Leaderboard

Popular Content

Showing content with the highest reputation on 12/19/24 in all areas

-

Our certificate was emailed over today , feels like another milestone on the build, despite the fact this will be our second Xmas in the house officially we have(now) completed .4 points

-

That fixes humidity, but not the CO2 issue you will have. You NEED ventilation. Your living environment will be bad for your health. Sorry I am going to very blunt - Airtight without ventilation is not a good or smart move. Add a couple of dMEV fans one in kitchen and one in bathroom(s). You then need to allow air in somewhere.3 points

-

MCALPINE TUNDISH 19/23MM X 19/23MM (5684V) (9) Write a reviewAsk a Question Clear non-return valve manufactured in polypropylene with 19 / 23mm universal compression connections. Prevents backflow in overflow pipes. Valve opens with the weight of the liquid, allowing it to flow through and then closes once the liquid has passed. Mechanical Non-Return Valve For Use in Vertical Position2 points

-

Not crazy about this. You're sandwiching layers of very low permeability. AKA foil faced PIR and the VCL. Yes in my preferred flat roof makeup with ventilation above the insulation. Any cheap breather/felt will do to throw any drips off the PIR.2 points

-

OK so we got permission today to export a max of 6kW on a single phase, all we asked for - so good news. When I get time I will post everything I sent them, suitably redacted, to help others contemplating this route. Although ours is somewhat specific to UK power networks.2 points

-

It's not just the VAT. I've undertaken several deep renovations myself, as well as having managed & priced them commercially, and they always turns out to be more expensive than rebuilding would have been - unless you're doing much of the work & discounting the cost of your labour. In addition to strip-out costs, many things just take more time and/or cost more. For example, building a doorway into a new internal wall is more-or-less 'free' - the extra costs are roughly balanced out by saving 1.5m² of blockwork. On the other hand, knocking a hole through an existing wall, well that's a couple of days work + additional materials. Then there are things you find that you didn't expect that need fixing - walls, floors & ceilings out of level; botched DIY; sagging rafters; dry-rot; lead water mains; cracked sewers, whatever - which also takes more time to fix than fitting from new. And making an old house properly airtight - which is highly recommended - is almost always more complex because it wasn't considered as part of the original design. There are good reasons for not demolishing. Maybe you just want to tart it up & flip it. Maybe you need to live in it because you have nowhere else and a caravan is out. Maybe the building has a particular heritage value (whether listed or not). Or, as with my current project, maybe it's an apartment - which kind of rules out demolition! But if you do decide to renovate then do make sure that includes a thermal upgrade to at least Building Regs standards. Better than that if you're concerned about future energy costs and / the future additional value that it's likely to provide.2 points

-

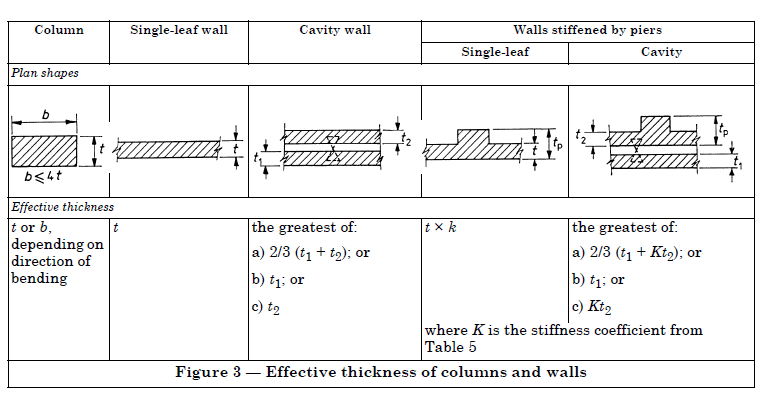

Good advice. In a standard cavity wall (say 50-75mm cavity) the two leaves act together. When doing calculations we derive an effective thickness of the wall. A bit like this bit from the the BS code. But the strength of the wall as @Iceverge say rapidly decreases exponentially the thinner the effective thickness. There are other kinds of masonry walls. Solid walls are say built with English Garden bond. These you can't really take down the inner skin in any practical way. There is a wall called a collar jointed wall. Here the cavity is no more than 25mm and fully filled with mortar. One key thing here (collar wall) is that the wall ties are much thicker and more robust. Ancon do a wall tie for collar jointed walls. A collar wall tied with the right ties acts like a solid wall so you get more bang for your buck. It's a good idea to value you time. £20.00 per hour seems reasonable. That's £160 a day. A trade rate up near Glasgow can vary from say £100-120 a day for an inexperienced labourer up to say 220 - 250 a day for a good experienced joiner( chippie)... more for a spark and techy folk. Now if that is all through the books and you are doing an extension there may be vat and an extra contractor profit / overheads to go on top of that. When you look at it this way it can be good or bad! If your time spent on site is doing some work then you win a watch. You efforts are tax free and not subject to contractor profit for example. Any time spent keeping an eye on the builder is still worth while as it can head off disputes and extra claims for cost later on. It can help keep the quality of workmanship up too.2 points

-

A warm hello Alot of my searching and reverse engineering for answers often brings me here, I've noticed alot of ideas get debated here, many other sources of information only entertain doing things "the done way" I red a fantastic post on here recently about using an indirect coil on a cylinder to heat an UFH loop, and the answers provided were very constructive and interesting. There was very good insight not just "no, thats a terrible idea" which makes a very refreshing change. I have to admit, I am abit of an imposter, I am not in a bricks and mortar property, but a liveaboard 60ft narrow boat. Alot of the boat is being built with the same knowledge applied, at least towards insulation, heating and electrics. Very recently I have reverse engineered the basic principle of a thermal store, and installed one into the boat. I will try to help others aswel where I can, I have previous employment in Paint spraying and Plumbing, unfortunately the latter tends to only be common domestic and maintenance areas, rather than all out heating engineering (annoyingly) I've had to self teach myself that having left the occupation sometime ago. I have registered because I am abit stuck when it comes to choosing my wet underfloor heating method and hoping to find some answers or ideas, back when I did my plumbing apprenticeship, underfloor heating was extremely rare. It does exist on boats, but so far I've only found one mentioned, it was apparently very successful so it seems achievable, but I need to get my head around some basic principles first, and the knowledge is obviously fluently applied to houses. Thanks for reading and look forward to contributing1 point

-

Slightly concerned about the amount of insulation you've put into every void inside the cabin space to lift the temperature when your diesel tanks are below or just on the waterline getting chilled with the outside temperature. This will cause excess condensation to your tank's and even more water in your fuel. I know or hope you've got a water separator in-line, but it won't help with the rapid increase in contamination of your fuel in your tank's. So by curing one issue you could be creating another for your self. Please don't install a hybrid unit over the top of your gearbox / final drive as it causes a major strip down just to change a control cable.!!! Back ground. Factory marine technician and a few year's working for river canal rescue when I got bored after taking early retirement.1 point

-

1 point

-

1 point

-

Well done The final milestone You also answered a vat question that I asked earlier Does it matter how long your in before making the vat claim NO1 point

-

Well done. The final stages are seeming to take an age on mine. We will get there by year 21 point

-

Hi, After a year of struggling to find the right property and a purchasing falling through, we are looking at options for self build / conversions. We have equestrian requirements, so are looking for larger plots. I have a family member who has done multiple self builds, but I am hoping this forum is a, good set of advice, especially around more eco homes1 point

-

1 point

-

1 point

-

Brilliant - well done, no comes the VAT reclaim, the rerating by the Local Authority and lifetime of increasingly minor snagging!1 point

-

Hello GTM_88 I've lived aboard boats - usually ex-MFVs - in the 1970s. The only way I (we) found to keep things 'straight' was to throw masses of heat at the problem, and have a similarly massive through-put of air. That way books didn't go mouldy, and shoe leather retained a passably polished sheen. Hence the several tonnes of coal in the bilges, and two iron stoves. A Webasto diesel heater in the Dog House helped too. Wimmin : all - each and every one - who came aboard for any length of time always complained about the draught. One way of dealing with CO and CO2. Nowt to be done about the ducks hammering the weed off the waterline though.1 point

-

Will be short term let, probably AirBNB so worst case it will be out for a weekend. I go there weekly so not too worried about keeping batteries charged1 point

-

I have a Greenwood CV2 dMEV fan in a summer house, I had to pull the cover off to see if it was running they make so little noise. Would pull about a 100th of you humidifier electric.1 point

-

I did consider this but we're thinking of possibly renting out this house and I've got to be honest, the wife struggles with my home automation, let alone guests1 point

-

Looks lovely but pretty pricey. I can pick up Drayton TRVs on ebay usually for about £27. £90 a pop per rad is going to bankrupt me. Liking the Home Assistant integration though1 point

-

Since CO2 is heavier than air, fatalities from asphyxiation have occurred when, at high concentrations, it has entered confined spaces such as tanks, sumps or cellars and displaced Oxygen. (Thinking outside the box…) is it worth a trickle fan extracting air (co2) from floor level where excessive co2 will be highest and incoming (trickle vents) at ceiling/window level 🤷♂️1 point

-

Very much so, the trouble is I've foiled the entire boat effectively sealing it, it's basically air tight, so Inturn moisture can't escape, I have a meaco 25L dehumidifier which runs from a 48v battery bank. I was looking at installing a MVHR but I decided I couldn't be bothered with the amount of work adding even more time. I'm hoping it's less of an issue in regards to condensation/mould though, because I don't have any surfaces inside that are cold enough for moisture to condense onto, every metal surface is insulated with spray foam insulation with foil insulation over it. in theory moisture in the air can't cool and create excessive moisture build up. Its taken ages to DIY apply three rounds of spray foam insulation messing around with a spray foam insulation kit and heated blankets to warm the bottles. The thinest being about 45mm and I think the walls have ended up being roughly 70mm and it has double glazed windows. It does make a huge difference though when inside is very very warm and you leave a window open, the rising warm air pulls alot of moisture with it. This was another thing that got me onto underfloor heating though was the hope it irons out the rises and falls in temperature and (fingers crossed) means the internal temperature doesn't drop like a brick at times. I've not got gas onboard either so I'm not putting moisture into the air using a gas hob.1 point

-

I do have a timber cradle under it tbf but it's under the main bowl, its coming away from the worktop where the half bowl is as it's shallower, once I've redone it ill put someting in to support that as well.1 point

-

I looked at using adhesive for ours, but when I thought of the weight of a double sink full of water I decided to fix it mechanically.1 point

-

HepvO can be installed vertically or horizontally, or any angle in-between. When installing horizontally a minimum allowable slope of 1/8” (3.175mm) per foot (30.48cm) must be maintained to ensure good drainage. This can be achieved by using the HepvO Angled Adapter supplied in the HepvO kit.1 point

-

1 point

-

Well in a house built in the 1850s, beggars can't be choosers. I'm reasonably happy with the improvements made so far. We still have a few draughts and a couple of rooms to insulate, which might get us to those types of numbers.1 point

-

Welcome to BuildHub. What a great intro! As you've seen, lots of our members enjoy getting back to first principles when it comes to working with things like UFH, MVHR, ASHPs and the like, especially where there's a novel angle (like UFH in a boat).1 point

-

Correct. It just means you require formal Planning and the proposal will be reviewed against Planning policies. If your LPA have policies which relate to building infront of the notional building line, then you should check those before applying.1 point

-

take the humidity limit up a few % and see if it comes out of boost. IIRC ours was a bit oversensitive out of the box and yes, get a trap on the drain1 point

-

When you isolate individual circuits, you are only isolating the phase (live) conductor. The neutral remains connected. If other circuits in the installation are energised, there will be current flowing in the neutral. This, combined with the resistance of the neutral, means that the neutral will have a small voltage difference to earth/the neutral at the origin. Normally that doesn't matter because the current can still only flow along the neutral and through the RCD. However if you touch neutral and earth together (e.g. when cutting a cable) this creates a parallel path which will allow some current to flow through the circuit you have created. Since this bypasses the RCD, it causes an imbalance and causes it to trip. Time delayed RCDs - like all RCDs - still display shorter tripping times as the current increases above the rated value. For example a 100mA S type RCD at 500mA is allowed to trip in 40ms - a lot less than the 130ms minimum with a 100mA current. If you had a phase to earth dead short then the current imbalance was likely into the hundreds of amps, and therefore well outside the parameters the time delay was specified/designed/tested for, so all bets are off. The time delay is really for situations where e.g. a human is in the loop, rather than cable shorts.1 point

-

Right, I've investigated further. I've actually had it running with the condensate drain not attached to anything, just draining in to a bowl. There seems to be lots of air being sucked up the short length of corrugated pipe, and this seems to be causing the gurgling. If I put my finger over the end and then take it off, some water drains out. I did this a couple of times until no more came out and the gurgling stopped. It seems that the constant flow of air up the drain pipe was preventing water from draining effectively. Is it normal for air to be sucked into the condensate pipe? I guess when I plumb the thing in, a ubend/trap would stop the air flow and the water would drain more freely? Anyway, I've switched the thing off for the night as there is clearly a problem.1 point

-

I cannot emphasis this enough. There'll always be more work to do than one person can manage and you need a metric to value your time. £ or € or $ is a pretty good one. Let me give you some examples. I stupidly chased our walls with a 9" grinder ( because I had it) rather than pay €120 for a days rental of the proper tools. It took me about 20 hrs of pure torture. My mate rented the machine and did his house in an afternoon. At €20/hr it stupidly cost me double what his did. I can lay blocks, but I'm slow and I don't like doing it for more than a couple of hours as I'm too soft. I reckon about 10/hr would be average. That come to about €2/block. Maybe that makes some sense for small projects but no way for a large house. Gains can be made where you do the donkey work of someone who's more highly skilled. Like UFH pipe laying or pulling cables for wiring. Plumbers and sparkles are expensive laborers. Another example, my mate, extended a cottage. 4 men took 2 days to crowbar and sledge down an old stone chimney. All unpaid, family, mates etc. then they took the same again to break out the old floor. Then the same to take off the roof. Had they hired a digger and demoed the house their mate time could probably have saved them multiples of the cost later in the build.1 point

-

Yes - Normal concrete: Has a thermal conductivity of around 2.25 W m−1 K−1. The thermal conductivity of air is around 0.025 to 0.03 water is around 0.6 W/mK at 20°C Good point Red is flow temp, green is return temp, yellow is power1 point

-

Temperature is not energy, or power. Imagine that you had an equivalent surface area of radiators as an UFH system. Now while that is often not practical, once you account for floor area that is covered in furniture and rugs, which reduce the power the UFH can deliver, you may find that the areas are not so different. We should really be calling radiators, UFH and fan assisted, heat or thermal emitters, they all do the same job.1 point

-

For V4 it was a ‘requirement’ to have either an EV or battery storage. They have just updated to V5 which again states the requirement for an EV but excludes battery storage as they have a new tariff due shortly for that. You have to declare that you have an EV, but they do not check. I think some people had said they were looking into EV ownership and they were still accepted onto the tariff.1 point

-

Correct. The strength of a single skin is much less than half of the double skin. It would need temporary support during the work. THe support gets in the way. You would not live in the house while this was happening, and should move heavy furniture out. A new outer skin could be tied using brackets screwed to the inner wall: that is the least of your issues. It's not only structure though. Do not ignore the detailing at the foundation ( does the widened wall fit on it still?) Or at the roof. How does this new outer face line work with the current eave and gutter...you probably have to extend the roof at eaves and gable.? And at doors and windows? I wouldn't dream of doing this. Not with my house and my money anyway.1 point

-

We can't rest on our laurels though we need an industrial strategy that aligns with exactly the products and systems you describe.1 point

-

0 points

-

Welcome to THE forum for people like us - although, to be fair, I don't live on a boat! The thing about underfloor heating is that it is one of the oldest heating technologies, other than an open fire, being developed by the Romans - now if I know my Romans you can bet that some mad Caesar asked for a heated floor in their 'barge'!0 points

-

We did not upgrade this was new build so a single application for everything, just need time to pull it all together and redact the private parts (See if Pocster reads this) so I can publish it.0 points

-

Welcome. I have a bit of experience with boats, my first paying job was at a boat builders, my sister ran a narrow boat scenic trip business for a few years. I have often thought that UFH on a narrow boat is a good idea, but as already mentioned, the temperature difference between the canal water and the floor temperature can be a problem. In reality, there is not much free floor area in a narrow boat, the name is a giveaway. They are really corridors. You could fit an air to air heat pump as that could be easily incorporated with some forced ventilation. The volume is not great. Around 50m3, or 62 kg of air to heat and change every hour or so. A couple of years ago, I made up some internal secondary glazing to cover my double glazing. This has made a huge difference, mainly because I have a lot of glazing compared to wall area (a problem with small buildings). If you can retrofit something, it will help. Acrylic fitted on the outside also stops fishermen breaking your windows. You say you have fitted a thermal store. What sort, size, temperatures and why. Do you use a log burner? What do you do for electrical power? There was a project boat at Birmingham University that was all electric, cheaper BW licences as well. Could have a 'secret' generator on board for when the boat is moored under trees. Where in the country are you based? The canal network is large, even Cornwall has 1.5 miles of canal.0 points

-

I helped my mate for free with the build, pouring concrete, groundworks, airtighess and some basic carpentry. I didn't do any of the fooling with the manual demolition though. I've learned the long way my time isn't worthless. I did offer to drive my digger straight through it though.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)