Is that OK with a single downpipe serving both gutters. I tried a few online calculators and think it is but not sure. Roof is 142 m². The foul run is 12m to the IC and then about 12m to the bathroom, so the max allowable. The rainwater run is about 24m, which seems OK as Part H says 45m max from rodding eye to IC (!). In the road, the storm main drain is alarmingly deep, 2.2m. The foul main drain is just 1.2m deep. Think I will need a trench box. Then I just have to convince the engineer to change his design and tree people to let me (hand-) dig nearer the chestnut tree. D. (IC = inspection chamber. Part H = building regs.)1 point

-

That's a bit treacherous; don't tell Sir Geoffrey. ? Don't trust Yorkshiremen; they keep trying to steal Robin Hood from Nottinghamshire. Welcome from the sunny Midlands. That's interesting. Time to tell b-i-l that he is the human equivalent of a coelacanth. Real question - is this is bijou domestic "garage", or more like Bristol Street Motors?1 point

-

? your very brave to mention those words so soon........ It’s a a bit of a hot subject on this forum but rest assured most of us understand what your talking about!1 point

-

Welcome Nige ive a good mate who is a Nigel and we spoke about the annual league table of new names for babies. Seems there were no Nigel’s at all in England last year... Anyway less nonsense, welcome too from Scotland ?1 point

-

1 point

-

1 point

-

I have used Fermacell in the past. It is a real pain to work with, expensive and your sparky will hate you when they try to cut out backboxes. I also found it seems no less prone to mould than plasterboard. I have used Knauff Soundshield Plus in the past. Good value, sound attenuation, tough etc.1 point

-

1 point

-

Quite looking forward to wiring in the wet and cold under a tarp with a small fan heater blowing on my hands so I can pick up the bootlace ferrules and my feet frozen. Be a bit of a busman's tbh. Anyone guess the optimum run off angle for a cap stone and the concrete mix to go for?1 point

-

1 point

-

Our ensuites are all wet-rooms. No UFH upstairs. The floor temp is typically around 22°C so they aren't really cold. The pan area gets hotish after a few secs of shower stream. We do use a mat in front of our ensuite toilet to keep the old tootsies warm when sitting contemplating. ? I personally don't see the need for UFH in the ensuites but this is a personal preference. We also have a 30cm window blade in each of our 3 ensuites. The main reason is that we decided not to bother with any shower screening so we do end up with some water splash on the flat area of floor outside the area of the tray area. It's a 30sec job to run the blade over the floor and shower walls after a shower, and (with the help of the MVHR extract) the room is pretty dry 5 mins later -- and absolutely no mould anywhere.1 point

-

I don't think it's a good idea to fill a narrow trench with all the above tbh. Maybe a much wider single trench but not 'squeezed' in like sardines. If you ever needed to replace a section of the drain pipe then you'd have to excavate a long enough trench to lift the cables / pipes out of the way to facilitate further excavations to suit. Typically these services go down and are then never seen again, so down to paranoia to some degree, practicality to another. If, for arguments sake, you were a developer, perhaps you wouldn't really give a hoot, but if you owned this for the rest of your days then maybe worth a second thought..... A machine driver can blast through ground works like my kids go through food and clothes, so personally I'd just stump up the extra for the fines ( sand / dust / pea gravel etc ) and set the services into one 'side', and the drainage into the other. Segregation is nonsense, given what I've uncovered over the years!!!1 point

-

How does that feel, knowing (or at least heavily suspecting) where the money paid to you by one of your favourite clients is coming from?1 point

-

...and grave stones. Just make sure you put the writing on the correct side - on top for high-up shelves, underneath for low...1 point

-

And we're done: Need to infill this bit between fence and pillar. Probably just do an infill same as the fence: And I guess similar the other side where I'd like to redo the falling down neighbour's fence the same as mine. All needs a damn good acid clean off and the odd bit of missed pointing here and there. More drilling for conduits next and routing of cables for pillar lights and so on. Need to figure the cap stone moulds too.1 point

-

AFAICS it seems to be mainly Scottish and seems to be a 44 page document, but I need to see where it comes from before properly commenting. Looks like "micromange your life when it is entirely unnecessary" law.1 point

-

Re para 55/79 - we went through this process. We did a pre-application advice request (definitely recommended) and the planners came back with "no, unless you are minded to go the para 55 route, but that is VERY hard". We then did a second pre-app on their advice, which included a request to go to the Design Review Panel. Planning authorities are obliged to use an independent body to do design review for para 55/79 and our panel was typical in having 5 architects and a landscape designer. I put together the design and access statement in cahoots with the architects and at the actual meeting I did the introduction and the architect did the main pitch. We were very quickly given a unanimous thumbs up by the panel. Then, although para 55 (and now 79) say exceptional design OR innovation, our planners said they require innovation and recommended refusal. We didn't claim innovation because although we were using all sorts of new techniques (advanced SIPS, solar, electrical battery, thermal battery, etc. etc.) which have led to our energy positive certified Passivhaus, none of it was innovative in the sense of being used for the first time. Our local councillor was keen though and required it to go to the design committee, where planning duly recommended refusal. In my pitch I said "what's the point of using a professional DRP and then picking and choosing whether you like what they say" and, much to my surprise, the committee agreed by 11-1. So now we are living in it. The Design Review Panel now offer a more informal service, much like the pre-application advice process offered by Planning, so that a potential applicant can test out their proposal and receive feedback. We'd certainly have done that if it had been available when we were going through the process.1 point

-

1 point

-

We have a UNiQ eDual12 pcm58 which we use with a myenergi Eddi. We had a lot of early problems, partly poor communication with Sunamp (now a lot better) and partly with the controller, now replaced. Once fixed we have been 100% solar powered with only one recent tepid shower because we were seeing how long it would last without charging (4 days) So now all is happy with that, and a lot of thanks goes to JSHarris! We also have 2 x Dual4 pcm34 batteries, heated by a low temp Daikin ASHP, that went through the same problems as the pcm58 battery, but are now working with their new controllers, albeit never used in anger. In retrospect these were a mistake for various reasons (some ours), especially as each one was comfortably more expensive than the big battery. However, now we’ve reached the week when there is typically going to be insufficient solar to power the big battery and we’re starting to fire up the ASHP again for ufh, we’ll be experimenting with using the smaller batteries to preheat the water heading to the big battery. Will report back..... (Situation is a new energy positive certified Passivhaus)1 point

-

Slightly, but if you turn off the AC, then turn off the DC at the isolator nearest the panels, then do a dead check, you're safe enough. Usual golden rule applies - never, ever, assume a switch works, always test to be sure it has! Second golden rule - never use a voltage detector pen/screwdriver, they are notoriously unreliable.1 point

-

1 point

-

Actually I think in this case the OP means W not kW, otherwise: ..this would be a 12MW generation plant, which would need maybe 50 acres of land and a 110kV supply ? (enough with the smart-arse replies already)1 point

-

Common sense should tell you not having any outside rodding access is not sensible. ???????1 point

-

Got a quote online yesterday.... £1500 for 18months. They did ask me a load of extra questions as I've demolition, deep excavation, retaining wall and basement. They won't cover the demolition unfortunately.1 point

-

0 points

-

Another one for a motion movement sensor night light. I had one built in but my ensuite and dressing room are all one room with a dividing wall down about 2/3rds of it. My wonderful electrician put the sensor so it goes on as I go through the dressing area and if i'm longer than 2 minutes in the loo(which is rare but has been know) the light goes off so I have a back up battery one. I wouldn't have bothered with the built in if I had known, a few of the battery ones which are not expensive, would have been plenty. The batteries last about 6 months so no big deal there.0 points

-

I've a normal, "quiet" light switch in the bedroom so we can turn the en suite light on with using the click-clack pull cord. SWMBO is a pita though for getting up in the middle of the night, using the loo then coming back and LEAVING THE F***ING DOOR OPEN! Not that it annoys me in the least.0 points