Leaderboard

Popular Content

Showing content with the highest reputation on 05/27/24 in all areas

-

haha. Funny, but not pleasant. I am going to be doing the installation myself for this very reason.2 points

-

Go and talk to a plumber ask him if he would fit one. guarantee if you fit it he will say don’t call him when it fails. lots of things work, but is it right, is it a robust solution or just a rough way of doing something not for me I’m afraid, 50m of poo filled pipe is not something i would want to mess with. and I’ve spent many hours in poo filled trenches. I will leave it for you.2 points

-

Done. For the project that starts now, not the one that is finishing @LindaP Interesting. I didn't understand some of the questions, which suggests we see sustainability differently. I've found that before. My company entered a sustainability award process once, and they told me after that 2 of the judges gave 100% because of innovation, attitude and leading the way, whereas 2 gave low marks because they didn't understand that efficient design is saving materials (and carbon) and because we weren't using wind turbines, solar panels gshp etc. The next ear I made it easy for them, explaining every decision and colour coding. For example the question on how much we were spending on sustainability. Nothing is my real answer, as it is all designed with sustainability in mind. How do you put a cost against not doing something, or making use of the existing structure in a novel way. You include gshp but we know that many are installed where they shouldn't be. So is it the decision to do something that interests you most, or the best decision? The end of the building's life could be an interesting question too. is it going to be easy to dismantle and recycle? where does the eps go? We are not installing solar. does that count against us? Or is it a pragmatic decision that it will require carbon to make it, and to reinforce the roof, that may never be recovered in energy harvesting I wonder how different the answers from BH will be to those who are less hand-on and less technical. eg having a house built completely by others. I am not criticising. It has made me think how difficult it is for you to set these questions, and that we are not all aiming for the same thing.2 points

-

2 points

-

On some platforms, using Chrome, you can right-click the image and select "Search Image with Google". Alternatively, you can click "Search by Image" on the main Google search page and paste the QR code in. For now, the URL is https://surreyfahs.eu.qualtrics.com/jfe/form/SV_3Q0AQK2oW2enwii2 points

-

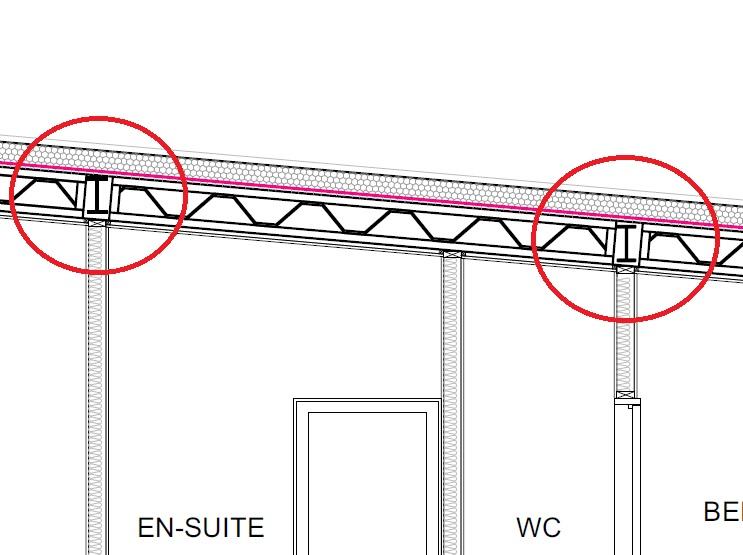

I see this sometimes when going from masonry to timber frame. A strip of DPC under the soleplate. I am not sure what your top plate is doing. It does not seem to support anything.2 points

-

A proper loo, which will very, very rarely be used for anything other than a pee, would be a useful thing to have in the cave, saves me dropping sawdust if I’m making stuff or sweat if I’m rowing in the house as we don’t have room for a downstairs loo right by the back door. So it’s worth it to me to construct a water level to give me some accurate levels before I finalise my plans. Thank you for the inputs though folks, much appreciated.1 point

-

Rather like underpinning, cutting through the full depth of a wall, to fully replace a DPC or all the bricks should be done in short sections, so that the rest of the wall remains supported, with several days between sections. It's not something that can be done in a morning... ...so if they also used an angle grinder, rather than a disc cutter, I guess that the just did something superficial on the outside. In which case, how - if at all - did they join the plastic DPC to the portion of the slate DPC that they left deeper in the wall? I fear that they may have made the damp situation (if there ever was one) worse. I'd be looking for a different builder.1 point

-

Apunsa like you've got a good builder, fair play to you both trying to resolve. As for why he didn't spot it.... Damp bricks in a pallet would change the colour strongly.... They could have just put the colour variation down to dampness.1 point

-

Completed. Just to say I built in brick and clock for longevity and I like solid/heavy (some call thermal mass!!) buildings. When you think the Romans used concrete and some of it is still standing.1 point

-

I would advocate a good trial on any machine you are going to buy. Get it hot and use every function. Repairs on plant are often much more expensive than the equivalent fix on a car. Having let my heart rule my head a few times and discovering something was far more worn out than it appeared to be make sure you do this. Also write the price you're willing to pay on a piece of paper and DO NOT EXCEED IT. A good auctioneer will wrangle a small fortune from an unwary buyer. I bought a secondhand chainsaw from a dealer/hire shop recently, very pleased with it. He had obviously gone over it and made sure it was all kosher. Much less risky than a ln auction.1 point

-

I did exactly this, long spirit level with block taped to one end to create the fall, no high tech to go wrong .1 point

-

The best thing I learnt in preparing for it was to use a 'prepared' spirit level, jacked up at one end with spacers blocks and sticky tapes.. that made it so easy compared with jumping in and out of the trench to use a hi-tech machine. or buying a fancy laser. I'm sure that the errors of 1/2mm every time added up, but you can always do a proper check occasionally.1 point

-

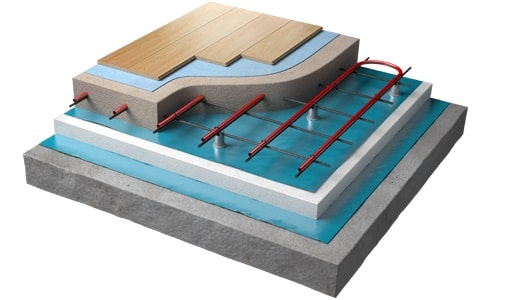

About a month or so back I did a post about reconciling my as-measured slab performance to a theoretical treatment. In short you consider my MBC slab in terms of either the 100mm slab area where the UFH loops run (say 10 tonne), or the total slab volume -- that is: including the load bearing 300mm ring and cross beams, plus the 200mm cross-bracers (say 17 tonnes). In terms of overall heat retention and release the best fit approximation was about 90% of the higher figure: the whole slab effectively acted as a heat battery and not just the areas with UFH looping. Even though the specific conductivity of concrete is relatively low, there is a lot of rebar in the slab and it is an extremely good conductor (see this post for numbers) and over the hour to few hours timescale, the heat is spread throughout the slab, and v.v. is the UFH is off and the heat is being slowly radiated into the living space.1 point

-

Set it up correctly for the house, the static doesn’t matter as it will be raised up on stands or blocks, you can also have a fair bit of pipe above ground for the static to get a good fall, install a rodding point at the static end and jobs a gooden. word of warning when connecting to the static make sure you strap the pipe up securely, I know a chap who used his toilet for months without knowing the pipe had come of, poo mountain under the caravan.1 point

-

Thanks Saveasteading for your considered reply - you're right - the questions on sustainability were tricky to put together since they can be viewed in different ways. E.g. I am really interested in using ICF - however, concrete is v much frowned upon from a sustainability/eco-friendly perspective. But what if it means your building stands for 500 years rather than say 100-200 if you use timber frame or a more eco-friendly but less enduring build technology? The survey was also put together using previous responses from an NSBRC (National Self Build and Renovation Centre) survey, so I just included all the items that had been previously highlighted as either sustainable or energy efficient. So far, from the replies I have received (but not taking into account any of today's reply from Buildhub as I have not processed them), unsurprisingly, the top three ranked construction elements are (i) insulation, (ii) MVHR and (iii) construction method. So as you say quite rightly, it's basically fabric first approach that will deliver energy efficiency and longterm performance. Thanks again for your comments... all welcome.1 point

-

they are great fun, at our recent one a hire company had gone bust so huge lots for sale, probably all serviced etc. but we didn't need anything they were selling. Cheffins near Cambridge are good because you can have a really good trial. That's where we bought our excavator, hubby drove it around for 20 mins, dug in their ready pile for testing. Not cheap, but we wanted one for the whole build and to sell again after when we'll probably get the same back. Watch our for VAT if it has belonged to a business and our local auction has 25% buyer fees plus VAT Years ago we found them more honest, we bought our lawn tractor with AF (all faults) label for £200 and rebuilt, not much wrong with it. Nowadays nothing is labelled. Ours also regularly has building materials like heras fencing and scaffolding towers which are always useful. I feel the days of genuine bargains has gone, we bought a 'lot' of 3 mixers for £30, 2 worked one was repaired and 2 were sold for £50 each privately. We are still using the other one for our build. Good luck and enjoy yourself.1 point

-

Its a good idea , saving money on hiring and disposal, and priming the tank for real action. as @joe90says, it is temporary and so the bco will not be interested in the pipes until the final run goes in. If it blocks then you can clear it. But the digester and soakaways have to be right and inspected. But beware the levels. Joining the dots is fine as long as all the falls stay within the design parameters. But things go wrong. Spirit or laser levels can be out of adjustment. Groundworkers , if you are using them, don't necessarily understand geometry or how laser levels work. You may encounter obstructions and have to revise the design. On our steading project I did the design and the hands on laying. When we found obstructions (big boulders, other pipes) we could make informed decisions as we went. These always mean going steeper for a bit, although bigger pipes was an option. the digester ended up 100mm lower than the original design. as it went in last it didn't matter, but the hole was getting uncomfortably deep. You don't want to end up lower than the tank intake, or to have a flat last run to make it fit.1 point

-

we buy lots from auction, it really is buyer beware and we've been seriously bitten once for about £200 when we were assured by the auctioneer that it was fine and didn't obey our golden rule, always view. It was pretty much a pile of parts. Hubby did get it going, but probably took a whole week of hours to do so, Other than that we stick to better quality stuff, Kubota excavator, stihl chainsaw, dumper and lots more. There is no honour amongst farmers to outsiders, maybe to each other, but they just want as much as possible. We like deceased estates as the stuff is more often working. Do ask yourself 'why are they selling', they will never tell you the truth and if it was good then they would sell privately as auctioneers fees are huge. So, after rambling my point is, buy if you can climb all over it, pull the starter to check it's not seized and you can fix it if it doesn't work.1 point

-

I will complete later when home 👍1 point

-

They can't find the plots for the right money. They dont have savings/ disposable income to undertake the project. They don't have take risks. (Done the survey)1 point

-

Yep me done to - via my phone which takes great pictures of QR codes.1 point

-

The answer is YES. and a temp connection using two 90’bends (or better still four 45’ bends ) will get you back to the tank, it’s only temporary.1 point

-

If you asked me to guess, I would think that the landlord is in control of access roads. Would an enquiry to the landlord help?1 point

-

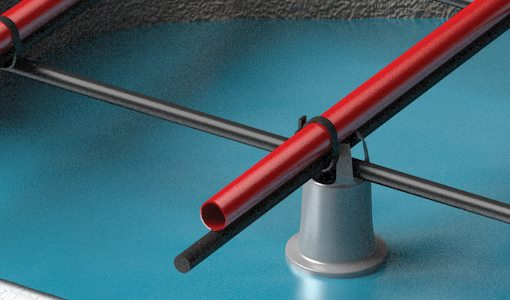

Yup. I’d rather the extra pipe / volume / storage tbh, particularly if it’s not a huge house. Not running pipes under things like kitchen islands etc is just a complete waste of time and effort in a passive type setting, as a) the temp is too low to cook your cornflakes lol, as you’re only ever getting the floor to a few degrees about room target temp so just entirely moot tbh, and b) as the heating is on ‘long and low’ the omitted areas will warm up anyways! It’s in an insulted basket, so the heat will eventually get there folks, and there’s nowt you can do to stop it. I will leave a pipe at the start of the run of fixed kitchen / other units, stopping about 150mm into the dead under-plinth space, leaving an unheated perimeter of around 450mm in the slab, and then it’s ‘fill yer boots, matey’. I’ve been installing / or been in and around / specifying M&E for these types of (PH style) systems for over a decade now, first ‘taste’ was an MBC PH TF, and not looked backed since. These Pert pipes are 1000% kosher to attach near to / directly to steel reinforcement mesh and the results are always excellent. Damage to the pipe must literally be malicious to get it to the point where it’s a total loss. “People of Buildhub, go forth and zip-tie”. 🫡. El Presidenté.1 point

-

I routed rainwater into the pumping station to help to keep it flushed out of the nasty stuff!1 point

-

Tbh he very likely passed it on as his own observation. Whatever if it gets it sorted. The powers that be would be more likely to listen to him than me. Saying that, an email from Joe Public on this sort of this thing nowadays tends to sort it as it leaves an undeniable paper trail.1 point

-

Some while ago I bought a large rotovator from a farm auction. There were 3 of them on auction and pre auction I had a look at them. All 3 refused to start. It became clear there was another bidder wanted them all, he got the first 2 but I won the third. When I got it home I found the mixture screw was missing from the carb. I found a replacement and then it worked. I strongly suspect the other bidder removed the mixture screw from all 3 before the auction so if anybody tried them, they would not start.1 point

-

SIPs will need some sort of machinery to erect, the panels are big and heavy. Stick build can be done with just manual labour- I did my place that way, two or three people can lift an entire gable end wall.1 point

-

My other half told our friends that I have become a snagging pia. Apparently everywhere I go now I spot poor workmanship and bore her by pointing it out. The other week we were in John Lewis in Edinburgh. As we walked down the stairs from the car park I noticed that where the stair handrail returned back along the flight the angle hadn’t been cut correctly and the handrail stuck out 5mm from the next run of handrail. I only noticed it because I was running my hand down the hand rail and felt it.1 point

-

1 point

-

I’ve bought a lot of things at auction both agricultural and general. Luckily it’s all worked although I’m relatively handy at fixing stuff. It is a risk but my experience so far is positive. Stuff at auction will be well used but most of the mechanical stuff and engine based stuff seems well serviced especially if it’s come off a farm. What I tend to do is look at the cost of spare parts for the thing I’m interested in and see what’s the most likely part that might need replacing worst case or how much a professional service would cost. I factor that into the auction price.1 point

-

We messaged the builder and said having thought about it we aren't happy and he said isn't happy with it either and said he is going to sort it. We are both on the same page! In fairness, I think he would have come back on Tuesday, seen it again and not been happy but I'm glad we raised it! Thank you everyone. Yes, we were just trying to be helpful. We like the guy but he did reply and say no its not our job! Maybe, I'm probably now just obsessing and getting all stressed about it. Thanks everyone for your advice I really do appreciate it.1 point

-

Fire curtain is mental for a dwelling. OK for commercial, like on an escalator for a high end retail store.1 point

-

That is normal. remove the gravel then either wash it and reuse or replace it. The mucky gravel can be renamed 'free draining compost' as loved by succulents and herbs, Good idea. A small pipe will be enough to shift that small amount of water. Make sure hat it can't work in reverse.1 point

-

This is the most noticeable thing. Our house was up a year before we installed the MVHR last month. Even though I’d been managing the humidity using dehumidifiers and opening windows etc and the house was pretty dry generally the MVHR unit completely changed the feeling of the atmosphere in the house. Most standard houses are full of cold bridges with no mechanical ventilation and average insulation and they generally don’t show any/much mould.1 point

-

It's amazing how forgiving houses with a mechanical ventilation system are at controlling mould and damp really. I suspect your situation never even came close to being a problem.1 point

-

This detail is ok. I don't love it however. 120mm seems a bit slack when it comes to insulate for the roof. I would improve on this. How are you planning on keeping the zinc roof on? It appears to be just sitting there. 22mm ply would be better for screw pull out strength if you're planning on fixing into it. Why the service void under the pozi joists? Why not run everything through the webs? That eave detail is very very tight to the wall. I know it's an aesthetic decision but if the chutes get blocked you are asking for water infiltration to the ICF or behind the ICF render and the timbers that hold the chutes on. It isn't robust enough for a moist climate in my opinion. In any case you'll get lots of staining on the render as is. Your logical place for an airtight layer is the ply, joined to the concrete core of the ICF via the wall plate. 1. Set the wall plate on a thick bed of permanently flexible mastic type sealant. 2. Run the ply to stop atop the wall plate. 3. Tape the wall plate to the ply. For the eave detail add rafters tails to move the chutes well out from the wall.1 point

-

Discovered/realised far too late the same thing with balcony steels for my "cold bridge free" MBC build. When I raised it, MBC foamed in PIR insulation then wrapped it in aerogel blanket. I'd probably have gone even further than that if I'd had time to consider it. Someone said to expect mould on the plasterboard where the steel comes into the house, but we've never had a moment's problem in over 8 years.1 point

-

How? What measure of efficiency? You've lost me here. @Nick Laslett MBC have been doing this with their slabs for a decade.1 point

-

That is a great find. Bit annoyed all my searching in 2019 didn’t unearth this. I did look at Warmup, but must have not looked hard enough.1 point

-

I'm pretty sure most would be fine tied to rebar in a concrete slab, but if you want an absolute guarantee that that's OK from a manufacturer, here's at least one. WarmUp Forte Grid System - https://www.warmup.co.uk/underfloor-heating/water/forte-grid-system https://www.warmup.co.uk/wp-content/uploads/Warmup-TS-Forte-2016-09-29.pdf https://www.warmup.co.uk/wp-content/uploads/Warmup-TS-AL-PE-RT-v1.0-2016-09-29.pdf1 point

-

Is it terrazzo surface you are going for? If so then a big chunk of the cost will be tooling for 157m2 you will get through a vast quantity of industrial diamonds and the associated pads.1 point

-

Go on the "developer" bit of your sewerage company (Wessex Water?) and look for build over agreements. Most now have a "self certify" system where if you meet all their criteria they'll agree a build over (for a fee) and give you the detail you have to use where actually building over the sewer. It'll be easier than diverting.1 point

-

1 point

-

Mine is brick and block and very pleased with it and worked out cheap per sq m compared to most.1 point

-

0 points

-

Thank you survey now completed. I am happy to complete a survey but could not be bothered to be a detective first to find the damned thing.0 points

-

At its most basic, a compost loo is a bucket and a lid. You can go upmarket and get a urine diverter and do a mini garden soak away if you like. A bale of straw works too. Managed properly they don’t smell and I would rather have one than a stinky blue cabin any day. I set one up on site and nearly everyone was happy with it, bar the electrician, who had a tantrum and nearly went home 😂0 points

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)