Leaderboard

Popular Content

Showing content with the highest reputation on 01/24/24 in all areas

-

Update - I changed the EV and it's working fine now. No water out the overflow pipe, ON pressure = 2.2 bar2 points

-

As long as the adhesive is flexible and has a good hold they will behave as a composite panel and you will be surprised how stiff it becomes. Once did a temporary floor and put thin tiles on 6mm ply so it would peel back up easily … oh god no! It might as well have been 18mm ply.2 points

-

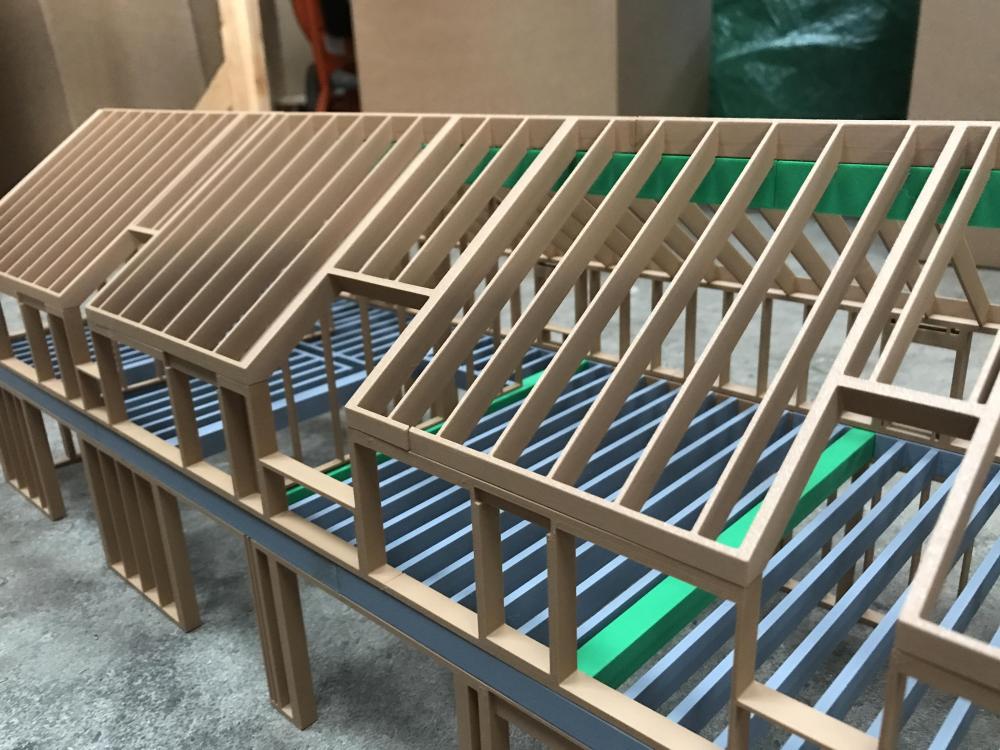

2 points

-

I doubt that precast insualted panels are a standard construction method recognised by lenders and insurers. ICF can be hit and miss even though it's fairly common now. Explored any other options? Timber frame with block skin for example? For the floor spans you are talking you'll need some steel in there to take the spans, a 150mm hallowcore plank typically spans about 5-6m max. Have you spoken to an architect or SE yet? Don't get stuck on details until you've the big stuff sorted.2 points

-

Just randomly bumped to my old topic - have an update. Actually it was not wet - just a different colour and I panicked as a first time buyer. DPC is in place. On one side brick was cleaned and on another dirty - that's why there is a difference in colour. After 2+ years no any problems.2 points

-

The door between the house and your internal garage The rest are fine unless your over three floors1 point

-

That depends what you mean by 'better'. As above, the thermal conductivity of BioFib Trio (0.038 W/m.K) is is higher than PU foam (0.023–0.026 W/m.K) so it's less good at retaining heat. So, as Garald says, PU foam is useful in a tight space. It's also useful if you need load-bearing insulation. In other circumstances, a natural insulation (but not sheep's wool) may be better. For example, BioFib Trio contains 92% natural fibres - a blend of hemp, cotton & linseed fibre. Unlike PU foams, mineral wool & other similar products, many natural fibres - particularly hemp and linseed - are very good at moisture sorption and desorption - that is taking water vapour from the air into the fibre's cell walls, and releasing it again. There are several technical benefits to that, provided you have a construction that's vapour-open ('breathable') to take advantage of those properties: it reduces the risk of condensation improves thermal comfort by keeping the air within a comfortable relative humidity range for longer improves air quality by keeping the air within a healthy relative humidity range for longer (at <40% RH respiratory infections are more likely; at >60% bacteria and mould thrive) tends to reduce heating and cooling requirements (adsorption of moisture releases heat, desorption takes heat, though research into quantifying this in buildings is limited) There are also non-technical benefits - it uses renewable materials, has low carbon emissions, supports (potentially local) agriculture, and It's also a pleasant product to work with.1 point

-

1 point

-

Similar, those are conduits rather than capping and no need to hack out that much block.1 point

-

What is your relationship with this builder? Is he doing any work for you? If you are getting cold air out of a socket it is because of a failing in the building design or construction. While sealing the "problem" might help it is not addressing the cause. If he is about to do work for you and considers this normal, you might want to think again.1 point

-

3 phase cable is probably twice the cost (4 core cable vs 2 core cable) Another issue though is what infrastructure is in place already. We are near the end of a single phase 11KV spur. If I really really really wanted, or had to have 3 phase, then about half a mile of overhead 11KV line would need to be upgraded from single to 3 phase, and the transformer feeding our house would need replacing with a 3 phase one. You can imagine the cost of that would be completely stupid.1 point

-

1 point

-

It's at this point I usually remind people that the point is to use less energy rather than more energy. Maybe add the max power of your car chargers and the heat pump and add 20%. It could be that the DNO doesn't care much anyway and there's no change in cost. Or you could ask for 100A and see what they'll give you. They won't change the size of the cable their planning to use, so it'll just be up to the marketing department. It's a bit like deciding between a 3L engine and a 5L. Yeah, more is better right? All your single phase mates will be on 25kW or less anyway. At 63A per phase you'll have twice that.1 point

-

1 point

-

I think default holiday temp is the frost temp - this can be adjusted up to 17 in optional settings - info in the manual1 point

-

As a neostat owner, I feel your pain. Horrible system. You'll need to set each stat to holiday mode and set holiday temp by losing down the power button g and getting in to the control menu. I can't remember what the default holiday temp is.1 point

-

I'd want £3k to do a proper design and no supervision. It could be much less if you've a good builder who knows how to do it, or if you read up all the regulations yourself. Try googling architectural technician, or services. Or building drawings. Architect is a protected title. Going right to the boundary creates msny issues. £40k diy feels right assuming a practical design.1 point

-

I think it is more to do with reducing air flow through the blockwork. I have just trowelled on a coat about 2-3mm thick. It is thicker where the joints are. It covers all the holes and reduces air permeability. I am using sloppy 1:1:4 cement:hydrated lime:sand. I am crap at plastering so it has given me the chance to practice on bits that won't be seen.1 point

-

1 point

-

Just had a quick look at my energy monitor, yesterday I used 5 kWh, a week ago, it was 22 kWh. Down to the small storage heater, and in Moron Gardens, flowers are coming out, and the fields are being cropped for daffodils.1 point

-

Did 9kWh the other day from my vertical panels. Well pleased. Was just generating 3.2kW between the clouds, but wife has dishwasher and washing machine on, so that's all disappearing very quickly.1 point

-

I agree the floor insulation is a simple upgrade. With the pitched section of roof you could have, say, 120mm between rafters and 40mm under. For the flat section, mineral wool. Stick with the 150mm cavity wall and poly beads. Wall ties, lintels etc are easy to get hold of and no redrawing required. I am doing this currently, with a parge coat and insulated battened service cavity.1 point

-

1 point

-

My mistake, you're absolutely correct. Regs have been updated since our house. 200mm cavities are very usual in our area (Cork). Maybe wise!1 point

-

1 point

-

We got similar from Topps. Big discount for what they call a pallet order, which I think means too much for the car. I think this can vary by region and branch. Still close to £30/m2 but it's classy. All long tiles bend and you need a wedge and clip system to lay them, which will add a few£ /m2. You must see an opened pack to look closely at the pattern. Does it look like a print or wood? How many repeats? Real wood has zero repeats. The shop people don't necessarily ' get it' that this may matter. The display panels can even have coincident patterns which shows they don't understand. But that's me, and maybe it doesn't matter to you, or visitors or future buyers. With 15 to 20 patterns and reversing you have 30 to 40 ways.1 point

-

For precast plank floors remember that you need artic and crane access. For 8m span they'll be about 200mm thick then insulation and screed above. I agree that considering the build method is worth considering early, but also that there can be too much detail. Can I ask what draws you towards precast panel walls? I'm not against it, but it wouldn't be my first choice. 2.5 storeys is tall and skinny. Where are you with planning permission?1 point

-

Why do people get so hung up about thermal insulation, it really is not difficult. The main thing to remember is that the power, in watts (W, J.s-1) that passes though a material is approximately proportional to three things, conductivity (k, λ), temperature difference (∆T) in kelvin (K), and thickness in metres (m). In arithmetic terms, the thermal conductivity of a material is written as W.m-1.K-1, or W/m.K (as I have never found a way to write a superscript negative sign on my Android phone). Different materials have different thermal conductivity. Taking extreme ends of the spectrum, natural diamond conducts at a rate if 2200 W.m-1.K-1 and a pure vacuum, for these purposes, is 0 W.m-1.K-1. Now we don't, in the real world, work at the extremes. So let us stick to some more common building materials. Ordinary brick, k = 0.72 W.m-1.K-1. Concrete k = 1.28 W.m-1.K-1. Timber k = 0.14 W.m-1.K-1. Mineral wool insulation k = 0.038 W.m-1.K-1. Expanded polystyrene k = 0.04 W.m-1.K-1. Polyurethane foam k = 0.03 W.m-1.K-1. Orientated Stand Board (OSB), 6% adhesive k = 0.16 W.m-1.K-1. Plasterboard k = 0.19 W.m-1.K-1. There is, obviously a lot more materials and it is down to whoever is calculating to find and check figures. An example of this is granite, there are a lot of different types and the k-Value can range from 1.73 to 3.98 W.m-1.K-1. So do your research. It is not normal to fit a metre thickness of any insulating material, If we did, none of this write up would be necessary. Because we use fractional dimensions i.e. 0.2m when planning the insulation levels of a building, the more common thermal resistance (R = K.m-2.W-1) is used. There are two advantages of using the R-Value, it takes the thickness of the material, and the area of the material, into account. Converting from the k-Value to the R-Value is really easy, just divide the thickness by the k-Value. R = l / k R-Value is often quoted and one thing to be careful of is that imperial units are often quoted. You may have noticed that R-Value has somehow introduced a m-2 unit, this comes about from dimensional analysis of all the International System of Units (SI) units W, which is kg.m2.s-3 and some arithmetic rearranging when combined with the other units, m and K. This is a useful as we do not have building elements that only have thickness, they also have area. The most useful thing about R-Values is that they can be added together to give a total thermal resistance (ΣR). Taking a simple wall build up of:) Outer: Brick, k = 0.72, 0.1m thickness. Full Fill Mineral Wool, k = 0.038, 0.2m thickness. Inner: Brick, k = 0.72, 0.1m thickness. Plasterboard, k = 0.19, 0.012m thickness. The overall thickness is 0.412m (dimensions may vary, so check). Using the sum (Σ) of l / k for every component makes for a long equation, and it is usual to use a spreadsheet. ΣR = 0.1 / 0.72(outer brick) + 0.2 / 0.038(mineral wool) + 0.1 / 0.72(inner brick) + 0.012 / 0.19(plaster board) ΣR = 0.139(outer brick) + 5.263(mineral wool) + 0.139(inner brick) + 0.063(plaster board) ΣR = 5.604 K.m-2.W-1. Note here that the effects of the mineral wool are dominant and that large R-Values are better. It is not normal to talk about a house, or wall, having an R-Value, but a U-Value (anyone know if R should be proceeded with 'a' or 'an', sounds like it should be 'an', but U sounds better with 'a'). Changing to U-Value, which is W.m-2.K-1 is simply a matter of taking the inverse of the R-Value K.m-2.W-1 U-Value = 1 / R So in this example: U = 1 / 5.604 U = 0.178 W.m-2.K-1. If the wall, ceiling, roof or floor is of timber construction, the technique is just the same, just that the appropriate areas also have to be included in the final solution, so you work out the U-Value for all the studs and noggins, plus the OSB thickness, and then the U-Value for all the insulation and the OSB thickness. There is one other thing when looking at heat losses, and that is the air film surrounding them. Air has a very good k-Value of 0.026 W.m-1.K-1 and is really the component that is doing the majority of the work in insulation, the material i.e. mineral wool or polyurethane foam is just there to stop the air conducting by trapping it in place. Because of this, some allowance has to be made for any air voids in the wall build up i.e. a service gap. To simplify this, it has been decided that two standard values are used, one for walls and one for roofs, with no regard to thickness. The wall R-Value is 0.18 K.m-2.W-1, roof R-Value 0.04 K.m-2.W-1. So taking the above example, and extra 0.18 K.m-2.W-1 must be added to the sum of the R-Value. ΣR = 5.604 + 0.18 ΣR = 5.784 Convert to U-Value U = 1 / 5.784 U= 0.173 W.m-2.K-1. It only makes a small difference, and at the third decimal place, but is still worth including because when the numbers are rounded, it may be the difference between the desired value or not.1 point

-

1 point

-

Can’t comment on the wood pattern tiles but Presleys will give a discount for quantity, very easy to deal with.1 point

-

It shouldn't really leave the pan off the wall much at all, just to fill the undulations of the tiles/pan, allow for full contact and a longer lasting seal than your typical bathroom sealant.1 point

-

Can hardly blame the surveyor, on this occasion. They can't see the battens because they're hidden by the foam so they have no idea what condition they're in. Although the same could be said for any insulation, foam is known to cause problems in some circumstances (typically when the roof's been leaking for a while, no one knows about it, because of the foam, and the water has had no where to go but into the battens and ultimately rot them) Whilst it's a slog of a job, removing it is DIYable. You should be able to pick large chunks off relatively easily and then use a wire brush to do the rest. I'd certainly give it a go if I could save £6,000!1 point

-

I'd use concrete with small stones, just because it's cheaper and faster. I'm sure you've some insualtion to slot in first then foam in to place.1 point

-

I worked for myself for around 23 years, general building, extensions and the like, subbing in where required. And as @ProDave mentioned there are loads of bodger's so getting reliable subbies is near impossible, if they're any good, they work for themselves, or are nearing retirement and want cash. For me the end was the endless reg changes for electrical work and the associated fees for part p, then CIS requirements of posting 0 returns every month or getting fined, VAT returns, waste carrier licence blah blah blah, just an endless list of people / government with their hands out. I just wanted to earn a living, not run an organisation, but that's what you end up with. All this before you meet the customers and The "Google says you do it this way". Now my house build is nearing an end I may have to go out and earn a few quid, I know I can earn good money doing what I do, especially up this far North, but I'm not interested in starting with all the guff again. I think the black market is calling. At least Scotland don't have Part P😉.1 point

-

Especially so with the porcelain planks The Italian planks are more realistic prints and usually have 16-25 variations of pattern Most shop prices are 45-55 Expect to drop down to 30-331 point

-

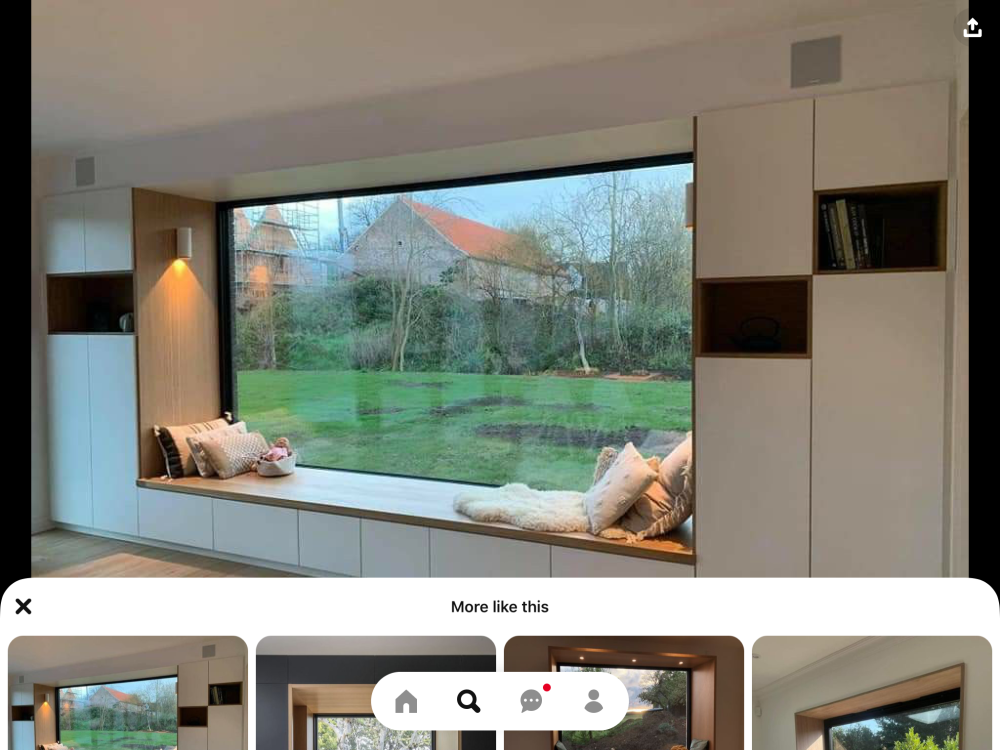

One issue you'll have will be rainwater - looks like you'll need gutters at each boundary thus bringing your walls in to accommodate these. This doesn't really need an architect per se. There are a number of surveyors/technicians who prepare plans for extensions like this and get building regs and planning approvals for householders. Most builders know someone who will prepare designs and drawings for potential clients of theirs. Once upon a time the local paper had small ad's for "plans drawn". It's that market you need. Ask friends and neighbours. If you have a builder in mind ask them - you need a "plan drawer" although the skills of most match or exceed many architects particularly as to practicality and interaction with the local authority.1 point

-

Tell the wife that, she complains every time she uses the hob - its induction. She misses the gas hob, I don't and I do most the cooking.1 point

-

1 point

-

Putt my chef's hat on for a moment, if people can't cook, then the choice of hob is irrelevant. Those that can cook, prefer an induction hob. And don't fall for the nonsense about 'you need thick based pans on an induction hob to spread the heat', that is only said by people that can't cook.1 point

-

I agree with all of this. Only thing I would add is that the other advantage of gas is that it continues to heat the pan when you lift it up. E.g. if you’re wanting to toss something or make an omelette/pancake spread out a bit. But, a huge advantage of induction is that it requires a much lower safe zone above it, which means you don’t need a really ugly cut out in a row of wall cupboards if your job is installed along that wall. Looks better in my view, as well as useful storage directly above your cooking area.1 point

-

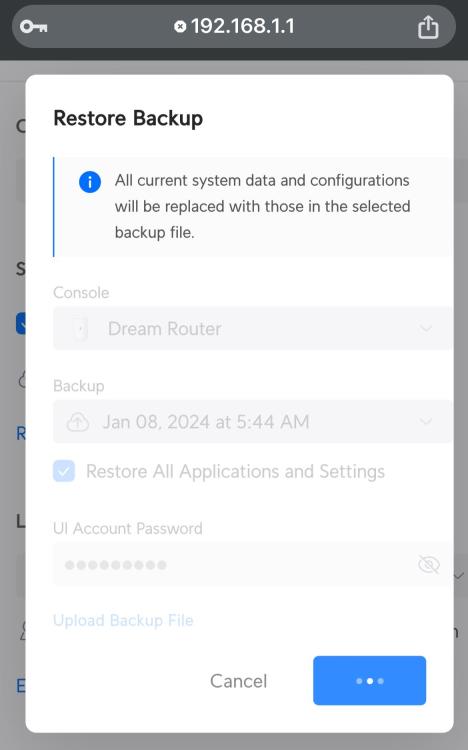

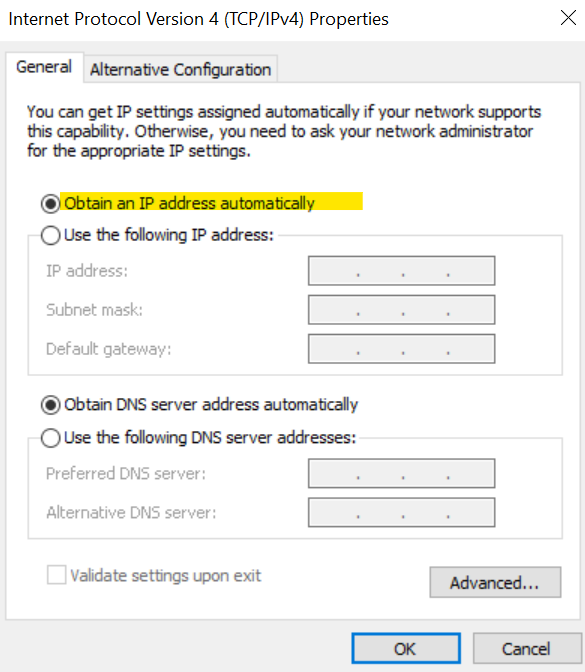

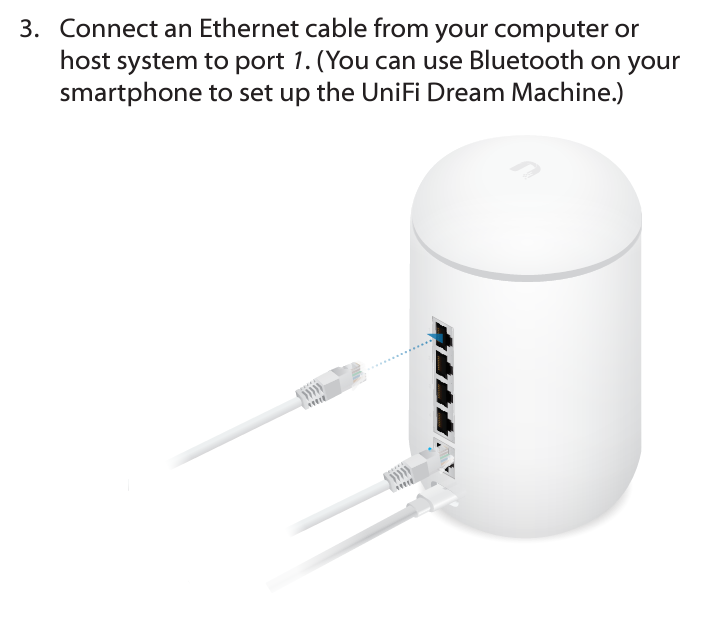

PPPoE is for the Broadband/WAN connection and DHCP is for the LAN connection (The DMR is the gateway between the two) So, setting WAN to PPoE will not effect the the LAN side. If your phone has connected previously and you haven't disabled the DHCP Server on the DMR we can assume DHCP is still enabled. Since you are not familiar with DHCP, it's likely that your laptop is also on its default Network settings (ie. , but it's worth checking. Is teh Laptop set up to automatically configure it's Network settings. If so, then this is use DHCP to retrieve it's settings from the DMR. On a Windows machine, the TCP/IPv4 Properties for the Ethernet connection should be set as below Switch the Laptop Wi-Fi off and connect a network cable between laptop and Port 1, then reboot the laptop. Ref. https://www.4gon.co.uk/documents/User-Manual-4075916.pdf You should then be able to open a browser and type http://192.168.1.1 and land on the login page for the router.1 point

-

We have oil boiler and ufh. I decided to fit a thermal store which acts as a buffer between the two. The room stats control the flow of water from the store to the UFH and floor loops The stat on the store controls the flow from the boiler to the store. The two sides, in and out of the store are independent except for the master On/off switch. When the store needs topping up the oil boiler runs flat out until the store is satisfied. No cycling. To get it to do this I had to turn the pump up to maximum and the boiler flow temperature dial up to maximum. This way the actual flow temperature never hits value set on the boiler temperature dial so it never cycles. The big question is it worth it? The store is big and has lots of pumps and mixers and leakes quite a bit of heat into the store room it's it. It's also not ideal should I want to switch to a heat pump. If I did that I'd probably use the store only for DHW and connect the UFH direct to the heat pump. This would allow the heat pump to run at lower temperatures. It's a 300L store which means we always have that much hot water available for high flow rate mains pressure showers. They are fantastic. Do what @Originaltwist suggests an see if you can detect any cycling. If it's short cycling a lot then perhaps looks at a buffer tank. If it never stops cycling even on very cold days that suggests the boiler is too big. One option might be to fit smaller jets if available for your model. That can also improve efficiency a few % on some makes. As for the "leave it on all day"... I think UFH is best suited to households that have one person at home most days. Otherwise the system can spend ages heating the house only for you both to go out just as it gets warm. If you are both out working I would set the stats to "set back" to say 16C about an hour _before_ you leave for work. Most likely the house will still be warm when you leave due to thermal inertia. See what happens. It might even be possible to do this even earlier if the house is well insulated. Then have the temperature set to say 20C about an hour before you get home. If it's not actually reached 20 when you get home set it to 20 a bit earlier. If someone is home in the daytime then 18 might be better than 16. Depends how active they are. We have ours set back to 18 or 16 C at night depending on the room.1 point

-

I suggest you sit by the boiler with a stop watch to see if it's short cycling. My neighbour's oil boiler goes 'whoooof' about every 3 minutes - crazy.1 point

-

1 point

-

I put ice cream and hot coffee in a thermos once - it didn't work out as was claimed..............0 points

-

0 points

-

An early girlfriend of mine found it ........ (series of annoyed expletives deleted in advance of publication) to reverse into an empty double garage. She it was who confidently told me she had topped up the water in the radiator in my VW Beetle 🥶 .... Left Hand Drive split rear windscreen. My God I was cross.0 points

-

@SteamyTea , I agree with you: it's easy. Put as much insulation in as is sensible. But just the look of the text of your post fills me with dread. I mean it's take a good few years for your insistence that there is a meaningful difference between KwH and kWh ..... to get through to my innumerate skull0 points

-

Same here. Left the CT1 for I think 36hrs until putting any weight on it". My tiling doesn't look too bad from this angle...0 points

-

Don't forget to purchase the matching crimp tool! https://www.tlc-direct.co.uk/Products/GPJCCT.html It'd be totally outrageous to use a totally standard set of needle nose pliers to crimp them, wouldn't it 🤫0 points