Leaderboard

Popular Content

Showing content with the highest reputation on 11/18/19 in all areas

-

3 points

-

Says the person who doesn't bother actually researching such things. Why not get off your backside and go find out for yourself. Your apparent laziness is beyond belief. I do wish you'd stop treating our members with such contempt. You're not happy to be proved wrong in anything. You know nothing about building a house but act like no one else does either. I'll keep sniping here for as long as you are so rude and arrogant. I wouldn't put up with it face to face and a forum is no different.3 points

-

Nobody is trying to impress buddies/gangs, we are just working hard to get projects done, help others, learn and prehaps have a bit of banter. This attitude is terrible brings down the general feeling of forum. ?2 points

-

Make sure when you set up any accounts you use your own name As it may compromise your self build status I run a LTD company with several accounts But for the self build I opened three accounts in my wife’s and my name At merchants that I already had accounts at2 points

-

Even that went from a polluted brown field to production in about 4 years. There is the last tin mine that was productive. For the last 20+ years there has been arguements about reopening it. Latest twist us that they could not build housing nearby because if the noise that the mine may make. 20 (expletive deleted)ing years to do nothing, the UK really had to get a grip on development and rethink our planning system which is hurting the country at every level.2 points

-

Thanks all! Good advice. Just spoke to the MD of a different timber-frame company this morning. When I mentioned this choice he also said emphatically to choose the concrete slab every time as it gives a much better result and he said it won't cost much more. And his company offers joist-floor solution! I will be visiting him next week and he said he has test-built examples at his factory of houses using both floor types to show me.2 points

-

You have the ultimate bargaining power - payment. Up to you if you want to use it. You have two options: 1) Let him call the tune, and you pay up regardless of whether you're happy or not. In which case you can't keep complaining here - you've decided a path of no confrontation vs getting what you want. Now that's not necessarily the wrong path if you value avoiding confrontation above getting what you think you've paid for. For your follow on work, make sure it's nailed tight on detail and avoid any repeat occurrence. 2) If you believe that you have a strong case that he's not doing what he agreed to, then state that and give him the choice of making good or with-hold part / all payment until resolved. Let him take you to court if he wants. Yes he may walk off job but you will have the funds for another builder to complete the outstanding tasks. You can't let him hold that over you, otherwise you're back to 1) above. When I had my basement built on an agreed price to an agreed schedule, there were still some discrepancies - they wanted a bit more money for 'extras', I wanted a discount for a few things they skipped. While it was all matey during the build, that conversation was decidedly awkward and I didn't relish it - I don't naturally enjoy confrontation, however I stood my ground and we agreed a resolution. Attitude was able to go back to matey and get some follow on tasks completed. Builders are usually fairly thick skinned individuals (whether they want to be or not), and while a small minority are outright crooked, most will turn a 'grey' situation to their advantage as I'd imagine they get screwed the other way as often. In your case, mistakes have been made by his team but you chose not to go down the full plans route so there is grey in the middle and he's taking advantage. You're back to options 1 or 2 above. Good luck.2 points

-

Well, it is up and the top on. The scaff structure feels very sturdy (I ordered a bunch of spare lengths and we added diagonal braces as we went till it all felt rigid). Only took two lengths of scaff across the top (with braces to centre span) before the sides felt rock solid. So decided to leave most of the rest off and support the tarp with rope along the lines of @Cpd suggestion. That's holding well, will add more to make it more of a web but ran out of time today. As per @Visti the cover is just sitting over it, tied off to the building rather than the scaff. Went with a big 8m x 10m sheet of clear mono cover tarp which appears to be much the same as the scaffold sheeting @Ed Davies recommended. Foolishly ordered the long sides to have the fewest pieces, had an entertaining time trying to juggle a couple of 21' horizontals and freestanding legs before they were clamped together. With hindsight should have done that as 8' lengths with couplers and built it a bay at a time... The wedge-joined-to-a-rectangle shape made it impossible to get the tarp totally taut as a single plane. So instead decided to tension it into natural sags that run downwards to the outside edges at front and back (like a poor man's butterfly roof) - had a bit of light rain today and it's run into the fold and out as expected. Still plenty of headroom under the droops to work. So far very little wind and the forecast for the next fortnight is fairly calm and light rain so hopefully it will hold up ok. Now just need to get the old tarps off the roof itself, will use them to enclose the sides against driving rain / splash from the tarp "gutters". As it's going to be pretty draughty up there my plan now is to borrow a couple of electric patio heaters to warm/dry the boards rather than trying to heat the surrounding air.2 points

-

Yep, pretty sure that's right. Apart from anything else, my playing with steep angles for winter generation earlier in this thread wouldn't make any sense if those angles were from the vertical.1 point

-

Designing is easy with loopcad and you can sometimes make a decision to move the manifold for example that a supplier won’t do for you. I would get everything from Wunda on a list then ring and ask for a discount - add in all the auto actuators and a Wilo manifold and it’s not going to save you much elsewhere. I spoke to them at Construction Week and said they need to start doing lower temperature Esbe valves for near passive builds too.1 point

-

The more insulation the better, but obviously every job is different you probably need a chat with your builder, or do a test hole and see what you have there now.1 point

-

It's not a closed in cellar with only one exit. Our back door opens into our back garden (house is basically 3 floors). Entry/exit through kitchen too.1 point

-

I think it's a combination of the angle of incidence and the longer path length of the sunlight through the atmosphere. Overall annual production from panels is reduced noticeably for more steeply mounted panels but winter production is severely clobbered by the shallow angles most panels are mounted at; they need to be mounted nearer vertically to optimize that. For a point at the north end of the runways at RAF Syerston (between Nottingham and Newark - an arbitrary East Midlands point I happen to be sufficiently familiar with to pick as a point with a clear southern horizon) putting the panels at various angles PVGIS gives the following outputs: 35° - Annual: 1020 hours, December: 35.8 hours. 75° - Annual: 889 hours, December: 45.8 hours. 90° - Annual: 752 hours, December: 44.4 hours. One of the reasons people say that PV falls off a cliff in winter is that they only look at the output for relatively shallowly mounted panels. For that 75° case the month with the maximum output is April with 96.8 hours production so not much more than twice the December production. Actually, for 75° the worst month for production is January at 43.7 hours. December is the worst month for 35° mounted panels. I guess that's to do with the mix of direct sunlight and indirect sunlight scattered from clouds.1 point

-

It wouldn't be if there was no way to search the web for sites like: https://www.jablite.co.uk/ and https://www.insulationsuperstore.co.uk/browse/insulation/insulation-board/floor-insulation/jablite-insulation.html1 point

-

Your still clinging on for some reason trying to find a major structural fault with something which isn't an issue. For the sake of your own mental health and ours just move on.1 point

-

Often when selling stuff to the trade they will alter the terms of the sales. In exchange for discounts / credit accounts they will offer a shorter amount of time to return a item and returns can incur a restocking fee. I would imagine that some trades are less picky about the item they receive and less likely to return stuff. Not helpful info.......but felt like mentioning it1 point

-

Just create a trade account. You don't need a company - many "trade" accounts are for sole-traders with no ltd co. I have a couple I setup as "AS Developments", any credit check they may run will be against you. It's just smoke and mirrors but works. Though in this case maybe that horse has left the (tool) station ? I know mixed metaphors and bad joke all in one1 point

-

@BotusBuild Best plan is to buy a site loo from ebay. Renting one is very expensive. I bought mine for £500 delivered & have just sold it on ebay for £425 buyer collected. If I had rented one over 3 1/2 years would have cost a fortune. I used accompany called D-tox to empty, clean & refill it for £25 =VAT As my build has been sporadic there were long periods when it wasn't used so it didn't need servicing that often.1 point

-

Not exactly the same but we built our basement slab on EPS 200 grade - the number after the EPS is the point load bearing capacity of the insulation in N/m2 (I think). EPS is also more water resistant than open cell insulation (like XPS). You would be able to get away with a lower grade - we have an entire basement, foot thick RC walls, plus house sitting on our EPS just figure the loading per m2 Not sure in your case whether the membrane needs to be under or over the EPS but if it's butted tightly together then the concrete will not run down into it - we had the membrane on the top of ours and the EPS sat on a sand blinding layer on a base of compacted type 1.1 point

-

Depends what you use and if the room will be heated ..? If it is, you need a minimum level of insulation in the floor. I tend to use 25mm Jablite instead of blinding, then the DPM, and then Kingspan/Celotex as the lower layer is more pliable and accepts the stones etc. even where it’s been compacted with a whacker plate.1 point

-

Yes, that’s what trade accounts generally are. People who buy in bulk and then sell on to customers, not Johnny New Build who is buying for himself. It’s a way to retain their loyalty by giving up a little of their profit. You won’t be a repeat customer so they’re not bothered about dropping the price for you, although some will if they want a sale. It’s also nowt to do with VAT as they have to include VAT to trades buying over the trade counter too.1 point

-

Trade discounts are usually used to lure you away from another supplier. For example, Howdens offered to beat TP last month on some doors over and above their “standard” discount. This is because they are nearly next door and know who buys where ....!1 point

-

Also, as a rule of thumb when using CSM, weight it, then weight out twice the amount of resin. You won't be far out.1 point

-

1 point

-

It is a bit if a combination of things. RH is really only a problem when very high, and in a hot place. If you warm the boards, curing can start sooner on the first layer. But don't think that will be a problem. What may be worth while is upping the catalyst a bit if the final layer is put down more that about 15 to 20 minutes after the first layers. Trouble with having the resin warm and the boards cold is that it reduces the pit life of the resin. Do a metre by metre square at a time until you get a feel for what is going on. And don't do too much if there is a chance that it is not going to cure in about an hour and a half. Curing will not catch up the next day. Sun us out in Aylesbury.1 point

-

I can't find the picture at the moment but if I get a chance later I'll go and take a pic of some of the work on the local church. They napped the flints square and it looks very impressive.1 point

-

It seems to me there could be more potential problems with a metal web joist ground floor than concrete. So I would use concrete.1 point

-

So you have now made the sail, get the hang of the GRP and you are well on your way to making a boat. Make sure it is warm enough to lay up the GRP. You could use cobalt accelerator if it looks like the temperature is too low. If very low, then amine accelerator (have used that for very quick repairs when about 0°C.1 point

-

Morning mr @zoothorn now how about this, every time you ask a question and I reply we can have a little bet that can be judged by the forum, so if you ask a question and I answer incorrectly I will lose, if I answer correctly then you lose. Why don’t we say £100 a question just to make it interesting for sombody who cannot look up the price of a sheet of insulation you seem very confident that I’m wrong, so should be an easy £100 for you. What ya reckon,1 point

-

That thin bit of steel is a timber frame lintel - probably a Catnic. It will be twice the price of a concrete lintel - it’s a specialist piece of kit.1 point

-

You could actually install an in-line fan above the ceiling where the current one has its power supply, and make the pipe join using that. They tend to be more powerful and quieter. I had this done to a tenant’s house and we installed and we just did a fan with backdraft shutter, a decently long flexi pipe to the easiest place to put the outlet, and a cowled grill in a gable. Have had no reports of problems. F1 point

-

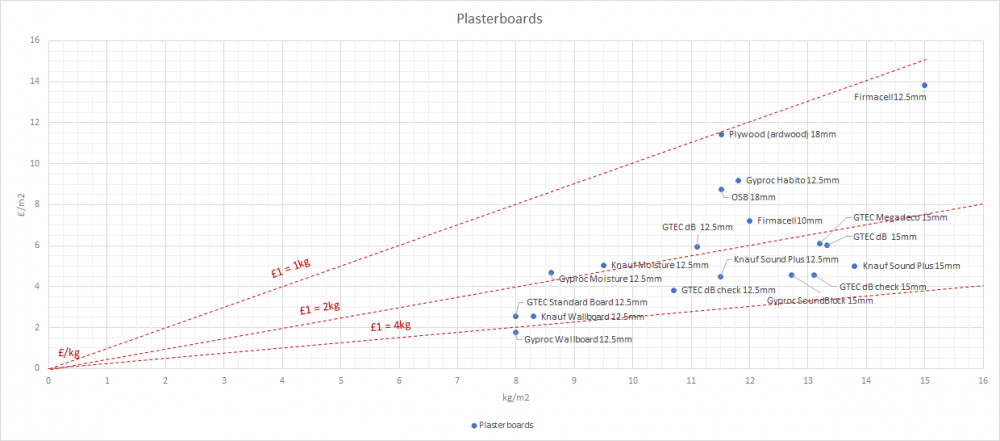

@Moonshine - doing a review on the £/kg and it looks like the no brainer if going for acoustic performance is bog standard wallboard at 4.52 kg per £ I may as well double up on standard board which will give me a surface density of 16 kg/m2 at £3.53 per m2. That is a full pound pound cheaper per m2 than the most economical soundboard GTEC dB check, and gives an extra 3kg/m2 to boot. Why have soundboard at all? Is it a question of labour? @Nickfromwales - 100% correct on ply... a very expensive approach. I'll be doing it strategically as recommended1 point

-

1 point

-

Boost fan for the old fireplace... Grandparents used to have a blower at the side of the chimney breast to get the fire going.1 point

-

LOL no need in uk till you go over 3 floors. we don,t have earth quakes here the italian spec one is 150mm -so you can have that if you want but that is 20% more concrete cost ,if someone was worried --drop some rebar in it -cheaper than more concrete ?1 point

-

1 point

-

Spiral is better as you have drawn it UFH supplier is smoking crack... Minor tweak to yours - don’t go under the WC pan in the shower room.0 points

-

Yes, or 10 300 W loads for an hour, or a 30 W load, like the security light I have just fitted for my Mother, for 100 hours. More interesting is how much water and air you can heat up. Water takes 4.2 kJ.kg-1.K-1, air is easier to remember as it is 1 kJ.kg-1.K-1, but oddly, stone, concrete and brick are less at about 0.8 kJ.kg-1.K-1, pine is 1.5 kJ.kg-1.K-1. Taking just water as an example, and 100 litres (or kg as it is the same) of water at 40°C and an incoming mains water temperature of 10°C That would be: 4.2 [kJ.kg-1.K-1] x 100 [kg] x (40 - 10) [ΔK] 12,600 kJ To convert from kJ to kWh multiply by 0.00027778 3.5 kWh So today, your PV has given you a free bath. (If you take the reciprocal of 0.00027778, you get 3,600, which is the number of seconds in an hour)0 points

-

One should be careful of what one wishes for!!! Yes, it's just in the preferences; I'm still here though - as it's better than eastenders. I can't see a reason other than cost that you needed the collars lower. With more thought you could have insulated under the slab, but that's hindsight for you. I've got loads of issues on our gaff that aren't perfect, but its better to have it 50% right than 100% unbuilt, that is the only way of getting perfection in this game.0 points

-

Trust that it doesn’t have a wooden beam going through the middle of it like our Jacobean Chimney did :-). Yes it did catch fire eventually.0 points

-

It was -7 here last night and forecast to be even colder tomorrow. I have pretty much given up hope of getting my last velux window in now before the spring.0 points

-

Heard on the news that the factory in China, which was a field in January is now making cars. From Wikipedia The Shanghai regional government approved the agreement to build the production facility in July 2018, and a long-term lease was signed for about 86 hectares (210 acres) of land in October 2018.[1][3] Construction began in December 2018 with the installation of secure fencing and site offices. The General Assembly Building was nearly complete by August 2019, and manufacturing line equipment was being installed for both batteries and automobiles. News reports in August noted production could start as early as November 2019,[4] and CNBC reports that Tesla is expected to manufacture more than 6000 vehicles at Gigafactory 3 by year-end 2019.[5] The plant had begun initial production of Tesla Model 3 cars by October 2019.[6] How long does it take us to get planning and design a building, let alone build one.0 points