Leaderboard

Popular Content

Showing content with the highest reputation on 08/07/19 in all areas

-

I'm currently painting. So Iv been watching a fair few pretty repetitive how to roll x.. Videos. But I thought this one was short and informative enough to share.4 points

-

The chances are that it will need a pretty high peak current to operate, something that a battery can happily provide, but which a generator or mains DC power supply might struggle with. Best bet might be to keep the battery but just charge it when you use it, so that it stays topped up. Even a fairly tired battery may still be able to provide a fairly high peak current.3 points

-

I've worked Up to 7 days a week for the last 4 years - almost all (except for three months) on my own. Few days off here and there, most weekends I work at least half a day. I'm retired, getting fitter by the year, losing weight, down in the dumps occasionally. But mostly head-down-arse-up-go. The most important thing is having a supportive other half. I would have thrown in the towel a couple of times if it weren't for her. 146 sq m. Roof on, windows in, some carcassing, first layer of plaster on, first fix. Zero experience of building before I started : well, I mixed concrete for my dad and few times - he did have a slipped disk after all. Often I work very inefficiently indeed. Because I haven't got a clue how to do stuff. Takes me about 5 times longer to get things done than anyone else. It's the stress of the c@ck - ups and the lack of knowledge and skills that gets to me most. Its rare for me to be able think and so plan strategically, often, I ' ... wish I'd thought of that last year ...' I could not do this job without Build Hub. Yep, I'm a Mod, so I would say that wouldn't I, but seriously for me, this isn't doable without Build Hub. How the Hell @nod and his other half did it as well as full time jobs I don't know.2 points

-

We have finished at just under 8oo per sq mtr on a 285 sq mtre build with a detached double garage on top of that I haven’t counted the vat claim in that Of around 30 k But we have just spent 10 k for the outside paving My wife had hoped to spend the 30 reclaim on landscaping But with labour the best reputable quote she got for laying the 420 am mtrs of paving and drainage was £51000 Supply and fix So don’t under estimate how much you can save by doing it yourself The total cost for doing the paving ourselves will be around £12000 It has taken us two years We both worked long days Fri Sat and Sun Every day except Christmas and about a dozen day when we where waiting for materials Every evening I would do at least three hours sometimes til midnight on a Thursday We have a house that is worth £350000 more than we have put into it We both worked full time in between We haven’t scrimped With a large German kitchen and three German bathrooms But if we do decide to sell Cutting costs on these would Have seriously impacted a sale price Hope this helps2 points

-

Why does the expression“third world” float into my mind?2 points

-

Welcome. A few years back now I had a lodger who had a stroke. While she could walk reasonably well, the foot dragging was a problem, she could easily trip up. So any door thresholds need to be eliminated. She had no real use of her right arm, and limited use of the left one. This caused problems with things like taps and controls on things like cookers. Also made door locking difficult. For a laugh one day, I tried to do everything just using my left hand. Gave up after 20 minutes as I could not roll a fag. Oh, and depending on which side is more able, if there is a difference, then the bog roll holder position can make a huge difference. Try and design everything so it can be accessed easily from both sides. And doors that can slide both ways are much better than normal fixed hinges doors, eventhough they are horribly noisy.2 points

-

I managed to avoid the joints completely because the house is so small. In fact the roof pitch was set at 42 degree rather than 45 since this kept the floor-apex gable height to 16ft. In the event, Novaar sawmill (who are fairly local to the OP) supplied me with 4.9m lengths. If it's only going to be a handful of boards in the middle that need a joint, then careful placement of a window would hide those. Alternatively, you could make a fairly bold move and have a joint line at the eaves level. Have the upper triangle of the gable stepped out slightly, to give a drip edge. If you don't fancy either of those, then you would have to go with butt joints. But I would cut them with an angle and treat the ends. And I would definitely stagger the joints. Lots of juicy details in this document: https://www.gov.scot/publications/timber-cladding-scotland/2 points

-

1 point

-

It's all about speed. Light aeroplanes don't have brakes in the air, so speed is proportional to approach angle. The landing speed (especially for a taildragger like the Chippy) has to be nailed accurately on the approach, and pretty much the only way you can bleed off a bit of speed and height is to side slip (as the Chippy does in that approach). That's really only for a bit of fine tuning, though, it won't get rid of the sort of speed that you'll get if the approach is too steep.1 point

-

I would buy them if I did not already have mine. That is the price you need to be buying them for to make DIY install viable without any FIT any more.1 point

-

One thing to watch if thinking about making a recess (which seems a good idea) is that some alarms need room to side off sideways from the base and some (like the Kidde ones) need a screwdriver to be pushed into a slot in the base to release the unit. However, I think it should be possible to make a larger recess to allow access/release movement. Have you thought about wall mounting them? No reason why they shouldn't work pretty much as well when mounted high up on a wall as when mounted on the ceiling.1 point

-

Make a little recess in the ceiling - you know, a bit like a downlighter. I'll get me coat , Ed1 point

-

Cavius make some really nice small ones at 40-50mm in size and are wireless and battery though so would need to ensure BCO was happy.1 point

-

I only personally use Aico. That doesn't address the low profile issue, it just ensures a good quality product. Aico do a combined heat and CO alarm that may reduce "ceiling clutter" in some rooms, but unfortunately they don't do a combined smoke and CO alarm.1 point

-

? With gutters, I'm at the YooChube video stage : a la How d'ya fit Lindab gutters then squire? Professionally, I had a fairly thick skin before I started this build. But since the build started, it's a lot - and I mean a lot - thicker now. When that happens ( get disheartened) to me (once a month or more) I try and do something to inspire me - I've been known to go and lurk around building sites - sometimes ask for permission to look at things on sites (told get lost occasionally) - I learn a lot doing that. Don't tell SWMBO, but I might treat myself to the odd nice tool now and again . (My Bosch laser spirit level is the mutts nuts) Would that I had the confidence, @patp ...1 point

-

I hear you! I am in the dumps just now with my build. Ready to sell all my tools and give up at the moment and I don't even have any reason too really, just all going too slowly for my liking and feel like time is conspiring against me to disappear while nothing of note has been achieved in a month. A summer month at that! Just had a roughcaster here - he has left me disheartened as I suspect I am no further forward to finding one! He seemed to offer more thoughts on everything but his bloody part of the job and kept telling me what I would need to do to certain parts of my build. The gutters are not on fully, "Oh are you going to fit gutters, you will need gutters or you will get damp problems", what is going on there, pointing to part of a roof that hasn't been tiled yet! I bit my tongue and managed to hold of telling him I know more about buildings than he does! Unless his price is particularly good I don't want to see him again - even then, I don't think his price would be worth it!1 point

-

should add we have done all the PM to date, which even at this stage has kept us busy sorting services, groundworks, steel quotes, foundations, etc, etc1 point

-

well we are very early in the build phase, site cleared, elec on site and water booked. Got more clearance work being done over next few weeks which includes laying entrance drive, making levels right for pile foundations, etc. Then piles go in. Now, none of this we could do ourselves (digger job was very difficult on a steep slope). BUT starting to get quotes in for the less skilled bits (concrete pile caps, simple retaining wall, etc) and its clear a lot can be saved by doing it ourselves. So plan is to do the simple concreting, probably get the steels designed, supplied and erected seperatly (lots of small steels, all can be man handled). then get a builder in to put frame on, and windows in. FLat roof so i will GRP myself (booked a free course). Then onto the inside, where we will do as much as possible. In total i reckon we can save £100K plus, easily. We would probably save a bit less if trades didnt try to rip you of but that aspect seems endemic1 point

-

Thanks Ian You should be so proud at what you have achieved so far Talk about never give in1 point

-

Up the battery to a leisure battery and then add an Oxford bike charger to the side - it will trickle and maintain the battery and a leisure battery will easily provide what you need capacity wise1 point

-

We haven’t done so much this build as we managed to get prices for labour within a budget we could afford however in our last build both working full time and my son in law working full time, we spent every hour we weren’t at work working on the build. Hubby would come home At 4pm have a quick bite to eat and start and we would be at it till gone midnight, my son in law spent every weekend for a year with us from 9 in the morning till 6 at night.we were out until 2 in the morning moving scaffolding for the builders next morning, we spent The bells at New Year’s Eve laying under floor heating pipes, by the time the house was finished we vowed never to do it again! It was a large house 385m2 and it was the only way we were ever going to complete it as we had a very small budget and we got mucked about a lot with various trades so we had to take on things we knew very little about. Personally would never go this route again but probably that’s more to do with getting older!1 point

-

If its a 12v lead acid cell they can benefit from being kept on a float charger when not being used. This is a mode available on some regular battery chargers. In float mode it charges to a slightly lower voltage so you can leave it connected all the time without it overcharging or "boiling" the cell dry. I found cells kept on float live longer (retain their capacity longer). If you leave them alone they self discharge and they really don't live long if left flat.1 point

-

I think the pump may have a separate speed control wire, and that the relay is only used to turn the pump on and off. When standing next to the Sunamp PV when it was charging, it was noticeable that the pump speed kept changing, as the power output from the heating element changed (this was with excess PV charging). I think the pump they use has either a 0 - 10 VDC control signal or maybe a 4 - 30 mA one, a check of the pump model number should show which it uses.1 point

-

It depends. You can get 240V cherry pickers which plug in - if you look at the motors on the hydraulic pump(s) it may be possible to get direct replacements that are 240V - control circuitry could be left as is and just run it using a 12/24V DC supply (assuming that is what it has) and a relay to run the motor on mains. It is probably how I would do it - simply put back in the DC motor if you want to change it back. Alternatively as @JSHarris says, it will probably demand a fairly high current and therefore need a hefty transformer but not impossible. What about connect it to a permanent charge system? I am not sure if yours is 12/24V but you could fit a constant supply charger to the cherry picker and a mains lead, when in use simply plug it in, the thing will charge all the time and when you use it the load will come from the battery - presumably you are not driving about in it constantly and going up and down in which case the constant charging will effectively leave you with a "mains" supply. Lot's of options. It's just how far you want to go.1 point

-

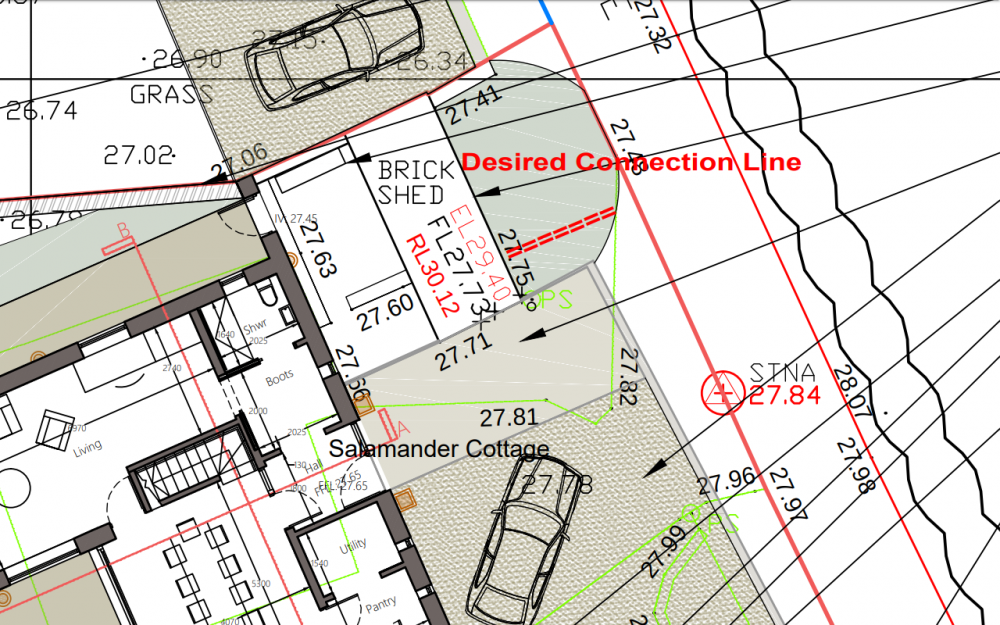

I think I have followed both the manufacturer's guidelines (Atlantic Plastics, Talis Intex 2) and those issued by United Utilities. In the same vein as this post, could you please have a look - thanks. I'm a bit jumpy about getting this right because UU are coming to inspect my work soon. I'm not that confident about it either...... This is the layout of the; stop tap, non return valve , and the drain off tap. Bottom 'row' is incoming, top 'row' outgoing Thanks @Conor and @epsilonGreedy. I'll be sure to Moisten everything before tightening. (why?) Not use PTFE tape. Tighten just beyond hand tight. (instructions say the thread should not be visible) Use a Sharpie to mark a depth guide to help me check the 'fit' By accident, it seems the incoming pipe may well come out of the ground at the correct angle to match up with the meter box. I'll have more on that adventure later today. Is the sequence of piping and valves correct above, please? Thanks Ian1 point

-

Not in our case - extension and renovation completed 5 years ago, on to mortgage company no 2 since then and only thing they wanted to see was copy of planning approval and final BC signoff.1 point

-

Its you Ferdi.... Never been inside a cow for a good look round mate ....?1 point

-

Or a long screw or rod down through the joints (need a long drill bit).1 point

-

Yes that is reclaimable as it is materials required for the build of the dwelling. Are you doing it yourself or are you getting a contractor as they should zero rate it1 point

-

1 point

-

Yes, we did exactly this. We had a pole that was in the way, together with power and phone cables that draped over the plot and restricted what we could do with the big digger. The first stage is to identify who owns the pole(s). In our case, the pole belonged to SSE (had a sign on it, and was engraved with an SSE reference number) so I contacted SSE initially. They agreed to move the pole and allow the power cable to be re-routed underground, for an agreed price. Our ground works chap dug the trenches and laid ducting and SSE provided new power cable that was pulled through, then SSE turned up and placed a new pole in the corner of our plot, connected the new underground cables and removed the overhead cables. They left the 'phone cables on the old pole. I then called Openreach and had a real battle to get them to do anything. Eventually I got hold of the mobile number for the local engineer, who was great. He told me that moving the 'phone cables would be free of charge, as it was SSE moving their pole that had caused the need for them to be moved. He free issued Duct 56 and cable, I agreed to lay it all underground and he then tried to organise the removal of the overhead wires and the connection of the underground ones. This was a real PITA, as jobs like this are a very low priority for Openreach, so we waited weeks for them to do the work. In the end we absolutely had to have the overhead wire down, as it was holding up the build, so we were advised that if there was an "accident" on site that brought the wire down, Openreach would come out straight away to fix it. As luck would have it, the digger jib accidentally snagged the wire first thing one morning, and an hour later Openreach were on site connecting the new cables up... I then struggled to get anyone to remove the old pole, with SSE telling me it was their property, me telling them to get it off our land, and them ignoring me. In the end I slipped a few pounds to an Openreach Polecat crew who were replacing a pole in the village and they pulled the pole out and laid it down in our verge, where it now sits, staked in place, as a barrier for tractor tyres.1 point

-

Hi and welcome to the forum. Good luck with the project, I hope it progresses well for you.1 point

-

> @Onoff I have found a 3d-print sculpture in honour of @onoff's avatar. Never met the man himself, so cannot comment on whether it is a selfie - but I bet he likes donuts. Quite interesting how from the front it looks aspirational, whils from the side it suddenly becomes a traffic warden. It may be the colours.I am not aware that this has been printed yet; presumably it will take some processing. The title is "My Precious". Obviously. When the machine arrives you can make one ?. Credit: https://pinshape.com/items/45627-3d-printed-chubby-gollum1 point

-

Decision day arrived and passed. So extension one agreed because cause they were busy. Extension two agreed because they said the footprint and floor area were bigger that the planning permission that is currently in place - it wasn’t, this house is smaller and lower than the current planning permission. They were about to reject the plans this time because the volume of the house is bigger (the current planning permission is for a chalet bungalow). So even though the footprint and height is smaller, they are moaning about the volume of the house. We will find out by the end of the week what they say. I know now they are short staffed and under pressure but they use deadlines as the day they actually look at plans, it is sheer incompetence.1 point

-

1 point

-

@Onoff I had the same issue with mine when changing gear or going into reverse it would jump off the gearbox pulley. This was after I abused it by pulling out fence posts, dragging chain harrows and a field roller for a fair while . I fitted a new drive belt and it's been perfect since. Judging by the pictures it looks like the belt needs to go up to the upper notch on the engine pulley but I will take a look at mine in the morning and confirm.1 point

-

A friend of ours who is a site manager built a house in his garden He finished just as We completed on the purchase of the plot I asked about a warrantee and he replied I have t bothered They will carry me out of here in a box Well Two years later this amazing plot of land came up and with a possible 300k profit His forever homes goes up for sale I asked if the lack of a SW would be an issue he said Nahhh It never came up Well the sale progressed nicely The chap who was purchasing wanted to know about the solar panels running costs MHVR Then he got a call from his solicitor requesting his SW That his sale fallen through He just said Nahh Get a retrospective Warrantee Test holes around the foundations etc How wrong I was The Surveyor ? who visited him didn’t seem that interested in the house Just the BC cert and the rest of the paperwork He has an oak porch that they wouldn’t cover (Green) and a flat roof that they wouldn’t include He paid about £800 more than I did and took an indemnity with a separate company for the flat roof Think about £100 we have some green oak and a similar flat roof Buildzone didn’t include ours either1 point

-

Mass [kg] is the amount of stuff in a material, it is not the weight that is affected by gravity. Force is mass times acceleration. The unit is the newton [N] Area [m2] is what it is, the length times the width, or pi.r2 or the integral of a curve, which is just the area under a line on a chart. So taking a mass of 1 kg, and acted on by Earth gravity, 9.81 m.s-2 over an area of 1 m2 1 [kg] X 9.81 [m.s-2] / l [m2] = 9.81 N/m2 So the 400 kg window sitting on a strip 4.2 m long and 0.1 m wide: 400 [kg] X 9.81 [m.s-2] / (4.2 [m] X 0.1 [m]) = 8743 N/m2 8743 [N/m2] /1000 = 8.743 kN/m2 N/m2 is often written as N.m-2 and is a pressure, in derived SI units, pressure is also known as a pascal [Pa]. 1 N.m-2 = 1 Pa With a bit more arithmetic trickery, it can also be expressed as 1 J.m-3 which is energy density. For more about the pascal: https://en.wikipedia.org/wiki/Pascal_(unit) Usual disclaimer, it is late and I have had another record breaking night feeding people. Is EPS a true solid, or can it flow over time as the air inside it is compressible?1 point

-

Welcome to BuildHub - I bet you were only expecting build advice! its amazing the advice available on this site. good luck with the build - where will the extension be taking place? in what area? You never know - we may be able to help if nearby.1 point

-

Welcome to BuildHub. ? By complete coincidence, I was listening to a podcast with Paul Stamets (mycological legend) today. He's presently undertaking research into combining lion's mane mushroom extract (which stimulates myelin production) with niacin (which stimulates peripheral circulation). His focus isn't MS, but clearly any support your brother can give his myelin system the better. It'll be some time before results are known, but if you're interested in getting ahead of the science in a fairly low risk way, that's one avenue. Another option is a ketogenic diet, which appears to help some sufferers. I only know about this because my own diet is largely ketogenic, and I've seen mention of MS a number of times in articles I've read on the topic. Hopefully I'm not teaching anyone to suck eggs. MS is such a horrible disease, and I hope your brother's progression isn't too steep.1 point

-

In some area MS charities offer Hypobaric Oxygen Therapy (HBOT). When a relative suffered a head injury he had quite a few sessions in one of their chambers. While there we met several people with MS that said it helped them to a limited degree. I don't think it's available on NHS or even if there is science to back up the claims they make. Just thought I should mention it in case its not something he's investigated.1 point

-

Welcome to the Forum. Hope we can help. I don't know if these are still available? Perhaps he's already investigated. https://www.gov.uk/apply-disabled-facilities-grant and https://www.moneyadviceservice.org.uk/en/articles/funding-to-adapt-your-home-for-accessibility#dont-forget-to-claim-vat-relief "If you’re disabled, any building work you do to adapt your home might be zero-rated for VAT. Find out more about VAT exemptions on building work on the GOV.UK website."1 point

-

Google found some info.. Try contacting.. Timber Decking and Cladding Association.. https://www.tdca.org.uk/ Looks like they have guides with drawings.. No 9: "Detailed openings Vertical Clading" https://www.tdca.org.uk/media/3778/woodcampius_css9.pdf Elsewhere.. About page 13 onwards (pages aren't numbered) http://www.woodcomponents.ie/wp-content/uploads/2016/03/MTS-Cladding-Detail-and-Design.pdf Some of the example photos show joins staggered on adjacent boards. On my horizontally clad out building I staggered the joints over at least three different positions so they didn't form an obvious line. Bit of info in here .. https://www.silvatimber.co.uk/media/pdfs/Thermowood/Thermowood-Technical-Instructions.pdf .. mentions chamfering the lower edge of boards (page 7).1 point

-

1 point

-

Technically there's no such thing as a "self build certificate", and one shouldn't really be needed, but some people have found that the rules aren't often understood, so there are versions of a self-build chit around that can be of use in keeping contractors happy. We only had one that was funny about zero rating, and I gave him this: VAT Exemption Certificate - blank.doc1 point

-

@Gooman, I tend to buy my Wemos modules in batches of 10. This is my favourite as well but I am a bit biased since I am on of the lead developers for the NodeMCU Lua firmware for the ESP8266 and ESP32 modules.1 point

-

Just work out the compressive load on the insulation by dividing the weight of the window with the supported area under the cill. For example, if the window weighs 100kg and has a support area under the cill of 2m x 0.1m, then the compressive load is 500kgf/m² (100kg / (2m x 0.1m)). Converting that to units of force (Newtons) gives a force per unit area of about 4.9kN/m². EPS 300 (at 1% compression) is rated for 100 kN/m², so would be overkill. Even EPS 100 (rated at 45 kN/m² at 1%) is massively stronger than needed. Check what Nudara use (I doubt it's going to be less than EPS100) and then do a quick calculation to see how things look. (To convert from kg/m² to kN/m² just multiply by 0.00981)1 point

-

Trevor at Cylinders2go will give you a good price too, if you want a comparison. He did a group purchase discount a while back for the forum posse1 point

-

Well it's as close to a lawn as it's going to get. I'm pretty happy with it to be honest. It's took a lot of work to get it to this standard from a cow trodden tufty field but it's well worth it. Best advice I can give to anyone else wanting to do this is keep mowing it once a week, start on a high blade setting and work down as the grass improves. Chain harrows work wonders to pull all the dead grass out and smooth out lumps and bumps . And roller it plenty as well.1 point

This leaderboard is set to London/GMT+01:00

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)