Leaderboard

Popular Content

Showing content with the highest reputation on 06/29/23 in all areas

-

With the great weather in the last two weeks, following on from the slab pour, we will endeavour to pour the walls of the house tomorrow. I'm thinking I won't sleep tonight. Mentally listing all the things I wanted to do, and re ticking them off. First 7 cube is arriving at 8.30. 🤞 I'll leave this picture with you....4 points

-

If you have a towel radiator in each bathroom it will give plenty of heat for the bedrooms. The UFH on the first floor is money wasted.2 points

-

2 points

-

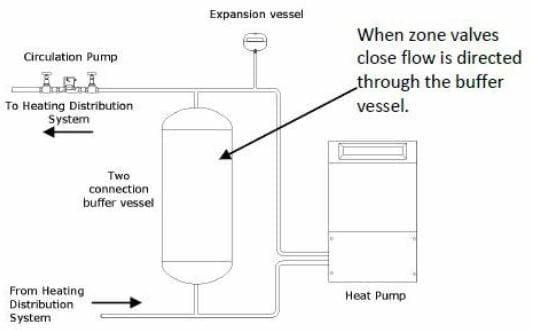

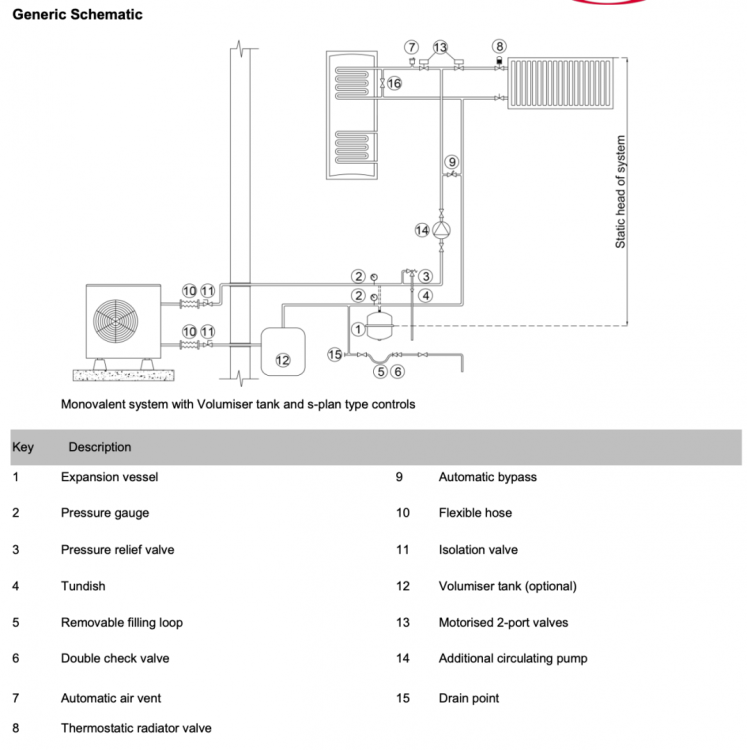

A 4 port can be connected as a 2 port, just flow in the top and out the bottom connection, blank the other two ports off. You would normally have the buffer position so all the flow goes through it for the whole heating system, so after your return tee (UFH and radiators) for a return line two port. Item 12 in the attached drawing If you want to do it across flow and return, install instead of the bypass like this2 points

-

Think I would dig a bit deeper in those areas to see how deep they go. Be careful you don't fall down a mine shaft or old well. Tie a bowline around your waste if you go in the trench.1 point

-

No it won’t Unfortunately both comments will be there for all to see You can withdraw your objection1 point

-

1 point

-

Indeed. People’s spend with MBC are quite significant as they do foundation and frame packages, so the £12k insurance (or an uplift of £6k vs the other routes) seems to me to be ‘not insane’. MBC are spitting out houses at a fantastic rate, so I doubt they’d need to steer their business off its current model. May be a different story if they were struggling to make ends meet, but I guess they’re not.1 point

-

1 point

-

I would say that if its in and flush to the face side of the wall you should be OK. Its not perfect but I doubt that you would get much in the way of damp issues for the bridged millimetre or two. Think of face brickwork where nobody wants to see the DPC sticking out of the wall and it is pointed over. Thousands of houses have been built like this without any problems. Otherwise i would say that the blockwork is of good quality, well thought out bonding and full joints. Just how I like it. The ties should be at 750 mm centres though and not 900 mm like those are.1 point

-

No need for any central heating in passivhaus. We get by on a single plug in rad downstairs. The only good reason I can think of for UFH upstairs is cooling.1 point

-

... unless you have to ....like water companies or railway companies or energy companies. Sometimes nationalisation works, sometimes it has to be made to work for a bit, others it is indeed best avoided.1 point

-

1 point

-

Yup. It would be better if the buffer could stay within the heated envelope, but it does come with quite an excellent insulated jacket. You'll need to insulate the pipework very well of course, but losses should be minimal.1 point

-

Basically yes, it's just adding system volume, to give the boiler something to work on, when just a zone or two is on.1 point

-

Or cast a base for sun umbrella? Bucket with a pipe in the middle.1 point

-

6m x 4mx 150mm thick = 3.6 cu m + 10% = 3.96 cu m (ordering 4 cu m) 🤔1 point

-

Oh yes, I have added approx 10% (as I can’t afford to be short) and have a space for it, and washout 👍1 point

-

As long as this is designed with smaller aggregate and a plasticiser to increase flow, then ok. Absolutely do not add water or allow anyone else to do so. Extra water reduces strength and increases shrinkage cracking...whatever anyone else argues.1 point

-

make a form-work and make planters? Or even a bucket to make large flower pots.1 point

-

Ultimately the government want rid of the PRS . Their actions prove that - to be eventually replaced by build to rent . For the government much easier to regulate and hedge funds etc get a better return on investment. Can you imagine though the tenants they will choose ? . They will pick the best of the best . The issue that the media pick on is single mum , 2 kids , been renting for 10 yrs ; now rents increased or LL is selling up . The PRS to some extent is used in place of social ( council ) housing . It’s not designed for that . But the government sometimes go down the wrong path and then create a way out . A sink in every bedroom many years ago was pushed through as legislation . Needless to say - spot the numerous problems there . In the end it was then “ upto individual councils to enforce or not “ . Afaik no council did it . But the media loved it “ all tenants have a right to water “ etc. . All this because of 1 obscure case and an MP getting some limelight …. Perhaps we will get further dilution if it’s “ upto “ councils to decide …..1 point

-

Kudos for that great air tightness result👍 There are undoubtedly many ways to achieve a quality result, but engaged, competent and motivated workers appears critical almost regardless of build system. Cheers1 point

-

Thanks @IanR for that clarification. I appreciate the build time for an MBC-style is faster, but I'm drawn to Adam's offering due to the lack of credit exposure, reduced transportation costs/emissions, plus his undoubted experience in executing.1 point

-

That is the point surely. When other fillers harden and crack, this stays as a seal. We used to use a very expensive mastic tape on steel cladding laps. Doing an extension after 10 years it was still sticky, moving with the building and keeping it air and water tight.1 point

-

No I don't think so tbh. I refer you to 20+ years of political rhetoric and media coverage. A platform of ignorance has been built, that is believed and malice uses as leverage. F1 point

-

Unfortunately the construction industry, it appears, is full of chancers and has only a small proportion of experts. Experts are a good and very necessary thing, chancers less so.1 point

-

If you're curious we managed to solve it. The issue (for us at least) was caused by using cuts of slates there instead of full ones. That's why they were lifting when the PV panels were placed down. Solved it by taking the lead flashing off, stripping the bottom row of slates and refitting full ones. Was only 40 slates and took less than an hour, but all sorted now and the panels and trays site nicely. Appreciate the prompt reply! Glad you're enjoying our Instagram updates.1 point

-

The big risks for passive house IMO are. 1. Airtightness We (me mostly , Mrs and my bro) did this on our masonry build. Zero experience. 0.31 ACH. DIY blowerdoor really helped too. 2. Continuity of insulation. Blown in beads for us. No gaps. 3. Thermal Bridging Tricky in a cavity wall but I did the best we could. For a TF house I would always suggest pressure blown in dense pack cellulose. This will sort the continuity of insulation. If you blow it in behind a transparent A/T membrane you can actually check this prior to boarding out. It also really helps with airtighess. I don't know if any sub 0.2ACH ratings without it. Then couple this to a layer of EWI on the TF. Woodfiber boards, rockwool frontrock or EPS(moisture calcs dependant) would work really well. By lapping the insulation over window and door frames you will get superb thermal bridging figures. So in short my suggestion, 15mm fireboard. 47*44 mm service cavity with Rockwool batts. A/T membrane. 220*44mm stick build timber frame with cellulose blown in. OSB racking. EWI Cavity Rainscreen.1 point

-

Any detail for ANY part of the build is down to; The individual(s) you select to undertake the work Their (proper) understanding of what you wish to achieve Their ability to execute the work to the required standard. Their tenacity; to research, learn, adapt & overcome. This is why I am a very busy bunny, as I cannot do a bad job and the results I attain speak for themselves. You can build your house with broken pallets, it matters not one bit, as long as the person in charge of AT detailing actually give a feck. Anything can be achieved if you employ the right people. The products, and installation instructions, are available at glance, so educate yourself as to how these need to be implemented, or employ someone to act on your behalf. The best diligence is your own1 point

-

Me and my joiner built our timber kit, I don’t see any less quality, it’s just cutting with a chop saw and nailing with a nail gun. Get a bench set up and away you go1 point

-

1 point

-

@SlivenClod Our sub base was the remnants of a building site (type 1, gravel, sand etc). All manner of stuff that was well compacted and not particularly level. I levelled the spot that each pedestal sat on before placing the tiles on top. It all looks nice but if you were to lift the tiles up it’s as rough as a badgers arse underneath.1 point

-

Start here. Knock 1/3 off and work to giving the builder that amount. We had 300k. Paid the builder about €200k to finish their job. We spent the rest on kitchens, tiles, flooring professional fees, painting, curtains, some second hand furniture etc. It quickly adds up. Any particular reason for ICF? Similarly any particular reason for passive house?1 point

-

@Ferdinand thank you so much for your valuable insights. Well wishes much appreciated. It’s back to the drawing board armed with all comments here.1 point

-

I’ve been using this for my air tightness tape around the windows and doors. https://www.ecologicalbuildingsystems.com/product/tescon-primer-rp Really good stuff, was warned not to get the aerosol version as it could damage the EPS. I’ve just been painting this stuff on with an old brush1 point

-

Just a follow up to this with many thanks to @Omnibuswoman Sent a letter to HMRC in April with all the details their phone line suggested. Got a letter from them last month asking for all the information I had already given them. This week we found they had repayed the whole amount plus nearly 70 quid interest. For this alone, membership of this forum has been worth it let alone the other useful stuff I keep finding. Shame the refund just covered the archaeological survey so it's not spare as such but certainly very, very welcome.1 point

-

They want you to show them what it will look like, in picture form, easy to understand. It suggests that they are conceened that it might look out of place or overbearing. It is your opportunity to show them it isn't. My business had to do this several times. We selected the views that either concerned the planners or neighbours and took photos. Then our inhouse architect generated 3d views of the building from that, or these, spots. Then one is photoshopped into the other. If your design is already done in a 3d design suite then this is easy. What is your position on this? Used a designer or diy?1 point

-

We use an EPS rasp and a leaf blower or handheld vacuum on each opening as required Refina do a tungsten carbide rasp with the awesome name of TigerClaw.1 point

-

I would put a string line up 10 mm off the wall at the far end of the house above the shed in this case and pull it towards the front of the proposed wall and move it until it is 10 mm off the front of the house so it is parallel to the house and 10 mm off the face then I would plumb it down with a straight edge and spirit level and remember to mark it 10 mm back from the line. If the pipes etc. Foul the line then move it to 100 mm or any dimension you like off the face. As long as it is parallel the jobs a good un.1 point

-

If we are worried about shrouded (or not) pins on a 5A plug, then I have to ask WHY do we still allow the sale of light fittings with BC or ES lamp holders that have NOTHING to stop fingers touching live parts with the lamp removed? We do lots of things in the name of electrical safety, yet we ignore this one totally outdated, totally unsafe design, and carry on allowing it to be used in new installs.1 point

-

Just read the report on ASHP installs against the grant scheme on the BBC - source of graphic below. It is seems interesting / instructive that the coldest places, where you may think heat pumps would struggle, have the highest take up. While, perhaps the stand out insight is that the UK - despite our proclaimed aspiration for leadership in green technologies is in last place on this list. Given these insights one wonders if we might be approaching the point of being able to say that, in this area, we are becoming something of a joke! Image source: https://www.bbc.co.uk/news/science-environment-660331990 points

-

My contractor brain is always reducing costs while my SE brain maintains quality. I shouldn't give all the secrets away.0 points

-

Most of us don’t have one of those telly tubby designs 🤣0 points

-

Quite so. I was just thinking, what if your sub base has tamped down 10mm high. You might have a lot of concrete for your gnome moulds.0 points

-

Ah, Mike, we're just procrastinating. And the time to procrastinate is now! Don't delay !0 points

-

Love the customised rake float. Dpm, then another progress pic please for your 50 "clerks of works" on here.0 points

-

I dont want to stray too far off of the thread here but based on these glowing comments i wondered how far away from me this company operates. You know.... Just in case. Turns out its less than 10 miles down the road ! who knew.0 points

-

That stuff is straight from the deepest depths of hell. Iirc Impey or Wedi sell it for sealing around their wet room shower formers and it is just such a PITA to remove from yourself, your tools, your hair (when you forget it’s on your hands and you scratch your head, pondering how to get your Stanley knife down from the ceiling after trying to shake it out of your hands and it flies off), and anything else it touches. Fantastic stuff as a product, but what a bastard of a thing in every other respect, as it literally NEVER cures.0 points

-

In a previous house I had new windows installed, and being new to self build, got a local FENSA registered company to make and install them. The guys who turned up had never install windows in a house with internally recessed stone mullions and I had to show them how it was done. I turned out neither were building trades people, one had trained as a butcher and the other had only ever been in sales. So much for “experts”!0 points

-

You maybe on the wrong bandwagon. I suggest you give me your current SE battery and swap to a more bespoke/flexible manufacturer for your niche requirements0 points