Leaderboard

Popular Content

Showing content with the highest reputation on 08/04/19 in all areas

-

Well it's as close to a lawn as it's going to get. I'm pretty happy with it to be honest. It's took a lot of work to get it to this standard from a cow trodden tufty field but it's well worth it. Best advice I can give to anyone else wanting to do this is keep mowing it once a week, start on a high blade setting and work down as the grass improves. Chain harrows work wonders to pull all the dead grass out and smooth out lumps and bumps . And roller it plenty as well.5 points

-

Something like this, if you can be certain of the rail diameter search for that. https://www.amazon.co.uk/Vankii-18-25MM-Adjustable-Replacement-Bracket/dp/B07NR8KPSH/ref=asc_df_B07NR8KPSH/?2 points

-

I was trawling the Internet to find out what the functional earth found on some RCBOs was for and stumbled across the following video that explained it along with a full teardown of how everything works, a demo of the bimetallic strip and arc arrestor in action before then finally overloading it to destruction: Thought it might be of interest to others!2 points

-

My only observation is that present gable end looks stark and uninviting, i.e. no windows or features. Design the extension to look nicer, e,g with a window or some other features. If they refuse it, there has to be a planning policy reason for refusal. I would like to see them show the planning policy that says "it does not address the street" If they start discussing it with you just make it clear you will appeal if it is refused.2 points

-

The whole principle of a telescopic ladder is flawed to me. About the only time I see them is surveyors using one to look into a loft, and when they extend the thing and gingerly climb up it, I cringe. If I have a proper ladder I would always offer it. They seem to use them purely so they can rock up to the job in a shiny saloon car that would not easily transport a proper safe ladder. I have NEVER seen a tradesman, i.e electrician, plumber, joiner, decorator etc use one. The principle seems to be lets make a ladder that folds up small enough to go in the boot of a car, and sod the fact it is a basically unsafe ladder. It would be far better to put a pair of roof bars on the surveyors car and give him a proper ladder imho. Now I will let the forum tell me one good reason to use one of these that I may have missed.2 points

-

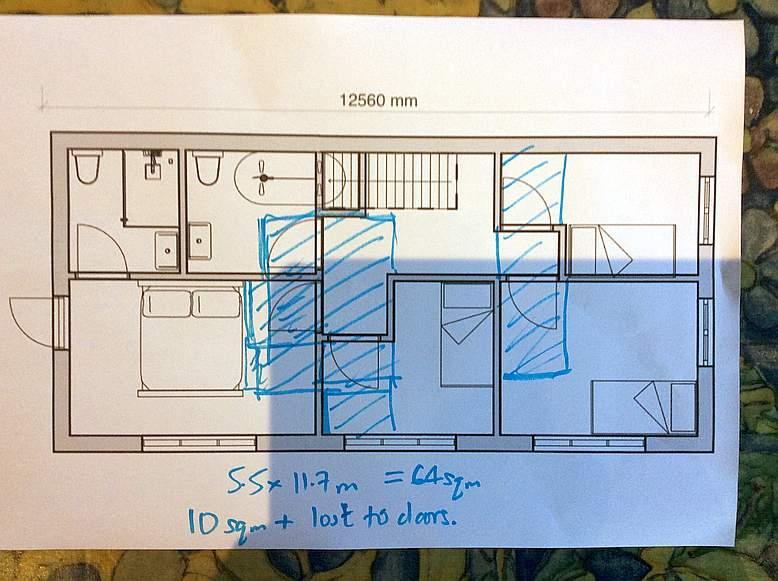

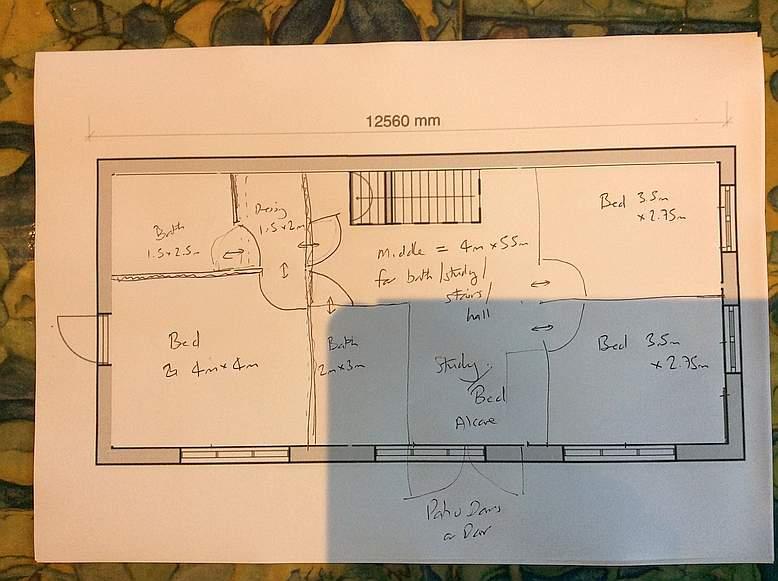

@K78 Let's play giraffes, and I'll stick my neck out. Been musing on this over breakfast. Am intending to provoke, though not assail. It is really helpful that you posted the 3d view. I think there are a few things with the underlying approach. 1 - You are mourning the 20% of your floorspace which has been stolen, and trying to fit what was there into a smaller space. You are, so to speak, trying to put a 1000 piece jigsaw onto a table designed to hold a 750 piece one. So it ends up feeling cramped. You need to be creative with what you have now. 2 - The design (whoever did it) is taking a conventional bedroom floor and putting it below. Even - by the look of it - to the extent of retaining windows that are designed to stop people falling out. At ground level that is irrelevant, other than for the need for toughened glass at low level. 3 - The ground floor is not integrated with the outside. Even in the original version, the only exit to the garden is through bedrooms. WTF? 4 - Crucially, this turns the upstairs into an isolated viewing gallery on stilts. There needs to be a flow from upstairs -> downstairs -> outside, and back again. That is a key aspect of your bedroom floor design. The flow needs to belong to the whole house not just the people with those bedrooms, unless you have an alternative. 5 - As it is on the Ground Floor, Mother Nature has gifted every room a free balcony. Use them rather than shutting them out. 6 - There is a huge problem with light downstairs - eg the hall has no external windows in either version except those on the stairs. This risks the bedroom floor feeling like a dungeon or a space you got to once a day to hibernate. Avoid, unless this is your intention. Someone could come back saying they met the Minotaur. IMO you need to be thinking about light and space and how you will live here, rather than about how to fit things into the walls you have been given. So 1 - The walls keep the weather out, and should not keep your family life inside. Since you have the glorious position of a garden outside your bedrooms, think of the garden fence not the house wall as the far side of the bedrooms. Useful when your floorspace has just been shrunk. 2 - Do something with those windows - you had patio doors in the original version in bedrooms. Get them back, and also use some lower level windows. If you put them low enough for seats, then the rooms feel bigger. 3 - Do something about circulation to outside without forcing people through the most private rooms. 4 - Work out what you really need. The original plan had 7 spaces in about 80 sqm. Now you have 6 spaces in 65 sqm, plus you lose a further 10sqm+ to space for opening and walking around doors. Not efficient. 5 - Address the light and circulation to stop it feeling like a dark, dead end. 6 - There are many ways to address this. I would make it more open plan, and open up the middle space (where LH space is master suite, and RH space is 2 further beds which are possible small doubles - 11 ft 6 x 9ft.) with patio doors at one side, and big stair windows at the other. I think a void near the stairs somehow would help. I think my best suggestion would be an open well, round staircase - which would be a talking feature. Ideally I would like a full height stair window, even if translucent, but budget may dictate a dog leg stair. But get light down there, somehow. 7 - I would also remove that middle wall upstairs, but that is not the core of this debate. 8 - Such a space as 6 would sort out your top -> ground -> garden flow. That would be a suitable indoors / outdoors 3 storey social space. 9 - I would treat the space as the office / study area, and perhaps use it (or somewhere else) for an informal sleeping area, either via a sleeping alcove or sleeping platform (even above the desk). That gives you back all your facilities by stacking the space. Such a platform could also be up under the roof somewhere. 10 - Your family bathroom would also slot in there. If beds were upstairs I would say go 3 ensuites and no bath, but this may form the loo for people in from the garden. 11 - Assuming you have worked it through, trust your feeling that a proposal is right when you think it is. Two plans below. First is the space you lose to doors. Second is one possible idea. Consider carefully how big things actually need to be. Ferdinand2 points

-

Home Farm. I feel for you and am not surprised the local RSPB were unhelpful. You will need to lobby at a higher level. If they are wishing to remove hedges you might have some leverage there. You need to raise specific objections. Objecting to fertiliser spreading will not get you anywhere, access for lorries delivering/taking away stock, delivering feed might. You might want to contact George Eustice (back as farm minister). He has quite strong views on sustainable farming. This link https://www.cornwall-aonb.gov.uk/blog/2018/5/1/the-future-of-the-farmed-environment-in-cornwall contains a talk he gave over a year ago on his vision for the future of farming and CAP payments AB, worth watching, it also explains how the present system works. Tom Tolputt's presentation also worth a look at. It is possible to farm without antibiotics. My son has a pasture fed organic dairy herd and doesn't use antibiotics (except in very rare circumstances poss 1 or 2 cows a year, they are not milked if he has to), his cows are outside, they don't get mastitis, they are milked once a day only, they will milk for many years not the usual two lactations of many commercial herds. He uses breeds that are hardy (largely jersey crosses) and that don't need to be fed grain/soya. His farm is a carbon sink, they have also introduced beavers to control local flooding downstream. He does not use any synthetic fertilisers and because he mob grazes he fertilises as he goes rather than creating a slurry pool. I have never used antibiotics here, I breed poultry (all sorts) for meat and eggs, beef, lamb and pork (admittedly I am very small scale), my cows and sheep have only ever been fed grass. The biggest issue around food production today is food is just too cheap, there are also too many in the chain between farmer and consumer, all taking their cut, the result is some producers looking at the best way to maximise their profits, large scale IPUs are one way of doing this, if you are only going to make a few pence (it really is pence) profit on a chicken you need to produce an awful lot of them. If you live in the country then buy all your food direct, it's easy, and eat seasonally, do you really need fresh tomatoes or strawberries in January or apples in June?2 points

-

Agreed. Taking enough time to soak in your ideas is the most important step, especially when you have such tight constraints. That is partly why I am throwing out a lot of opinions. There may be ... perhaps ... something useful amongst the dross. You can do a lot even with a small space, such as constrain it with a window so that you only see the interesting bit and your mind fills in the rest, or eg put in a window that hides the top of your fence from view from say .3 to 1.5m and put a raised bed outside at .3m height so it is like having a huge windowsill full of plants, with the fence 1m or 2m away painted green. ATB1 point

-

Anything below 800mm will need to be toughened/laminated. Anything within 300mm of a external door will need to be toughened/laminated.1 point

-

That would be my understanding. Toughened inner for safety reasons, laminated outer for safety and security.1 point

-

Think number one is okay. It's only a basin. I'd have a 110mm branch with pipe coming up thru floor in 110mm. Suppose the rules might be there in case future occupants connected different appliances. Number 2 id prefer rest bend bottom of wc with sink and dishwasher connecting into top of this. Same as above connection wise1 point

-

Your alternative is presumably a 2 or 3 sectional ladder that will fit in your vehicle. I am happy with the Wickes own brands as they seem to be rebranded Youngmans - eg for the 3 section ladder and work platform I have had for a few years. Ferdinand1 point

-

Ok a flat face not a chamfer. Hold the connector, with the rubber washer as in your picture 2 against this. You should see as the nut tightens up it'll squash the rubber in / against this. Hand tight plus a bit is usually all you need. Have read once hand tight then tighten a 6th of a turn more so one flat face more round.1 point

-

Because we are trying to do it with lower thermal losses, different energy inputs, consistent and reliable outputs, at known quantities, and lowest capital expenditure. Why I like vented system heated by a simple electrical element.1 point

-

It's the latter Ed. Rather than connecting to some help agent who might give you the bum's rush, I thought that Nick or Jeremy might have the direct current contact. I haven't spoken to anyone in SunAmp since Jan 2017. The current system is based on an RPi + SSD with two USB serial connected ESP8266s doing the sensor collection and relay control, so it is independent of the IP network. However, after a couple of years running, I've decided that in terms of timeliness Internet access is more critical to the house occupants than control of the SunAmps. (It took us days for us to realise that one of them had failed. Ditto for the slab which we heat overnight. I posted separately about once where I had a failure in the Wills heating and the slab heating was off for a day in November IIRC; the house cooled down by about ½°C during this outage.) The way that I demand any heat (whether SunAmp or Willis) is that the maximum on-time request is 35 mins and the so the HA system reissues the on commands every 30 mins as needed. This gives a reasonable fail safe: if the HA fails then the ESPs will shut down after 30 mins or so. Minute-by-minute control at the HA level isn't needed. The biggest source of outages since we've lived in the house has been power cuts. (We bought AEG ovens for our kitchen, and the small Microwave / grill /oven was a piece of junk that kept tripping the power, so we've since replaced it with a Bosch.) The RPi was OK, but everything else would die because the kitchen and utility are on the same RCB in our power distro box. My current thinking is to keep all of these control devices on a private control WifiLAN: the HA RPi is gigabit-connected to the house switch, and I'd use static IP allocation for the control LAN on a private SSID with the RPi running hostapd. I don't need to set up routing tables in the RPi, since by design my control ESPs only communicate with the HA mothership. I've got a spare RPi, and ESPs so everything is cold-swap repairable. The control system will keep running if the rest of the house or BT OpenReach network infrastructure fails. This will be no less reliable than the current setup.1 point

-

I recommend parking your car somewhere so that there is a wall next to the passenger side. Don't try for super close just comfortable. Get out and push a tape under the car until it reaches the wall. Open drivers door as far as needed to get in/out easily. See where the end of the door comes to. We were surprised and ended up adding a meter to our garage. Back of the envelope based on a Ford Focus …. Car is about 1850mm wide. You need at least say 150mm on passenger side and around 600-700mm on driver side to get in/out reasonably easily making 2.6-2.7m. Double it to give 5.2-5.4. So at 5.6m wide there would be no room for a bike down the side or something like a ladder on the passenger side wall? So yes I agree with ProDave that 3m per car is a reasonable minimum width. A focus is also 4.7m long so the space left might effect the type of garage door you have.1 point

-

Any 110mm pipe that is going to be under 300mm deep really needs to be concrete capped, even if it is only to protect it when you landscape over as a whacker plate will stick MoT1 through UPVC pipe with ease1 point

-

1 point

-

1 point

-

I was at the NEC build show and was accosted by the chap that’s always there selling these things I politely said no thanks in any case there not allowed on building sites He got very upset and told me that someone had been having me on It’s years since I’ve seen a ladder on site Other than fixed to a scaffold Theres a reason for this One or two sites are even objecting to stilts that are over a mtre1 point

-

I have some Telesteps and they are very useful. I choose to use them in preference to any of the other ladders I have around that size. I don't feel they are unsafe or lacking rigidity.1 point

-

This was the one I used. 1-2 years of tenants and going strong. https://www.ebay.co.uk/itm/172603618735 Whole thing1 point

-

Have you got a picture or street view of the other houses on the street with the 2 storey protrusion?1 point

-

1 point

-

In general, steps are preferred, as they don't translate vertical loads into horizontal slippage. With a slope at the base of the trench foundation, when a vertical load is imposed the foundation will want to move sideways down the ramp formed at the base.1 point

-

We're going with a mixergy tank, in part because plan A was sunamp but it's just looking to finicky (and, not convenient to use with a heat pump) The current discussion on failure mode analysis and designing for line-replacement of parts has me wondering about the overcomplications of Mixergy, I don't think it's too bad because - we're not planning to use it to predict usage day by day, just to allow us to have effectively 200L of hot water tank but expands to 300L when there's free energy coming off the PV - the fanciest bits of the internet connection are for the predicting the future parts. Without that I think we'll get fair use from it primarily through local schedule control. - if the fancy controller or cloud service eventually breaks, it just becomes a normal tank, not a dead lump of salt. The only thing that does concern me is the heat plate exchanger and circulation pump assembly they use for getting most effeciency from a low temp heat pump. I have not idea how tightly the speed control for that is coupled into the rest of the controller circuit. Obviously it already had double immersion as the primary backup, but maybe it would be prudent to order with an internal coil too so we have that as a backup (I have half a mind we could warm the ufh from that, if it became necessary to use it as an E7 time-shift store).1 point

-

The Sunamp PV is pretty simple, simpler than most oil or gas boilers. It's just a question of getting support for something which was made in the hundreds, not the thousands. What I can't figure out from this thread is with @TerryE has had any problems getting said support or hasn't tried yet.1 point

-

It wasn't so much a great nervousness about SA that prompted me to request an additional unit so much as our experience at work. OH and I run a small manufacturing business and our machines are all varying degrees of old. The mechanicals themselves are robust and have stood the test of time very well but the thing that leaves us most exposed is potential motherboard failure on one of our bought in brush making machines as the electronics go back to the late 80s and will no longer have manufacturer support in a few years time. I was pondering this whilst discussing the SA with Nick and it struck me as an obvious and easy to achieve way of time proofing the SA unit as one can never be sure how long manufacturer support will be available, particularly with a relatively young company who's owners may want to sell it one once established.1 point

-

I have a set and used them plenty of times. I hate heights of any kind but never felt unsafe on the set I have if I'm being honest. Yeah sure they are more bendy than a normal set of ladders, but the great thing about them is ease of getting them through someone elses house, without much risk of scraping a wall. Yes they are not a replacement for a good set of ladders, but they are still very very handy and I have no regrets buying them1 point

-

Probably no reason why the PCB mounted relays in the Sunamp PV control board couldn't be replaced with remotely mounted SSRs. Most SSRs accept a wide range of input voltages, so there's a pretty good chance that they would switch OK with the signal that normally drives the electromechanical relays on the PCB.1 point

-

Yes, we record to a box, but to SSD rather than HDD, and we only record when motion is detected. I'd personally not touch ring.com with a very long bargepole. They share data without explicitly telling users they are doing so, and I have a general policy of not letting anything I rely on for privacy or security connect to the open internet. I still cannot get my head around people who willingly install listening bugs in their houses, so that the likes of Amazon, Google, etc can hear all that's said if they wish to. Hardly a week goes by without the flaws in the security of this stuff, or flaws in the way it's used, getting a mention in the media. For example, over the past week alone these two stories were published, one about staff listening in to recordings made by "home microphones", the other about Ring sharing access to devices without explicit user consent.1 point

-

1 point

-

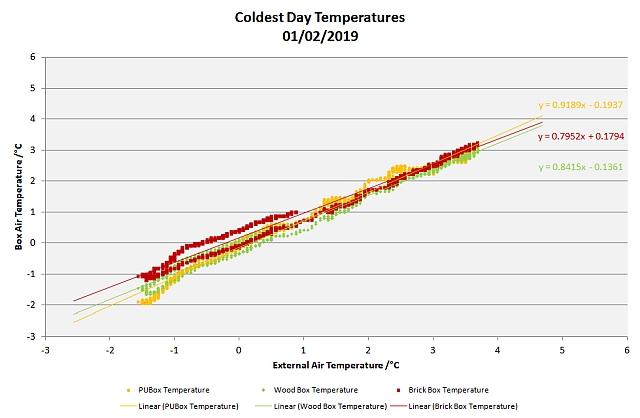

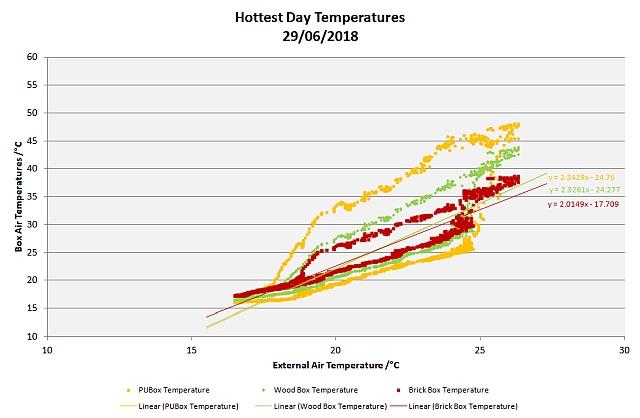

I have been running an experiment for over a year now, just three boxes, exposed to the weather, with the same volume of different masses in them. This does not model a house, but shows that during cold spells, there is effectively no difference. Hot spells are a bit different. Mean temperature days are so variable that it is hard to draw a conclusion from temperature differences alone. Below are the coldest day and the hottest day charts. Lots of variation on the hottest day.1 point

-

The phrase "Mow it into submission" comes to mind, That is what we did with part of our garden before we finally got around to levelling it properly.1 point

-

Check this thread where @JSHarris installed a precharged A2A1 point

-

Good first post. You need to put some serious insulation in that roof, as and when you do bits. I know people who lived in one and it was very cold upstairs / warm downstairs. Do you have space for an L-bath? They can be only 800-850 wide.1 point

-

1 point

-

We discussed ladders here - though not really telesteps. If I were concerned I think I would look for a UK or European branded one, and treat it carefully. Or find one that was a brand rebranded for the store - as Wickes do for sectional ladders (Youngmans?) and cement mixers (Belle?). Mine came from Aldi, and I am happy as I only use it for light duty mainly around home. Sources to ask: Pro-Tradesmen doing their business, perhaps "Trade Rated" on SF. I do not know how to check the mechanism, however I think one joint feeling weak would be a flag to replace. Ferdinand1 point

-

Same T1200 mower as mine. Hopefully have mine back running soon having only just got two broken, bastard 1/4" studs out earlier today.1 point

-

Nick, they were installed an 17 Jan 2017, but apart from sharing my good experiences on the forum, I've not had anything to do with the company itself, so perhaps you might have a bit more leverage so thanks very much for your kind offer of doing the contacting. Having a replacement / spare controller would avoid me doing one of the options below The cell is themselves as a simple as can be: about the size of a 20 ltr Jerrycan, with water in & out at the top and a safety vent on the other side. The heater and mechanicals should have a 10-year life at least. The weakness is the control board and especially those these budget mechanical relays. Other than the relays, the main design weakness on the boards are the couple of chunky electrolytic caps on board which (depending on quality) tend blow or leak in that 10-year time frame. I've been brooding about this, ILS and reliability. Sorry ILS - Integrated Logistics Systems and probably JSH is the only other sad fart on the forum that I could had this conversation with. The military were into this stuff 40 years ago and probably still are: how you repair and maintain kit in the field; when you repair in place, when you junk and replace, when you sap out and send back to central maintenance for repair, etc. The current wave of consumer devices don't even think about such stuff any more: if its broken then get junk it and get the latest model. But for me as an end-user, I don't want to be out of water or heating for weeks just because some manufacturer has declare a model end-of-life. Parallel failure modes are good; they give you a step improvement in MTBFs. Serial failure modes just make things worst: example a single engine plane and the engine fails -- you are going to come out of the sky and you might get out of with you life. A twin rotor Chinook is far worse - either rotor fails and you are going to die, but with a twin engine plane when one engine fails -- you will need to land at a nearby airfield (though the latest twin jets such as the 777 have can an ETOPS rating of over 300 which means that "nearest" can be 5 hours flying away.) So having twin SunAmps means that I can risk taking a month or so working out the best approach. (I also have one working system to instrument and to work out the operating characteristics.) By way of another example with our UFH: having an ASHP + Willis means that neither system is critical. Back to the SunAmp, my preference would be switch the 240V AC with a couple of panel mounted Crydom SSRs which can be driven by a 50mA 5V TTL input. Field replaceable on failure. These and everything else could be driven by my favourite ESP8266 or ESP32 and could configured as MQTT clients driven directly by my HA system, and this would also simplify my central panel as these would now be always-on devices from a power distribution PoV with no active control functionality.1 point

-

Good point Mike. I have 3.5tonne Land Rover. Ergo, I can only move a trailer with a digger that weighs 3.5 tonnes LESS than the weight of the trailer. Hence my Kubota 203alpha AND three buckets is bang on the limit for me. If @patp you have a bigger tow machine you can tow a bigger digger. Don't forget the bucket weight is added to the digger weight.1 point

-

3.8T is a biggie- 1.5T is all you are going to need if that is too small then you probably need a 6 or 8T machine. You cannot move it yourself and the market for such size machines is largely commercial and not self builders.1 point

-

There are pros and cons to a decision either way. Local circumstances and risk appetite are important factors. Diggers damage things, break down, eat budget. But if you can mend things, maintain the digger and re-sell it at roughly what it cost - what's to lose ? Here's my answer: I took a year and many posts on BH on whether to buy, and then which one to buy: long story short, after 4 years, we're nearly ready to sell our Kubota. I have put 500 + hours on the engine, replaced the tracks, maintained it to a very high standard - dealer only on site servicing. Cost via the purchase route Initial outlay £13k Off the top of my head: new tracks, new track clips and a full 500 hours service £700. Replacement hoses £50. Bits and bobs - massive shackles, official Kubota lifting hooks £150. Massive lifting chain £100. Say £14k Sale: very worst case £10 k Nett cost: £4k Cost via Hire 500 hours (same engine hours as above) = 62.5 days For my type of digger, the cost is £150 per day plus transport : £210 62 * 210 = £13,020 Nett cost: £13k The kicker is that through the purchase route, the digger is available 24/7 at the drop of a hat - sometimes all that was required is a fifteen minute job with a digger that saves a two man / day job. And you cant get that level of utility with a hire digger. Nobody can arrange a hire to suit the requirement for a 15 minute job. Finally - and this surprised me most - most of the jobs done with the help of a digger had nowt to do with digging Lifting, smoothing, nudging, squashing, anchoring, hammering (posts), blocking, holding still enabling one-person working where two would have been required. Even my wife loves our digger " Best thing we've bought to date" she's happy to repeat to anyone who will listen. "Better than the scaffolding?" "Well just about, yes" The key thing is context. Perfect for us : maybe not for you. A 3.8 for £9k? Hmmm - I'm wincing a bit. How many hours on the engine, what are the tracks like, look at the track clips, and how sloppy is the main ring? Proportional controls?Service Schedule fully stamped? With your own digger there's one big disadvantage, yer mates all want to play on it- so I have a garden gnome ready for them. His name is Clarence. "If you can lift Clarence off the ground without knocking him over , you can have a play". To date, only one young lass has managed it. Diggers need a gentle touch.1 point

-

We hired when we wanted one, also at £50 a day, although several years ago. The chap was at the end of the road, brought it down, with diesel. All the advantages and no hassle if anything goes wrong.1 point

-

Any pics of the timber frame construction supporting everything? As in pre the floor going on. Might help @zoothorn on here who's aiming for something similar on his stream bank. +1, I thought 30m2 was the limit? Tbh I'd have expected it to have been built on piers...1 point

-

Run the cable down to the ground and then through a conduit buried in the ground? I assume you're thinking of PoE cameras so only a single cable involved for both data and power.1 point

-

I also used plastic plumbing for our build, and never having used it before I found it pretty quick and easy to use. However, like @JanetE, I opted to use copper where the pipes came out through walls to connect to stuff with compression fittings (like shower mixers), and also where any pipes were going to be visible, like those running into units to connect to taps etc. Copper pipe just looks so much neater, when it has to be on show, than plastic. Getting the plastic pipe to run in dead straight lines is challenging, plus the fittings for plastic pipe are a lot bulkier. Having to look at untidy plastic pipes every time I open the cupboard under the sink would, I'm sure, drive me bananas!1 point

-

Where it all began in 2009 on our family croft in Skye. Once we selected the site we put in outline planning for a three bedroom 1 1/2 storey house. We then undertook the legal process of decrofting the house site to enable a future self build mortgage. For the next few years very little happened as we needed to save money towards the project. In 2013 we submitted a detailed planning application for a traditional 1 1/2 storey property which was in keeping with the local vernacular. As with outline planning this was easily achieved and we could now concentrate on creating an access and making the site a serviced plot. The access road was to run through an area of woodland so the first job was cutting down a number of trees. With the trees now cleared and stacked as future fire wood, we arranged for an excavator to form the access, clear the site and put in the services. This work commenced in 2015. The first job was to scrape off the top soil. One of the unexpected costs of self building can be how much an access can be to install. Our access is fairly long and we also need over 100 tree stumps cleared, soil/clay excavated and some form of hardcore put down. Although we are building on clay we also had access to hardcore about 100 meters away. A borrow pit and track was created with enable the hardcore to be quarried with the clay used to fill in the hole and eventually the turfs put back on top. This results in the ground being reinstated to the same condition. With the necessary rock extracted we could now complete the access. Organising services can take a while if these are coming long distances, crossing third party land and road crossings. Unfortunately we had all of these to contend with. Electricity was the hardest to achieve but this task was eventually overcome and a temporary supply was on site. Our water connection/telephone cable were far more straight forward. With the site levelled off and services ready for contractors our initial works were completed in 2015. For the next few years we continued to save money and completed a few small jobs such as installing a gate at the access. In 2017 we decided to rethink our design we were able to achieve a non material variation. In early 2018 we submitted our building warrant and arranged a self build mortgage. After nearly a decade we were now ready to start building!1 point

-

quick check and yes they do a unit that can take all TYPES OF HEAT INPUT INCLUDING PV https://www.google.com/search?q=solvismax+price&biw=1536&bih=754&tbm=isch&source=iu&ictx=1&fir=DcN8vJE9Hn3_PM%3A%2CiB1MWAiX8QQ81M%2C_&vet=1&usg=AI4_-kSEghvAnWVVKEJnQ7fbL0pDgLiYOw&sa=X&ved=2ahUKEwjSsfDr3eXhAhVkURUIHb2ABQgQ9QEwBHoECAkQBA#imgrc=K8ckQKoj-eldTM:&vet=11 point