Leaderboard

Popular Content

Showing content with the highest reputation on 10/17/23 in all areas

-

My house is highly insulated and air tight and we have only just turned the heating on 48hrs or more after the temps dropped. Very true. Thsy said I think the key is to ditch the system of "sub contract" building inspection and move back to an independent public inspection body. Builders are perfectly capable of building to the required standard as long as the inventives are right. Having to redo an entire site because you skimped on air tightness or insuslation and the inspector won't just sign it off to stay employed will be a pretty good incentive. HPs can work at a technical level. Almost any home can be kept warm by a HP. There are some issues with placement of the equipment in some circumstances. Space and planning rules can be problematic. Modern units can achieve better gas to heat efficency than a gas boiler even at high temps (scop greater than 2.5) But when people say "HPs don't work in retrofits" what they really mean is "won't be cheaper than a has boiler". Which is true. You need a scop better than 3.5 to do that and that can be hard to achieve in retrofits without major work. But the gas/electric price ratio, and hence the break even scop requirement, are in part regulatory artifacts (and our generation infrastructure). Right now the way things are set up, electricity is priced as though it was gas generated even if it is generated by wind at a lower cost. Many of the "green taxes" fall on the electricity unit price not the gas price. If the pricing ratio were to shift via generation changes and (maybe more crucially) regulatory changes then it would be much easier for HPs to work. For example if elec was only 2x price of gas, it would be much easier for a HP to be cheaper than a gas boiler. If gas and electeixty were the same price, hardly anyone would install a gas boiler and the conversation would be "gas boilers just don't work in old leaky houses"3 points

-

Or we concentrate on tidal and offshore wind. One offshore wind farm came on line today which can provide Scotland with electric for 2/3 of all homes. The next big one to come online is 4x that size.2 points

-

How about the upfront price to build, the MWh price of delivered energy, the relatively small lack of power modulation, with the associated slow ramp up and down. Then there is the security of supply of the fuel, there has not been a mine open in Cornwall since the 1998, and I don't think there is much uranium ore there, that comes from South Terras, near St. Stephens, and they are all a bit angry over that way, probably because the mine closed in 1930. Then we have to agree where we are going to bury the waste. It will be in Cumbria, they just want a lot of cash to do it. There is also the skill set needed to build and run a modern reactor, skills the UK does not have at the moment as there are only 3 EPR PWR in Europe, and I don't think any are working right yet. Then there is the planning system to negotiate, at lest ten years of horse trading. And solar and wind are cheaper, even after adding storage. We can build a GW of offshore wind in 18 months, not the 20+ years a new reactor takes to not be build.2 points

-

The good thing about switching to HPs now is that right now, we produce heat more efficiently by buriing gas in a Ccgt, sending the elec to the grid and then using a HP at thr other end, than we can by just burning the gas in the house. So from a co2 perspective HPs are already a win *even if* we have to boost the grid with gas stations. We would still burn less gas overall. And then that ignores the fact that the grid is getting lower and lower carbon all the time. Capacity issues aside, direct electric heating is now equalt to or lower carbon than gas boilers (gas boilers are about 200g/kwh grid is consistently getting below that).2 points

-

So it looks like I've got a charnwood C4 or C5(would have to measure up to confirm when I get a chance) Yes it looks like it does support a rear flue adapter based on the info online. So that could be an option. Given the super limited clearance ive got no idea how they managed to fit the existing flue pipe to the top of the stove and fit it all in. Feels like this was definitely fitted into an undersized recess I think my first thing I need to do is get some of the brickwork out of the way and get a better idea of what I'm working with and my options.2 points

-

Hi @James94 Always good to have a fall on the lawn to stop standing water. We found that it was very important to have the fall on the clay below as well. If not the clay underneath will act as little ponds. M2 points

-

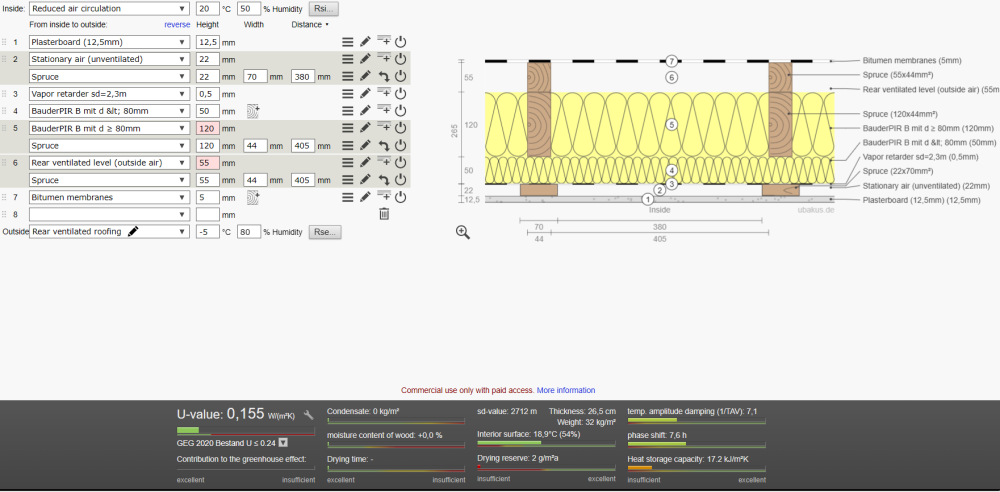

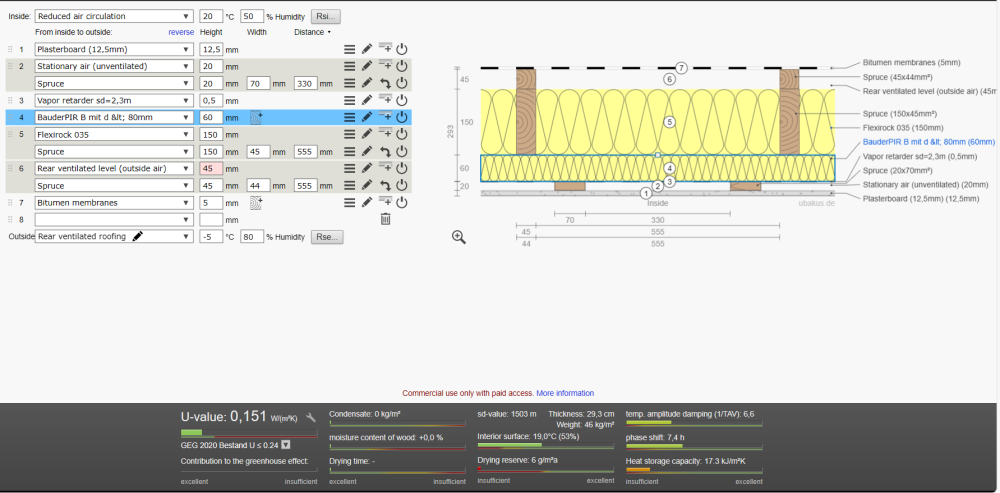

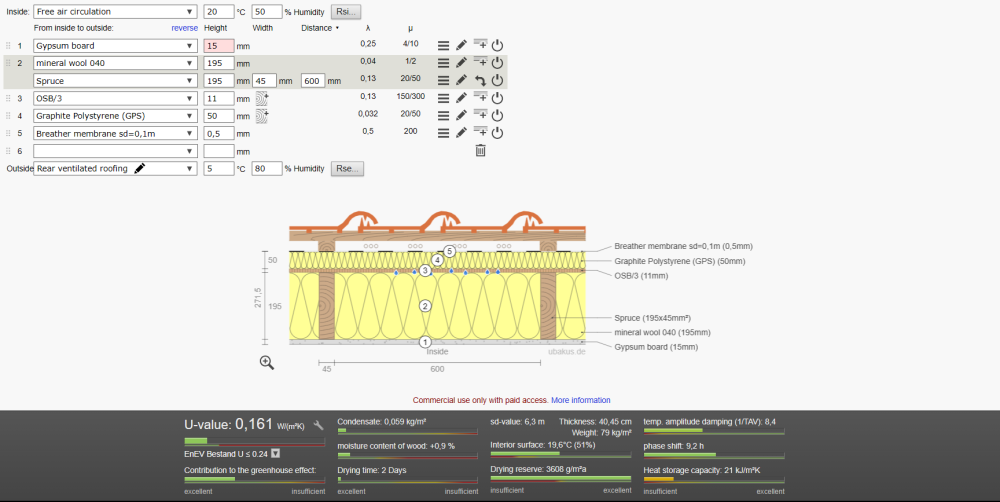

Here's a drawing of what you have. I've added a 20mm service cavity. I like Robin Clevett apart from his instance on using PIR between rafters and stud walls. It has a poor decrement delay (phase shift), requires fantastic attention to detail to get a tight fit, doesn't perform particularly well in fire or noise situations. Returning to 195mm rafters at 600mm centres would be far easier + cheaper. Buy Rockwool flexirock ( or similar) batts and just shove them between the rafters. You'll get a tight fit easily and they can flex with the roof timbers as they contract and expand. No wastage either as there's always a corner that the offcuts can be stuffed into. At the moment I'm doing my garage. Note the ventilation gap above the membrane via batten and counter batten. I was going to use blown cellulose between the rafters but I got a good deal on the rockwool. I'm beginning to regret this TBH as my rafter spacing isn't suited to the batts and I'm doing too much cutting. I'm coming around to the idea of using as external layer sheeting as the airtight barrier like the Americans. I did my garden office/pumphouse recently and taped all the joints in the OSB externally. It was super tight and much easier and robust than taping an internal airtight membrane. That coupled with a layer of external foam would be super easy to apply and eliminate all thermal bridging.2 points

-

If this were mine I would get rid of that brick hood completely , I think it dies not look nice ( just my opinion), I would make a larger opening much higher, you could still have a brick arch if you want or an oak lintel (far enough away from the stove , this was mane on m6 last build and worked very well.2 points

-

I think there will be resistance to swapping from gas to heatpumps in the new build sector. Gas boilers are generally massively oversized as there is no cost penalty for this - and right now this allows shoddy building practices to go un-noticed. Fit a correct-to-the-design heatpump instead - and it will be evident if the building is substandard - eg. missing insulation / gaps between sheets in the cavity / air leaks etc.1 point

-

Rules of thumb are generally pants, and the radiator suppliers not much better, as they are just built on rules of thumb also. As mentioned above there is a spreadsheet on here. Before I used the one here I did my own long hand calcs, both gave similar outcomes.1 point

-

1 point

-

I suspect a plan to whip support amongst the sector of the electorate who are reflexively against anything with a whiff of "green mumbo jumbo" or to do with "that Greta girl". Head lines achieved. Mouth breathers convinced Sunak is all that stands between them and meat taxes. Realistically there is zero reason why new builds need gas connections. They can be designed from the ground up as easy to heat via HP so none of tgr "but you need to replace all your rads!" or "where will you fit the giant tank!?" applies.1 point

-

Hmm. Actually, I'm blaming the gas industry. The heating industry (boiler manufacturers) are the fools for trying to jump on the bandwagon and sell something that is of no use to their customers. The 80/20 proposal was attempted to be sold to the government as a stepping stone to a 100% green hydrogen gas grid, for heating domestic buildings. The 80/20 stepping stone only delivers a 6% reduction in CO2, at the boiler, however, since there is no green hydrogen available, even in the medium term, for domestic heating. It would be, at best, grey hydrogen (made from gas) or worse, black/brown hydrogen, made from coal, which are the current cost effective ways of producing hydrogen. Due to the processing inefficiencies, the manufacture of such hydrogen gives off far more CO2 than the 6% gas that's being saved by the 80/20 mix. The 80/20 proposal therefore increases CO2. Since the argument is now lost for the 100% green hydrogen, gas grid, just on the basis of the cost of green hydrogen, the 80/20 stepping stone is a pretty pointless adventure.1 point

-

Because there's no ban yet, and those new connections today may continue to buy gas until their boilers are irreparable post-2035. Then the heating industry are fools. 80/20 gas/hydrogen mix was an attempt to bluff the government. Thankfully it has now as good as failed. Yes, the point is often missed that changes now are only in preparation for Net Zero. And while they will immediately deliver a CO2 reduction, which is positive for the 2030 and 2035 targets, it won't actually be Net Zero until some point in the 2040's.1 point

-

1 point

-

1 point

-

How about another silver birch in the middle of your yellow circle, that should reduce the issue for most of the year. Otherwise you need to put in some small scale land drains. Assuming the soakaways aren't full and the water pooling is due to the slow movement of water through the sub-soil to the soakaway. From your explanation, if the soakaway is in the corner then a 150mm wide trench to the corner, with some branches off to capture the whole area should do a good job. You could get away with Ø50 perforated land drain pipe set in shingle. The trenches around 350mm - 400mm deep. Put 75mm of shingle in, then lay the pipe in and add more shingle on top, stopping it around 75mm from the surface. Ideally you'd line the trench with a geotextile material, and fold it over on top of the shingle, then the drains won't clog up over time with silt. At the very least cover the top of the shingle with a strip of geo textile and then back fill with top soil.1 point

-

Suggest you need to take it apart and figure out what has gone wrong / take the rigger it to someone who will do the same / see if you can buy new riggers off the shelf / figure out an alternative mechanism yourself.1 point

-

Can the ridge beam be brought down so the rafters sit on top? Means no cold bridge at the ridge and a simpler fixing detail.1 point

-

Really depends on your house heat load. At Passivhaus flow rates from the MVHR, this kind of heat supply is limited to 10W/m2 of the property (statement from Passivhaus is any more than that the air smells burnt). Also they have a quite high water flow temperature, so not that good for CoP if using a heat pump, in fact not suitable for a heat pump as the Paul page has a water flow temp of 70 or 75 going in.1 point

-

Cannot see anything in that video that isn’t available almost everywhere, are you talking about a truss clip, this sits under a truss and nails in the side. Or there’s something called a triple grip, this nails to the side of a joist and down to a wall plate. Do a pic of what hat you want to do.1 point

-

I think it’s not so much the home-owner issue. R290 has been resisted due to more complex manufacturing and maintainance, and probably lobbying by the fgas industry to keep the means to their privilege. There are rules for R290 charge levels indoors so that in the worst case scenario it still can’t explode. Yet ‘natural’ gas is still actually piped into almost every home in the UK !1 point

-

I guess you’ve checked to see if there is a rear exit flue option on that stove? Some stoves have the option of top or rear exit flue and if yours does that may solve your problem.1 point

-

Yes, I have the eddi Grid Limit set to 8A, ie ~2kW: https://www.earth.org.uk/note-on-solar-DHW-for-16WW-UniQ-and-PV-diversion.html#2022-09-23 When doing solar PV diversion the eddi regulates/modulates the amount sent to the Sunamp so as not to cause any import from the grid. When doing (boost) top-up from grid the eddi regulates/modulates the amount sent to the Sunamp so as not to exceed the specified 8A limit on importing from the grid. Rgds Damon1 point

-

Exactly the same for us, joiners cut all the compound angles for the gable end ridge beams on site. They made softwood templates first to establish the correct compound angles to cut, before cutting the real beams, all supplied a bit over length. I had some offcuts of Kerto beams left outside in the rain for a very long time without delaminating.1 point

-

You could get its big brother : https://www.pichlerluft.at/pkom4-system-solution.html The PKOM 4 does have twin coils1 point

-

I have been heating the house with just a stove, three 1/2 years in now, and, an electricity bill for heating of £10 since June 2020. Just needs the right house design and the right location.1 point

-

1 point

-

I bloody love mine. If you build your house right, and don't scrape the bottom of the regs to pass U values, your house will be warm and cosy no matter how you heat it. We still haven't had our heating on this season yet. Our annual energy consumption is about a quarter of the national average for comparable size.1 point

-

If heat pumps aren't the solution, what is the solution to heating your home without causing unsustainable global warming? If you have one please tell us! Its really, really 'cosy' in the places that have wildfires or heat waves due to global warming, not so cosy in the areas that have suffered flooding due to the same cause, and wont be at all cosy when tens of millions of human beings are displaced from their homes by a climate that's not liveable in. Heat pumps take longer to heat up but you leave them running for longer to compensate. Running costs of a heat pump which has been properly set up are currently broadly comparable to gas (that's, however, a political decision because relative energy prices are driven largely by politics not economics). They are much cheaper than any other form of electric heating. Many people with heat pumps report higher levels of comfort. They aren't perfect by any means, but neither is any other known way of heating homes. As to electric cars, imagine they had been there first, and then someone tried to sell you a car that you couldn't refuel at home, that is driven by a series of explosions and contains an explosive, oily liquid, doesn't accelerate anything like as quickly, and needs more expensive and more frequent servicing. Are you going to buy one, I thought not!1 point

-

Listened to the TED talk abouot Lifi - it sounds the future of data transmission. Here's the company details. They have working technology now. https://www.purelifi.com/about-lifi/1 point

-

not sure whether to laugh or cry at this one! well done for just doing it though. that happens a lot.1 point

-

Over the last couple of weeks I learned 2 things from my (non regular) bricklayers. 1. No point in explaining anything to them they won’t listen anyway. The Tony tray was like explaining nuclear physics to them. I had to give up and do it myself just like any soldier course anywhere on the site. 2. A cordless circular saw with an old blade is perfect for cutting Ytong and I presume thermalite blocks. So quick and good cuts which in turn reduces waste and improves blockwork quality. From building 2 houses to joist I have less than a third of a pack of off cuts that WILL be used.1 point

-

No wonder you are confused, I do this from time to time as the day job and suffer also. Bear with me.. The way I get my head round this is to think about how a speaker works.. an old one say one up from an Amstrad... take a step back and imagine yourself in flaired trousers.. listening to Santana you may not have been born then but.. there are pros and cons to that too.. the old days were not that great at times.. so be glad you missed it! Anyway at the bottom you had the "woofer".. a big speaker that provided the base.. If you took the cover off you could see it moving... to be able to move it had to move lots of air but realtively slowly. In the middle was a middle size speaker, you can't see this moving but it provided the middle frequencies. It moved less air back and forth but more quickly. At the top was the tweater that was a small speaker. It delivered the high frequency so moved the air a little but quickly. A light weight partition wall works in at least three basic ways. The big and low frequency air movement caused by the woofer, in the modern world equal to you having a low frequency " wind episode from your bottom" is resisted by the weight of the plaster board. The air gap takes out the high frequency and the glass wool the medium. All three layers act together to dampen their frequency response so it almost impossible to separate out each layers and tie that into the stiffness of the wal studs. As soon as you change the stud spacing (and length) any calculations need to be revised as the studs change the frequency response of everything that is attached to them.. As a starting point I would not look to save on the insulation thickness.. go for the 75mm as the labour cost to install is the same. Medium density wool will work fine at 75 mm. Go for at least a plaster board of 10kg/m^2.. but you'll find that standard 12.5mm plaster board just falls short, if in Scotland. To get round this you can use Gyproc Wall TEN or often just skim coat the standard 12.5mm plasterboard.. gives you a much better job than Ames taping. The critical thing is to stop flanking sound transmission. If you can pack the top and bottom of the wall so the sound does not get around it that will really deliver results. Just remember that if you keep making the partition more heavy it may overstress the structure holding it up. If you spend time on the workmanship this will deliver the best result. Ideally this is something you want to do yourself (fitting the insulation) as you will take the time to do it right... few builders take the time to do this the right way.. unfortunately. Lastly if you have wall sockets make sure they are not transmitting sound so insulate behind them. But before you adopt a solution just check with the spark that they are happy and don't have to uprate the cables.. Hope this helps.. keep your head up.1 point

-

1 point

-

I definitely wouldn't do a double 90⁰ bend. From memory you're only allowed something like 6" total horizontal run, and anyway it would become impossible to sweep the flue after that. Are you absolutely sure there's no rear flue option? Your stove looks like a Charnwood. Mine came with the option of top or rear, but you won't see it without removing the lining bricks inside. (If you do find a rear flue exit, I can sell you my genuine Charnwood rear flue adapter!) 😁0 points