Leaderboard

Popular Content

Showing content with the highest reputation on 02/25/18 in all areas

-

2 points

-

My bollockometer came with a little chart that showed the accuracy at different distances and how large the sample area is.2 points

-

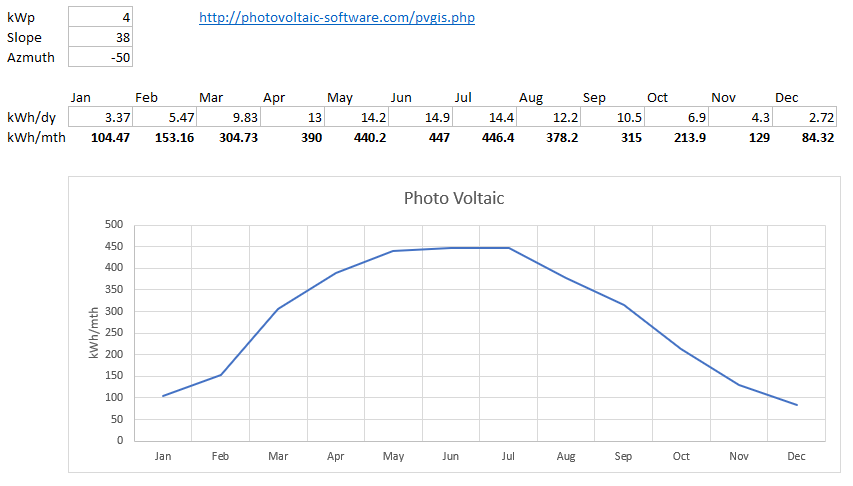

@JSHarris already covered this, I was slow on the ball! I used the online PVGIS tool (recommended to me via the forum) to calculate the potential PV performance for our build in our lite version of a PHPP to review whether it was financially viable. Slope and Azmuth you can calculate from your plans, and the kWp of the system is dependent on how many panels you can fit on the roof, i.e. the roof area, and the kW performance of each panel. Plug in your location, and that gives an estimated kWh/day.2 points

-

2 points

-

2 points

-

My kids used to say, "Daddy, isn't it true that its only the really old animals that are about to die that we eat?" and I'd reply "Yes, of course"... There id say "You enjoying your lamb dinner?" and 4 smiling faces would spin around and say..."More please! And dont forget the mint sauce"2 points

-

2 points

-

I’m doing a “hybrid” install as like @joe90 I picked up a decent Mitsubishi/Kingspan unit for less than £60 in an auction and it was brand new. So far I have the terminals and the ducts in back to the location the unit will be placed - I will most likely build a silencer as part of the distribution system. I used a spreadsheet to work out the duct velocities and found that I could drop to 55/63 standard electrical duct for the distribution with no real issues. Terminal plenum are made of off the shelf uPVC solvent weld fittings and the terminals themselves are from Toolstation ..! Very nice white steel two part terminal with a galvanised steel flange that has been glued / plastered into the wall or ceiling as they fit with about 2mm tolerance into a piece of soil pipe. You can just see this one in the top corner. They have a foam gasket on the outer part and are a 1/6th turn to fit them - you can see the coarse thread in the image on the website. There are no sharp edges to the valve itself and they seem well made. There are two where we have them wall mounted, the remainder are ceiling mounted. I may also fit carbon foam filters into the extracts in the kitchen - there are two - so that it keeps grease out of the ducts. Total spend so far is £150 on ducts, £150 on 12 terminals and parts (that’s a solvent cap, solvent stub branch, bracket and offcuts of pipe) £60 on the unit and the most expensive was £80 on the proper Mitsubishi controller ..! Another £100 should see me done including filters and externals.2 points

-

(I know, I know...the photos didn't paste in and I will have to do them one at a time...I'll get 'round to it I promise...managed the first dozen, more to come) Part One-Wind And Watertight For Under £6k I'm new to blogging and probably have nothing much in terms of knowledge to impart but some of you might be interested in building on a low budget so here goes. After many years on the waiting list we got offered a plot on the famous West Highland Way about 3 miles north of the starting point in Milngavie, just north of Glasgow. For £4k we get a 20 year ground lease around 100ft square, ground rent is £90 per month and of course membership of the community group that collectively owns the whole estate. See more about Carbeth Hutters here http://www.carbethhu...o.uk/index.html we needed planning permission and Carbeth is itself a conservation area so we kept to the hutters spirit of ingenuity and self-everything and splashed out on some graph paper from the local stationers. We made several models from foam board (thanks JS Harris) and finally paid the fee and waited... I'll add the plans when I find them but permission was granted and we stated work digging the footings by hand. Oh I should say at this point so far we have not paid for one trades person nor used any machines other than a Makita saw and drill and a Hitachi gas nail gun. Many thanks to Dominic Stevens and this website for teaching me all I needed to know about the mysteries of marking out http://www.irishvernacular.com/ In May we braved the rain and pressed on building 14 (dodgy bricklaying) piers one big one using cobble stones the rest using concrete blocks from a reclaimed mono bloc driveway. Our near £2500 load of timber arrived and it was time to see if the 'water in a tube' method of levelling the piers was accurate or not...first big confidence builder-it was bang on level across a 4m span I really wish I had bought OSB flooring as the chipboard got soaked a dozen times...its fine now but we have a few swollen joints that will need attention before final floor goes down. Lots of wet days and rain dripping of noses but a nail gun is a great stress buster for us Social Work types and the wall panels and trusses were complete...time for a big hut raising weekend! The June weather was kind and we got a lot of work done but the tarps had to go back on as the floor was still getting soaked... Magic, frame complete Roof is almost there and again we had 8 volunteers over the weekend...including schoolboy nephews who kept wandering off with tools! Then end of June saw the EPDM roof being stuck on with the stickiest of glues but close to water proof at last. On the odd evening we managed to get the windows in... Got some nice doors from Gumtree for £40 so in they go and by the end of June we are almost there Insulation and building paper on Oh and Gumtree found us some kitchen bargains so shipped then up as its nice and dry inside now *smiley face* Cladding And Lighting Weather was sh#t all July so had to bash on through the rain... Sparrow Fart recommended the Hitachi nail gun and as I'm on my fourth box that's 7000 nails so far! 90% Finished...90% To Go... Nearly there...hearth and fire needed to go in as it was getting too cold to work... Got a reclaimed dance floor 57m for £250 so that went down too. Finished off the ceiling joins with some 5mm ply, looks okay. Finally got the dry toilet finished but not *commissioned* it yet. Put some furnishings in for a trial run. Just some plumbing, wiring and joinery to go. Oh and the view from daughters window... Diy Plans-Graph Paper And Pencil I am putting these images up simply to show that you do not have to employ professional help to submit planning applications. For most of you serious self builders designing the house of your dreams I suspect that this will be the only way to go but my little project is different from the norm in many ways. Firstly Stirling Council (in fact the single planning assistant that deals with the Carbeth community huts) is hugely helpful and happy to talk on the phone and comment via email. Secondly reading through previous applications I noticed that some drawn on foolscap (with imperial measurements) passed first time and the more professional architect drawn submissions had lengthy correspondence in the file. I went with the spirit of the old hutters and splashed out on some graph paper and a sharp pencil. I kept what I could vague so as to allow a bit of flexibility as the build progressed. Eight weeks to the day after submission we got a green light with four simple conditions. Having read some of your experiences out there I feel your pain and hope that ion the future this minefield of a system can be improved and made more consistent…I’m not holding my breath though… Attached Files Planning drawings 1-2.pdf (2.12MB) downloads: 75 Planning drawings 3-4.pdf (2.14MB) downloads: 29 Planning drawing 5.pdf (1.05MB) downloads: 26 Carbeth site plan hut no 3 Jan 15.pdf (254.28K) downloads: 28 Interior Fit Out And Decoration The low tech approach continues as does the re-use and recycle theme. Bought a load of Michelin road maps from the charity shop to make my feature wall background and topped then off with a few nice ones I picked up in Poland during the summer. Probably spent about 20 quid in all. Went to the local mental health wood recycling project (boy, they are not cheap!) and spend 15 quid on an old scaffolding board to make this kitchen unit. Might add some hooks underneath and a couple of shelves on the map wall to complete this corner. I might have mentioned before that around my office Monday is the day that the Council bin lorries come around for bulk uplift. The area is all tenement flats and there is no room for bulk trash in the back court so the local arrangement is you put it on a street corner before each Monday morning. It does make for an Aladdin's cave of goodies and there is a fair bit of 'help yourself' going on before the bin lorry arrives. in fact plenty of stuff is labelled, like a TV with remote control taped and a sign 'saying perfect working order'. Anyhow I helped myself to this worktop and slotted it in next to the beech free standing units from Gumtree to make a little sink unit. Looks okay I think...the rest of the worktop was cut up and kept the wood burner going to keep us warm during the freezing weather outside. Dry Toilet And No Smell Whatsoever Apologies for the pic of the loo, warts and all so to speak... This is the 'seperate' plastic toilet from Sweden that has a front funnel and back void. The thinking is to seperate the solid and liquid waste as it is the combination Of both together that causes the smells we don't like. Urine runs to a soak away and the solids and toilet paper (and sawdust which helps the drying process and Erm...helps the appearance should you peer into the pit!)end up in the bucket below. There is a small fan running constantly which you can just see on the floor behind the urine waste tube. The fan is powered from our 12v battery and draws next to no power at around 0.1 amps. This provides an airflow which removes odours and aids the drying process for the solid waste. Once the bucket is full it can be sealed with a tight fitting lid and left for 18 months when it will be safe to use as compost. Some folk toss it on the fire but not sure I fancy that job. Still needs a lick of paint but all in all very pleased this all works as promised in the literature. As the blog title says there is no smell at all and its really a pleasant smallest room. Balcony, Wood Store, Somewhere Nice To Sit Decided simple was best and to crack on with the decking out front. Rescued some fallen trees from nearby and rested them against a quickly assembled frame of 6*2 treated joists. This gave us a nice deck to work on the roof from... Always keep a tidy site Ebuilders...you don't want a wayward screw sticking into the foot of one of you volunteer helpers who come to play with trainers on! Bit of good luck, we had one 4.8 length of decking left over so fashioned up three nice steps to the front door. Lucky for us 800mm wide was just right. Finishing Touches If you wait long enough, what you want will come along in Gumtree. Seller said they were £100 per metre and I can believe that. 4m of them in the back of the car and the suspension was riding low! Anyhow, had no confidence in grouting these the normal way so borrowed a piping bag from SWMBO and took my time squeezing it into each gap so it was just proud. Ran a pencil around the gaps and hey ho it looks great. Now just some stove paint to buy and a few dozen more jobs before its finished... Exterior views1 point

-

Hi everyone, I recently posted a topic regarding a survey I am currently undertaking for my Planning Masters degree, and I've been bowled over by the responses I have got so far on this forum. This is a polite request asking to see whether anymore members would be willing to fill out my short survey. I'm specifically looking for more insights from people who have gone down the custom build or group build route. The link for the survey is below: https://docs.google.com/forms/d/e/1FAIpQLSezNby01KGReNIszG6zYr3kM8kDJgW9sRP4shYUw5uyYUTphw/viewform?usp=sf_link I also promised I would share the results as they came though periodically. As I don't want to bias any further responses, I'd rather not make the results public, but am more that willing to share the results with anyone who is interested by email or PM. I have also surveyed Local Authorities for their views, and will share these results as they come through too. Many thanks and I look forward to seeing your responses.1 point

-

1 point

-

No it is actually a brand of chocolate which you melt onto the pipe and you get a perfect reading. NOT1 point

-

apply some black magic marker or the like to the pipe (or the shiny PHE) first, as clean copper doesn't give a good reading.1 point

-

1 point

-

Doesn't seem to on ours. IIRC there is something in the blurb about the pleated filters that says they are made from a hydrophobic material, so the thing tends to repel moisture. Edited to add: I've just checked and this is the case, plus the filter on that side is a G4, presumably because all it needs to trap is house dust1 point

-

1 point

-

Sorry quoted the England regs. Missed you are in Scotland. It seems that a short and free conversation with your local PV installer on options / costs / returns might be worth it, at least you will know. As per @JSHarris, PVGIS is a great tool.1 point

-

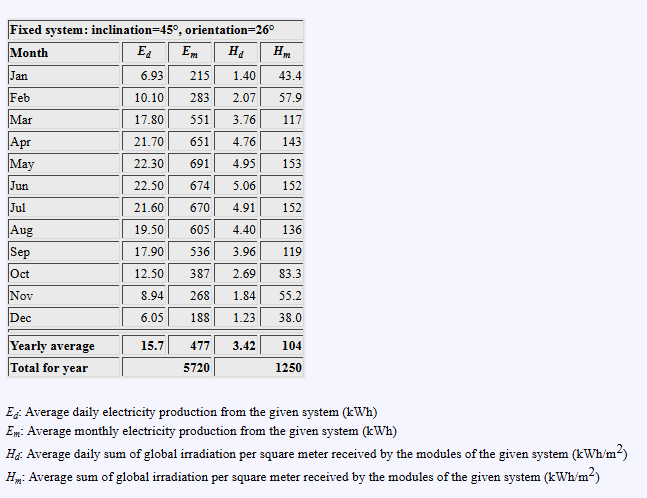

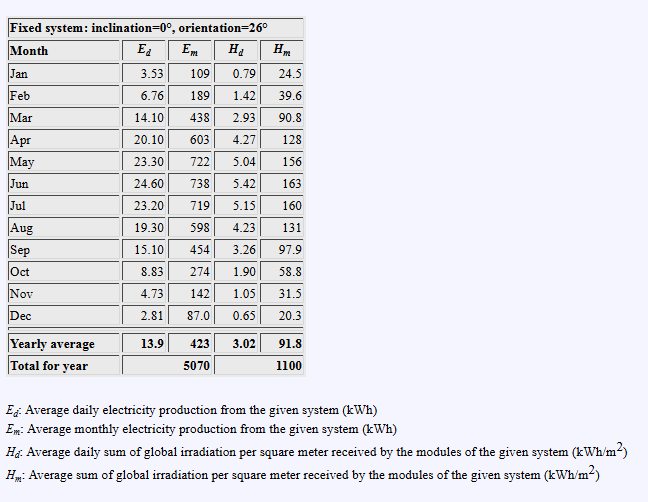

It's easy enough to work out using PVGIS: http://re.jrc.ec.europa.eu/pvgis/apps4/pvest.php?lang=en&map=europe As an example, our 6.25 kWp array that is angled at 45 deg and faces 206 deg (26 deg W of S) has a PVGIS predicted annual output of 5720 kWh The same array at the same location, but horizontal, with no shading, gives a PVGIS predicted annual output of 5070 kWh. Not a massive difference really, but the flat orientation has a lower output in the winter months and a slightly higher output in the summer months:1 point

-

Not trying to convince you re PV (in my view, the case is diminished if you cannot use the generated power effectively, and an ASHP is a part of that usage), however PV is permitted development even in conservation areas provided panels are not fronting a highway. https://www.planningportal.co.uk/info/200130/common_projects/51/solar_panels/21 point

-

Intersting, but that would clearly just leave the OP short, or out of DHW..... plus as per my last, you do NOT want the boiler modulating all winter to follow the ufh demand as you'll be way out of condensing range. You need to do the maths. Guessing isn't as good as finding out it IS worth doing. Remember you said this is a life property so thats hopefully a long time and a lot of grid gas and electricity to buy, possibly into retirement. Could you not just ring the planners and ask them outright?1 point

-

I thought I had this all sorted out!! I am so confused now Do I really need to read up about Thermal stores again? Nooooooo1 point

-

I think I suggested this before, but submarines used to have a timed shower valve that would sort this problem out. You pressed a button and got just enough water to get wet before it shut off. You then lathered up with a flannel, then pressed the button again and rinsed as fast as you could to get all the soap off before the shower shut off again. Pressing the button again did nothing, you only got two shots of water for each shower.......................1 point

-

This is where i cause murders, because I would put a much bigger boiler in, a 300L TS and do away with the buffer tank. Your enemies here are your expected DHW needs, eg it'll likely be all in the morning, a bit thorough the day, and another load in the evenings. If theres 4 of you then I would suggest the bathing may well be back-to-back and even simultaneously at the peak Having no PV in a "for life" property seems a bit counter productive to me, have you had that as a planning condition or just discounted it because of the cost ? Sunshine will remain free, gas will rise continuously. Id seriously rethink that approach as a zero-renewable solution isn't ideal imo. You dont want the boiler to modulate down as far as the ufh would need as you'd then be outside of the condensing range and your efficiencies would plummet. The TS would be set to sit at around 65-70oC, return set to sit around 50-55oC and thats achieved by pulsing heat in in chunks rather than trickle charing as its consumed.1 point

-

This is what the filters look like in ours: They are a tight fit into a pair of channels top and bottom, with a neoprene seal at either end to make sure nothing gets past the filter.1 point

-

1 point

-

1 point

-

1 point

-

I went with. Local steel stockholder, I told the they needed to deliver using a vehicle with a crane (Hyab), no problem, they came with a truck mounted crane that could lift 9 tonnes, a real monster of a thing at no extra cost.1 point

-

I think most of it is imported now In my case it had to be hot dipped galvanised Which nearly always has to be sent off Two lots of carriage I found a local company that sends off all of there steel So the cost was much less If you are struggling for a way to offload You could contact a steel fabricator who would supply and fit your steel for not a great deal more If you use a builders merchants They will simply contact a steel supplier and add there bit on Tge advantage of this would be that they could bring it on a grab wagon and then can offload it for you Ive used both options in the past1 point

-

Only takes me minutes to walk to MacSalvers, everything ever needed for the home and heart, and guerilla warfare.1 point

-

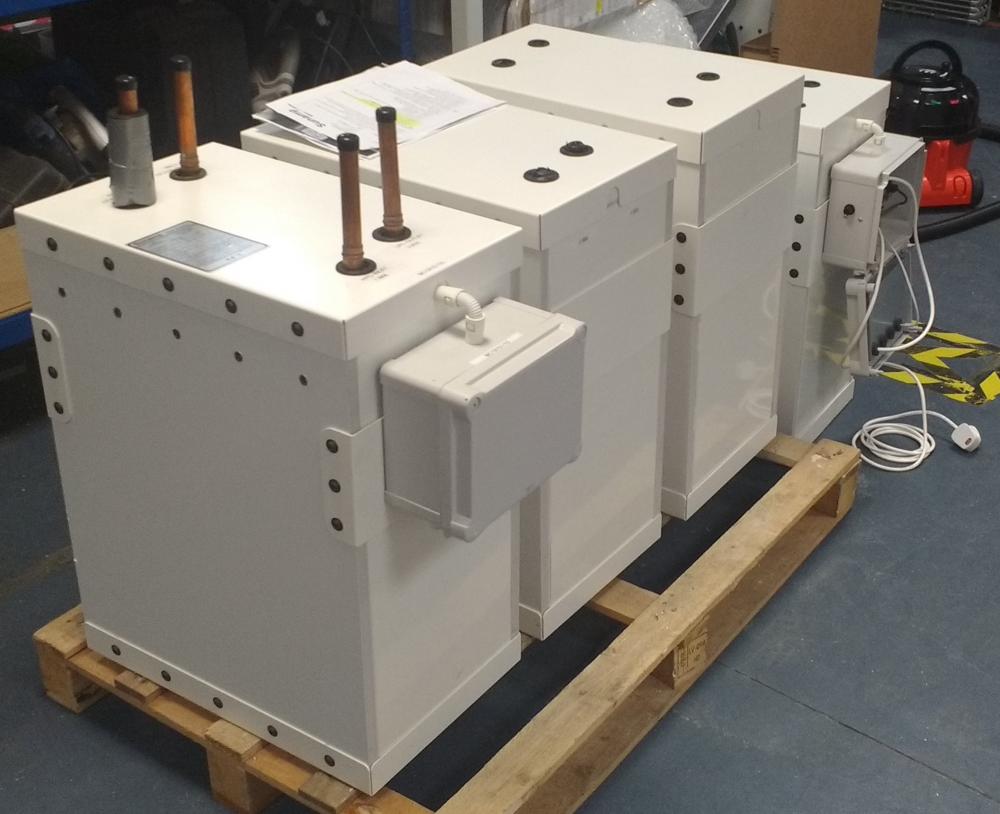

There are two different units,the Sunamp PV, which has a built in circulating pump and water heater to heat the batteries and the Sunamp Stack (and variations of it) that just have the heat batteries and some plumbing and control equipment, so they can be heated by hot water.1 point

-

Hilliard designed the slab, and these people designed and put the ground improvement columns in here is the blog post about it. The company were very particular about our soil profile, in addition to our separately commissioned report, they got me to dig three trial pits, then their engineer jumped in and grabbed a few handfuls from the bottom of the hole to make absolutely sure . And I was like a girls blouse about the process.... of putting the piles (ground improvement columns) in. Mercifully, it's unbelievably quick. Cost £6500 for 64 piles; time 3 days and four meetings. I visited a site where the company were working to have a look at the process. I know I've said it before, but it's unbelievably fast.1 point

-

When we lived in Dumfries and Galloway we either drove around 60 miles to Ayr to do a "big shop" or drove 60 miles to Dumfries. Most of the time it was quicker to get the Seacat over to Belfast and shop there...........1 point

-

Caley Sheet Metal in Inverness would be worth a call, obviously I'd speak to our local BMs (Jewson and Rembrand) too. Haulage from Inverness via Skye Express but you'd need some way of offloading at your end. If you want to save a few quid, a long trailer and a squad to lift it off at your end? That's how I did quite a bit of my timber.1 point

-

1 point

-

Keep the TripleX cleaner- will be good to clean the solar system with ... And the other @Nickfromwales can have in his pot noodle ...1 point

-

There's deffo nowt lurking behind the TS anywhere, either furry creatures or otherwise . I looked and there was a fire extinguisher, 2 bottles of that triple X stuff and shit loads of dust. No extra / missed components.1 point

-

If it’s going to be on show is there any way you can get it swapped for a glulam beam ..??1 point

-

Overheard in Lidl: "Brooklyn, which flavour Pot Noodle for tea, blue or green?"1 point

-

Depends where the steel is going - what is it supporting ..? Most of the steel cost is in the shipping so get it as close as you can as it’s pointless paying to ship it 200 miles.1 point

-

Steel is very cheap at the moment Try several steel suppliers Quote can vary by as much as 100 %1 point

-

Steel stockholder will be cheaper but you will need 3 or 4 strong lads to get it unloaded as it will be 115kg and unwieldy. Benefit of a merchant is that they will have a hiab to unload it. You may also find if you shop around that they can pretty much match any price anyway.1 point

-

1 point

-

Not quite so good for those of us English living / working in Scotland tho! Bollox, that settles it, I'm working from home on Monday (and Tuesday, and Wednesday ........ ).1 point

-

1 point

-

1 point

-

1 point

-

Following on from this thread Iv decided to drag this update back to the correct thread as it is barely about the bathroom. Either way the news hot off the press is we have just finished installing the UFH pipes ?, i still need to test them but the actual laying is complete. Also in the mean time when either I was alone or waiting on deliveries I have installed just over half of the frame therm 32 upstairs and celotexed between the rafters above where my walls are ( the PITA ones to fit.) next job is to get all the mesh up on the little concrete spacers. Box off the shower area. Get the bco out on Monday and look to pour the floor next saturday ? here are some pictures. If I pull my finger out I’ll have a video up by the end of the weekend.1 point

-

Hi Crofter, If you do have a wifi signal (maybe next door's?) then I can recommend the Sonoff TH16 https://www.itead.cc/sonoff-th.html wireless switching from phone, timer, temperature or humidity sensor, it is keenly priced with a nice free app that's easy to program. Two models available TH10 (10 Amps) or TH16 (16 Amps) Scenes can also be set up so setting up a local "IFTTT". If WiFi is lost the controller will still carry on as the program is stored in non-volatile memory. Should you want IFTTT from another operation ie weather control then i would recommend https://ifttt.com/ and set yourself up a free account. Itead https://www.itead.cc/ manufacture lots of other control gear in the Sonoff range - all good value. Kind regards AndyT.1 point

-

1 point

.thumb.jpg.84720b9262bdfdd639b2257471fce9e7.jpg)