Leaderboard

Popular Content

Showing content with the highest reputation on 11/26/22 in all areas

-

Do you really mean less load, or running less of the time? A heat engine, any heat engine, is ruled by the laws of thermodynamics. So all the inputs are summed, then all the outputs are subtracted. They must balance, even if the temperatures, or quantities, seem, but on the face of it, very different. Push any heat engine to either extreme, they fail, even a gas boiler. The idea when designing a system is to make them work in the most efficient area, most of the time. Efficiency, unfortunately, can be measured in different ways, and often is. It is not unusual to hear someone say they have a very efficient boiler, based on what? Their house being hot? The running costs being low? The ratio of primary energy to delivered energy? Never running out of hot water?2 points

-

The point is, if you buy the kit and install yourself, it will probably still be cheaper without the grant, than getting the £5K grant and paying for an MCS install. A monoblock ASHP comes charged with gas and does not need an FGAS installer.1 point

-

Ok.... The job is done. Really struggled with the rods as the blockage was SOLID and even though it was a 1200mm manhole, was tough getting the rods in. In hindsight a jet would have done a better job. Had to use the rods with no attachment and punch through it. Anyway.. the blockage was at the bodged backdrop as expected... But I pulled out chunks of rock and smashed pipe... I think what happened was a pipe was damaged at some point and not properly cleared out and the debris a cumulated at this one point and caused the blockage. Getting my civils mate back asap to sort out the manhole and do a proper backdrop arrangement. But otherwise a nice day moving 100tonnes of clay 🤣1 point

-

My UVC's pressure/temperature relief discharges to an internal soil stack via a HepVo. This soil stack has an AAV at the top - is is not vented to atmosphere. This was approved by Building Control (England) because we have an outbuilding that has a WC and the stack there is vented to atmosphere. Because of this, all the soil stacks inside the house can have AAVs fitted and none vented to atmosphere. Jeremey Harris explained it on here. Not sure though if I'm missing the point on Passive House - soil stacks internally are not a good thing? P.S. the plumber refers to the HepVo as a "fanny trap". You have to look into it to realise why 😯.1 point

-

good luck with that. digger hire, muck away, stone, pipe, relay slabs. Someone who knows what they are doing to do all that. Be looking double what you are budgeting. Take out the drains insurance with british gas or whoever, live with it until feb. Please ignorance and make a claim.1 point

-

think about it. truss delivery arrives at 2pm, you have been paying 2 or 3 chippies to sit around waiting from 8am. they get a 1/4 trusses on then that's it for the day. The lorry driver takes them back and you try again another day. Doesn't sound very sensible does it. You (not the driver) offload, stack against the scaff then book in the chippies and a crane and hope weather plays ball.1 point

-

1 point

-

1 point

-

Found something suitable: https://www.stoveworlduk.co.uk/eco-design-stoves/ecosy-newburn-4-idyllic-4kw-defra-approved-eco-design-ready-multi-fuel-stove And not extortionate either1 point

-

Hi, yes you will have to excavate the connections. Moving and dragging are very different. Mole is usually air powered, starts from a excavated hole and basically hammers it’s way through soil and pops out in another excavated hole at the other side of the road etc. dragging is used where there is an existing clay or iron in larger machines, a cable or chain is passed through the existing pipe and a winch pulls a cone shaped ‘buster’ through and a new pipe behind it. if the length to be busted is only a few metres we did one with a home made cone, length of chain, taped the new pipe behind the cone and pulled it through with a mini digger. But if you allow 800-1000 for someone to do it you won’t be far out … speak to someone at your local utilities contractors or council depot, they always know “someone”1 point

-

Larger units do have a higher min modulation yes, so you need to ensure you don't go too big. But slightly larger can be good i) so heat pump isn't needing to run on max ii) DHW reheat times are better. Ours 7kW unit is able to modulate down to 25% which at 7C outside and 35C flow is 3.2kW. If possible try to get a hold of the perforance tables for the ASHP you are looking at which will give you a cleaer idea or min/max output under different conditions. If it can run at more than 7kW, that doesn't mean it will need to for heating, there is DHW also though. I don't know about all manufacters but our ASHP label says 7kW, but it's maxumum output is anywhere between 4.6kW and 12.3kW depending on the outside termperature1 point

-

If you discharge in to a slightly pressured or blocked, stack blanked at either end with aav, that could have been installed years ago, if you have an event, the flow will take the easiest route which may be out the open part of the tundish. ie not safe. The pressure relief operates on an assumed differential pressure, any blockage, or increased pressure on the unpressurized side, will increase the lift pressure on the valve, so will open later/ at a higher than designed pressure. The worst case is, it doesn't open at all and your cylinder explodes. Sounds a bit dramatic, yes, but the only purpose of the pressure relief is to protect against a run away heat source that hasn't been tripped by the temperature switch.1 point

-

If it was just a straight pipe a drag buster and pull in new pipe would be most cost effective way to save the path but still not cheap. Your big problem is the two connections as these cannot be done without access. I would sacrifice the path to save the porch (assuming the pipe isn’t concreted in you will be able to get a new pipe under the porch by digging access pits either side. not easy to price but a gang of 2 with a digger should do it in 3-4 days depending on access and obstacles etc.1 point

-

What seems to be aeons ago I started my self build - a bungaloid conversation which pretty much ended up as a full newbuild with a few remaining old walls because we couldn't change the planning for newbuild when we found out how bad things really were. We're weather and water tight and this summer finally moved out of the caravan into the house which still needs lots of work. We're still on temp electrics with extension leads everywhere! Athough we've had hot water for a while, I'm installing rads this weekend to give us some heating. The last couple of days has just brought the house down to a little chilly and my wifes wants some comfort. Anyway, to the moral of the story.. I had no building experience before taking this project on and I've done everything myself so far. When it came to the heating system I applied what I've now learned is a common self-builder trades scepticism and decided to do that myself, especially when I saw the prices involved. Our budget had already been hit because it was set for a 126m2 conversion and then had to now cover 196m2 so the truth is we ran out of money especially due to recent material price inflation. Mid Covid lockdown I decided to embark on a Gas Safe training course and after 18 months passed my ACS and installed our gas boiler, following which I've registered with Gas Safe and started up a small one man band to earn money to complete the build. I'd never even dreamed of going in this direction in my life so it's all down to doing the self-build. Surprisingly I've been run ragged by work, almost from the off and I've recently done 2 fairly major installation jobs, at least for a newbie. Doing this work has meant I've had to learn a completely different mentality which has beena bit of struggle. For example, trying to source materials and products at the best price is just too time consuming. Trying to make everything up myself instead of buying packaged/complete products has gone out the window because when customers are paying for my time, it actually ends up more expensive, both for them and for me - for example, making up my own ch or water distribution manifolds versus buying ready made manifolds. Buying for convenience has become so much more the order of the day. It's also incredibly difficult to balance quality and cost for the customer - I'm torn between trying to be perfect in the work I do and the associated costs to the customer. It's difficult not to drop standards in the rush to finish a job when the customer wants it done and when seeing the poor standards of so much work out there, even in such a regulated area like gas.. This has given me such a different perspective which is also changing the way I continue to build my house. Maybe I won't try to get everything so perfect and actually appreciate more convenience even if there's a minor financial cost to it. I might even get some trades in to help me finally finish the house off!1 point

-

I've installed the Honeywell T6R now a couple of times and really like it. Good for Opentherm too, if your boiler supports it. You can by it single channel for heating only or with heating and hot water. Honeywell technical support is excellent too, at the end of a phone line with a video link facility too if needed. App used to be quite clunky but I think they've recently updated it. It's Homekit compatible if you're in the Apple ecosystem. The only downside for some is that it needs to be plugged in and won't run on batteries. https://www.resideo.com/gb/en/products/comfort/thermostats/programmable-thermostats/y6h920rw5031-smart-thermostat-wall-mount-kit-with-hot-water-uk-am-pm-y6h920rw5031/ Probably overkill, but if you want to go full on then the Honeywell Evohome is great and is openthern and heatpump compatible with the right receiver, but it takes a bit to navigate the settings and get it set up right - well, that's what I've found with a priority hot water set up, which it sensibly supports. Mine's on a simple 2 zone heating setup now with PDHW. https://www.resideo.com/gb/en/products/comfort/thermostats/smart-thermostats/atp921r3100-en-nl-fr-thermostat-pack-atp921r3100/1 point

-

I have been searching for decent prices on 9x2 and about a month ago I found the same website you found and was poundering the same question ( I can't collect from London). I came to the conclusion you might be able to get a similar price if you contact your local merchant and ask for a full pack. Prices are coming down but it seems there is still a lot of expensive stock still sitting in yards and they are also now used to charging a fortune for anything less that a full pack. Seeing quite a lot of reports of building sites shutting down as they can't sell houses at the moment so there is a lot of potential for downward pressure on price. This is also the cheapest site I could find for OSB and sheet materials, handy for reference comparison for your sheet materials https://sheetmaterialswholesale.co.uk/osb-3-board-18-x-1220-x-2440mm/1 point

-

Aw, that's a shame. They were not too bad a bit of kit. How interested would you be in repairing it?1 point

-

Greetings! It is a little detached standalone bungalow. Rather unusual to see on an urban street surrounded by rows of terraced houses.1 point

-

More likely a pressure relief from an UVC could let off a lot of steam (literally) and it NEEDS an open vented stack for that to escape. A waterless trap won't allow it to vent. A 22mm copper pipe exiting the building seems the lesser of 2 evils compared to a vented 100mm drain stack.1 point

-

What is the build standard of the rest of the house? i.e. standard, or all air tight membrane and service void? A cold loft is the hardest thing to detail as not only cracks like this want sealing, but EVERY penetration, every light fitting, everywhere cables drop down into a stud wall etc etc.1 point

-

The advantage of an ASHP bigger than needed for space heating, would be quicker DHW re heat times. But it would not be able to modulate down low enough for heating needs so would indeed be cycling more.1 point

-

d) Buy a sheet of 30mm PIR and cut into strips. Put that on the screed with full sheets on top. Fill 5mm gap with foam.1 point

-

1 point

-

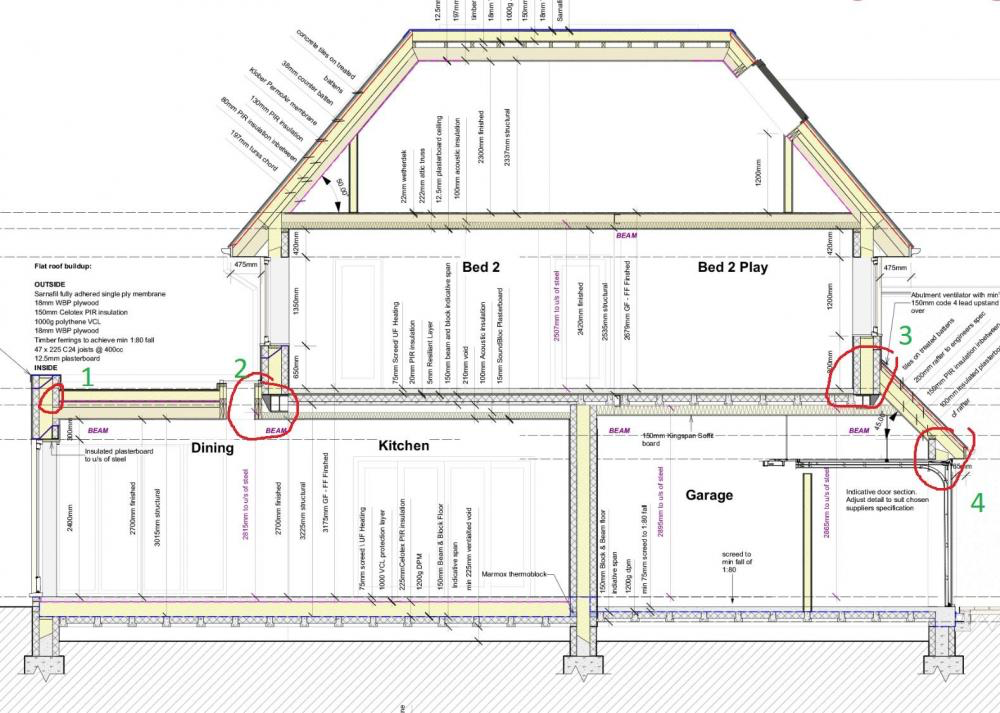

You had previously posted this plan which shows the position of the steels better. There is a little cold bridge there. The plan does not show a PIR edge around the upper floor screed. This would make a big difference to the cold bridge there and indeed all around the upper floor as the screed touches the blockwork as shown. They are not shown on the ground floor either, I would assume the builder has added them in if he knows his stuff. I guess the interior upper floor blocks could also have a Marmox block between them and the steel which would also reduce the cold bridge. Finally you could maybe put PIR between the beam and the steel if there is space. The vertical posts should not be a concern as they are not in a heated area. If there is a concern it would be heat getting not the horizontal beam and via that into the posts.1 point

-

Finding good roofers, flat or otherwise is a real challenge... I'd like to replace my pretty new flat roof with a GRP one but finding somebody decent with a conscience to do it is a real challenge.1 point

-

Here is a simple graph. Oil has a lower condensing temp compared to gas1 point

-

Just bringing this thread back up as we're now back to using the UFH and still struggle to get this 7° delta T. After much purging I'm confident now that all air is expelled. And following @Nickfromwales suggestion of opening up the manifold pump I did indeed find a tiny piece of metal. Wunda sent me out some manual actuators and have suggested to use these to achieve the correct delta T before sending me out new Salus ABA's. I'm going to set 1 loop at a time and the system was cold, as had been off for a few days, prior to restarting. The loop length I'm working on is 80m and flow rate should be 2 l/min, however I'm currently at 0.6 l/min and achieving delta T of 7°. Strange this is flow temp was set at 45°, and has been constant since I started this yesterday morning however now it's suddenly creeping up to 47°. Will see if that settles in the next hour or so. Temp of the room in question is gaining heat but extremely slowly, up from 14.5° to 18.5° since 1300hrs yesterday. Am I wrong in expecting the temp in the room to be up higher by now?1 point

-

Yes, it is crazy. But to know the difference between crazy and sensible the question needs to be asked. All credit to you, therefore, for asking it. If the idea were sensible, everyone would be doing it. If this board demonstrates one thing it's the creativity and drive that self-builders have. And at the planning stage all sorts of ideas bubble up. Some need tempering with experience. If you can, get permission to view a pour on an ICF house. The forces exerted are huge. As I know to my cost: cost as in I'd be able to change my car now if ..... ahhhh, never mind just look at my posts about ICF1 point

-

You and me too. Blame the tax system for screwing up your perspective on make vs buy / DIY vs pay. When working for others "the cost is the cost" and you make rational decisions to buy kits, prebuilt assemblies etc. When the government takes a fat wedge* you end up making what would otherwise be irrational decisions because your time to yourself is effectively only worth 1/2 of what it is to somebody else. Congrats on having the ticket! If you're literate you're going to be run ragged indefinitely I suspect. Heat pumps next though? Loads of gas fitters out there. Few competent heat pump folks. Even I'm tempted to start fitting the things. Or would be if it weren't for all the MCS paperwork needed to chase grants in the current climate. Once they quit subsidising them and the paperwork overhead disappears the installs will start getting fun/cost effective/profitable all at the same time... *20% in VAT and 30% for basic up to to the best part of 50% in income taxes past £50k (straight income and employer/employee ni or income/ni/corp tax/divi tax - it's all much the same)1 point

-

Well done on getting the gas safe certification. Due to similar stories I am considering doing similar with some of the trades for our self-build. My dad taught himself every trade as he didn’t trust anyone in our house 😂1 point

-

Well done for keeping going and getting the gas safe. Being in one of the building trades is handy as you get to know a lot of other trades working with them, and you get to know the ones you would be happy working in your own house, and the ones you would not let in the front door. So when you do want to employ someone, you know who to choose. And yes one of the things I hate most about being self employed is ordering all the materials for a job, not always as easy as it should be.1 point

-

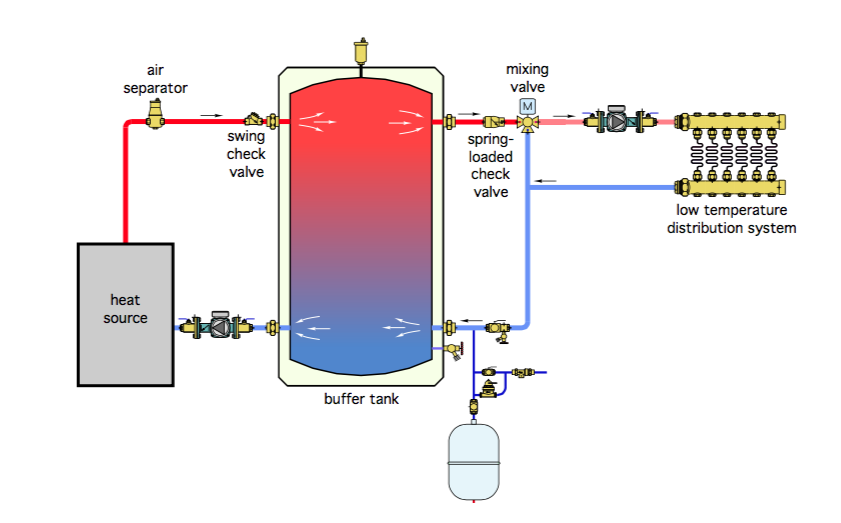

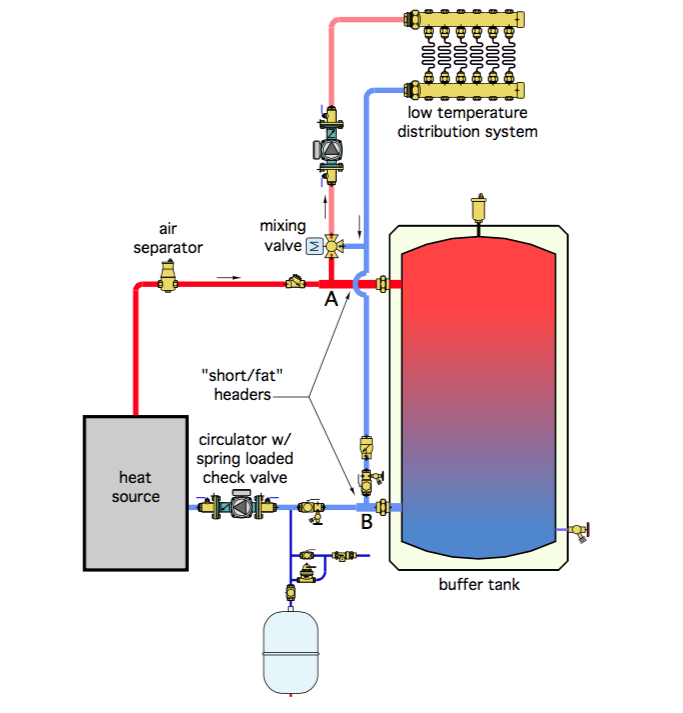

There are several ways to add a buffer.... https://blog.heatspring.com/2-pipe-versus-4-pipe-buffer-tank-configurations/ Figure 1 is what I have... In my case the room stats control the right hand side via a wiring centre. The wiring centre performs a logical OR function to control the manifold pump. The boiler/left hand side is controlled by a stat on the tank (and an optional timeclock). The left and right hand sides work independently from each other the only common thing is a Switched Fused Spur that powers both sides. However there are alternative ways. The two port system in Figure 4 is claimed to be more efficient but I've no experience of this approach.. The idea with thus approach is that flow from the boiler can go direct to the UFH. The buffer only takes "excess" water that the UFH doesn't need (for example if only one loop is calling for heat). I think this approach is better for ASHP systems as they have lower flow temperatures and this approach helps maintain the flow temperature.1 point

-

If you are considering UFH, how much insulation are you going to fit under it. Heat loss to the ground is greater with UFH than radiators or forced air systems. If you fit post heating to your MVHR, chech that the airflow is large enough to transfer enough energy. It is easy to put in larger ducts at the design stage. You mentioned 'thermal mass'. This is a contentious term and has no basis in science. What you actually mean is thermal inertia, which is the product of the specific heat capacity and the thermal conductivity. What that boils down to is the time it takes for the air in the house to drop by 1°C when there is no extra energy input i.e no heating. Brick and concrete are not very good, timber and cellulose insulation are very good.1 point

-

Just out of curiosity are we talking a full UFH type of manifold or just a old school micro bore type manifold? We are using a ufh type manifold on our upstairs rads so we can control flow temp from thermal store and no TRV's just room stats via phone app. I dont like painted copper pipes as it's very rarely painted nice (always paint over the valve nuts etc). I do like plain copper or chrome pipe especially to towel rails etc. I would not have push fit fittings on show either as the pretty bulky. Most of our jobs we took the white mlcp (uponor) plastic pipe rite to the radiator valve and used a chrome nut. Never had any customers complain. Ps carpet had yet to be fitted at that job.1 point

-

Possibly but I am sure before I have seen if you use a waterless trap you don't have a tundish. Anyone more knowledgeable care to comment?0 points

-

Welcome. That looks like an interesting old area (almost 'Open All Hours' as some are around here), where a couple of houses (or landlords) have cashed in their back gardens for a windfall. Interesting that there seems to be no off street parking, as would most likely be required now in that location. Possibly it is a bungalow due to light requirements of neighbours, either statutory or because they owned the plot. For acoustics I recommend the trombone. Very good for reminding neighbours how thin the walls are, and that they need to keep the noise down.0 points

-

Or Fakro even 😄. We put a Fakro roof window in our last house as we didn't want Velux. Worked as it should, no problems.0 points