Leaderboard

Popular Content

Showing content with the highest reputation on 05/28/19 in all areas

-

The apprenticeship for bathroom fitting is about 8 years and can be done online.4 points

-

One thing I learned early on was to ask anyone who you found to be good for recommendations for other trades. The good people always seem reluctant to recommend anyone they viewed as having lower standards than themselves, so this was a pretty good way of helping to select people who did a decent job. Our biggest problem by far was finding good people who were available when we needed them, and that was at a time when the building industry was a bit in the doldrums.3 points

-

2 points

-

Everyone says this now and it is rubbish most of the time. Cement used in the UK is made in the UK from UK sourced limestone, clay and mudstone, brick, tiles and block all made in UK from this cement, place is awash with sand and stone quarry's, timber is mainly UK sourced and Scandinavian which so far has been impacted little from Brexit. Fuel costs are the main variable in construction materials, timber another bulky items being worst. Timber is actually very reasonable form source, if you live near a mill do a direct deal and it can be about 1/3 the price - once you start with the wholesalers then each stick that moves by truck gains 10-18% in cost for fuel. Brexit has not actually changed any tariffs or import duties "yet". It has had an impact on certain UK manufacturing for UK supply in that people are sticking to British suppliers more so if post-Brexit things go bad then they are already using UK suppliers - different if non-UK owned business or supplies are mainly for export. I have also been told in manufacturing that UK plastic output has increased, costs have gone down and this impacts British made plastic items from light fittings to uPVC windows. Someone recently nearly doubled supply costs on me and blamed Brexit, when I pointed out their entire supply chain was UK based and that I felt they were just being greedy and that I was not prepared to be lied to and ripped off they soon started to offer me ways to reduce costs. I told them they had shown their true colours and I was off elsewhere, the MD of the firm called and said he would honour the original quote (within about 5 hours of first email) - funny as I was told that the costs were now double and they could not possibly supply me for the same price... I said no thanks. Just contractors jumping on an excuse I think and I call people out on this if they try it, they often panic.2 points

-

Same here. Do be careful if you "supply and fit" with small traders who are not VAT registered as any materials they supply will have VAT included, they cannot recover this and so will pass the VAT on to you. You cannot reclaim this VAT as the materials were purchased by a third party. I purchased my own materials in these cases - so became a labour-only service.2 points

-

The flat roof on our extension was covered with a PU liquid membrane - Desmopol. Whilst we initially had issues with the roof construction (fall and quality of finish) all those clouds have blown away (nearly; I struggle to let go of such anxieties) leaving me quite a fan of this type of coating. Of course, it is too early to comment on longevity but there are various 'features' to it that appeal: - Single covering with no joins - Very flexible and seemingly very tough - Easy to re-cover should the need arise (damage or planned renewal/maintenance) just by putting another coat over the top (when it comes to doing this I'll definitely be DIYing it - my roofer clearly showed there wasn't much skill in it!) - Minimal risk of failings around upstands etc unlike other coverings that depend on careful detailing - Can be used with zero degree falls (good for my roof that doesn't fall quite as much as it should due to an error in furring calculations!) The technical director of a roofing supplier (who supplies all types so I don't suspect bias) told me that, like seemingly many building technologies, here in the UK we seem to hold tightly on to 'traditional' methods and so new/novel techniques can struggle to catch on despite offering improvements and being used widely elsewhere (particularly on the continent).2 points

-

I costed up Isoquick, Kore and Supergrund and all came out within about 10% of each other, which was about £120 to £130/m² for the design and materials (SE fees for the structural design, foam insulation, steel reinforcement, concrete) without labour. This cost could be reduced by just buying sheet EPS and fabricating the corners etc, although you'd still need an SE to do the structural design. The longest jobs are levelling the blinding before laying the insulation and fitting and wiring up the reinforcement.2 points

-

I use a flow temp as high as 16°C and that seems to work fine. That article is BS. At the temps we run, I barely get a mist of condensation on the small amount of exposed metal pipework around the UFH manifold. It doesn't even generate enough to drip onto the floor. I doubt the floor temp falls much below around 20°C, so definitely no condensation there. I don't even bother with a thermostat - just turn cooling mode on when the weather gets hot enough for long enough, and program it to run when the sun's up so it's mostly powered by PV.2 points

-

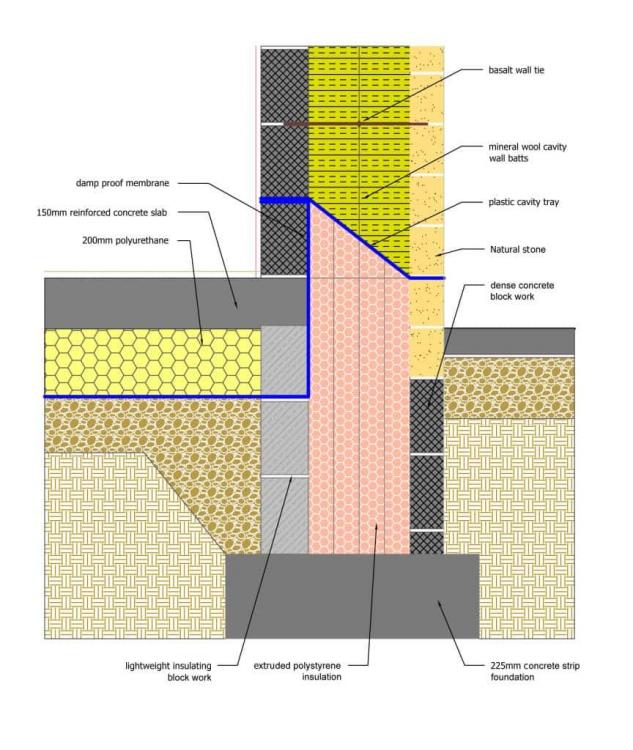

Yes, I did traditional foundations but with modifications to make them insulated. I got the idea from https://www.greenbuildingstore.co.uk/golcar-passivhaus-ground-floor-foundations/ My builder altered them slightly In that he has done this before and the DPC above the skirting has lead to cracking so he lowered the damp course to floor level and added a second DPC in the outside skin above the ground level.2 points

-

Bloody awful, I would not pay for work like that, end of. And people that want to DIY worry about getting it right when paid tradesmen do that sort of thing. Pah1 point

-

252sq metres plus the separate garage! We asked advice from my bro in law who is a specialist commercial roofing contractor.....he fits both brands. His preferred product was Fatra, he gave us reasons at the time but I cant recall the detail. He did not fit the roof for us (he is not local to us and in any event was very busy on large commercial jobs) just gave us his professional opinion. Its been on about 18 months and (keeping everything crossed!) no problems so far. We went for hidden gutters and they are made with the membrane, there are big drains into the 2 downpipes we have, that amount of roof has a lot of water flow to drain. some pics of work in progress. We did have a smaller commercial roof done by bro in law in this product about 10 years ago and its never given any trouble.1 point

-

Under catalysing is a cardinal sin in the composite industry. You can get hardeners that have different 'speeds' so that you still get full polymer crosslinking. If you have not already fitted the roofing sheets, you could coat them in GRP before fitting. That way you can do it inside and only have a few joints to seal site. I have never understood why it is done totally onsite, that is just making an easy job difficult.1 point

-

1 point

-

I agree, a 760mm door is going to be a bit on the tight side. I made the side door on my workshop the same width as all the doors in the house, and they are all 838mm. To answer the question, I've just checked and our internal door linings are all 30mm thick, so allowing for two of those, plus a working clearance for the door, plus enough width to pack the lining true, I'd say that the rough gap needs to be around 70 to 75mm wider than whatever size door you go for. You can get slimmer linings though. I believe some may be around 25mm to 28mm thick, which might knock a few mm off the rough gap needed.1 point

-

1 point

-

The internet suggests that you add 2 inches to the width. BTW that is narrow for a workshop door.1 point

-

There's no substitute for a bit of GRP experience when doing a roofing job, as it's probably one of the most potentially difficult GRP jobs to do, just because of the extreme sensitivity of polyester resin to slight changes in temperature. I've seen experienced GRP boatbuilders struggle when doing roofing, because of the need to fine tune the amount of catalyst to add. What's worse, is that you can run the risk of under-catalysing the resin and have the styrene evaporate off before the resin has cured, leaving a sticky mess. I've done a couple of roofs with GRP and found that the secret is to mix the resin very quickly and quickly empty the whole mixing pot on to the roof, then roll it out. If the resin sits in the pot it will warm up and start to cure too quickly, and spreading it out slows this down a lot, giving more working time. This only works well if the roof isn't hot, though. Not a good idea to try and do a roof in bright sunshine. Equally not a good idea to try and do a roof if there is a trace of moisture anywhere, as moisture is a real enemy when it comes to GRP.1 point

-

@scottishjohn spot on. Was using 1.5-2% and was just going off too fast. Used 1% for the top coat and was much better. I'd also suggest you have loads and loads of spare buckets, mixing paddles, gloves etc... It's very messy and brushes etc are one time use. And have extra tubs of resin and catalyst... Better to have too many and have to return to shop than not enough just when you get to your last sheet...1 point

-

so to be fair all you grp issues were due to your inexperience of its use grp is the way to go ,if its really hot use less hardener . don,t do it when its frosty wait for a dry day .do not fit new sheeting your going to cover with grp weeks before ,as it will get wet and that will cause adhesion problems ,or rot of boards if you seal it in If you must then it needs to be covered until your GRP day don,t try to do it when its very cold --and damp most professional roofers will not grp a roof unless its new boarding as well ,because of above problems always under harden if anything --but try to be accurate with mix and mix it up very well .lumps in mix is hardener not mixed in and you have a hardener rich bit ,so it goes off quicker in that bit--do more smaller mixs than one BIG mix ,untill you got the hang of how far it will go and how quick you can use it up after your first mix you will see how long it is before it starts to go off . if gel time is too long then make next one slightly more hardener ,and i mean slightly 1% is normal mix ,1.5% -2% is a quick setting mix for very very cold day on a stinking hot day 0.5%--it iwl ljust effect gel time -- it will still harden completly with 0.5%well mixed up seeing your resin bucket smoking,because too much hardener is not funny or good use of resin lean on the roller --should be see through if you have done it enough ,and if surface is wet with resin -you used a bit much --but not a problem + if you laying 2 layers don,t put as much on second time and roll it hard for see though finish I have used a special grp that is uv activated and will go off in any conditions ,but its expensive and only really for emergency roof repairs in winter . it has a shelf life of 30 days and once you open it it will start going off in the daylight .1 point

-

Yes, good call. Another thing is their availability. If they are eager to get started or text/email/call to say they can start soon then that often rings alarm bells, are they not busy? Even a excuse like a cancelled job will make me wonder, did they only have 1 other job in the queue. I had a guy who kept texting me saying he had availability this week, or he could do it now and I went right off him - as much as it is a pain, the guys who are difficult to get hold of, take days to show up and then cannot start for weeks/months are usually the best.1 point

-

I've only experience with GRP. When it goes well, it's great. But tbh I had loads, and loads of issues. First sheets went down in cold weather... Resin too viscous and then ran out. Next time, it was quite sunny and warm.... Resin started going off too soon. Went lumpy and ended up having to bring a lot of it down. And last attempt was in the evening in perfect conditions. Went well. And to cap it off, when I did the final part of the top coat, left it too late in the day. Got cool and a heavy dew descended before the resin fully dried, so left a white, dusty sheen to to. At least it was only a shed! I'd use it again, as I know what to expect, as it's cost effective, and one on its bloody solid and I can't see it failing or leaking in my lifetime. But I can see the advantage of being able to use a product and not having to worry about a light shower, or getting catalyst mix right. You can see the light dusting on the RHS. Still, happy enough with it despite the multiple mess-ups!1 point

-

Peter - I was talking about the silicone, not the sanitary ware, answering the OP question (I should have quoted) ?1 point

-

Homebase basin/pedestal and bath. Bernstein wc. Mix of Geberit, Hudson Reed and Bristan shiny bits. Somehow it all works.1 point

-

To answer OP question "I have not purchased any acetic silicone and so was looking for recommendations on what brand to buy?" ... I've done a bathroom (our current house) and the mother-in-law's cloakroom (finished a couple of weeks ago). I used a mixture of B&Q's own brand and some other branded stuff that I had left over. There is not really much difference between them as long as you think that "white is white is white" ? Good Luck with the fit out1 point

-

Depends on various factors, if you have the spare head room then building on top of existing floor may be possible, remember you want as much insulation as possible in the floor and then possibly screed with ufh pipes in it and then final floor coverings it all ads up very quickly and suddenly all your windows and doors are to low...... you also need to be sure you have good drainage in the wet season.... again it would probably be easier to rip up the old floor, dig down to footing depth instal any required drainage and start a new floor build up. I am going to do this in my shed, it’s got an old concrete floor that I am going to rip up and redo. The house also had a shite concrete floor but due to factors outside my control i will be just bodging this up for the time being.......1 point

-

Hoots mon! Dont do it: there's only wailing and gnashing of teeth in self-building. ? But hard as it is, it's equally rewarding, and the welcome here as warm as the job is difficult.1 point

-

How to put this? Ermmmmm, mind if I hold on too? It's really difficult to get some trades to come and work, unless you're in their networks.... so here are we with exactly the same problem. Slightly different starting point but essentially the same problem. I've forgotten how many times I have looked at Clive's thread ( @Onoff ) about his ablutions. Let's try and get ours done before he finishes his, eh?1 point

-

@soapstar, at the moment we don’t know who we’ll use for sub contracting, we’d prefer to use local tradesmen if possible1 point

-

From the article: If there's really a pocket of cool air on the floor (I'm sceptical) then there will be a very limited amount of water vapour available to condense so these two statements are contradictory.1 point

-

Can't agree with this enough - is exactly what we did. Before engaging a QS however I'd try and narrow the fabric options to one or two (i.e. timber frame / ICF / Block etc), then decide on your performance level (near passive, decent SAP, BR minimum). Once you have your shell, the fit out is probably the same from that point forward. You're also free to send your planning drawings right now to the slew of TF firms for a budgetary quote - you'll notice that you'll get a variation in prices as some include bits others don't so good exercise in doing apples to apples comparison. If you can deal with that then you've already taken your first steps down the PM route As Ferdinand says above - a QS will tell you exactly what you need and will use standard pricing to cost it up. Your task is then to bring in those items cheaper, either by cost reduction, spec reduction or elimination. While I respect architects and what they offer, designing to a budget is not a skill that many of the ones I encountered seem to have. We politely parted company with ours when they wanted £10k (back in 2014) to discharge planning conditions and engage building control - did these both ourselves, drawing on experience of others here (mainly Jeremy) and using the detailed drawings & calcs from the TF firm & our basement SE as the starting point. the BCO told us what was missing and we went and found it - quite an easy process tbh.1 point

-

Happy to oblige - point I'm making is that the number of trades you need to engage with at any one time is manageable - especially if you use a single contractor for the groundworks phase and are going the timber frame package route as that gets you to a watertight / airtight shell (minus doors & windows) fairly quickly. That said, you can achieve similar with block or ICF using a single contractor.1 point

-

A fall is the angle built into a flat roof (usually 15%) that enables rain water to flow off it to a gutter. If it's completely flat then you'll just have a big puddle. The fall means that if you want to use it as a balcony, you need to install a deck over it that is level - we did this on two small balconies (1m x 3m) and it cost about £5.5k supply & fit inc glass (ex VAT) for both together.1 point

-

LOL. yes i,m sure i,m not an Isotex salesman ,although expect some discount ,if i ever get this plot.LOL I like your canadian IGLOOS -- I stand corrected they build hi -rise-- but they will still use lots of bracing , which is not used in Isotex or velox and durisol builds in europe ,australia ,russia . It would appear in far off places, woodcrete is more popular than poly --think its because the poorer people can build it a bit at a time ,mix the concrete by hand and fill the blocks I wonder if in uk it is cheaper to hand mix ? maybe not. seems the mix is not as critical for woodcrete and it drys out quicker cos the water content seeps into the woodcrete drying it out quicker and allowing concrete to firm up quicker and reduce the time the standing hydraulic pressure is a problem ,which is definitely the enemy of poly systems causing most blow outs I am guessing 30 years younger and if it was cheaper to hand mix and no need for expensive pump --I would be looking hard at doing it that way . home from work and do 2 or 3mixs in an evening,soon be done , hunt the net +u-tube ,its all there to see I agree with the wp concrete for basement --but if BC insist on tanking as well ? is that a bit of overkill ? they use external stick on tanking membranes on sips paneled basements in the states not that i like the idea of sips walled basement ,but it must be water proof1 point

-

Did you know that 77.35% of online statistics are completely made up. ?1 point

-

As a tip, we had blinds made to fit our front gable glazing. Be prepared for a hefty bill, as there are only a few companies who are able to make blinds to fit a gable and they are far from being cheap (think thousands, not hundreds). The blinds do nothing to keep the solar gain down, unfortunately, we needed to fit external infrared reflecting film to the windows to help reduce that, but the blinds do add privacy. With hindsight, we could have saved money by opting to fit smart glass to this elevation, as even though it would have cost perhaps £1000/m² for the glass, it would have been worth it overall.1 point

-

@oldkettleTo be honest BC only visited twice, one to look at the foundations and then when the frame was up. Their fees included the inspection of the cabin and the house. Since then I’ve not involved them in the cabin, we just finished it and moved in. No doubt in 20, 30 or 40 years our relatives can sort of a completion certificate! It was our architect who suggested we add the cabin to the planning application for the main house, mainly so we had something formal and to stop anyone suggesting we didn’t have permission. The description of the cabin in the planning application was vogue, we simply added a front and side elevation of the cabin in a small space on the house plans, no one questioned it. However it’s in Band A for Council Tax purpose. Looking at the accounts it cost a grand total of £30k to build. The cabin has a formal bedroom, a bathroom with shower and a living room with corner kitchen. Above the bedroom is a storage mezzanine, this contains a double mattress on the floor and is used by us when we have friends to stay over. In future it might get BC sign off and use it as a holiday let.1 point

-

Been there done / doing that.....3 times.....never again I keep saying..... for me it’s so frustrating not having the money to knock down and start again, I know you want to keep the “look” and do the right thing but having done 3 renovations of buildings very much like yours I am now fully convinced that in the end it cost me to much time and money and I would have been better of starting from as close to scratch as possible. The effort involved to get these old buildings up to spec while trying to work around all the damp and rot is mind boggling...... however it’s your life and your money (I hope) and in the end all we can do is warn you to be carful and consider other options, we want you to succeed! It looks like a great place and a great project and I look forward to following your progress and will put in my tuppence worth when I can. Col (pic) of one of the 3 money pits I am currently still trying to get under control.....jaded... noooooooo1 point

-

Have you a copy of the Home Builders Bible? Pretty much does what you ask, using a model house to base the numbers around. You can also get hold of SPONs to price individual elements. However, may be worth getting a QS to independently draw up a costings worksheet from your plans - we did this (£1500 plus a PHPP analysis) and it was money well spent as I was able to target each individual element and set my self the goal of beating the price. Regarding getting sub trades vs a single contractor, not that complicated really. You just need to break the job into logical stages by trade and then go get quotes to compare. On our build we had the following trades/contractors in the following order (quite a few trades overlapped at end) - Electrician (site prep for relocation of existing power, supply to caravan and container/site office) - Groundworks (demolition, site prep, basement & services) - Scaffolding (design & erect, 12 week hire) - Timber frame (design, supply, erection & return to insulate & finish airtightness detail after doors & windows fitted). - Windows & doors (supply & fit contract) - Roofer (supply & fit, also fitted the velux that I purchased directly) - Render contractor (supply & fit) - Guttering contractor (soffit, fascia, parapets, guttering & downpipes) - Front door (supply & fit) - Electrical first fix - Plumbing first fix - Joiner (boxing in, door frames, pocket door preparation etc) - Plasterer (supply & fit board & skim coat) - Decorators (supply & paint) - Tiling (I supplied) - Plumbing second fix - Flooring install (supply & fit) - Joiner (hang doors, cills, skirting and architrave) - Resin flooring - Kitchen (supply & fit) We then moved in, and about a year later started - Landscaping (laying patio, prepping for driveway and gates, wall building etc.) - Resin driveway and gates were by separate specialist contractors. - Internal & external glass balustrade & balconies (Supply & Fit) - Electrician still coming and going to finish driveway lights, external power etc. As you can see it was mostly supply and fit (that way everything is VAT free). We supplied some of the groundworks material (EPS & GRP light-wells), Velux windows, MVHR I fit), first & second fix timber, internal doors & ironmongery, bathroom fittings (Megabad), bath, sinks, tiles, wood flooring and all the landscaping materials. I'm sure I've forgotten something here but you get the gist. Key to my success was getting a fully insulated airtight timber frame that included felted roof, floor decks and all internal stud walls as this took away any concerns about the structural elements being in multiple hands. We shared the TF design with the SE doing the basement spec - that was my main concern but both elements came together without a hitch. Main frustration was trades getting delayed on other jobs and throwing out your schedule, but you just need to roll with it. It also gets a bit busy near then end with plasterers, joiners, painters, tilers, plumbers and sparks all trying to get done!1 point

-

the span on that cottage would lend itself to SIPS roof ,then you would have high ceiling living space-- I am guessing the floor will need a new concrete one,time to go UFH ?,so by the time you done top and bottom -all you are not doing is the walls your 600m thick walls have same insulation value ,or less then than a 300mm insulated wood frame --so the new house would give more space internally on same foot print then cover it with stone facia --it will look the same you going to want to change windows at some point --so again -you can see why i,m suggesting you think hard before doing anything1 point

-

Hi @soapstar, we didn’t receive detailed quotes from either builder, which perturbed me ever so slightly, as I like to know what I’m paying for. Having previously done some homework with our costings, we know that we are being overcharged for some of the products ie the sewage treatment plant is £3k more than if we purchase it ourselves! After meeting with @ultramods, my husband and I have decided to go down the sub contractor route. I will PM the build, along with my husband when he is at home, this will hopefully allow us to build a house within our budget without having to sacrifice some of the design features. Good luck with your build ?1 point

-

Just to say thanks for all the help and advice. I finally got the approval. I'm now having to sort out the conditions, which shouldn't be a problem and then I'll get started. Thanks again.1 point

-

In practice, I've found that there's no problem with running a flow temperature of around 10° to 12°C directly into the UFH for cooling. The floor surface temperature is the critical thing, and this never seems to get below 17° to 18°C, and so never attracts condensation. With an air temperature of 22°C and a floor temperature of 17°C the humidity would need to be about 73% to start to cause condensation on the floor, and we never see more than about 55% inside the house, and then only in cool, damp, weather. With a room temperature of 22° the floor surface could be safely cooled to about 14°C, as that would need an RH of about 61% in order to create condensation. If the room was warmer, say 24°C, then for a maximum RH of 60% the floor surface could be cooled to about 16°C, more than enough to provide very effective cooling in most cases. For a belt and braces approach, it might be an idea to measure the RH and use that to set the minimum flow temperature. This would allow the floor surface to be cooled to, say, 13°C for a room temperature of 24°C and RH of 50%.1 point

-

1 point

-

just get some sheep on there - temp elec fencing and water is pretty straightforward. Get hold of a local sheep farmer he / she will either have a few barren ewes or tups hanging about. No need for any fertiliser at this time of year - Nitrogen will just bring more grass, P&K is OK but you aren't after yield. Sheep grazing will get the grass to tiller out & the little black pellets soon disappear. Sorted at no cost.1 point

-

1 point

-

maybe this should be a word of caution to all and to send the supplier a letter which states that if delivery more than 4 weeks late it will viewed as a breach of contract and you require a full refund . they will be the ones stating the delivery time not you and it is not unreasonable for them to get it right within 4weeks of due date If they have a problem with that then change you choice of blocks it is up to them to give you a realistic delivery time when they want some money . if they want up front payment there is no trust involved in the deal --,so it should be a simple contract issue quite sure they are some legal eagles out there who have seen such supply contracts in the past1 point

-

The self-builders guide to the construction phase. Thought I'd start a thread where we can comment on any books we have found of use. Kicking it off, I've just finished The Self-builder's guide to the construction phase by Vince Holden. I found it a good read and it has addressed to a degree something I've struggled to find elsewhere - namely a detailed breakdown of the order to do things on site - like scaffold lifts and avoiding unnecessary changes (and thus cost), who does what after who and so on. Certainly for someone of my knowledge level this is helpful and for some reason seems to be skirted around in other self build books I've read, who allude to it, but are short on the detail, which always stuck me as odd given how important it is if you do not know. This book definitely gives you a handle on that issue. It also deals nicely with some of what the various trades will want from you and from each other and who you need to have a 3 way conversation with if managing the build yourself. I've really enjoyed the read, and also available by Holden is his guide to project management, although I have not read that. The one down I have is that this paperback book is 294 pages, can be read in a day, but costs £24.95 at the time of writing. You can look at this one of two ways - either he's split what should be one book (600 pages would not be unreasonable at that price for a specialist subject) into two, meaning just short of £50 for both, or since you will save far more than £24.95 from even utilising one bit of the advice he gives, then it's good value.1 point

-

The Green Building Bible - currently in it's 4th edition. It's not a how-to build book, but rather an excellent overview of options, explaining them all in sufficient detail for the non expert. I wish I'd found this 3 years ago when we first started researching options as it covers concisely what I've been researching for all that time and would be great for informing the decision making process on your build, power and insulation direction. This one read would have settled it all! It also has sections on green gardens, water saving and harvesting and so on. It is in 2 volumes, with volume 1 (482 ages) starting with the reasons we all need to think green now in our building and then step by step taking you through the learning process of fabric first, CSH and the path towards Passiv (which so many of us self builders are clearly using as an aspiration at least) in a logical order, through power and heating options, the varying build methods from ethically sourced timber frame right through to yoghurt knitting straw bale construction - but it also covers the dangers of falling for Greenwash and is in fact very practical - it is about green building and living, but certainly is not pie in the sky Swampy stuff. It's definitely the most comprehensive overview all in one book that I've seen. Volume 2 (295 pages) goes into the more technical details of form and function, energy ratings, the technicalities of materials thermal performance, ventilation, the realities of renewables and geography, lighting, heating & cooling, energy monitoring and so on. normally I find such stuff dry as dust and an unfortunate necessity but I'm actually enjoying reading this! I would say the articles are "bite size", but that would imply they don't give enough information, which is not the case at all. Rather I think, it is like a collection of articles (maybe it is?), which is actually a good way to learn I think. Both volumes (they come together) also have a few adverts in and suppliers lists, but these do not detract and perhaps have helped subsidise an extremely useful pair of books!1 point

-

As a complete novice when we first decided to build our house, I bought the Housebuilders Bible (10th edition ) and I found it very good to give me a complete overview of the whole building thing. I really like the budgeting sections and am currently using it for our renovation, to give me an idea of costs. But I agree that it does not really tell you how to do it - just the things to think about. David Snell's 'Building your own home' was very similar and again useful for me as a beginner. Then I found The Site Managers Bible by Len Sales and I liked that for explaining the process of using builders and contracts as well as other subjects including a useful Health and Safety. but a book on the actual 'How to do each bit' would be particularly useful, especially the order in which stuff should be done. So I may be looking for The Building Construction Handbook. The OH can read the technical sections and I'll do the rest. Thanks for the pointer and idea for an excellent post.1 point

-

I found the Housebuilder's Bible good as our first introduction to the whole subject I guess, but was disappointed by lack of detail (bear in mind this is simply my own opinion based on what I want from a book that declares itself to the "Bible" of self building) for the actual self builder and again a detailed explanation of the proper order if you are managing the project yourself. It is covered, but not in the way it is in The self-builders guide to the construction phase. Now the Building Construction Handbook and Building Services handbook I really love and these two books really deserve to call themselves the "Bible" of their specific areas (but don't). If you could read and absorb these two from cover to cover you'd truly be an expert. They are aimed both at the trade as reference and as course reference for building trade students. At £27.54 for 966 pages the Building Construction Handbook is just absolutely jam packed with technical drawings and information, and I really mean jam packed without a single word wasted. Because the books are a reference for builders and for students they take you from "this is a house" all the way to cross sections of every part of a building you can think of. Unfortunately Amazon don't have a "look inside" tab on this one so it's hard to get just how comprehensive and well laid out it is. They are not primarily written for self builders and are technical manuals really, but eminently readable in how they are written, even by me who once didn't know a noggin from a stud or a Wide Lady from an Empress ( they are names for slate sizes ) before getting these. I actually cannot recommend these books enough. The Building Services Handbook (£30.19 new) by the same publishers takes you in 756 pages from Water regulations through to things such as calculating drag on long sewer pipe runs, cross sections of how loos, taps and other systems work, water, supply, drains, gas, electricity, earthing, sprinkler systems and fire, wind and solar calculations and so on. Just for working out my sewer line run and inspection points that will satisfy BC this book has paid for itself. Similarly to the Building Construction Handbook it's used as a reference for experts and a course book for students, which sits nicely for us non expert self builders. Even if you are not doing the work yourself, I think having a proper understanding will let you deal with the trades far better and I think being able to drop in some of the technical language and appearing informed may also prevent you being taken for a ride in some cases! Amazon does feature a "look inside" on this one, so it's worth taking a look at the contents page.1 point

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)