Leaderboard

Popular Content

Showing content with the highest reputation on 05/03/23 in all areas

-

Hello All! I'm a Welshman living now in Slovakia. Lots of self-building going on. Original log-built farmhouse dates from 1912. Presently almost at first fix of a 65sqm two storey extension with 1.1/2 size garage below workshop. Also includes an entrance hall and family bathroom above. Two of us have done almost everything, except for help laying the concrete subfloor. The extension walls are timber frame, modified larsen truss, 300mm with sheep's wool insulation. I will be putting some questions up shortly about the plumbing for the extension and rear of the house, the 'front' half (shown below) having been restored/rebuilt in 2006/7. Lots has been learnt from that work, poor design decisions on our part, poor implementation by contractors etc. Which is in part why I'm doing most myself!2 points

-

For your paint, I would empty it, clean it out, brush/vaccum it down and then just blast on a sealer/paint type thing. I did the inside of my shed with a concrete and wood sealer, it looks and smells like white-spirit, I just blasted that on. As for the foaming, take care here, you don't want to seal it all up then start dampness/mould because there is no air movement. Foam is good for some things but often misused and really is the devil. I don't know the full details of your building but just think it all through before you potentially cause issues. I might be more tempted by a mesh and staple gun to insect proof the place.2 points

-

I at times export at nearly 252 volts causing my neighbours EV charger to trip out for overvoltage. The transformer is 150m away with only 2 properties fed of a 185mm cable . My array is 10kWp via a 6kW inverter. I remember when looking at PV several installers tried to sell me "witchcraft" voltage optimisers. Could these be not used to regulate voltage for export?2 points

-

I did wonder if this should be in the MVHR section but actually it's more about the technology side of things so figured Boffin's Corner might be best place... The reason for posting is that I'm always really interested in reading about what other people have done with all things home automation, electronics, DIY etc and figured that the very people behind all that might well be interested in what I've been up to too. I've also got a bunch of graphs which for some reason have always appealed to me and I'm sure I can't be alone in that! So here goes! The follow graphic illustrates what it's all about, and that is essentially the 'command and control' of our Titon MVHR unit. Titon do sell an LCD touchscreen controller for it (although I'm not entirely sure if it is compatible with our particular unit) but it is pretty expensive and I figured I could do more for less, and have more fun in the process! It is based around the following components: Raspberry Pi Zero W - This is the 'heart' of the control system and monitors temperatures (using DS18B20 1-wire temperature sensors) in all the ducts (supply, extract, intake and exhaust) as well as humidity in the extract (using an AM2302 humidity sensor) and (soon) air quality in the supply (using a Plantower PMS5003 particulate sensor). As I will elaborate further below, with all this information it can automatically boost on humidity rises, cut back or turn off the ventilation entirely if outside air quality suffers, report heat exchanger efficiency etc and likely more things in the future too (I've been thinking about putting summer bypass under its control and perhaps complete fan control too). It also creates the graphs and serves them up for viewing in a web browser. Shelly Uni Smart Relay - Used as the interface between physical boost switches in the house and the MVHR unit so as to increases their utility in terms of allowing different actions for short vs long presses, but more importantly it also provides an easy way for boost and setback to be triggered from other triggers whether that be from the Pi, widget buttons on our smartphones and voice control via Alexa. Shelly 1PM Smart Relay - Used to monitor the power consumption of the MVHR as it was something I was interested in understanding even before fitting the system, and it used to also serve as a means by which to disable the ventilation in response to a fire but I have since decided I don't actually like that and would rather the ventilation kept working. It is still connected to the smoke alarm circuit though and will alert me via app/SMS if the alarms do trigger. Raspbery Pi Pico W - Acting as a 'mobile' means to interface with a PMS5003 air quality sensor whilst I am still playing around with it, but when the sensor goes in the ducting I'll read it directly from the Pi Zero from then on. So breaking down some of the functions further... Heat Exchanger Efficiency With knowledge of the supply, extract, intake and exhaust temperatures you can calculate heat exchanger efficiency in real time. The Paul Heat Recovery page on the subject describes two methods in more detail and the following graph illustrates what are fairly typical efficiencies figures (high-80/low-90%) I see from the unit: Automatic Humidity-Related Boost The Titon does have its own humidity sensor with an adjustable (but unmarked) threshold and whilst I've never actually tried it I've always assumed it would be susceptible to false positives (triggering when it shouldn't) or negatives (not triggering when it should) and perhaps more to the point was always going to be a bit of a pain to fine tune (and adjust seasonally) given that the unit is in the loft. So, given I am monitoring humidity (in the extract manifold) anyway if we look at a typical graph it is easy to see when boost needs to be triggered: Those peaks correspond to showering and cooking (e.g. mostly the hob) and as I said are really easy to spot with a rate-of-rise calculation. The Pi takes measurements every 5 minutes and as a starter-for-ten I set it to trigger the boost (via an API call to the Shelly Uni) if the humidity rose by more than 5% within the 5-minute window. This turns out to have been a perfect threshold as it has never knowingly missed a shower (or pan of boiling water) or triggered when it shouldn't have in the several years it's been running now so I've not cause to make any changes. Automatic Ventilation Setback This is the most recent addition to the control system, and is still work in progress but as it's been so interesting to me I thought I'd share the not-quite-finished product... Our neighbour (who thankfully we get in really well with, but even friends can be annoying!) bought a wood burner for their recently-built extension. We've been mindful of what we might be breathing in from it as it seems barely a day goes by when there isn't some article or other written on the subject. Indeed, on occasion over the winter we've seen smoke coming from it but more to the point we've been able to smell it through the MVHR too. Granted, this is mostly when I've seen the smoke and have jumped up on a chair to sniff the incoming air from one of the vents and it seems the planets have to be in alignment for this to occur e.g. a cold still day with no wind, the neighbours using damper-than-ideal logs etc but it's happened a two or three times now and whilst I've been convincing my wife how sensitive the human nose is and that we shouldn't assume we're being poisoned I did begin to really want to quantify how 'bad' the situation really was. Aside from anything else it was a good excuse to buy another sensor, produce more graphs and give another aspect of control. Like others whilst we normally run the MVHR 24/7 and enjoy the fresh air it provides but this of course is only effective if the outside air is indeed fresh so my goal is to detect when it isn't fresh and either turn the ventilation down (whether that be both supply and extract, or perhaps just supply I don't know yet) or perhaps even turn it off temporarily when such a situation arises. The PMS5003 particulate sensor is a delightful little thing - the size of a small box of matches and costs around £15. You wouldn't expect much for so little but I've read several accounts now of people having compared them with air quality sensors costing thousands and them being a reasonable enough match, certainly good enough for taking measurements that are meaningful, consistent and reliable enough to feed into a home ventilation control system. The sensor is based around a laser whose light is reflected by the presence of particulates in its path from which the sensor can determine particle quantities in the 0.3-10μm diameter range which is exactly the region of interest when determining common particulate matter based analysis and determination of air quality. The following graphics illustrate the what the sensor can detect: The sensor does everything for you in terms of detecting the particulates and then presenting summaries of particle count and mass of different particle sizes over a serial line that I am reading with a bit of Python code running on a Raspberry Pi Pico W (currently powered by a USB powerbank for mobility): The Pico is configured to continuously read from the sensor and gets an update roughly once per second and, via HTTP through its wifi interface, I can request and parse these readings from a script running on the Pi Zero: I capture the readings once per minute which are then stored and can be graphed to show particle count of any specific detectable size but I am finding the 'all detectable sizes' (>0.3μm) summary useful enough: The particle mass figures are even more useful as they can be compared against Air Quality Index charts such as the UK's Daily Air Quality Index (DAQI) 10-level bandings shown below: Now technically the DAQI levels, like most AQIs, apply to 24hr mean readings thus non-continuous spikes as seen above don't really up the level - it's the 24hr average (as shown in the table) that really counts if wanting to compare against the index. The neighbours haven't been using their woodburner over the past week or so as far as I can tell and so it would've been rather boring to put the sensor in the supply manifold as ultimately intended so instead it's been sitting in our open-plan lounge/kitchen/diner and it's been quite an eye opener! As the following graph illustrates, cooking really does produce a lot of particulate matter: I think the first spike was preparing some halloumi burgers on the hob, the second the bread machine in action and the third some sausage rolls in the oven. What was really quite alarming was when my wife burnt some sesame oil in a frying pan... I was out at the time so have only got her word but she insists it wasn't that smokey (and to be fair when I got in later I could smell cooking but didn't assume anything more than that) and yet the particle count graph looked more like a nuclear bomb had gone off: The spike doesn't look all that significant until you look at the y-axis scale - a peak of over 3000 particles/0.1L which is over ten times the peak we'd normally see when cooking! It was interesting to see the PM1, PM2.5 and PM10 counts against the DAQI for that episode too: Whilst as mentioned it doesn't mean all that much shown like that given the DAQI is meant to be used with a 24hr mean (thus 13μg/m3 of PM2.5 in this case, which is still only Level 2 'LOW' on the scale and not the 195μg/m3, or Level 10 'VERY HIGH' as it might otherwise appear presented like this!) but it does make for an interesting perspective nevertheless. Some might say it also serves as a quantifiable measure of my wife's cooking skills but obviously I wouldn't... So that's where I've got to really! Next steps are to buy another air quality sensor as it seems a shame to lock this one away in the MVHR ducting as there are too many experiments begging to be done - lighting matches, candles, perhaps the barbecue and maybe driving around with it too (the sensor, not the barbecue) to see what the air is like on a commute or in a city etc. Also with two sensors I can have one inside the house to automatically boost when required, and one in the supply duct to do the opposite and turn the ventilation down/off temporarily if the outside air quality is lower than desired. I've written more than I planned to so well done - and thanks - if you've got this far. Hope it was of some interest, and if there are any questions or any way I can help you do something similar I'd be happy to oblige.1 point

-

We're just starting our self build on the Llyn Peninsula, north Wales. We've got as far as appointing a timber frame manufacturer but actually getting our existing house demolished and the foundations laid is proving to be a slow and frustrating process. Great start 😏 we have someone to demolish our existing property but haven't actually got a main contractor. The guy who is going to demolish and clear the site seems very knowledgeable and we may well work with him on the rest of the build. We will complete a lot of the work ourselves. In a previous life (40+yrs ago😂) I was an electrician and we've converted a cow shed/barn and Chapel over the years so I know which end of a drill to hold. Getting to this point has taken 3yrs, and I must admit we've had our doubts.1 point

-

Hello I had the Viessmann 200w installed recently and, as I wasn't able to find out loads from the forums in advance, thought I'd post a few initial impressions and 'gotchas' here that tripped up the installers a little as part of the installation. This was the most recent version of this boiler with the colour touch-screen (B2HF/B2KF). First gotcha, it doesn't come with a 'fittings pack' - there are several types you can get and whilst it states this clearly on the Veissmann direct website, this seemed to be news to the installers, and also the merchants who supplied the boiler. So our first install left us with a boiler hung on the wall but not connected whilst we waited for the fittings pack to arrive and then be installed. Second gotcha, it doesn't come with opentherm. I thought this was surprising as I believe the 100-w does, and I was hoping to use this with the Drayton Wiser system that we have installed (which I think is excellent, also). Third gothcha, there are three 'modes' of operation that have to be set during the commissioning process, and if you want to change the mode you have to recommission the boiler. However, you can do this fairly easily with the app (ViStart for the installer, and ViCare for the user - you can download both from the Google Play store). The three modes are 'weather compensation' mode, 'continuous operation' mode and 'room temperature dependent' operation. The second and third modes don't seem to make any use of weather compensation - and if you set it up in weather comp mode and then connect a stat, the stat won't talk to the boiler at all (lots of head scratching here from our installer). So, to get this to work with our Drayton Wiser system we currently have it connected on 'continuous operation' mode; there is then a setting to turn off continuous pump operation when there is not a call for heat, though oddly in this mode even if there isn't a call for heat there is a minimum flow temperature setting (default at 20'c). I am going to try and switch it over to room temperature dependent operation at some point to see what this does (my guess is it'll only work with a Viessman stat), but for now it is working fine - the boiler is firing when there is a call for heat and not where there isn't. Fourth gotcha, we've got a fairly large detached house and had previously had an older Baxi boiler which clearly had the pump turned right up to maximum. The Viessman has a variable speed pump, but I found that I had to adjust the minimum pump speed setting upwards somewhat to get the far-out radiators warm at the same time as the rest of the house. Fifth gotcha, Viessmann had apparently specified not to use inhibitor with the boiler at all. Our installer thought it was something to do with rubber hoses perishing. At first I was so surprised at this (as was he) that I checked with Viessman technical who confirmed this was the case. Apart from this, it seems a good boiler so far - it is keeping us warm, seems pretty quiet, and the App has a few nice settings e.g. being able to see exactly how much gas (in cubic metres) you use on any given day. Quite astonishing seeing this over the recent snowy weather we've had over the last couple of weeks. It's also nice seeing the modulation stats, as that was the main draw for us for this boiler, that it modulates very low. An interesting setting seems to allow you to limit the amount of time the hot water runs before cutting off (and then I think set a minimum wait period).... potentially handy for anybody with teenage daughters?!!1 point

-

What everybody else says.(some of it anyway) Then do your own test ( as ProDave and others). Tape over all fan and other ducts. Close or tape over window vents. Dont assume any builder understands airtightness. Then tell the testeron site that you need 0.8 ( or whatever) and are confident of achieving it. Difficult gaps to complete are at the eaves ( and there is a lot of it) and openings. Examine the detail, discuss with the builder. Supervise.1 point

-

After 3m you need to double the pipe diameter. 50mm minimum standard here.1 point

-

No cat, and a dog I let out when required.1 point

-

awesome. 40mm through the B&B it is then! I can then make the decision as to whether to up that to 50mm at a later date. I was actually thinking of putting more than one hep2o pipe in the larger bore ducting! thanks for the tip on 45° bends but in this instance I'll just send them up vertically from basement to kitchen through the B&B. any bends will then be under the ceiling in the basement. the foam wasn't to reduce the noise of the pipes it was so there wasn't a hole going through from the basement to the kitchen so making noise in the room below/above won't travel through the ducting to the other room.1 point

-

1 point

-

Make sure the brickies use full perp ends and not a smear and it makes life easier - ask them to point blockwork too. Wrap the joist ends a la Tony Tray.. Airtight tape on windows is expensive but makes a dramatic difference and doesn’t have the issues silicone can have sometimes1 point

-

Plus 2 We build block and block land scored similar It’s a myth that solids can’t be airtight I deal with airtightness everyday Mainly commercial But some of our housing sites are taking it far more seriously The testing system for the big companies is open to abuse with so many air test companies chasing the same business1 point

-

I built mine like yours and got a similar result and pretty chuffed with the outcome (no letter box or cat flap 🤷♂️).1 point

-

Boarding horizontal is fine as long as there is a row of nogs across the middle If you start from the bottom It would leave you a nasty it as floors and ceilings are rarely level Better to cut them 15 mil short and lift with a toe lift1 point

-

Personally after the first 90° elbow I always use 90° swept bends. Usually the kitchen sink starts with a 40mm waste pipe. A basin usually a 32mm waste pipe. Oh and a bath and a shower usually a 40mm waste. Showers some times bigger.1 point

-

Just a VCL. One has to be fitted somewhere, not that is the easiest place. Wall ties will (expletive deleted) it up.1 point

-

I did use a roller a bit but found a roller is not great if the thing your rolling against is rough, like blocks are.1 point

-

wall makeup ? Insulation ? Rad heats wall. outside gets cold. Dew point is close to inside surface. Dew forms when rad cools down. Just a guess. More insulation to cure.1 point

-

A coat of watered down pva would be the cheapest option then just coats of normal emulsion, splash the cash on masonary paint if you want. any expanding foam will do the trick, smallest can possible, or line up a few jobs and do lots at one time.1 point

-

I've just had 2 quotes for an Archaeological Desk-Based Assessment. One was £2200 +VAT + costs of accessing data (c.£160). The other was £1975 +VAT +data costs. Both DBAs allude to "further work may be required" NPPF Para 194 states (my emphasis) "Where a site on which development is proposed includes, or has the potential to include, heritage assets with archaeological interest, local planning authorities should require developers to submit an appropriate desk-based assessment and, where necessary, a field evaluation." I've therefore declared that submitting my own DIY ADBA is appropriate given the site's particulars and the very limited potential for any remains to exist.1 point

-

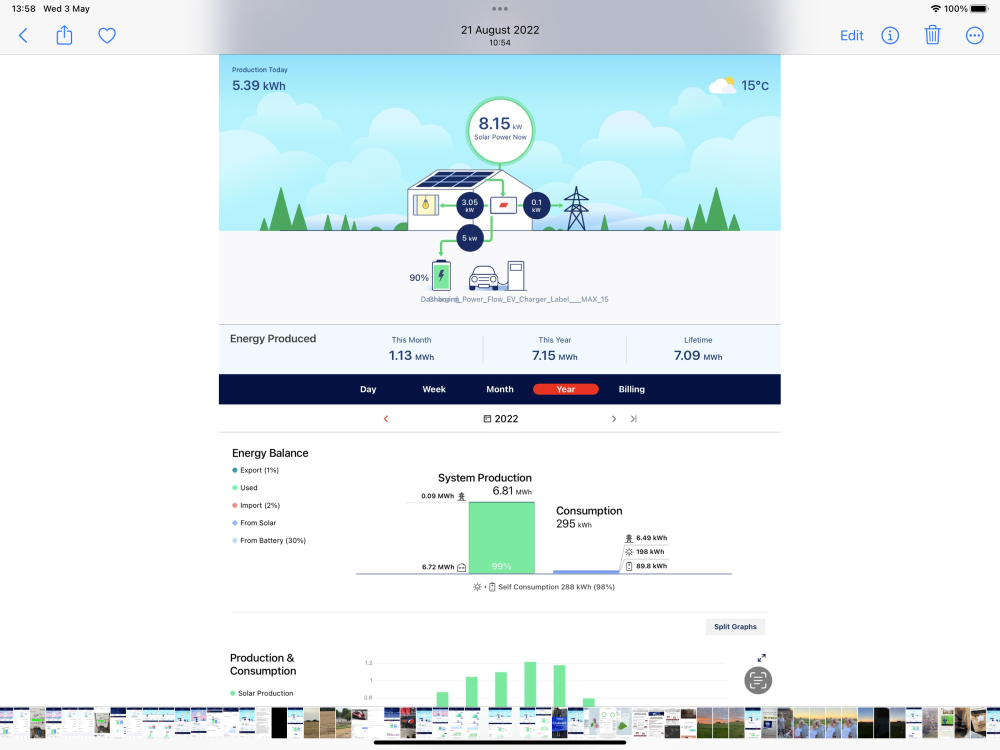

It’s solar edge dc coupled to 10kWh battery soon to be 20kWh. Excess PV goes uninverted direct to battery. SE allow 200% oversize with battery. I’ve seen the array generate 8kW with 5kW going to battery and balance to serve house load. I also have dhw divert This is from last August. Quite a handy feature of dc coupling.1 point

-

Turns out there’s another lintel above the one I want to replace. I assume the one I’ve just discovered is the original as it’s much bigger, I plan to leave that one in place, fit my new box lintel and build up between the two.1 point

-

What makes you think they may be copies? There is a lot of badge engineering.1 point

-

1 point

-

Hi @Achu Yes mostly the complaints are about what people do, or don't, want you to do with your property but nothing to do with conflicting with planning permission rules. Let them whine! It sounds like no one can come up with a planning rule reason why you shouldn't have what you want. Even the planning officer and highways feel it's OK. Ignore it all. Move on. Sort out the garden. Paint the house red. and stay polite. M1 point

-

1 point

-

@Dee You can get much longer lengths in by removing one noggin and lowering a length of pipe down, then under, then rotate it 90o to bring it perpendicular to the joists? Only a couple of connectors required then. DO NOT use solvent weld The snots of glue will cause havoc!1 point

-

Yup, I think I'll do it properly, in my instance, and just bite the bullet. Prob an extra 1 day of machine and muckaway, plus another one day for importing all materials to the top of the garden. Powered barrow and micro is around £700 p/w so I'll just accept that, and then use the spare day to dig a soil pipe in down to the house and drop a couple of ducts and a SWA in there at the same time. Nowt worse than regret, and I've done a few jobs here when tired / short of time, and they piss me off to this day when I look at them. Mechanical pencil is coming out. I'm going to print! 200mm EPS with 100mm concrete raft / slab with anti-crack mesh for reinforcement. Final answer.1 point

-

If you’ve had to go to planning I assume it’s attached to to house and you will need building control Who will want to see the depth of the concrete and what’s under them By the time you have buggered about with test holes You could have dug the old strip out in a couple of hours Check with building control He will probably make the decision for you1 point

-

>>> the installation which will be rather yikes. I suppose that would include paying for a transformer? Not sure which part of the install cost you were thinking of? No transformer charge if it's a 'Low Voltage' overhead line i.e. 230V per phase. Ask your DNO and they will give you cost / availability etc.1 point

-

Costs may not be as much as you think, it would be worth getting a quote from the DNO, but as you say, it may depend on available capacity on the line you’re connected to. Off-peak tariffs are available on 3-phase. We have Octopus Go on our 3-phase supply and it all works as expected, the meter just adds together the 3 lines to give a total kWh consumed.1 point

-

The first thing I would look at and consider is the existing building, make up, materials and how long has it been there. Assuming it has been there a while, is there any damage or cracking, subsidence etc. etc. that is caused by the existing foundations failing in some way? I would give the foundations a bash with a hammer and a cold chisel to see how hard the concrete seems, I would expose sections of the foundations and check for big cracks, bits that have fallen off etc. If the existing foundations are suitable in size, and pass all the other common sense checks above, then I would consider the new structure weight. How does it compare to the existing, if the walls are basically the same as before, with only a pitched roof going on, I would not be too concerned as the new roof load is supported round the whole build. Assuming you are pretty sure the founds are OK, and if not, even get an SE to come and have a look (dig some test pits and let them have a look), then I would probably just crack on and do it. Do you actually have building control on your garage or just planning? If the garage is small enough then BC won't be involved in which case do your checks above and carry on. If BC are actually involved, then it depends on your inspection schedule with BC. If they want to see the trench and founds then you need to raise it, if they don't really care as it's just a garage then on you go.1 point

-

To determine the suitability of the footings an inspection hole dug alongside the garage footings is usually done but you have stated you know the depth to be 300mm deep. Is this a guess or confirmed depth a usually suitability is checked first before being given the go ahead. The inspection hole can be dug by yourself but will need to be confirmed by an expert as proof.1 point

-

Suitable filler will be fine but remember the filler patches will dry a different colour hence the reference to looking like a marble cake. The rest of the property looks nice so imho if you have the money get it rendered but if your not planning on doing it yet and your gable end is not taking in water anywhere just finish your painting and forget the filler until your ready to get it rendered. Toupret filler is really good but just think how many boxes you would through trying to make the wall good, save your money and get it rendered.1 point

-

Boiler flues are either fitted to a fall or have a built in fall, so there should not be an issue with water getting into the boiler this way. The soil pipework looks a right bodge, but perhaps it is work in progress and hopefully gets properly finished, filled and painted as it looks an eyesore from your side.1 point

-

Clearly a poor DIY job, wrong fitting used to go round the external corner for instance, and leaking joints suggests torn seals at the joints as they did not know whet they were doing. But not your problem?1 point

-

Just put in an application via the developer portal (this is what developers use to put in applications for plots of land that have no infrastructure at all). I could even do this for you if you want. PM me if you want.1 point

-

Your house is basically same U value spec as ours but our house is a bit bigger... Our 9kW heat pump coped admirably with the cold snap in December. In theory we could have got away with a 5kW unit, but glad of the larger one as we only run it 7 hours a day on Economy 7. For a 5kW unit, it would have been running 24x7. Get it modelled in PHPP and use the figures it spits out. The SAP is shite.1 point

-

Very interesting section on your findings with the use of the particulate sensor, I think I have just found a new project to add to our MVHR system. Our MVHR (Domus HRXD) has been in just over a full year now, through two winters. I have a little issue with it's operation around temps below -1 and that the controller is a bag of poo The clock needs to be reset every time there is even a minor power failure. I have set the controller to a background mode so if my added on system or more likely me myself fails then the other half can use the original system and not my toys as she calls them. I am a fan of the d1 mini micro controller, node-red, mqtt and the Raspberry Pi. So my system is built around these. The bathrooms and kitchen have d1's with humidity, temp, PIR and light sensors. There is a d1 in the MVHR control box that has a temp sensor in each of the four MHRV pipes (as well as temp sensors on all underfloor heating returns. It also looks after the co2 sensor that is in the room extract pipe. This same d1 also switches the MVHR fan speeds and inhibit function. The control comes from a Pi3 running mqtt and node red. mqtt is the message hub for all the sensors while node-red provides all the control functions. For example, boosting the MVHR if the humidity exceeds a limit in any room, introduces a mild timed boost should a bathroom be used for a period but humidity remains the same, reminds us if the small bathroom light has been left on. Switches the MVHR to bypass mode dependent on the outside temperature, the internal temperature, time of year and time of day. The co2 monitor allows the MVHR to run at half the supposed level required. Should the co2 go over 400 it goes to a "normal" rate and boost if over 1000. Eight people in the building will push it to 400 and above. For something else to keep it busy it posts data to a database on another pi. Things like, what fan speed and how long to calculate running cost along with the various temps to calculate savings. Not to mention it's use in control and monitor of the shed heating and ventilation.... all OTT but a good bit of fun... now, must order one of those particulate monitors. Can't wait to tell the wife exactly how many particulates are getting up her nose and are causing her sneezing... I can see lots of brownie points for that one... not.1 point

-

I'm pleased to update we've got through the first chunk of the first full winter with no problems whatsoever after the 'bypass cartridge' was replaced. We've had our first service also (boiler engineer completely perplexed he was coming out to such a new boiler but I want to maintain the 10 year warranty!). Working really well. And gas usage does seem somewhat down on our old baxi, though there are other factors also that will have contributed to that. V happy with the boiler set up now. Love the Viessmann app and the Drayton Wiser system that's controlling it is brilliant.1 point

-

My husband calls himself a dog butler.0 points

-

Well his name is “big Jimbo” 😉0 points

-

0 points

-

0 points

-

kitchen sinks are 40mm not 32mm.. ducting them individually is a good idea, use either 32mm or 40mm PVC and use a pair of 45° bends to get them out of the slab as the Hep2O will like you for it … don’t foam them in, they won’t make that much noise. finished is it …….?? 🙄0 points

-

@Thorfun you’re having suspended ceiling in basement yes ? ( sure you said that ) . So no worries about access if anything does f up . Also remember @Nickfromwales hadn’t built a (expletive deleted)ing house on his own and I have - so ; WORD !0 points

-

Okay quite a lot of this is going over my head but I said I'd update on the 200-w and how this has gone. Same problem back again. Boiler heating on minimum burner when no heating demand. Seemed more intermittent than previous but just as annoying. Have to turn the DHW off and on before using the shower... So we'll ask veissman to take a look again... And I'll update again on here.0 points