Leaderboard

Popular Content

Showing content with the highest reputation on 01/23/20 in all areas

-

Same view as above. Gas is about 5p per unit, putting it in the same range as a typical ASHP, but you can get a gas boiler for a few hundred quid. Personally, I'm now going for a ASHP. This is because of my low heating demand that means I can use a 5kw monobloc ashp that can be bought for lass than £2k, and I can install it myself. That makes is near enough that same cost of a gas install (current house gas boiler install cost £2300). And, if I operate the ASHP on night tariff, it becomes significantly cheaper to run than a gas boiler. Another big reason is I want to minimise the life time CO2 emissions from the house, gas is 100% fossil fuel based energy and an ASHP has the potential to be 100% renewable4 points

-

Sadly that smell of success has been in the air a long time. But I thought it may be helpful to others if I shared experience to date, about 11 months after starting this thread. After months of discussions with SSEN I was finally advised by one of their own wayleave team that the only way to get any traction with having the powerline that runs over our land with no wayleave or easement moved at their expense was to serve notice to have the equipment removed. This I did in June. I then followed up a couple of weeks later and was told that as a matter of policy SSEN will not respond to such notices until the very end of the allowed 3 month period. After more and more chasing, well after three months from the date I submitted the notice, I received an email with a number of documents attached. One of these was a copy of their application to the Govt. for a necessary wayleave. Amusingly in that document it said it was only a back-up option as they were in negotiations with the land owner. I sent more emails asking when, having told the Govt. they were in negotiations, I might actually hear from them. Nothing for more weeks. Eventually just before Christmas I had an email from a new person in the wayleave department asking if we could meet on site to see what could be done and we finally met in the first week of January. At the outset I said it had been a very painful process. After initially being defensive he did as much as admit that it was a deliberate tactic adopted in the hope that most people would lose the will to live and just pay for the work themselves. Having spent half an hour there with a colleague from their design team and another from the team that would carry out the work he said he would recommend that they underground the cable at SSEN's expense if I agreed to dig the trenches and would sign an easement - exactly what I had proposed to his colleague some eleven months earlier! I dropped him an email earlier this week and apparently he is still waiting for the proposal of the cost split to be approved. He has also advised that it could take months to get the work scheduled. So my advice to anyone in a similar situation is that if this is now standard practice for SSEN then if you want to avoid the cost of moving cables start the process as earlier as you possibly can, because it could take 18 months or more to get it done.3 points

-

Time for another blog post as we now have 50 piles completed and a nice shiny ground beam linking them all together. The pilers took 6 days to drive the 50 bottom driven steel cased piled into situ just before Christmas, this was two blokes and a fairly shiny new looking piling rig. The rig, in its simplest form, was a 500Kg weight on a string that was capable of being raised and dropped repeatedly. It had some very fancy hydraulic outriggers and a track that could vary its width, but ultimately it was a weight on a string. The pilers said our required loading on each pile (150kN) was fairly modest and explained how each pile would be driven to set. This involved piling away until either a new 2m section was needed to be welded on or the pile started to move less with each blow. When they felt it was getting there, they sprayed a vertical line on the pile and used a welding rod held at one end, to draw a series of 5 lines on the pile, one after each blow. If the spread of these lines was less than 100mm then the pile would be capable of taking the 150kN load. Interestingly I only ever saw this done when I was on site and watching, not one of the piles done when I wasn't there had the vertical white line and marks - I'm sure that's fine.... From a cost point of view, the piles were £1,200 for mobilisation then £127 per pile down to 4m, anything beyond that was £30 per meter per pile. In the end we had 27 piles at 5m, 2 piles at 5.5m and 21 at 6m, which was a total add-on cost of £2,160. So the total piling cost was £9,710. After Christmas the lads returned and were joined by another crew of 2 and the 4 of them started work on the ground beam. The original plan had been to excavate a trench for the beam and just set the steel reinforcement into the trench. When the pilers first saw the site they said this wasn't going to work due to the water and soft ground and we'd need to dig down to the bottom of the ground beams, so they could shutter the beam. After having a concrete blinding delivered and placed level around the route of the beam, they spent the next week placing and tying the rebar along with positioning the shuttering. By the Friday morning it was ready for our first building control inspection. As we are having a Protek structural warranty, the idea of combining the warranty and building control inspections appealed to me. Protek assigned a private building control firm to oversee the inspections, so our approved inspector, a diminutive Welsh lady duly arrived to look at the work the piling lads had done. Happy with everything we were good to pour the ground beam the following Monday. Monday arrived and the concrete pump and wagons arrived at 9.00am, ready to go. The pour was uneventful, but I was badly unprepared for the splatter so had to pop home and get changed into some clothes I didn't mind getting covered in concrete. In total, I think it was about 35 cube of concrete, so a fair amount went into the piles and beams. The lads returned the following day and took down the shuttering and much to my surprise took away pretty much all of their rubbish. That left us with the ground beam in all of its glory. The ground beam was the most costly aspect of the endeavour. The cost for beam itself was £100 per linear metre, of which our beam was 124LM, for a cost of £12,400. The shuttering was unexpected (well not completely, but you can hope) and an additional £4,000. So the overall cost for the ground beam was £16,400, giving a total spend with the pilers of about £26,000. I'm including the costs in the blog as they might be useful for others as comparison. I'm really pleased with the job that they did, the whole thing is obviously very solid and I know we have a decent foundation for the house. It's so substantial it feels like it should be able to be seen from space.2 points

-

Sobering article by Circular Ecology, UK based experts in things like embodied carbon in building construction (provided the data to carbon footprint the construction of the London 2012 Olympics), that points to the idea that in the UK we are close to the point when new PV installations may never recoup their embodied carbon cost, let alone contribute to any reduction. http://www.circularecology.com/solar-pv-embodied-carbon.html#.XinkGhfLcU- So for anyone installing PV with the primary intention of carbon emission reduction, we maybe are not currently being offered the appropriate type of technology in this country.2 points

-

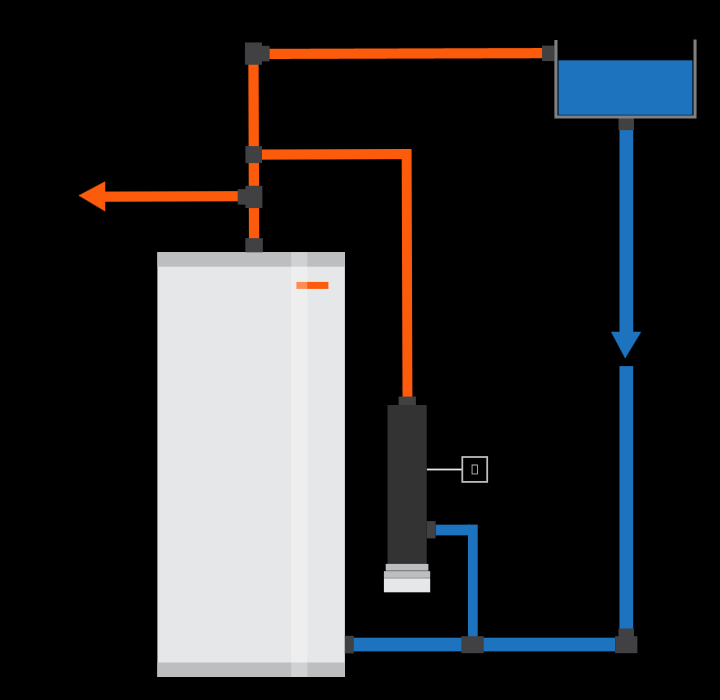

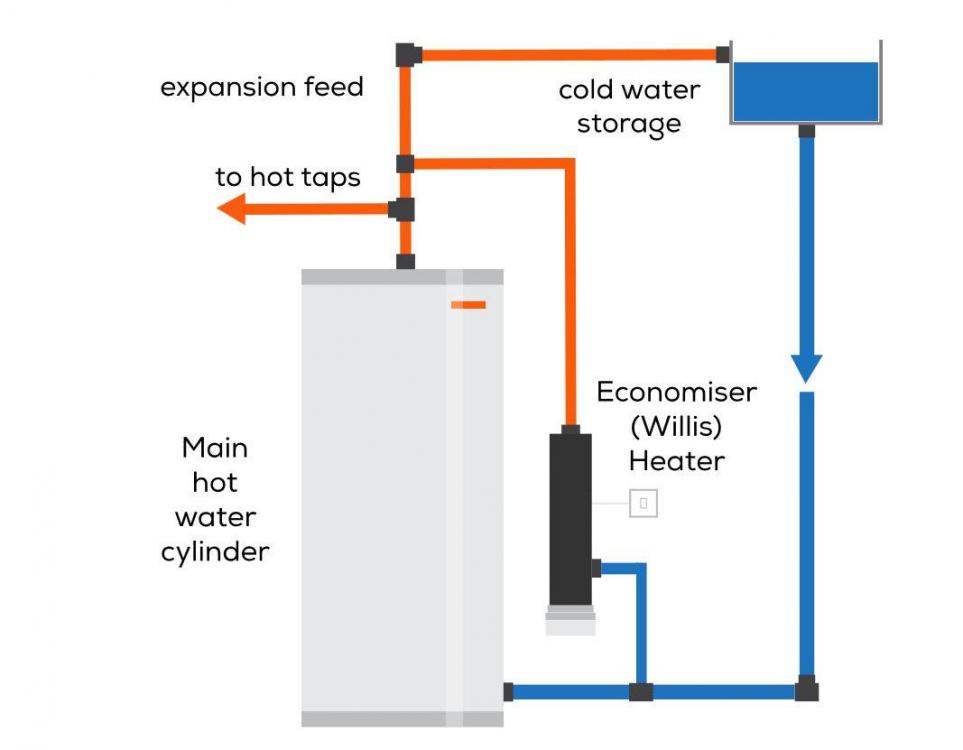

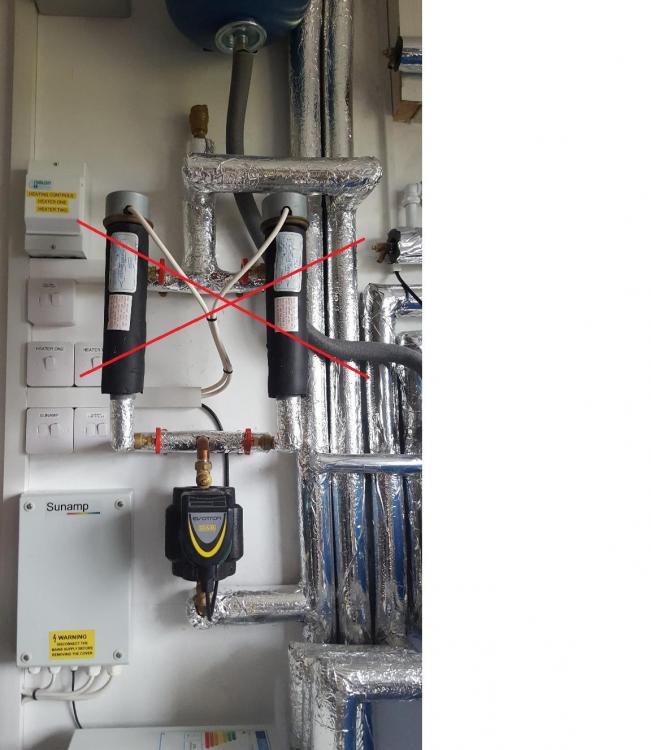

Those Willis heaters are mounted upside down! They are supposed to be mounted with the heating element cap at the bottom, so there's no air pocket trapped adjacent to the heating element bit above the side branch. This diagram (randomly nicked from the web) shows how they are supposed to be installed:2 points

-

Yes, if its available gas-over-ASHP was the consensus view that I picked-up from a couple of years of solidly reading this site. There is a gas main is in the access road immediately in front of my plot. And so gas it is for my new planned modern bungalow, which is sufficiently small that I can use just a combi-boiler. From a purely intellectual perspective, I would love to skip gas altogether and go electricity-only. But the economic perspective does not support this (yet). The initial capital cost for an ASHP is much higher than a combi-boiler and the payoff of an ASHP is not sufficient. Furthermore, at least for now, any buyer of my dwelling is more likely to have more confidence in a gas boiler than an ASHP.2 points

-

Since both my wife and me have fulltime jobs, we probably can't be onsite too often during daytime building activities.. A friend suggested that maybe a smart doorbell would be a cool solution. If builders have any questions, they can literally 'ring the doorbell' and ask their questions, have a chat with us, no matter where we are. Does this seem like a worthwhile plan? The doorbell would give a good video feed of proceedings as a bonus, but the hard part is getting internet enabled for this.. (neighbors don't seem to have wifi!). How often would builders have questions or other points to discuss with us?1 point

-

There seems to be a recurring issue with Willis heaters being installed upside down. The original MI's that were supplied with these back when they were pretty much only used in NI, had a plumbing diagram that was pretty near identical to this one, when they are used for their intended purpose, as a way of providing an immersion heater for a vented hot water system that didn't have one, and didn't have an immersion boss on the cylinder: I've seen a couple of photos posted here of upside down Willis heater installations, like these two (I've added the red crosses to show that they are fitted incorrectly): There is a problem with fitting them upside down, in that it creates an air pocket that cannot be easily bled, which then means that a part of the immersion heater element is running in air, so likely to overheat locally and probably have a shorter life than it should. This is best illustrated by looking at a Willis heater with the insulation removed, where the problem is pretty obvious. This is an upside down photo, annotated to show where the air pocket will be: and this is the same photo, but with the Willis heater correctly oriented, so there can be no air pocket: So far, the only photo I've seen on this forum with Willis heaters correctly oriented is this one (nice job @oranjeboom !): In addition to the risk of premature failure of the element by having an air pocket when these things are fitted upside down, I suspect that the electrical connections may well run hotter than intended (no water just under where they are to keep them cooler) and there may also be an increased risk of corrosion from the air trapped in the pocket. If anyone is using Willis heaters in an unusual configuration, given that they are ideal as a way of providing a simple heat source for low power UFH, then it's probably worth checking to make sure they are installed the correct way up. Willis never intended them to be used for anything other than the configuration shown in the diagram at the top of this post, and so probably didn't think that anyone might consider fitting them upside down. IMHO they could be better labelled, too, but I have a feeling that they are now made by several companies, rather than just Willis, so getting them clearly labelled etc may not be that easy.1 point

-

On the face of it, this seems to make sense. Except, as we decarbonise the grid, so the products made using grid energy get decarbonised. PV plays a large part of this decarbonising, as does wind. So comparing something manufactured a few years back with a much higher embodied carbon and energy content, with what is happening today is rather bad accounting.1 point

-

standpipe near meter, then remove standpipe and connect meter to house. they don't bother up here, as long as where you're correctly connected to whatever you've specified the connection is going to, they're happy1 point

-

There seems to be a manual download link on the page that you linked to in your previous post! It's got various installation and wiring diagrams.1 point

-

Build it out on the inside. I think there is scope for that if you wall is thin. I put my first one of these inside a louvred cupboard.1 point

-

Yup.... they leave there business cards on my landrover window all the time........1 point

-

That is because the era of Western culture with its free speech and free thought is over, we now live in a modern tyranny regulated by tribal belief mechanisms and a fear that "hate speech" heretics lurk around every corner. We had a good 250 year sprint of achievement since the Edinburgh Enlightenment, China and India are now in charge of humanity's destiny. We pontificate for decades over a 3rd runway for Heathrow, whereas in 24 hours China can place a city the size of London in isolated medical quarantine.1 point

-

I think it would be better to just be open about taxes. We don't really have an issue with 'sin' taxes anyway, and they are good at changing behaviour. It also seems odd that we don't tax at a higher level the things that are easy to tax, but we tax at a low level the things that are hard to tax i.e. income tax v corporation tax. I would like to see a large sign on council owned carparks justifying the charges and fines. Something along the lines of: 'Little of the cash raised here go to keeping the crap shops in the High Street' Or 'Taxing the local workers because the government has reduced income taxes too much' Or, how about. 'We privatised this as we don't give a (expletive deleted) for you' That last one would look good on an NHS carpark. https://www.fleetnews.co.uk/news/manufacturer-news/2020/01/21/jaguar-i-pace-offered-via-nhs-salary-sacrifice-scheme1 point

-

1 point

-

No heating on inside yet? This regularly happens with triple glazed, it shows they are "working" and not letting enough heat out to raise the outside glass above the dew point.1 point

-

I thought the problem was deforestation. If someone thinks forests are expanding I would like to see his evidence.1 point

-

If it’s sealed and pressurised then it would be periodic rather than frequent, but the risk of it being more problematic would be real. If you purge each loop one at a time it may push through, but that would be down to trial and error. If you’re putting an automatic bypass in ( so all rads can have TRV’s ) then fortify that with a gate valve so you can close that off 100% for future purging. You’ll need 100% of the pump flow to do the purge effectively, so you deffo don’t want the bypass operating whilst doing so. Closing the bypass / using it as isolation should be avoided.1 point

-

I recall your heating is 100% electric storage radiators? I wonder how your daily heat release profile compares to ASPH heating a concrete UFH floor as the slab lacks the thermostatic heat release controls of your radiators. It is unfortunate that people want peak sitting room temperature between 7pm and 10pm which is 13 hours after the nighttime tariff ceases.1 point

-

Small Ventaxia MVHR? Various models, some with humidistat etc. This link at random. I think about 70-80% efficient: https://www.i-sells.co.uk/mob/prod_detail.php?Lw_wcB1 point

-

I achieve ~85% on the night rate, and 100% heating and hot water. And I am wasteful with hot water.1 point

-

And here's an article from 2011 stating diesel is the best option for a new car, not petrol https://www.telegraph.co.uk/motoring/green-motoring/8461146/Petrol-versus-diesel-economy-challenge.html Parallels with this ASHP debate: 1/ the equation is dynamic and will change over time, so an article from 4 years ago may not be valid today, and certainly won't be at some point in the future. 2/ the way we define "best" tends to be purely in terms of direct economic payback, but as we found with diesel there can be other factors that people may make their spending choices on that go beyond the purely economic. All that said, yes I think the economic evaluation it is still in favour of gas. Yet we're currently in the process of cutting of the gas to our house and going the other way to ASHP, for the several of reasons mentioned above and also it's a leap of faith that by the time we sell (at least 10 years) we think/hope/trust this will be common enough it won't be seen as a drawback. Time will tell!1 point

-

Worth noting that even the leading eco self builders on this forum concede they do not achieve 100% heating off night time tariffs. Best assume 70/30 split (night/day) in your ££ calcs or worse if your build fall well short of passiv house standards.1 point

-

1 point

-

I use a similar strategy, I'm pretty good at scruffy anyway but I make sure I take my wife's 5 year old permanently filthy car when meeting someone for a quote.1 point

-

As I say if it won’t come off with a breaker you can go over it But being as it’s been on so long I would remove the lot1 point

-

I'm imagining @pulhamdown was meaning a lot of competition for the "most incompetent utility co" award. To continue my sorry tale, after 2 attempts and computer system reboot my emergency meter move was rebooked at 9am to be done before midday. Just had a call to say they're running behind and it'll be sometime this afternoon. I pointed out this is the fourth booking they've failed to keep for a single job. And we wonder why the smart meter rollout is going so poorly, with these companies in charge?1 point

-

Which ever system you choose A well insulated house does need much heating We never heat the first floor and have the UFH stats set at 18 The temperature rarely drops and when it does the boiler kicks in for a few minutes It costs peanuts to to run But I do agree at some stage soon new builds will not have the option of gas1 point

-

Personally I think I see the gas grid being capped off to new connections before long.1 point

-

I think it would be hard to outright replace/add to the window itself and get a good seal/overlap round the flashings/fibreglass. Although, one of the benefits of fibreglass is that you can cut sections out / add new sections and bond it all together reliably without too much hassle. But you could definitely look at putting something above the whole window assembly to stop rain landing on it. There are several ranges of flat roof window that use a plastic dome for that purpose - basically an umbrella over the window itself. It looks like sterlingbuild sell the polycarbonate domes as a standalone unit e.g. https://www.sterlingbuild.co.uk/product/rectangular-dome-only-single-skin-50x80cm and they're quite cheap. You would only need single skin as it's not doing anything thermal, just keeping the rain off the actual window. If they have a size big enough to overlap the entire current window you could just do that. You might have to be clever with how you fix it on at the sides (perhaps carefully drill/screw through the side of the window flashing with some washers for spacing, or maybe go slightly bigger and fix down into the top of the fibreglass kerb with spacers as required). If you leave a gap you'll still be able to open the window/trickle vents for ventilation and possibly even enough for cleaning if the dome is big enough. Or, I guess you could engineer some sort of flat glass canopy above the window but that might look more odd and be harder to achieve/fix securely - I suspect a horizontal pane of glass in mid air will get fairly battered by the wind.1 point

-

Quinetic all day long. https://www.tlc-direct.co.uk/Manufacturers/Quinetic/Quinetic/index.html1 point

-

1 point

-

the old saying "the quality is remembered long after the price is forgotten"1 point

-

We decided against ASHP for a couple of reasons I think if your home is well insulated bills will be low regardless of which system you choose1 point

-

It’s not a smart meter. Severn Trent fitted Landis & Gyr meters in the 1990’s and early 2000’s and these have a remote reader head that looks a bit like a black plastic container lid with 3 lugs on it. These are being phased out to be replaced with boundary box meters that have the whole lot at the isolator point for the meter and the stop tap You need to just lay the pipe from your point at which it enters the house to the boundary where ST identify the connection point, plus about 3 metres. That’s about £1/m to buy so there is no real saving in providing it to ST and also you have the issue if it’s damaged and it leaks (on their side of the meter) then basically there would be an argument as to liability.1 point

-

Why don't they give any COP data in their specification sheets? It's pretty clear that they look to be very much like are imported Chinese-made units, albeit fitted with a Mitsubishi compressor unit. Looking at the spec linked to above, for the inverter controlled unit, then it's possible to have a guess at some COP figures: Rated Capacity @35°C Water/ 20°C Ambient 17.0kw Rated Capacity @35°C Water/ 7°C Ambient 13.6kw Rated Capacity @45°C Water/ 20°C Ambient 14.9kw Rated Capacity @45°C Water/ 7°C Ambient 13.0kw Rated Capacity @7°C Water/ 25°C Ambient 9.9kw We can either assume that the above performance is using the rated power input, or that it's using the max power input: Rated Power Input 3.9kw/18.5A Max Power Input 4.7kw/21.3A Converting the performance figures to COP using the rated power input gives (I've highlighted the most meaningful ones, heating and hot water in cool conditions - they don't give any cold weather performance data): COP for A20/W35 = 4.36 COP for A7/W35 = 3.49 COP for A20/W45 = 3.82 COP for A7/W45 = 3.33 COP for A25/W7 (cooling mode) = 2.54 Converting the performance figures to COP using the max power input gives (same highlights as above): COP for A20/W35 = 3.62 COP for A7/W35 = 2.89 COP for A20/W45 = 3.17 COP for A7/W45 = 2.77 COP for A25/W7 (cooling mode) = 2.11 For comparison, the performance data for a Mitsubishi Ecodan 14 kW inverter controlled ASHP is (and Mitsubishi make it clear that their data is based on the maximum input power): COP for A7/W35 = 3.87 COP for A3/W35 = 2.91 COP for A7/W55 = 3.12 So, why does a Mitsubishi ASHP, that uses the same compressor as the Cool Energy unit, perform so much better than the Cool Energy unit? The difference is marked, bearing in mind that the max input power should be used for the comparison. Taking the A7/W35 condition, then the Mitsubishi Ecodan uses about 2.584 kW to deliver 10 kW of heat, whilst the Cool Energy unit uses 3.46 kW to deliver the same 10 kW of heat, so for that condition would cost ~ 34% more to run. The same sort of difference seems to apply for other conditions, although as Cool Energy don't actually give performance figures for either relatively cold air (the 3°C condition) or hot water at 55°C, it's hard to make an exact comparison. The question really comes down to two things. How well supported will the Cool Energy unit be when compared to any of the big name brands? And, will the reduced purchase price make sense in the light of the significantly higher running cost? For a house that needs the sort of heating power output for a heat pump of this size, then I suspect that the increased running cost is likely to exceed the difference in purchase price before too long.1 point

-

Could be a chance to push for a decent discount and let him use your build to promote the blocks as a viable option for other people.1 point

-

@K78 Looking at your pictures I can understand your concern about possible breakout with ICF and how you could install bracing to counter that. I like your idea of using the lego blocks and hope that you are able to complete your build using them. It's nice to see different construction techniques being used rather than the same old methods. Good luck with the project.1 point

-

Also - go and get on the chat with the guys at J W Grant's literally 2 minutes from you - everything more or less we have bought for the build has come from them. Also, excellent sheet material and building timber specialist round the corner from you in Anniesland. They do all the cladding and have their own mills they work with so can make any shape or size.1 point

-

Had scrappies knocking on the door the other day to ask if I wanted to get rid of my van. Is that about right?0 points

-

While standing outside your 2.5 million dollar property......... only kidding, good strategy if it’s in context.0 points

-

Has the print function disappeared for everything, or just that document? If it is just the document, it may be read only, or have similar restriction placed on it. I hope you downloaded it from a trusted source, Jeff Bezo had pictures of his todger copied.0 points

-

0 points

This leaderboard is set to London/GMT+01:00

.thumb.jpg.bac90f3bbf6868cf2118d010d936c99d.jpg)