Leaderboard

Popular Content

Showing content with the highest reputation on 01/30/19 in all areas

-

ROFL. I strongly suggest you wind your neck in a little there. Jeremy is just stating that concrete isn't always as perfect as you may like to think. Let's all play nicely shall we ?4 points

-

I fitted a pir sensor in the WC as I don't like pull cords, and I didn't have wall space for a switch outside. It works well, and in retrospect I might have put a couple more in other places. My mother-in-law did suffer a 'lights out' moment once, but to be fair, she had exceeded the allocated dwell time! ?3 points

-

She rarely gets 5 minutes to herself what with sorting kids and elderly parents. Maybe when the bathroom's done she can lock herself away with the Veet.3 points

-

Yep but through thick and thin you have kept going. You have made mistakes and got screwed over countless times but still you kept your chin up out of the muck and gutters. That's the secret, accept shit will happen and keep on going, celebrate each milestone and don't beat yourself up when it goes tits up. And don't be afraid to come on here and bare your soul, ask for help and try to figure out solutions. Go and read through as many of the blogs as you can and see it ain't an easy job being a project manager but with plenty of time and luck along the way it's definitely doable.3 points

-

Hi - take a look at my blog - From the photos down the bottom you should be able to see exactly what you have described above and this is the way forward. You may also be able to see the window manufacturers stub cill resting above our stone cills. Ours was a TF and as soon as it was ready, the windows went in from the inside.They protruded sufficiently to tie in with the battens which framed the opening, These battens are called fire stops which serve the same purpose as those red "socks" you will see in the photos too. I hope this helps.2 points

-

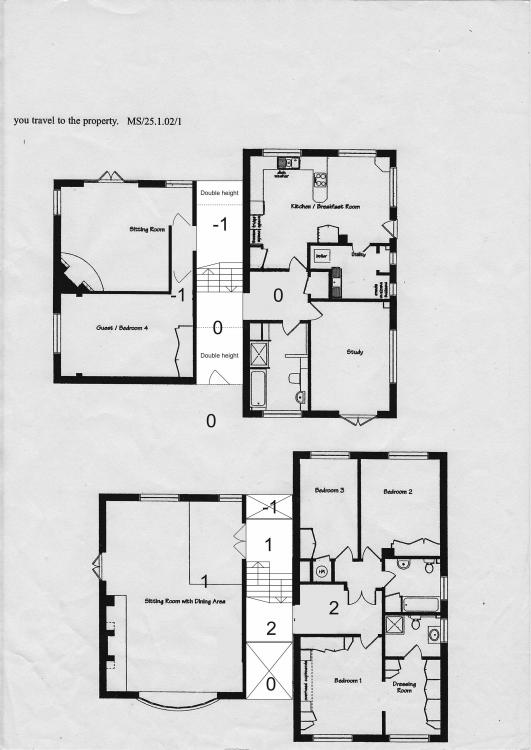

I have just looked at this from plan view. The idea below has a 2.1m wide circulation space extending from front to back with double height voids either end. The front door has been moved down to the same level as the kitchen. Stairs moved. Please note the arrows on the stairs always point UP. I haven't messed with the internal layout much.2 points

-

Split into two! That's certainly an option! But, there are lots of large 5 bed houses around here. We don't want to move any time soon and see this as an ongoing project. We don't need any more space, it's 2800 square feet and there are 2 adults, 2 children. The loft conversion may never happen for us but I'd like to design the potential into it rather than having to rethink in the future. Ferdinand, you have hit the nail on the head. The main reason for the new entrance/atrium is to allow light to transfer from front to back and through the house. All the spaces work well for us apart from the downstairs bathroom which could go and we could put a WC into the office. I don't want to go down the combined living space route. I did up our last place that way and it worked well but it was much smaller. It's just not needed here I think. The main issue is the light. There is no structure around the steam room - above that is the old entrance hallway so just ceiling and floor joists etc.. The house was built bespoke by a previous owner and had a sauna in there ... it's gone now.The EPC survey gave an E. It assumed no cavity wall insulation, but it actually does have. We've since replaced the boiler, fitted LED's and it's more like a B/C now I expect. Budget? I had estimates for the front entrance windows of 10-15k. I thought about the same again for the structural work. I'm very hands on with these things and did most of the work on my last place myself. If a new facade was required on the left I could budget for that. I have 100k to spend at the moment. I have a list of things we'd like in this order: Front sorted, rear extension to kitchen with large sliding windows, new garage, loft conversion. I'd do all internal fittings myself.2 points

-

we went with a similar mix- 140 of Frametherm 35, VC Foil Ultra, 40mm PIR, service void. As all the insulation arrived today, I've just sat with the calculator and totted up a guestimate of it's value and it's somewhere around the 6k mark.1 point

-

Just received the credit to my account, nothing to do with VAT reclaim process - give it a whirl! You don’t ask, you don’t get ?1 point

-

It's future proofed for putting a shower in at a later date, and the shower will go where a light switch would (unless I put a switch on the hinged side of the door...). TBH, now I've tried it, even if I had space for a switch I'd still go PIR sensor.1 point

-

Getting a mortgage on an existing house is not necessarily a given at a reasonable rate, no matter the equity if the only way of repaying is your new build. This was the route I took, There was plenty of equity but I had very little income so needed to roll the interest up until the original house was sold. I was only offered 70% loan to value, against their valuation which was 50k less than the Estate Agents valuation. Valuation fees, arrangement fees and 10 year insurance came to 5k and I was then rolling up 13%annual compound interest. Plus it was counted as a bridging loan so had it gone over a year there would have been more expense involved. Mine is a small and relatively low cost build, but in 9 months the interest amounted to 10k, (On 100k call down loan) so the whole thing cost 15k (that's 15% of my original build budget) . Luckily at this stage my sister decided to help me out and loaned me the money to repay and I don't want to think where I would be now if she hadn't, as that was in October, the loan was due to be paid by the end of November and the sale is not yet complete. Cost went at least 50% over budget, time scale more than doubled and I still haven't got the quality of house that I thought I would. I am not regretting doing the self build as I know I would have regretted it if I hadn't done it BUT if I had known then what I know now I wouldn't have. I totally admit my expectations that people would do what they were paid to do and general naivety about the whole project were a big part of the issue. 2018 has been by far the most stressful of my life. I am now comfortable in my new house and, so long as nothing else goes wrong, will in about 3 weeks be able to pay off everything I owe and still have a (very) few thou left over but self build is certainly a big learning curve and one that shouldn't be undertaken without lots of, hopefully unneeded, contingency.1 point

-

Awesome. Sounds very exciting. You are slightly ahead of me. Will watch with interest. And good luck!1 point

-

Well today brings a milestone. Firstly the arrival of a large truckload of various insulation types heralds the approach of internal warmth. and blockwork is complete. Having chimneys really plants the house, to me. the eagle-eyed amongst you will no doubt note the stack of PV waiting to go up, and the small patch of tile I've put on for a look-see. Finally. I climbed up to see the guys' handiwork on the chimneys and was truly touched to see this:1 point

-

Oh, its well out-of-date: I must update it. Thanks for spotting it. I've bought a plot, chosen my team and a TF supplier, and am just waiting for planners to give the thumbs up before starting everything.1 point

-

Well you've heard it here 10 times already but i'll reiterate...forget 20 quotes. It's more likely you'll need to put out to 20 co's to get 3 quotes back. Put down any idea that because you're building a whole house you've got sway with trades, what you're doing is just normal to them even if to you it's the biggest personal financial project of your life. I also think a 'do it when you like, but cheap' negotiating stance is an invitation to have rings run around you....they'll do it when they like anyway:) Man management in a corporate environment is of course a transferable skill...but do expect a very different kind of zoo. Good luck, you'll have fun...and a nervous breakdown maybe, but it'll be worth it.1 point

-

All I can say is that we are very happy with our Genvex Premium 1L MVHR, with it's built-in comfort cooling and heating. It does exactly what it says in the spec, and happily pumps cool air (at around 8 to 10 deg C) out of all the fresh air feed terminals when it's in cooling mode. As for electricity consumption, then at full power in cooling mode it draws between 400 and 500 watts. As cooling is only required when the sun is shining the running costs for us, with loads of PV on the roof are zero. However, if we didn't have PV then the Genvex would cost around £0.08 per hour to run, so not exactly expensive. I can only imagine that you were sold something defective, that failed to do what it was supposed to. That doesn't mean that all products of this type are as equally flawed, though.1 point

-

It's a thermal detail that isn't often picked up properly, AFAICS, but it is important. Window and door frames are the most thermally conductive parts of a window, so to minimise heat loss through them, and perhaps more importantly reduce the condensation risk, the minimum amount of frame needs to be exposed on the cold side. If there is insulation all around the edges of the frame, so that only the outer face that's visible is exposed to the colder environment outside, then that improves things a lot. If the frame projects out with no insulation around it, then the area of frame exposed to the cold side is greater (the outer face plus the area of the edge that projects outside the house insulation). When our windows were fitted I made sure they were set into the insulation layer, so the frames don't project out at all, as I was OK with having relatively deep reveals in order to get much better thermal performance from the doors and windows. If you choose to accept a deeper external reveal, then you need to close the cavity around the aperture with a firestop plus a batten to support render board, for a rendered finish. For a brick finish then the brickwork can be returned in to provide both the firestop and close the cavity externally An alternative, if you want the windows and doors to project out, with shallower reveals outside, is to fit them rather like an insulated Velux, with peripheral insulation so that the heat loss from the projecting edges of the frame is reduced. To do this probably means using fixing straps to secure the windows to the frame, then adding a suitable thickness of decent insulation all around the frame, within the cavity.1 point

-

If you want good thermal performance, then to minimise thermal bridging around the window frame it's essential that the frame be set into the insulation layer, and not project out into the cold area outside the insulation. Apart from the increased heat loss through what is already a thermally weak area, the window frame, there is also a condensation risk associated with having a cold window frame. If you do need to space windows out, then adding insulation around the edge of the frame, within the cavity, can mitigate thermal bridging a bit.1 point

-

I had the SIGA rep at my place today doing a demo on all the sealing tapes and membranes they sell you should be providing a weather proof tape to the outside and an air tight tape to the inside. Squirty foam just doesn’t cut it anymore and will make your triple glazed windows a complete waste of money if not sealed properly.1 point

-

I just done some on a project and I was surprised at how easy it was. We had 50x50 battens that are cut to the fit around the windows, they are then screwed onto the outside edge of window frame (so like a frame around the window) You then push the windows into the recess and the battens leave it sticking out by 50mm. You then screw through the battens to the outside of the timber frame. If you zoom in on the picture you will see what I mean. This will I’ll have a block skin on the outside of the kit so the windows will be recessed once the blockwork goes up1 point

-

1 point

-

I wish you were my wife. Were that from her you could replace the Exactly with Absolutely, the Right with Wrong and Both with Every1 point

-

I would be very wary of telling them they could do it whenever suits them but for that you want rock bottom prices, seems to me it would invite them to take it on, squeeze it in between jobs, like say ‘oh we’ve got a couple of days next week with nothing doing let’s get that one done , quick as we can cos there’s no money in it but it saves us being idle ‘then you’re inviting trouble, remember, the ground works, foundation and drains form a big part of the build (in my opinion) and if these aren’t done correctly it would only lead to more trouble along the line, I have no doubt you will be able to manage the build since you obviously have the time but it’s not always easy to get tradesmen to work in tandem with each other in fact in my experience they usually create problems out of the least thing and blame each other! we have done 3builds now and the first one 20 odd years ago we had no experience whatsoever, I still sometimes think to myself how the hell did we ever manage that and what made us think we could!1 point

-

I think it might be worth explaining the basic point of 3-phase. Say you're running a 6.9 kW device (say a heat pump) off a 230 V single phase supply then that'll draw 6900 W/230 V = 30 amps. That 30 amps will run through both the line and neutral wires incurring losses in both. You need two bits of wire into the house and to the heat pump each capable of carrying 30 amps so 60 amps worth of cable, in effect. If, on the other hand, you run that same heat pump off a 3-phase 230 V supply each phase will draw 2.3 kW so 10 amps each for which you'll need 3 line wires each capable of carrying 10 amps with the associated losses. However, if the power taken on each phase is exactly balanced then there'll be no current left to flow through the neutral; when one phase is pushing electrons into the neutral the other two phases will, between them, pull exactly the same number of electrons back out so, in principle, you don't been a neutral wire at all. In reality things might not be that well balanced so you will have a neutral but it only needs to deal with the worst case where you're taking the full amount on just one phase so it only needs to be a 10 amp wire. So, for three phase you'd need 3 x line wires and 1 x neutral wire each taking a maximum of 10 amps so a total of 40 amps worth of cable. Somewhat less than the 60 amps for single phase. In addition, in normal use the phases will be balanced to at least a certain extent so normally the current in the neutral will be smaller than that in the lines so losses will be less. This is all pretty marginal for most domestic situations, hence the controversy. Most likely you'd want domestic three phase because the DNO can only supply 80 amps single phase and you might, in some circumstances, want to draw more than 18 kW. Or, you want to feed in more than 3.68 kW without extra regulatory hassle. The basic requirement is that you can feed in 16 amps per phase, with single phase that's 3.68 kW, with three phase that's three times that.1 point

-

It's an indisputable fact that concrete structures can and do fail, and that many houses, commercial buildings and concrete bridges have had to be repaired or even replaced because of this. That's not scaremongering at all, it's just stating a plain fact. I wish I had taken photos of the Cornish Unit PRC house that I lived in around 40 years ago, as they would illustrate the point well (just do a web search, you will find mention of Cornish Unit concrete failures I'm sure, as they were pretty common). There's no difference in the inspection standards for structural timber between construction grading inspection and test and aircraft grading inspection and test. Both use the same techniques. Construction graded and aircraft graded timber will be assessed on the basis of species, density (often inferred from ring count), freedom from knots and shakes and strength. My local sawmill can supply really excellent timber, often locally grown, and every bit of timber I've bought from them has been first rate. Timber from reliable sources like this can't be compared to some of the poor quality stuff that is sold by the DIY sheds, it's like comparing chalk and cheese. The same goes for concrete. Get a good supplier, do the pour with experienced and competent people, at a time when the weather is within curing limits, and the result is likely to be very good. However, if any of those criteria are lacking, then there is a chance that the concrete may prematurely fail.1 point

-

Indeed, it's a balance. If you want a comfortable modern existence in a cold climate you're bound to do a certain amount of harm but it's worth thinking through where you'll get the most benefit, not just building out of whatever materials people in previous centuries felt happy with. I'm not advocating the use of concrete blocks in a house for heat storage. I'm saying that if you're going to use them to prop up the roof then putting them on the inside is better than putting them on the outside. Most houses have timber roofs which last long enough if the exterior is maintained. It's not a matter of the quality of the wood, it's a matter of sensible detailing and looking after the house.1 point

-

The problem is that I can't find any solid evidence to support the statement that you "can get good concrete - very easy". We have no way of knowing whether the concrete we are buying today is any better than the concrete that has been used to build structures that have been failing over the past few decades. We certainly know more about things like the placement of fabric within reinforced concrete, and more about the need to ensure voids are reduced by vibrating the mix, but the durability of concrete is still highly dependent on the mix being right, the climatic conditions at the time of the pour being within limits and most importantly, the skill of the people doing the pour. Get any of those wrong and there's a chance of premature failure. Also, you definitely can get good wood, there are well-established standards for structural timber. I owned a wooden aeroplane for a few years, that was built in the mid-1990s. That was made from very good timber, timber that, like structural construction timber, had been carefully graded and inspected. The fact that the DIY sheds and some builders merchants tend to sell a lot of really rubbish timber doesn't indicate that all modern timber is rubbish.1 point

-

The cheapest method is build the founds with blocks then fill with clean stone, put your insulation in and then cast your slab, with UFH pipes if your going that way. Beam and block floor shouldn't be used if you don't have do.1 point

-

OK with 3 phase you have 4 or 5 cables 3 live phases and on old systems a neutral + an earth --but as the neutral is really an earth -then modern things use only 4 wires each of the lives when paired with the nuetral give 240 vlots --approx so when you use all 3 lives and a nuetral on soemthing you get 440v approx you can split a 240 circuit from board by just using one phase+ neutral --so you could balance your load across the building by using the 3 phases for different circuits to pull even current long time ago you could save money by doing this --but I am told --don,t know for certain that it don,t matter anymore cos meters are tricky only reason for having 3 phase is to run big motors as they use less current for same load as single phase and there is a limit on size of single phase motor1 point

-

You're not actually bothering to read what I write, are you? Did you not note that I wrote (I've added emphasis in the quote to make it more obvious): There is good and bad in all types of construction, no matter what the material. Having experienced living in a concrete house that used to spall off lumps of the stuff whenever the weather got cold, and which was eventually condemned as being structurally unsound (along with several hundred other similar houses on the same estate), I know first hand that poor concrete construction is just as real as poor timber construction. If timber is kept dry then it lasts a very long time indeed, but sadly there have been far too many instances in the last few decades where construction companies have failed to recognise this.1 point

-

Having seen many wooden churches in southern Poland that were around 400 to 500 years old, as well as all the timber framed houses we have here in the UK that are around the same age, plus having lived in a concrete house that was built in the 1950's here (that ended up being demolished because of structural failure), I'm not convinced by that argument. Certainly very good concrete can last for hundreds of years, but we have lots of examples here, from houses through commercial buildings to things like motorway bridges that show that concrete can and does fail after just a few decades. We've also had examples of timber framed houses that have failed prematurely, notably the Barratt Homes fiasco in the 1970's, where they built houses with no understanding of the need to control interstitial condensation, and which rotted out inside a decade. A good timber building can easily last hundreds of years, there are many examples that prove this. Equally a good concrete building can last a very long time, but we have very few examples in the UK of long-lasting concrete houses, or any structure come to that. The Romans developed a form of concrete that we've only recently begun to understand. It doesn't use the same type of cement that we use in modern concrete, and is very different in terms of its longevity, and in particular, it's resistance to water and seawater.1 point

-

@Lift span, TWo more substantive posts to make on this, since I have been musing. This is several possible treatments around turning the Rantzen window into a two storey window with a vertical emphasis, and a flush entrance. Based on your statement that the house is big enough already I do not see the need for more space without a specific purpose, and we do not have an incontestable requirement. Yet. The entrance is patterned mainly to link it to the LHS via similarity to the windows, and the half and half division is treated as the line where the roofs meet. PErhaps your future roof room would be best in the bedroom wing, as it has NS facing gables for windows .. easier for PP at the front, as you could then have side facing obscured roof lights. Changing the existing without major building works will help the cost equation. I have not fully resolved the levels at the entrance, but I am tempted to treat the entrance at GF level, and the downstairs sitting room as a separate living area, and you go upstairs to the kitchen/dining sitting room which together count as your split level kitchen diner living space. THat can be changed by adjusting the entrance, but I think a single core set of stairs is much tidier and less discombobulating. I have not addressed external finishes. Here is your house in case anyone wants to play: TWo storey bay window under gutter. TWo storey bay proud of and slightly cut into roof. FLat window under gutter with S facing veranda with roof to help manage solar gain. I would personally go for that flat window one, as really major work is minimised and it is simplest, and it can be multistaged. A balcony above the veranda would be OK as S facing, or a 2 storey veranda if you want a dual purpose solar gain management idea which does something for you as well as for the heat. Ferdinand1 point

-

and concrete can out last wood by 10 fold at least --go to rome and see the 2000year old concrete there so long term the actual co2 etc is probaly less than building from wood ,which will be replaced many times . If you were building with green timber that was not processed + sourced on site then your argument would be more valid ,rather than kiln dried stuff which will probably have come from deepest russia or canada--cetratinly a long way cos most home grown wood is only good for chipboard /osb--which has lots of chemicals in glue and energy in in processing . any way these interior walls for thermal mass --are they dry built from rock ?-if not you have concrete there and your slab. you could always build a "cobhouse". LOL1 point

-

I used FreeCAD to create the model and .stl file. The cost of each of my hooks printed in nylon was 75p and they are 41.5mm long and solid.1 point

-

This article on Section 75 and possible issues is worth a read if planning on relying on this: https://www.moneysavingexpert.com/news/2017/04/revealed-section-75-credit-card-protection-may-fail-due-to-payment-processing-loophole---shoppers-beware/1 point

-

Just for info I went to Thingiverse and typed in "Dewalt"... https://www.thingiverse.com/search?q=dewalt&dwh=935c50e4a1c6da8 ...up came some battery adaptors other people have designed. This one... https://www.thingiverse.com/thing:1248463 ..is for a "Dewalt Lithium 20VMax to RYOBI One+ 18 volt Adapter" and is similar to both the blue and orange parts on your photo. I loaded it into Cura and it estimated something like 8.5 hours of print time.1 point

-

Using a periphery building as a warm up - probably at 30-50% more cost than anticipated - is a sure fire way to find out the hard way that you’ve got less budget than you really need, and spending it on something that you don’t really need. Look at the big stuff first - roof coming off is a game changer - running out of money half way through that is not a good place to be. Garage doesn’t get finished for 18 months..? What’s the issue .... Think priorities and work top down.1 point

-

If it works for you then that's OK, but it's worth bearing in mind why smart meters are being rolled out and why the energy companies are spending millions on promoting them. Smart meters won't save consumers money in the long term, that's not why they are being rolled out at all. The problem that smaller energy companies, in particular, and the government regulator, who wishes to promote a more level playing field for energy supply, has is that energy is sold wholesale on a 30 minute spot market, with the price varying widely from hour to hour. It can even go negative at off peak times, so generators have to pay suppliers in order to take their energy, as well as rising to close to, or above, the retail price, so suppliers lose money selling it to customers. At the moment, suppliers take that market risk. They try to guess what the wholesale spot market will do over the next 12 months or so and then set their tariffs so that they can make a profit. Unfortunately, with such a volatile market, and one that's been made more volatile with the increase in variable generation capacity (wind and PV) and the decrease in steady generation capacity (mainly nuclear), small suppliers often aren't able to stay in the market (plenty of evidence for small suppliers going bust, seven collapsed in the UK last year alone). The big suppliers may well have enough reserves to weather a bad spell in the market, hence the concern over unfairness. So, all the suppliers have been lobbying hard for years to try and get rid of the risk they carry in this volatile market and place that risk on consumers. Nothing particularly wrong with that, except the best way to do it is to introduce a means of being able to adjust tariffs every 30 minutes, so they track the wholesale price and then persuade consumers that this is being done for their benefit. The suppliers then carry no risk, and can just charge the wholesale price, plus their operating cost, plus their profit. It's a guaranteed profit scheme for suppliers. The problem comes when consumers want to try and compare prices. The only way to do that is to compare the average price, however, that's not very representative. For example, those who have electric storage heating and live in a cold part of the UK are pretty much fixed as to when they need energy, they can't just turn off their heating if the price rises for an hour to around 30p/ kWh (which it is predicted to peak at when the fully agile market is established). Most consumers won't have any way of being able to accurately predict their energy bill from one month to the next, as they will only know the price for any 30 minute slot after the event, or very shortly before. Tariffs like Agile and Go are really aimed to get users to fit smart meters, with the incentive of a tariff that, right now, may look attractive. However, once everyone is locked in to smart metering, then it will be near-impossible to make a judgement as to which provider gives best value, as that is bound to depend on trying to compare 30 minute prices against an exact pattern of energy use over a year. The suppliers know this; the pricing model will be more complex that that used by mobile phone providers, and that complexity isn't likely to result in best value for the customer. The other problem with smart meters is related to data security. The data standards used are far from robust, and there are clearly some privacy concerns over that. For example, think how useful it could be if a household's energy consumption pattern changes, such that someone with ill intent could be fairly confident that the house was empty. That's a pretty trivial example, but it illustrates just one potential vulnerability in the data handling system for smart metering.1 point

-

1 point

-

1 point

-

The two sides of the house seem so disjointed that I would be tempted to split them into a pair of semis and either sell on or live in one half and rent the other.1 point

-

Ive never been so excited about another mans bathroom before....1 point

-

Was going to do the deck lights...didn't: Didn't realise the front plate needed a bigger hole! Out with the tile file: A horseshoe of silicone; All baby wiped off. Stuck the riser thingy up too: And put the flush plate on as well. YES I know it's off centre. Realised it would be pretty early on during tiling.1 point

-

so from the top down we have 22mm chipboard then 50mm of rockwool RWA45 sound insulation & then I've put in 100mm of sound reducing insulation roll (given to me free of charge) & then 15mm PB. Inside the metal web joists also filled with some of this roll. Missus has been up stairs and created some noise and even without carpet the sound reduction is pretty impressive. Double boarding with 12.5mm would be another way of really cutting down the sound. We will make this decision just before skimming - easy enough to throw another layer on if we want. We've got plenty of height downstairs. I like a quiet house.1 point

-

Not building related as such but there are a number of tech folk on here who may wish to refresh their skills (or people who might want to learn). Udemy are running a few free online courses currently. They seem to be rolling out different ones daily so best to sign up asap to get the course for free as I imagine they will be time limited offers. I'm not recommending them as I haven't looked at any of them yet but might be worth signing up while they are free if any grab your interest. If I find any others later I will add them to this post. The Complete HTML 5 Course - use code FREEHTML5 Photoshop CC for Beginners with CC 2019 Updates - Use code FREEFORFRIENDS2018 Scrum Certification Prep +Scrum Master+ Agile Scrum Training - Use code PWRSCRMFREE Data Analysis with Pandas and Python - Use code APRILMAGIC Excel VBA Programming - The Complete Guide - Use code GAUNTLET SQL Masterclass: SQL for Data Analytics - Use code SQLMASTERCLASS Total Beginners' Guide: How to use an Android Smartphone - no code needed Microsoft Excel Masterclass: Complete and Concise - Use code HAPPYNEWYEAR The Complete Front-End Web Development Course! - Use code FBFREE18 The Complete C Programming Tutorial - Use code ALLFREEE1 point

-

Chucked the lights in. I'll sleep on it. Then SWMBO will decide!1 point