Leaderboard

Popular Content

Showing content with the highest reputation on 12/28/20 in all areas

-

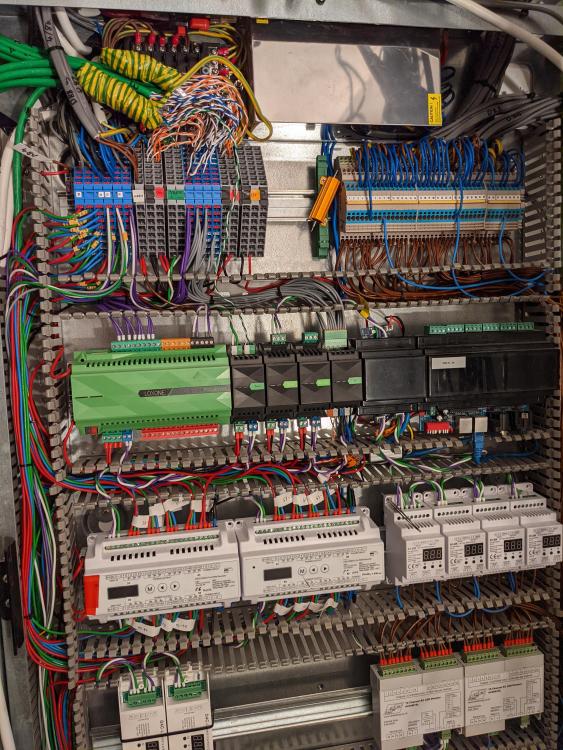

Couple more hours and I've got most of the low voltage runs terminated - top left corner. This is 24V LED strips, constant current fixtures and all the light switches and motion sensors. As I have used U/FTP CAT6A I have a lot of spare cores on each sensor run (max 3 devices per run). I also have to earth the shielding. For now I just bundled up all the spare cores and the drain wire and wrapped some copper earthing around it. Not very pretty but it does the job. Interested how others manage this (if you've used screened CAT cable). Pictures invited!3 points

-

Use the ply they have sent but TBH those notches aren’t bad. If you’ve got some timber offcuts you could also fill the gaps with even better. I wouldn’t bolt it either - plenty of decent D4 foaming glue and 5x50 screws will be fine. Those joists look ok - did the floor move before ..? And are you removing all the floorboards ..??3 points

-

Certain organisations are still blaming Covid where others have managed to move forward and adapt. As an example, many dog breeds should have their hips X-Rays and checked prior to breeding from them. The British Veterinary Association that grades the X-rays shut down completely and only reopened recently. They have a huge backlog. They have now shut down again and cite that they can’t do the grading unless on site. X-rays are submitted digitally so there is no reason why they couldn’t have adapted in the 9 months since the initial lockdowns but they’ve done nothing. Now UK breeders are sending their x-rays to be graded in the US or Australia as they have managed to sort themselves out to work remotely and returning the grading in under 3 weeks. They are a lot cheaper too. It’s just pathetic how many organisations (I don’t say businesses as most businesses have had to adapt or go under) are still blaming everything on covid.3 points

-

3 points

-

Now that the EU-UK Trade Agreement is finalised, and due to be signed, this new thread is about self-build in the new environment. There is a decent summary of the agreement here: at the Institute for Government, which has both the salient points of the agreement and an interpretation in human-ese: https://www.instituteforgovernment.org.uk/publication/future-relationship-trade-deal We will keep the focus a little (!) more tightly on self-build than the previous threads. Ferdinand2 points

-

We did it! Today we received a completion certificate for our new house - our home! It took us 61 weeks from breaking ground - and these included a very wet winter seasons, a change of builders mid-project, difficult neighbours, sacking the PM, a lockdown, tons of remedial works, and another lockdown! What a journey - feels surreal! Could not have done it without you lot here - love this forum totally Before and after pics are below2 points

-

Plenty of places where the holes are outside what's now considered proper. They're all still standing.2 points

-

For me, the deal is good news. I will hopefully shortly be ordering the windows for our Sun Room, something I was unable to manage in 2020. I was not looking forward to the prospect of having to pay tarrifs on windows imported from the EU. Hopefully this deal means everything remains the same with no cost impact on our window purchase.2 points

-

2 points

-

That should have had a DPC with weeps built in - has the lead tray also got weeps..?? And what is the lead sat on ..?? If those are dummy’s then I would have stood them on a DPC square and then put a hole through the bottom edge running back toward the roof to allow any moisture to get out. Looking at that, there is water getting in at multiple places - could even be coming in via the stepped flashing and into the void. Does it have some sort of corbelling to stand on the inside wall of the build as it’s too wide to just be part of the external wall..? Do you have access to the brickwork from the attic space ..?? I would be taking a couple of bricks out from the inside to get a camera into the void to see where is wet - that will give you an indication of where to start looking for the problem.2 points

-

I’ve got nothing to add regarding the damp issue... but I love the house2 points

-

That would be the answer, yes, but really not what we wanted. Nothing against LVT (we had Amtico in our last house) but really wanted these particular tiles.1 point

-

This is why I didn't bother asking them to come back and do these jobs. They are quite small and they just wouldn't do them carefully enough. I don't think they understand air tightness really.1 point

-

Kerb isn’t high enough by a long way - should be minimum 150mm from the deck that close to tiles. Also doesn’t look like it is insulated either ..? Roofing is rubbish; corner reinforcement looks like it was put on by a child. Needs 2 courses of tiles removed, ply put onto the roof lapped under the membrane then the rubber run up the roof. Kerb needs extending higher and preferably insulating but you may have problem with that now. And what is that socket blank covering. ..???!1 point

-

Frankly I would wallop some tight pieces of wood into those gaps with a bit of glue. Any bending of a floor joist compresses the top layer so if it’s filled (tightly) it ain’t going no where. I was always taught to drill holes in the middle of joists which compromises their strength the least. (Difficult to get copper pipe in tho, thank god fir plastic pipe!).1 point

-

Or you could just take a bit off the bottom of the doors that don't fit and with the front door you could leave the 1m area near the door for a mat well and just fit a low profile mat with a profile up to your floor.1 point

-

+1 and No action needed, use the notches, don’t drill any holes near them1 point

-

Agree with PeterW. I did just this 2 years ago on a few joists where my boiler was to be located. i used 18mm ply, wood glue and spax screws. its not moving. seen plenty of houses with plumbers/electricians notches and this depth never caused any bother.1 point

-

@PeterW one of these valves will be for the bath, it will operate a spout and a wand, so no problem there, I just want them to work if the input temp is low coming from the cylinder. He is probably unconscious at home as he’s ignoring my witty text messages today.1 point

-

1 point

-

Chamfering the corner does indeed seem to soften the look. The Fakita recip saw and Parkside multi tool made an appearance. The 45deg lap joints done on the DeWalt radial arm saw. I'll trim the top one once the Gorilla glue has set. Reckon I might need another vertical member at the change of angle. This is going to be one big, hinged door covered in plasterboard. It'll look a bit tidier with a good sanding. The black marks are from the coating on the Saxton blades coming off and mixing with the Gorilla glue.1 point

-

A few of us have the Hudson Reed Reign: https://www.victorianplumbing.co.uk/hudson-reed-reign-triple-concealed-thermostatic-shower-valve-round-plate-rei3411?1 point

-

I’ve found Matki to be pretty good quality. Lasted well in a rental property and their customer service was excellent the one time I need something. Turns out their office/warehouse is not far from me, so I drove over to pick up a replacement part and they gave me a complete shower and a load of accessories.1 point

-

We have got a Grohe 1000 thermostatic shower - it has been used at least once per day (except for holidays etc) for the past 11 years and its still as good as the day it was installed. When I bought it the chap in the in a really old local plumber merchants (been there for years and had bits stashed in every nook and corner but sadly closed a few years ago) said they were bullet proof, I have got to agree with him. We have very hard water and have never had any issues with it. When flushing toilets the temp stays pretty much constant. The only thing that I could say negative about it is that the body gets warm after prolonged use - the two newer versions that we have recently fitted send the cold around the body to keep it cool.1 point

-

1 point

-

1 point

-

I bought relatively cheap shower bar mixers but wanted thermostatically controlled for safety. Mine are not hidden units in the wall, spares readily available as they can “give up”. Was called it to a customer who bought an “all singing and dancing” fancy shower mixer that had gone wrong, just out of warranty and £400 fir a replacement valve, no thank you!!!!1 point

-

This thread has now been negotiated to a standstill and come to an agreement. It's time to move on. The new "Self-build outside the EU" thread is here:1 point

-

1 point

-

Yes I have (sort of). I have UFH in a screed on top of PIR on a slab . Stove on an inside wall so used two 90’ bends down and back under the stove/hearth. 4” soil pipe in the bottom layer of PIR , out through the outside wall with grill on to stop rodents. I am sure you can do the same with an insulated slab as long as the pipes are put in before the slab is laid like the drains will be.1 point

-

1) Can you detail how the electrical demand is made up? For an ordinary off-grid house it is unusually high. IMHO you are going to need at least two days worth of batteries. Also remember that electricity consumed for appliances then turns up as a 'casual' heat gain within the heated volume. 2) Is the heat loss rate really an instantaneous 15-20kW? or do you actually mean 15-20kWh per day, in which case it would be covered by the casual gain referred to earlier. If the former can you describe the property? Insulation and draught-proofing would seem to be called for. 3) I would meet the DHW by using a small dedicated ASHP along with Waste Water Heat Recovery (WWHR) if your space heating demand is actually 15-20kWh per day. If your heat demand is 15-20kW then DHW would be heated as a by-product of the space heating solution. 4) Electricity to be provided by Hydro/PV with an air cooled backup generator (Lister)1 point

-

I had this issue a couple of months back... not especially cold but very wet weather so high RH. Sentinel Kinetic BH. My issue was the unit was not mounted quite level (Had rotated a bit of it's screws into the roof beams), and so some of the collected water was passing the drain hole behind the Summer Bypass, and running to the front of the unit. The front PCB got wet, and the unit went haywire, reporting weird errors and fans spinning up and down. I levelled up the unit this time bolting it to the roof timbers, and a helpful friend cleaned up the circuit board for me, and everything is now fine. I keep checking the unit in the loft, and 2 months on no liquid has been seen. At the time I also cleaned the drain hole behind the Summer Bypass, and removed the bung to the front of the drain (I use the rear one), and checked it was all clear, and poured a little water in to be sure.1 point

-

Leaving aside the size of the individual components for a while, have you considered a combination of PV, CHP (probably home made), with thermal and electrical storage. The bulk of summer power would be from the PV, with the excess charging up the TS and a relatively small battery bank (4 kWh or so). Then in the winter the bulk is delivered by the CHP (a 20:40 split between electricity and thermal maybe). Again excess stored. The generator can be rectified to DC, and as long as the voltage us low (<600V I think) it can use the PV islanding inverters). A CHP system can run off bottled gas, or even gas from a bio digester. Really depends on how hands on you want to be. Making a CHP unit can be an interesting side project. Making a sound proof 'box' for it will be even more interesting, a hole in the ground may help.1 point

-

Any reason you’ve discounted something like a log gasification boiler ..??1 point

-

1 point

-

Thanks @Geordie. Not far away at all then, Ayrshire is definitely an expensive place for land up here, but have a read through my posts. This was the 8th bit of land I'd tracked down and tried for so keep at that dreaming. Everything eventually falls into place.1 point

-

Waterproofer will hold the moisture / damp in. That's the opposite to a cure ! ?1 point

-

Nothing to add abut the bricks - but great garage!!!!!!1 point

-

Same here with the bits of wood in tight & glued. Isn't the current hole drilling zone between 0.25 & 0.4 of span? Various drawings about. Maybe in the OSG? Electricians Guide To The Bldg Regs? I'd get up and look but it means leaving the tin of Celebrations unattended.0 points

-

0 points

-

You can, my Mother has one, trouble is, it cost about £1800. Turntables are not needed these days (well for about 30 years) as they can magically swirl the microwaves around now. My Panasonic NN-CD78KS has a limit to how close it can be boxed in (there also needs to be a ventilation gap for the hob), so I have left it free standing, not what I planned, and still may put it under the hob with a cooling fan (why I got a current sensing switch). I have though, moved the bin to under the hob, though I still, after 16 years, not get used it not being by the door, but my pirouettes are coming on nicely.0 points

-

0 points

-

I will take you up on it when I start the project. Next project is painting, did that for a living, so can think about the HA when I drip paint on the floor.0 points

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)