Leaderboard

Popular Content

Showing content with the highest reputation on 06/21/19 in all areas

-

Progress this week. More photos than words for now. HQ is set up, including the shower. After felling the trees on site, a few big machines visited to get the logs out. Leaving the site looking like this: The last few days have then involved a lot of muck moving and getting decent material out for the tracks and base, leaving us looking something like this: Next stop, foundations!4 points

-

I read about a case recently, where a council had told a bloke to take down the fence along his front boundary. 2mt high. He told the enforcement officer to sod off. The guy then got an enforcement notice. Told the council to sod off. The council then told him they would take him to court, and get an order for them to remove the fence, and charge him for the cost, and all the legal fees. He told them to sod off. Ended up in court, and because the hearing was near to the fellas' house, the judge said, "Lets go and take a look" They rocked up at the house, and the judge stood of the edge of the tarmac, which was the boundary, and stuck out his arm. Did'nt say a lot, and returned to court. The judge then said to the councils representatives in court, that if the fence had been either on or very near the boundary, that he would have been able to touch it with his outstretched arm. As he could'nt the fence could not be considered to be on the boundary, or even near it.... The result was he told the council to sod off.2 points

-

Actually I am not bothered about it, but it’s a bit of a competition on here to do well, is it not ? ?2 points

-

Hi All, We started a major refurbishment / part rebuild and found problems with the structure - this has forced us to change route and demolish and rebuild. Planning permission to do this is going through at the moment. Wish we had found this site earlier, we have already found some good threads.2 points

-

I haven't got mine yet, but the indication was, as people here are saying, a high B that might become an A when the PV is included. We all worry about it, because we think the effort we have put in deserves an A, most people have put in a lot more effort to this than me. But other than for how we feel, it will have no impact on the value of anyone's house. Most people don't seem to care, certainly not between an A and a B. So chill.2 points

-

And this is the whole point of smart meters. It's certainly not for our benefit!1 point

-

Have to get mine done again, so I can boast that it beats a Passivehaus. Currently 74 at 2000 sqft, but has had a 10kWp solar array added since ?. It currently says that 2.5kWp will put me up to 83 Hope it is linear, then I get 110. Bet it isn’t though. F1 point

-

The bar is tiny .. a couple of seats against the window and about 4 tables. The drinks below are Blood Tonic, which by rights should have blood in it to refresh the iron like a liquid black pudding, but did not, and Espresso served with a chaser of a tooth mug of water which I have not seen before in this country. It is in a place called Rawtenstall in Rossendale. Easy to divert there when heading M6->M1. At the end of a long cobbled shopping street with 1hr free parking ... so much easier than Lancaster ?which was very difficult. They served a nice big minestrone soup in one of those bowls which keeps it hot for about 15 minutes too long. And I love the China saucer. In some ways the feel is like the tea/coffee room attached to the Northern Tea Traders Ltd, which you go passed on Chatsworth Road in Chesterfield if you take the Buxton route across the Pennines. They have 20 or so types of coffee beans in wooden tubs lie a corn stores, but roast about a ton a week so it is always fresh. On t way out I nibbled another one of those chocs which was the last one left on a sample dish on the counter, which she then told me had been step one in preparing the next person’s coffee. Ooops. Ferdinand1 point

-

There are at least a couple dead on the road outside our house every warmish, wet morning.1 point

-

Not sure it is, really. There's a farm building conversion a few miles from here that has an EPC of A138. The house is pretty poor thermally, not a lot better than building regs. It gets the very high EPC because two of the attached barns have roofs that are covered in PV panels. IIRC it has something like 30 kWp or so, and somehow that lot got included in the EPC for the converted house.1 point

-

What really matters is actual annual energy bill, and I suspect Jeremy would get the prize for that one.1 point

-

It was quite some time before I realised that was not @Construction Channel, even though CC would obviously never fall through a hole in his own floor. The wide eyed “Qui? Moi?” expression looked similar to CC’s cheerfully ingenuous “You too can do this complicated impossible thing” wide-eyed look. F1 point

-

With surface water, as long as you can rod / jet, the ICs are not considered important.1 point

-

1 point

-

Because a 6mm trowel is a comb. If you apply correctly, you will get 6mmx6mm adhesive stripes separated by 6mmx6mm voids. Same on the floor means you won’t get a 12mm bed as the adhesive on the tile will fill the voids on the floor .... or near enough ...1 point

-

Today is the longest day. From now on the days get shorter. So it seemed a good opportunity to evaluate the first half years figures. So having just done my weekly meter readings, here are the headlines: Generation since late January 923KWh. Export since late January 57KWh So self usage 866KWh. At my current electricity unit price that is a saving of £128 If the second half of the year mirrors the first then I should be able to hit my self use target of £250 pa The total generation is well down on what PVGIS predicts. That is partly down to choosing an E/W spit in the hope that will make self usage easier. But the big issue that has come to light is those damned trees, and shading. I sited the panels on the one bit of garden that I though was largely clear of shading, and that seemed true at the start of the year. but as the sun got higher and the trees grew their leaves, it became clear there is a big shading problem in the mornings from the trees to the east of the panels that overhang a lot more than I appreciated. There is also a shading issue in the late afternoon from a tree in next doors garden. The trees to the east are mine, and I will be felling some of them, but I can't do that until the autumn as I will need to drop them into the field behind us, so can't do that now until after harvest. The total export is lower than I expected. Most of that occurs at mid day on a sunny day when the panels generate more than the immersion heater can use, and if nothing in the house is using significant power. If I was able to sign up to one of the new export payment schemes, I would have earned £3.13 for that export, or a predicted £6.26 per year. But to be able to claim that, I would have needed to have paid an MCS contractor to install it. I think it is safe to say the extra MCS cost would never ever be recouped by that tiny export payment. If you want to drill down into more detail about usage, it is worth noting that my PV dump controller has sent 324KWh to the immersion heater so far this year. That means only 542KWh has truly been used by something that would otherwise have imported power. It could be argued that the heat that has gone into the immersion heater has saved the ASHP from heating water. Assuming a COP of 2 when heating hot water, that is a real import saving of perhaps only 162KWh So perhaps the true saving is only 704KWh or about £105 actual reduction in electricity bills. Another point of interest, peak generation year was week beginning 10th May. Even this week has been lower. That may be the point when the sun got high enough to show up the shading problems, or it may just be that for the last 5 or 6 weeks the weather has been pretty lousy for the time of year?1 point

-

Get glass worktop protectors from B&M. Dead cheap, can still see the oak through and I put everything on them.1 point

-

I am sure there are good wet room installations, but I like shower trays fir a reason.1 point

-

I used 12mm for similar tiles on to concrete floor.. a tad too deep. 10 or 8mm would be better.1 point

-

You normally go the thickness of the tile So 8 or 10 mil Always back butter floor tiles But not that important for walls If your walls are flat If you do bb use the smooth edge of the trowel Couple of mil is fine Always bag mix1 point

-

One way to look at the disparity between the EPC/SAP and reality is think about what a good job you have done. Shame I did not read your meter when I set up the logger, and when I was last over. But according to my logger, you have used 6,109 kWh of electricity. That is only about a third larger than mine, and your house is at least 4 times larger. 6,109 / 200 = 30.5 kWh.m-2.year-1. Apart from the energy input from that smokey wood burner that is. Still, most of that goes up the chimney.1 point

-

You only use 6 X 9 inch block for pig houses. Can you not use soapbars instead like these https://stowellconcrete.co.uk/concrete-soap-bar-blocks/ All the walls you build should be plumb no matter where they are. Your only make more work for every one else who follows you and then you will get a bad name for untidy work. Your arms will get used to the lifting and your skin will soon toughen up. The motar should be the same as an ordinary block. Nice and creamy so you can tap the block down but not soft enough that it sinks.1 point

-

I don't know what an OAP is. My Mother is 90, she would understand it. She understood the mathematics of some multi-directional arithmetic I was doing a while back. A work mate of mine is 35, he don't, nor does his wife. So not an age thing, more a case of not having it explained correctly. There is less terminology than characters in a Soap Opera, or players in a soccer team, less to learn than in the Foxtrot. There are a few OAPs on this site, not counting myself in that group yet.1 point

-

Mine was a B85...I was hugely upset at the time given the efforts and expense we went to on everything. I think without PV its nigh on impossible to get an A under the current system. Given the current parameters your B is good...as was said to me.....doesn't make it any easier to swallow though does it!1 point

-

This is the problem with the EPC. It is really the underlying legislation/standards. They are generally worse case scenarios or the complete opposite. Nothing self builders can do about it. Except put in some PV on your huge garage roof. You like roofing, pull it off and fit some integrated panels, they will help keep the garage cooler in the summer. Your B is just one above my 1987 built timber frame house1 point

-

I think I qualify for impossible build more than them. Because the local building control are being bloody impossible to deal with ?1 point

-

I'd agree with the point made by @lizzie. I know of two self-builds where the directly employed project manager caused significant problems and cost over-runs. I'm sure there are really good PMs around, as I had meetings with two either of which I'd have happily used, had our circumstances not changed. It's really important to track down previous customers of any PM and see what they have to say. One of the people I spoke to I heard about from another person who'd used him and recommended him, and a personal recommendation counts for a lot, in my view.1 point

-

1 point

-

You don’t need the two parallel to each other to top right. One will be fine (and better as the flow is more consistent) what is the one middle top..?? Is that just a stack vent as doesn’t seem to capture anything ..??1 point

-

Oh and move the downpipe on the right wall to the top right corner and run the surface water down the top and left sides not under the slab.1 point

-

Lose them both, bring the connections past the under slab points and add a rodding eye on both ends assuming you have access to the back of the building ..?1 point

-

1 point

-

I would imagine walk on glazing is difficult to add after the build . Best Buy it now ....1 point

-

Plus the weight considerations - 750kgs! All the parcels go in there and we also have a letter box. Camera keeps and eye on everything.1 point

-

Should have, could have, would have added acoustic foam around the bath. Spa feature is pretty noisy. The foam worked a treat around the WC.1 point

-

1 point

-

I think you've hit the nail on the head, @jack. My reason for wishing I'd opted to install a split aircon system for cooling was largely driven by the fact that the MVHR just cannot ever shift very much air through the heat exchanger and always runs at a serious disadvantage, in hot weather, by drawing in hot air to cool down. Because an aircon unit just recirculates air, as well as having a very much greater air flow rate, it is both far more effective and more efficient to run. If retrofitting a split aircon wasn't such a PITA I'd already have done it. I dearly wish I'd made provision to get the pipes and cables in where needed, right up near the apex of our entrance hall. Being able to cool the air ~6m up, in the centre of the house, would make a very useful difference to comfort in hot weather, and the slight noise from an aircon unit up there wouldn't really be a nuisance.1 point

-

I don't quite follow this. Air conditioning is a closed system, so it doesn't cause "draw in" fresh air from the outside. You therefore still need to run the MVHR when you have the aircon running, otherwise you'll have no fresh air coming into the house. If you bypass the MVHR heat exchanger and draw in the air from outside for supply via the MVHR ducts, it still needs to leave somehow. Perhaps you're planning to use positive pressure provided by aircon, and to have that pressure cause air to leave via the extracts? Seems a potentially very wasteful arrangement if the MVHR heat exchanger is bypassed. I also think you'd need to carefully consider how you'd provide the cooled air at enough pressure to force it through the ducts - a standard ducted aircon system relies on much larger ducts than used in a typical MVHR system. Am I missing something? Perhaps a diagram would be useful.1 point

-

1 point

-

1 point

-

Just stuck some magnets on a wall as an illustration. The big magnet has a hole in the centre, which is just the right size for a pencil (if you want to mark the wall). The smaller magnets are showing the heads of the screws found by the larger magnet. Took me maybe 30 seconds to do this, and most of that was spent finding the first stud (others are easier as you can guess roughly where they will be):1 point

-

Hard to beat a nice strong magnet. I have a reasonably OK stud finder, but I don't wholly trust it, as it can struggle a bit at times. A really strong magnet will reliably find plasterboard screws, and once you have found one of those you can be pretty certain there's a stud or batten behind it. I then use lots of small (around 5mm diameter) magnets to mark the position of every screw head I find. The result is a map on the wall of where the studs/battens are, with no pencil marks anywhere.1 point

-

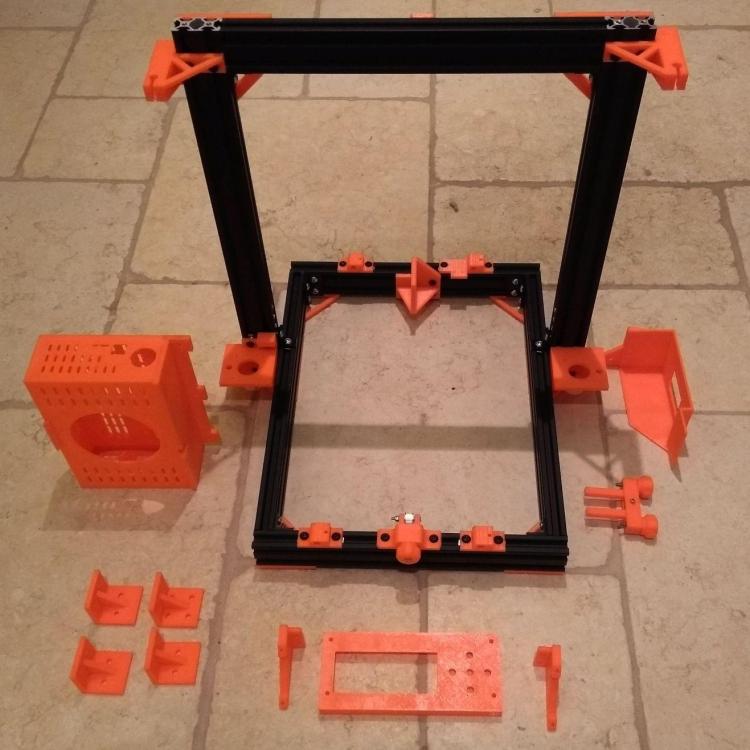

Update: I've now almost finished printing all the parts needed to upgrade my cheap Anet A8 to a metal frame. The log on the printer says it's taken about 65 hours of printing time!! Not sure I believe it. That might be the total time I've had the printer on? Still it wont be much different as I don't leave it ON when not actually being used. I've gradually learnt how to speed up the printing process but this is clearly the big issue for 3D printing. If you are "time poor" then a faster printer would definitely be a better purchase. The box on the left for the control electronics was meant to be printed in two parts, a 5 sided box and the lid with hole for a fan. The main part should have taken 9 hours to print. In an attempt to print it faster (6 hours) I turned up the speed too much and had issues with the stepper motor skipping after about 2 hours. Second attempt also failed at a slightly slower speed. In the end I decided to salvaged the back from one failed print and broke the rest of the box down into 4 separate sides in Fusion 360 and printed each separately, then super glued them together. Most of the parts are from this design https://www.thingiverse.com/thing:2263216 but I took parts from several other designs (the belt tensioners, electronics case, LCD mounting brackets, PSU cover) as people have improved these elements since the original was published. Think I have one more part to print before I tear down the original printer and transfer over all the rest of the stuff.1 point

-

It will end up at 8mm most. A 6mm trowel leaves 6mm grooves. If you butter and groove then back, you’ll get a bit of build but not 12mm.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)