Leaderboard

Popular Content

Showing content with the highest reputation on 06/14/23 in all areas

-

and the results are in.............. ........0.98ACH! i'm very happy and hit my target of 1ACH. could we have got it lower? maybe, but we calculated the internal volume at just over 1400m3 over 4 stories (basement, ground floor, first floor and loft) and it's got some interesting junctions between sections of the buildings so i think to get in below 1ACH is a job well done.5 points

-

We could only get 100mm in, which is insufficient really and why I chose to use it, hoping it would have better performance than 100mm PIR (or EPS). Incidentally, I also researched a lot before coming to a view, and decided to use slate tiles, rather than engineered wood to improve the heat transfer. I even chanced not using decoupling mats, as the plumber thought it would reduce the efficiency of the floor, which made sense to me. We used good quality expansion joints at the door thresholds and don't heat the floor over 35 degrees and I was ultra cautious about turning it on at all in the beginning.2 points

-

The only thing I would change is to switch to Octopus first and get them to fit your smart meter2 points

-

Life outside this forum is barren wasteland. There's nothing to live for. I suggest you apologise and pray for forgiveness whilst we wait the mods wrath...2 points

-

Possibly. What time of year was it laid? The air is more humid in summer than winter so if it was laid tight in winter it will be under lot of stress come summer. That and a very hot floor due to sunlight would be my guess.2 points

-

2 points

-

Diverter to barrel, then a hose on the tap, with outlet to the flower bed or anywhere, set to dribble the contents out over a day. That's suds.2 points

-

You could ask anyone to design anything and if the calculations came back as item x complies just, some may decide that’s fine go with that some may decide let’s go next size up. could be the same when sizing cable, a 6mm2 cable might comply ,borderline but leave no wiggle room, customer is paying for it so let’s go with 10mm2 covers the designer leaves a bit of wiggle room for future just incase things change when on site. I think you need to put this behind you and move on, still more challenges coming if you are managing to this detail, or invest the time finding a small builder with good skills and recommendations.2 points

-

Dropped my shorts and awaiting my spanking. Will reregister with the screen name Rodger'd1 point

-

1 point

-

I'm just saying in case it alters any real life designs. I'm not questioning the result but there is always more to learn. 1 is very good though, well done. Last time I supervised one they wanted the upper floors closed off by shutting doors. No suggestion of that with your multiple floors?1 point

-

Great result, the place is huge, so good effort 👍1 point

-

True . But better too see 1 dead rather than an entire string knocked out .1 point

-

1 point

-

You will get charged more in Beaconsfield if you pronounce it Beacon's Field. Less if you say Holtspur. If you live in Penn, pronounce it as Tyler's Green.1 point

-

1 point

-

1 point

-

1 point

-

Our does everyday at the moment. Cooling starts at 8am, hot water 9am, cooling goes off at 5pm. It just waits a couple of min after hot water before starting cooling circulation again. It will circulate through UFH until has reached the cooling switch on point, which cooling set point, plus target delta T, plus 2. So for us it will start cooling again at 18 degree return temp.1 point

-

We just have electric radiators in the bathroom to supplement the UFH for towels. Didn't bother with piping them up.1 point

-

Eh? You have conflicting requirements, the UFH will want a low temp and WC, the bathroom rads and cylinder high temp and no WC. So how about programming the rads to come on mornings and evenings 30 mins before you are going to want to use the bathrooms and heat the DHW at the same time? (Works well with our gas boiler.) IIRC Grant recommends S-plan setup so that would be easy to do. This will help prevent short-cycling under low load too.1 point

-

I think you need to give details of which diverter? and if you have it a link to the users manual. Immediate questions are HOW does it know "water hot" Does it have a temperature probe? What other connections other than the current transformer?1 point

-

I do have photos and screenshots of our messages. I have again contacted Hetas and see what they say now. I'm sure they will insist that he is given yet another opportunity, but why would I want someone back in my home who is deceitful, untrustworthy, confrontational and not least, prepared to put my family at risk ?1 point

-

Probably a letter to him advising that you are withholding payment due to poor workmanship, variation from original agreement and damage to property. offer to let him complete works at a future date specified and the works checked by an independent third party this more than anything from stopping him taking you to court ( some/ poor installers have no shame) then when he doesn’t meet these agreed terms find someone reputable to carry our remedial works and issue new certificate1 point

-

Flow restrictors? Under Approved Document G to reduce water use - been part of the Building Reg for may years. Depending upon the type of tap it may be possible to remove the restrictor - otherwise its new tap time.1 point

-

BC couldn’t care less if it was drawn on the back of a fag packet as long as the information was there.1 point

-

Well my brick layer was not convinced about full fill with batts but they do have a bba certificate. The outer wall was brick and one wall faced west and it was near the coast in Cornwall and after a very wet winter the bricks were sodden. I then installed the ASHP which meant I had to core drill that wall and when I put my hand in the hole the inner face of the bricks were sodden but the batts had absorbed no water vat all, to protect the bricks on the face (possible spalling) I coated the wall in water proofed and the rain then rolled off it like glass. I would suggest the cold bridging is minimal, the soil temp at depth is quite stable and above air temp in cold weather, like the wall ties ( I decided the cost of special wall ties was not worth their minimal effect) suffice to say that over the 6 years I lived there the heating from my 4Kw ASHP only came on in Dec and Jan for short periods .1 point

-

DPM - goes above your hardcore, you also need a layer of sand above the hardcore, to stop stones making holes in the DPM - then your DPM. You need a thin polythene later also between the insulation and the screed. It goes on before the UFH pipes and they get stapled to the insulation through the membrane.1 point

-

BC do not care how the drawings are presented or by what software. Providing they include the relevant and necessary information to review, approve and build from… then crack on.1 point

-

Nothing to do with the graft, it’s just (expletive deleted)ing time consuming and tedious. I enjoy the workout element!1 point

-

1 point

-

One example of many posts about this. PIR boards in cavity block walls is idiocy.1 point

-

You've asked the easiest question of the night. Blown Beads . EVERY. SINGLE. TIME.1 point

-

The beads haven't settled in the least. They bowed up the 450mm DPC cavity closer when they were blown in. Earlier this year I climbed into the attic and did a few spot checks to see if any settling had occured. None had. Similarly when I checked with a thermal camera there were no voids. We've used about 17kWh/m2 over the last 2 years in heating bills. A bit more than PHPP predicted but I'm not sure why. I don't think it is the beads. One thing that I think is important is getting wind tightness very secure as the nature of them is porous and susceptible to wind washing. (Where heat is lost by blowing through the insulation) If you are building a cavity wall I would recommend them or full fill fiber batts.1 point

-

1 point

-

Not sure how common, but unless you get PP first time, it can get expensive. We were badly advised to reject the LPA’s requests for concessions, and were advised to instead take the rejection and appeal. This turned out to be a questionable choice. We ended up getting more or less what we wanted about 2 years later, after a failed appeal and two further applications. Also spent a lot of money on a planning consultant to help with the appeal. All in all, close to £12k to get planning. Had we accepted the request for concessions, we would have ended up with a smaller extension, but probably a slightly nicer rear elevation and a much quicker approval, such that our build would have almost finished by the time COVID came. Instead, we started building mid way through lockdown.1 point

-

I can certainly agree with that. I don't like the information asymmetry, and much of the information is not 'difficult', but it's difficult to find out. I've done some of the planning related stuff myself rather than pay people, but the amounts involved up to this stage have been modest. When I move into the costly part of actually building, mistakes through inexperience are likely and become much more expensive. I'm unlikely to ever do this again so any experience I gain will be mostly wasted. I'm meeting with the architect this week and will have an honest conversation and see if we can come to a compromise that works for us both. The hand holding is worth quite a lot to me as a singleton, and I should have that in my mind.1 point

-

Did you look at the 412-page "compact" catalogue yet? It'd keep you busy for a couple of weeks... https://www-de.wera.de/fileadmin/pdf/catalog/EN-Compact-Catalogue-2023.pdf1 point

-

Look at the following brands for high-quality screwdriver sets. https://www-uk.wera.de/en https://www.wiha.com/gb/en/ The challenge is working out which set makes the most sense..!1 point

-

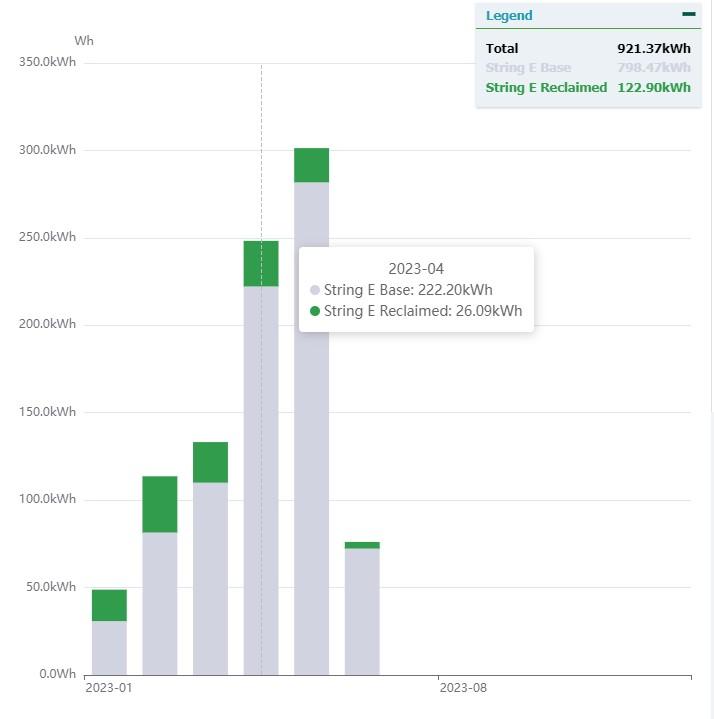

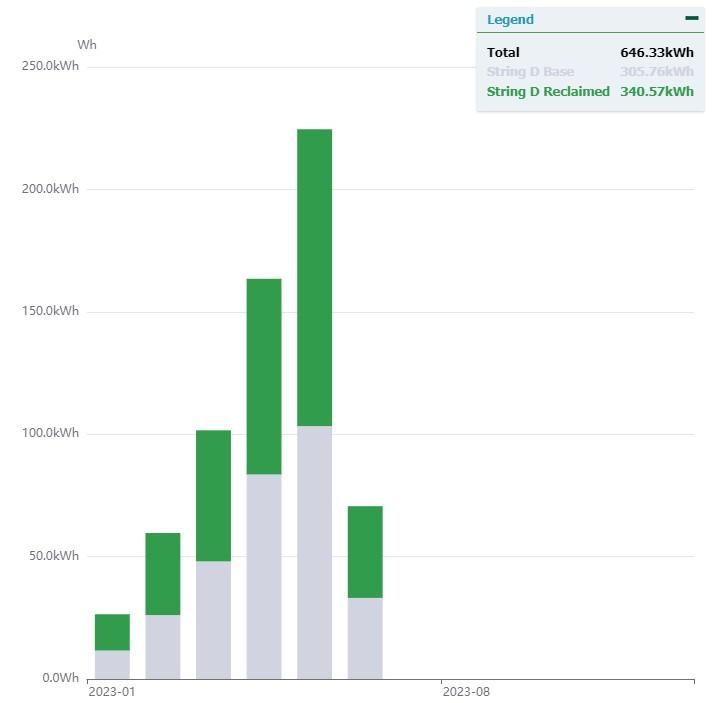

As others have said, it's highly unlikely to be worth while in terms of energy saved. There are optimisers on 32 of our 54 panels. Most don't do much, one set does. One string of 6 panels facing SE has shading on the bottom 3 panels from trees in the morning. I put optimsers on those panels and there is virtually no reclaimed energy Garage has 12 panels on one side with optimisers on 9 panels and shading in the morning and also doesn't recover much energy. The other side of the garage roof has more significant shading and optimisers on every panel. That recovers more energy, but it's not an amazing amount. There are also 8 panels on a shed which face 3 different directions and have significant shading throughout the day. These do recover a noticeable amount of energy. Conclusion, it isn't worth it financially, but for me it is for the monitoring.1 point

-

Well - this ignores some things . You could end up exporting at 35p a kw - like I do . I estimate I’ll earn £1000 a year from that . What no one seems to understand ( I do - I got a pw in 2020 and was mocked on here for ‘ a waste of money ‘ etc ) . Electric consumption is meant to double over the next few decades . Price will vary of course but ‘cheap’ days are gone ( bit like boe rate ) . Also when you have a battery you naturally are more ‘aware’ of usage e.g turn the (expletive deleted)ing light off . My ROI ( EV 4000 miles per year aswell ) is around 6/7 years at this point in time . If roi is everything then don’t do it . What do people want ? A return in 2 or 3 years ? . Yet buy a 300k house , mortgage for 25yrs and ultimately have bought it for a million quid ….. New Tesla for 80k , roi ? That nice holiday ; roi never What’s important to 1 person isn’t the same for everyone . I could just (expletive deleted) it have no battery , pv , EV and go on another holiday . Next generation can deal with it “ not my problem “. That view is what governments largely do hence issues with nhs / housing etc. Etc.1 point

-

I don't think you will get any money. You've asked 4 SEs to design one beam. None of them seems to be wrong, just differing. You would engage a lawyer who would engage a 5th (legal specialist) SE. IF they agreed that the design could reasonably be much lighter then a tribunal might award you a few£100 which won't cover your costs. BTW if I heard I was one of 4 SEs I wouldn't be interested in any more work.1 point

-

I you plan to sell in a few years I'd be careful about costs. It's not hard to build a house that is worth less than it costs to build.1 point

-

yep. 10kW inverter and 5kW battery approved here in West Sussex. 🙂 we live on a quiet road though and no one around here seems to have solar panels so maybe we just got lucky.1 point

-

While I'm all in favour of getting contractors to do a good job and addressing directly with them any problems - I think you need to determine first whether there actually is a problem. Tell him you're concerned about the issues you are concerned about and ask for an explanation - make this by polite letter by recorded post because that makes it sound like you're treating it more seriously than might be assumed from a quick text / call / email exchange. Send this to his home address / or registered company address if a company (get that from companies house). Also you can check rather easily what sealing requirement there is for the stove you have - either by looking at the manual or calling the manufacturer. Do the smoke pellet test yourself and get a CO reading. If you are still sure you have a problem ask him to explain / fix it - again politely but with a firm deadline. Use the final options if you have no other alternative.1 point

-

It’s unfortunate that when you pay for expert advice you often don’t get it - and to find out about needing timber frame panel drawings far into the process is very disappointing. In my previous life I would have taken my clients step by step through the building process and would have tried to explain in simple terms how they get from a brief to a completed home. I would have felt that if a client did not understand what I was saying then I needed to explain the process in a different way or in simpler terms. I reiterate what I have said in the past - I am a BCO and RA and if I can help with anything I will.1 point

-

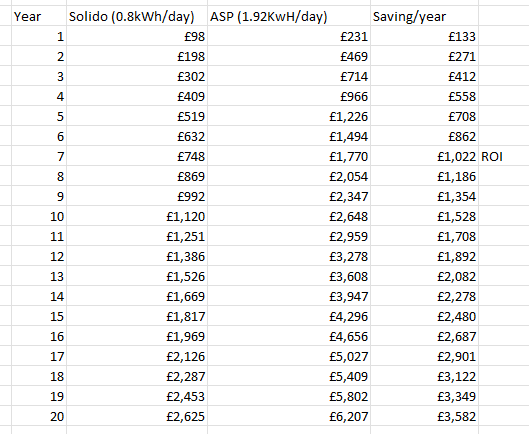

For anyone who comes across this - I have decided to go for the Solido Smart. The ASP currently is £1750 vs £2630 (Gravity outlet and delivered for both, plus VAT). It's 900 quid more expensive for the Solido however ROI is in year 7 based on the power usage, see below for table. This was costs per year and cumulatively added up, starting point was 33p/kWh and a 3% inflation rate over 20 years. So on year 7 the extra money is paid back and by 20 years it nearly pays for itself vs the ASP. Plus point is that the effluent quality and suspended solids is better by a factor of 2 nearly) on the Solido. Will I notice the difference, absolutely not. Do I feel a little better about it - Yes. The Solido also has a flat tank cover and you can move the vent elsewhere which means I wont run over it like the ASP. Both very good units and either would be a good purchase.1 point

-

Probably too late for the OP (I’m not here very often these days as it’s now 5 years since I finished my own build) but for the benefit of anyone else contemplating a masonry cavity wall, the Approved Docs for England (not sure about Scotland) expressly require a minimum cavity width of 50mm. The alternative is full-fill insulation. The relevant bit of the regs is Part A, Page 14, Sections 2C8. It’s also in Part C, Page 32, Section 5.15 together with diagrams showing the options.1 point

-

You'll need to bump the cavity to 150mm between the leafs. You prob have this anyway I haven't seen any examples of moisture getting across the cavity with beads that were installed correctly. Normally it's because of a badly fitted cavity tray, mortar bridging the cavity or an unsuitable mineral wool pumped into a very narrow cavity. There's a few threads here about boards in the cavity. Have a read through.1 point

-

@MortarThePoint Apologies for late reply. My observations on Full Fill Bonded blown Beads, Are they Full Fill: Yes very much so, in our wide cavity at least. I drilled a few trial holes around windows and doors to check in awkward to reach places. All full with beads. Are they Bonded: Kinda, a little hit and miss really as i found out when coring ventilation holes and lost a few buckets. The remaining question: Will they settle.......? Time will tell. Would I use them again? Yes, but I would core all holes in the wall first.1 point