Leaderboard

Popular Content

Showing content with the highest reputation on 02/23/23 in all areas

-

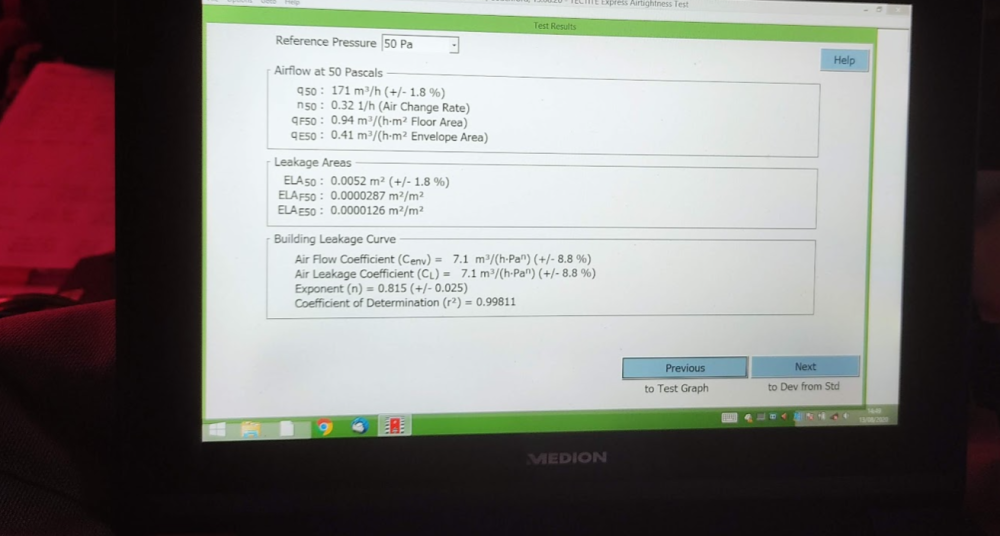

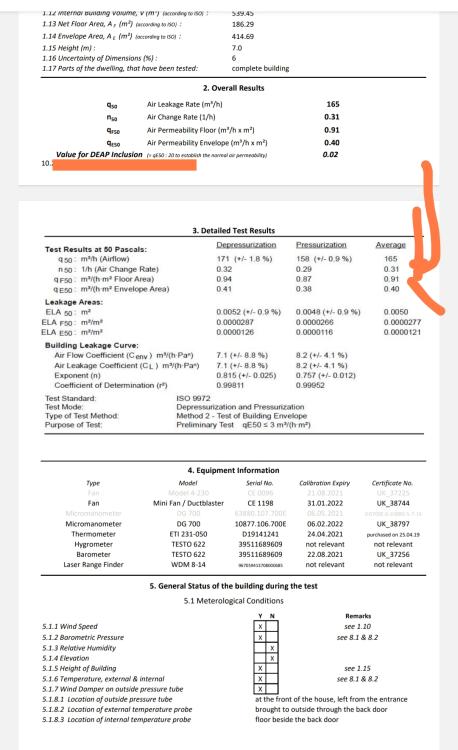

@ mods not sure if this is the most appropriate section. We don't have a dedicated Airtightness one. Time: 1hr. Cost €60 Materials: 1 X Sheet of OSB or PlY 1 x Used car radiator fan including housing ( I used a lexus IS200) 1 X Roll of Airtightness tape. 1 X length of automotive wire. 2 x Crocodile clips. 2 x wire connectors. Some short wood screws Tools. measuring tape. Jigsaw/circular saw. Pocket Knife. Large 12v powersource. ( I just used my cars battery in situ) Screwdriver Direction. 1. Measure an opening window sash/door of your house. 2. Carefully cut the OSB so that it fits snuggly into the opening and presses evenly against the seals of the window. 3. lay the radiator fan including housing on the sheet of OSB and trace the outline. 4. Carefully cut a hole out of the OSB just slightly smaller than the radiator housing. 5. Screw the housing into the hole such that the edges of the housing are all supported by the OSB. 6. Using Airtight tape seal the edges of the fan. 7. Connect the wires to the crocodile clips leaving enough length to reach your power source. 8. Insert the rig into the window and secure in place. It should fit reasonable snuggly, if it is an outward opening sash the vacuum generated will pull it tight to the seals. Consider using tape or a wedge to hold it in place. DON'T use airtightness tape. It'll stick to the window forever. 9. Connect crocodile clips to the power source. You can simply reverse polarity of the clips to swap between depressurisation and pressurisation. Testing procedure. 1. Close all doors and windows in the house. 2. Temporarily seal up/close all vents. 3. Ensure all combustion appliances are off and isolated such that there is no risk of fumes being drawn into the house. 4. Set the fan to depressurise the house. 5. Methodically go room by room using the back of your hand to detect and seal any leaks. Most are found at junctions between floors, walls and ceilings, sockets, windows and doors and wall chases. 6. Use a lighting candle to visually see any pinhole leaks (the flame will flicker). It's much more successful than smoke. Jamming the candle in a length of rigid electrical saves doing too much climbing and descending of steps. Be careful not to burn the house down!!!!! Outside View Using a candle to check leaks. Official test Final Result5 points

-

Yes we are. Many of us use wood burning stoves in an appropriate situation having assessed what harm it might or might not do and concluded in our case a very rural very low density populated and usually windy location, there really is not an issue so have chosen to use a WBS. I would not have made that choice if I lived in a more densely populated settlement in a windless valley where the smoke was likely to linger. But even when we make reasoned choices we are still told how bad we are and how irresponsible we are again and again and again by the same person. This whole environment thing is a case of each of us making the best choices we can in our individual circumstances. Few will be able to do everything possible, but just the best we can. And the "experts" don't help. If burning wood is "bad" then someone really ought to tell those running DRAX who keep telling us how carbon neutral and environmentally friendly it is. So prime example of even the environmentalists can't agree what is good or bad. No wonder a large percentage of the population is confused or frustrated by it all and many just can't be bothered because the message we are being given is too confusing and contradictory. All we should do on a forum like this is highlight pros and cons of different options and let the individual make their choices and don't keep slapping them down because their choice is not the same as yours.4 points

-

I've been hunting around for whether different types of PM2.5 pose more danger or not. PM2.5 is a physical description of size and doesn't describe the chemical effect of the particulate. I haven't found a good answer - it seems to be that the measuring equipment is pretty good at detecting PM2.5 but it is not very good at detecting what it is made out of. The indication is there are more chemically damaging types of PM2.5. But there isn't enough evidence to be conclusive. Intuitively, PM2.5 made of carbon is probably less harmful than PM2.5 made of VOCs, ammonium & sodium nitrate etc. Still doesn't mean a wood burner is a good choice for urban areas but the overall picture is potentially more nuanced.2 points

-

2 points

-

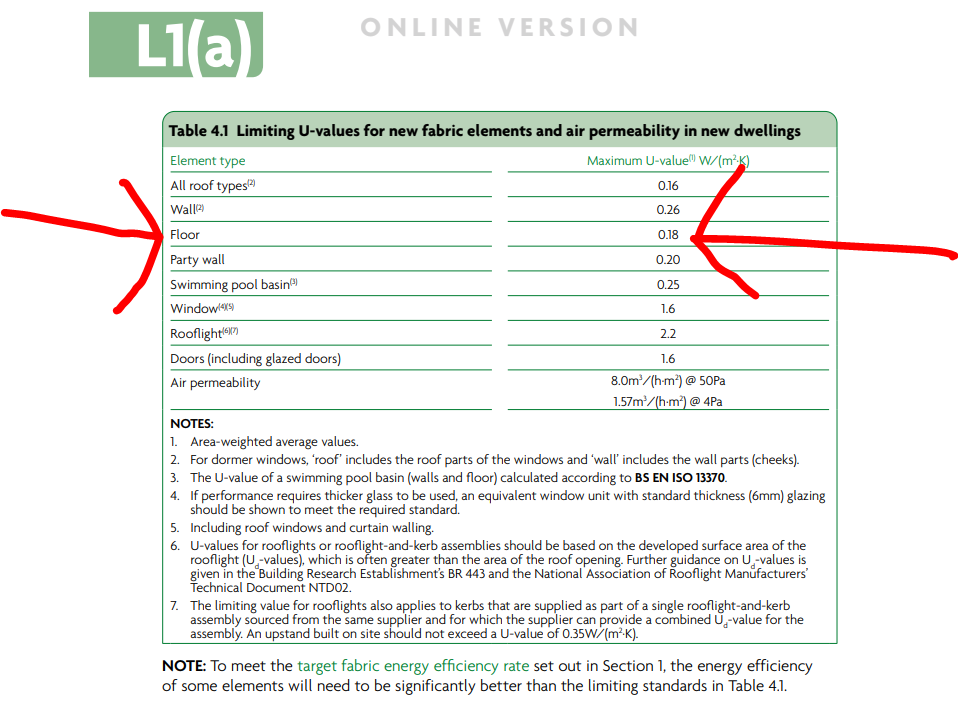

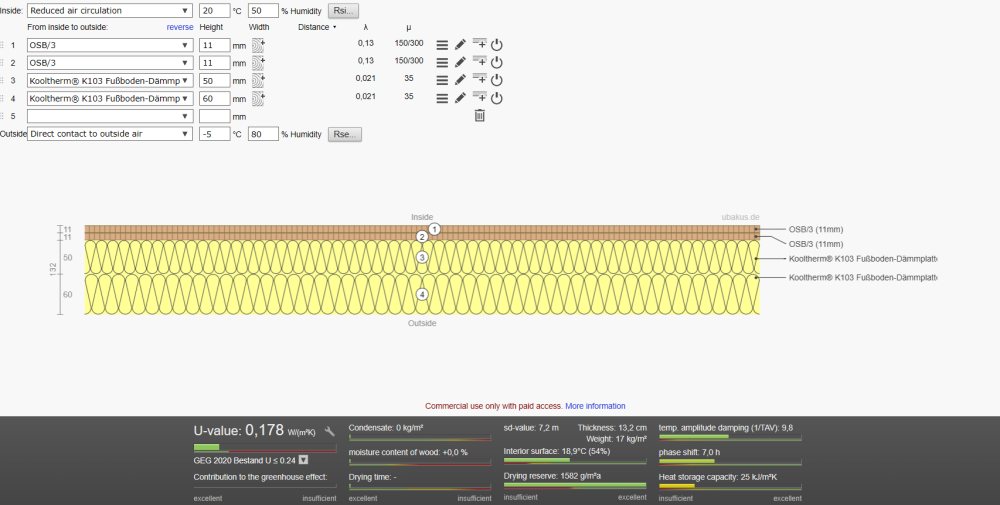

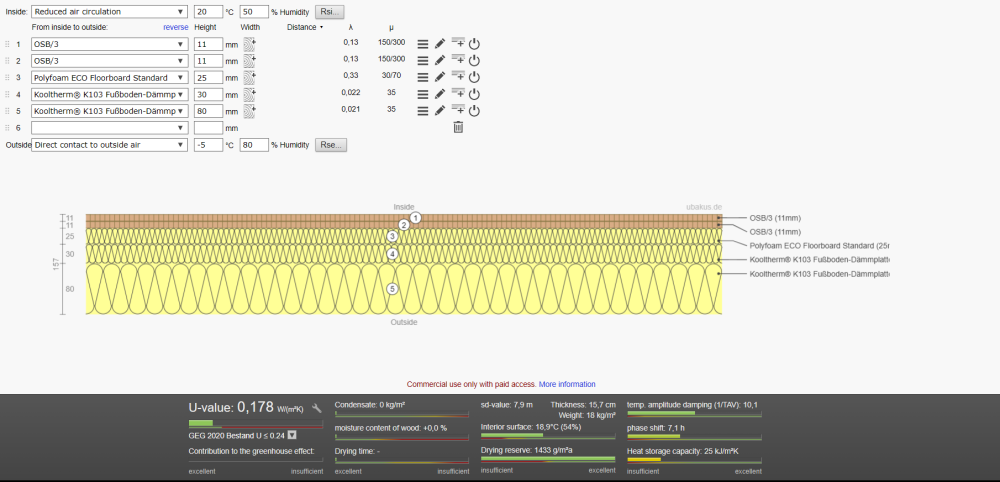

It'll be of value to yourselves, as occupants. Just remember that our B.Regs in this country are absolute and total dog shite, so attaining the minimum of the minimum will yield.......... ( drumroll please ) ..........even shitter results. If this is your house, and you don't want to pull the boards back off afterwards, because the house has issues with acoustic transparency, then do it right, once, and put the thicker stuff in now2 points

-

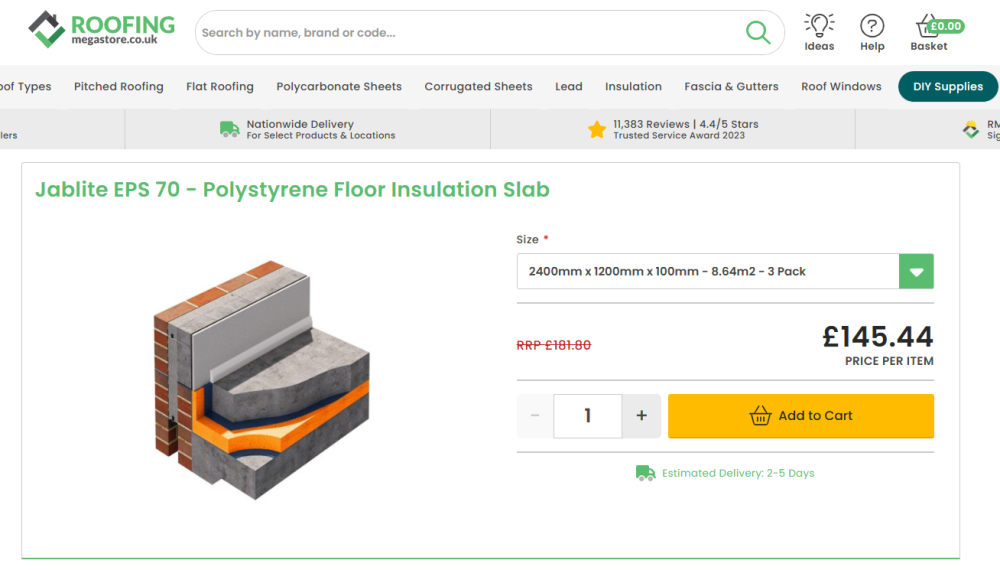

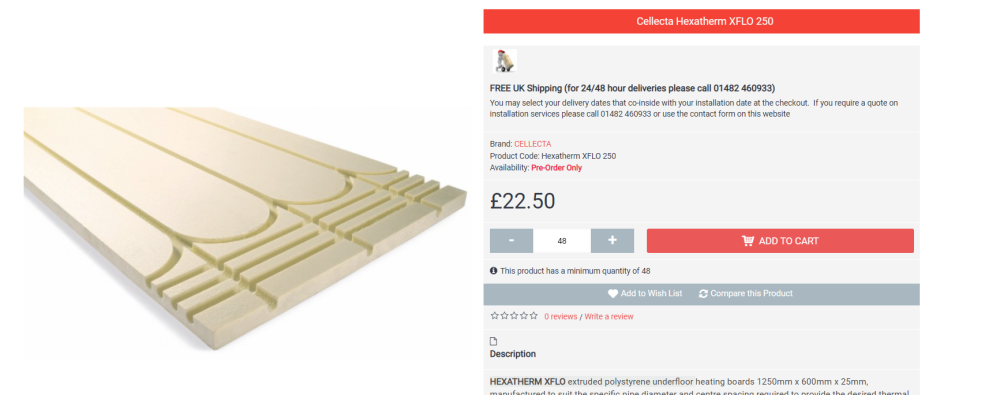

For what its worth 225mm of EPS 70 would give you the same U value as above but would only cost £12.60/m2. Over 250m2 UFH and phenolic speciality boards would be £21,250. EPS would be £9500. Bump it to 300mm for a U value of 0.12 and put some of the left over change towards digging out the old floor you'll still come out ahead.2 points

-

2 points

-

But unfortunately not yet and until smoking tobacco stops the tobacco industry does a lot of harm to the environment. https://ash.org.uk/resources/view/tobacco-and-the-environment The environmental footprint of a smoker The environmental impact of being a smoker was also quantified at an individual level, highlighting the sizeable individual contribution of a single smoker, whereby even one cigarette is associated with an environmental burden.4 5 The authors calculated the environmental impact of one person smoking a pack of 20 cigarettes every day for 50 years, these were quantified as:4 5 6 A total carbon footprint of 5.1t CO2 equivalent emissions, which to offset, would require 132 tree seedlings planted and grown for 10 years.13 A water footprint of 1,355 m3, which is equivalent to almost 62 years’ water supply for any three people’s basic needs.14 Total fossil fuel depletion of 1.3 tonne oil equivalent, which is comparable to the electricity use of an average household in India for almost 15 years.15 Tobacco’s efficiency and yield on resources was also highlighted, with the authors reporting that in comparison to the average consumer of sugar in one year a smoker contributes almost five times more to water depletion, nearly ten times more to fossil fuel depletion and four times more to climate change.4 5 Research predicts that by 2025 cigarette consumption may rise from current levels of six trillion to nine trillion sticks,16 this prediction has significant environmental consequences.3 5 16 This could result in required agricultural land use of 7.9 million hectares, water and fossil fuel depletion of 34 billion cubic metres and five Million tonnes oil equivalent respectively, and annual CO2 equivalent emissions reaching almost 130 Million tonnes.4 5 Summatively these findings have reinforced the ideal that smoking needs to be highlighted as a global problem affecting us all, not just smokers and those around them. Research evidence has irrefutably demonstrated the level of damage smoking is posing to the sustainability of our environment.4 52 points

-

@Adsibob try Wickes even if only for a temporary measure https://www.wickes.co.uk/Wickes-Windsor-Steel-Gate-Black---914-x-1880-mm/p/1908942 points

-

Sounds fine. I doubt if would make a difference but I think I would treat each of the twisted pairs as one wire rather than split the two ebus lines across each pair. i.e. take two of the twisted pairs into one ferrule for one of the signals and repeat for the other signal line. Dammit, you can't even refer to an ebus wire as + or - 🙄1 point

-

You need to prime these first, or the wet tile adhesive will just reconstitute the paint and the lot will fall off. https://underfloorheating-direct.com/ultra-prime-it-multi-surface-primer-39579-p.asp?gclid=Cj0KCQiAutyfBhCMARIsAMgcRJQDAkGRyn7AGC0-kosxI8Zl65oB8HirM96KPIT0ylPVK_u1EfnNRp8aAlUFEALw_wcB 50/50 with water and apply from a bucket with a sponge, with the solution not quite running down the wall. Wait an hour, then apply neat and leave to dry. After prob an hour or two you should be good to go.1 point

-

Chicken pen and lightweight coop would be a good use.1 point

-

@Thorfun I've no idea on either count. It was what I could find locally, and the borders installed it as they went. Best £2/m² I've ever spent.1 point

-

1 point

-

We used 50mm everywhere, every single wall and ceiling void, seems to have worked a treat.1 point

-

You need a better security camera with machine learning to discriminate small vermin from human vermin. 🙄1 point

-

Yes light definitely centre of the tile. It will look wrong otherwise and annoy you to the point that 5 years from now we’ll be watching the news to see someone has gone absolutely postal in the supermarket screaming at the lights.1 point

-

1 point

-

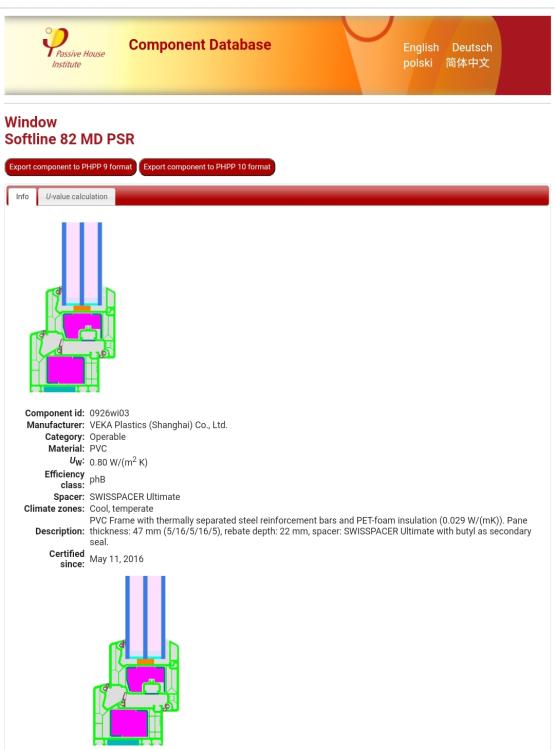

Easy way to look at things. Follow the line of insulation around the building (window is classed as insulation) there should be no break in the line upwards/downwards or vertically. It should be continuous across all elements of the building. The more insulation the better. Your block/brick returns make a gap in the insulation, so are no good as they act as a bridge from the heated inside to cold outside of the building. The cavity should continue to the window, either full fill that area with insulation or use a cavity closures. The window should straddle the insulation, so it gives the line of insulation mentioned above. Be careful with your choice of aluminium windows, as there are mostly poor performing ones out there. Make sure you get a whole window U value, before your commit to buying. Many try to give you just the glazing u value of 1.2 to 1.4. but have seen whole window U values for double glazed higher than 2, because the frame isn't well thermally broken.1 point

-

1 point

-

Sweet looking bathroom pocster. Hopefully it remains leek free. Funny story relating to my post about my shower build....it eventually leaked. Not from a fitting, but from the diverter valve. Getting the faceplate off was a pain in the ass due to vast quantity of silicone use. Tried dental floss, rubbish. Got it off using two wall paper scrapers in the end. Had to replace the diverter in the end, and resealed it using minimal silicone this time. Best of luck!1 point

-

1 point

-

The heavier the door the better the sound insulating value but don’t lower the wall insulation to match the door!.1 point

-

Certainly not. I agree with you about burning wood, in fact burning anything probably isn't much good for the atmosphere. We all have to exist and make decisions about how our choices affect the planet. I was pointing out that there are other unnecessary things we might do that affect the environment.1 point

-

late to the party here but +1 for wall washing lights. you have a couple of walls where artwork can be displayed so could have wall washers at each end and then central outside the doors? if you have the time download Dialux and render it out different ways to see how they look. at least then you can make a more informed decision!1 point

-

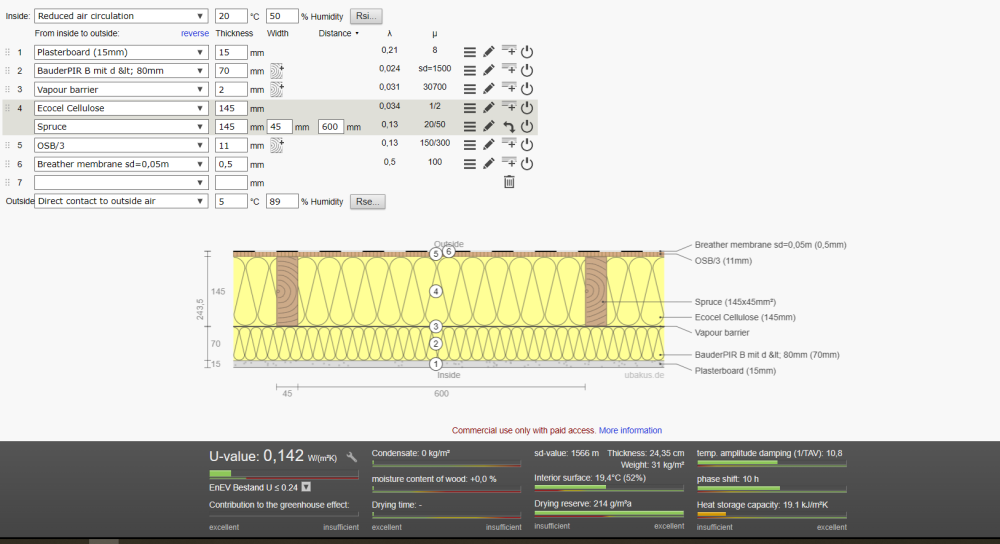

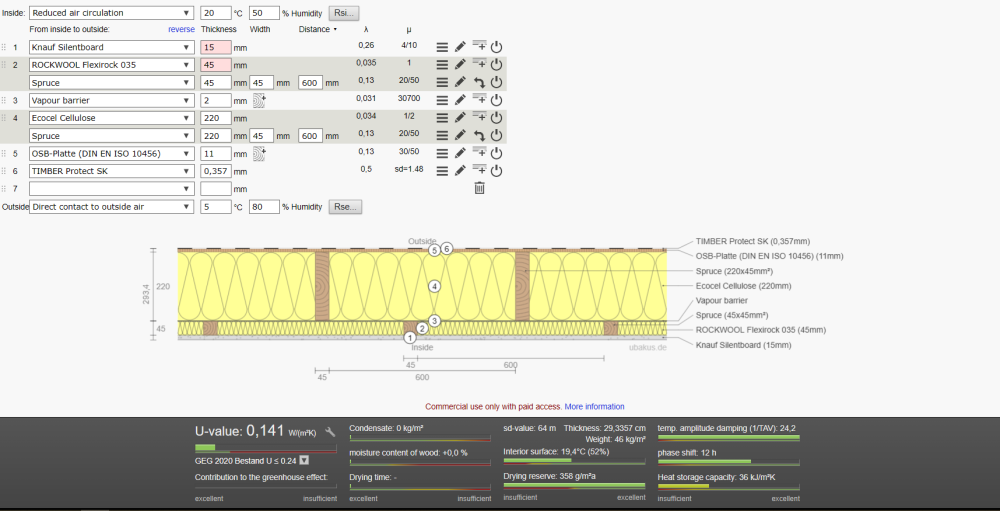

Rockwool, cellulose, hemp, anything is better than Oil based products unsurprisingly. Ask you TF company the question about this build up. 225mm timber is an off the shelf item. Better at damping the temperature swings and much superior for airtightness. You can inspect the cellulose install too and ensure that no slumping has occurred before boarding out. Better Still swap out the OSB for @IanR Egger MDF, you'll get an element of EWI for the studs from the MDF. LOWER!!!!! it's not rocket science. Head for passive levels. Best money you'll spend! I'm going to do a post on my rig later.1 point

-

1 point

-

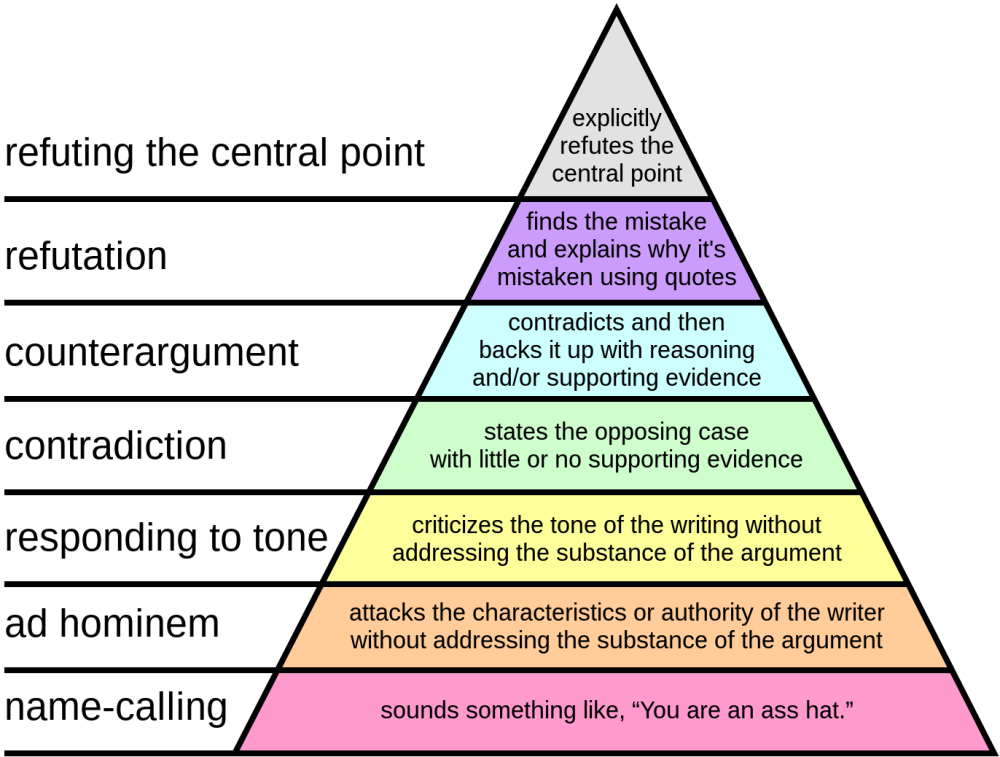

Thanks for acknowledging this But it was also the bottom 3 of the pyramid above. I don't think anyone is attacking you personally, but your statements, and it is useful always to see opposing arguments.1 point

-

You will need to speak to the EA, but they are usually pretty good with these now (I know off a few contractors who have used them on jobs). Providing you have a detailed design, justification for using one and acceptable percolation tests. You mentioned "Southern Water" so you may be on the south coast, take a look here: https://www.homeseptic.co.uk/infiltration-tunnels/ These guys are based in the south (I have no affiliation) but have some good information and also carry out installations.1 point

-

1 point

-

Depends, if you can use infiltration tunnels, then you can drive over it. Local ground conditions, building control etc will want to approve the design for this first. Also depends if you have a septic tank or STP. If you have septic tank, no chance, as you need the aerobic air content from the soil. If you have a STP then you *may* be able to lay a re-inforced concrete slab over the drainage field. This will probably massively depending on the winter water table level of the site, percolation value and percentage of the drainage field that will be covered by the slab. It won't be boggy (if it is, it has been sized incorrectly or the percolation testing has been done incorrectly, giving a false reading). Most domestic properties have it under their back garden and you would never know its there. They don't smell or cause any issue to the soil (when installed correctly). Its all down to design and local conditions, speak to a qualified drainage engineer, get your percolation testing done (professionally) and then give your designs to your building controller, (they will usually just say yes or no).1 point

-

1 point

-

ITS group, 4.5pkW. couldn't go higher due to the size of the roof and single phase connection. No batteries yet. Just gone a full year so might do the calcs on that.1 point

-

Some sort of block and beam floor. Can't tell if the infill between the T beams are standard blocks, large blocks or insualtion blocks. Looking at the very bottom RHS suggests an insulated type infill, e.g. https://www.cemex.co.uk/suspended-floor-systems Further reading here https://www.bdonline.co.uk/cpd/cpd-4-2017-insulated-suspended-floor-systems/5087724.article Pretty standard stuff these days, tho not that widespread. Normally overlaid with more insualtion and then a thin screed. Inherently "bouncy" over longer spans, natural quality of reinforced concrete beams. Bugger all you can do about the bounciness if that's what is annoying you. Unless the builder has exceeded the manufacturers / engineers span tables or inadequate intermediate supports. You'd need a camera survey done via the floor void to confirm. As it's a recent build, the design drawings and calculations etc should be available via building control.1 point

-

It might be what we have. They call them piped ditches. Years ago it there might have been a field side ditch which your land drained into. It might even have been your responsibility to keep it clear. Then when the road was tarmaced or widened they put a pipe in it, fill and tarmac over the top. In some cases these are indistinguishable from regular road drains. In our case soakaways wouldn't work and so when we came to discharge our planning condition we proposed discharging surface water into this piped ditch. They asked Highways or the EA (I forget which) who responded saying "They wouldn't want to make flooding further down the hill worse". We responded by proposing a rainwater recycling tank with the overflow going into this piped ditch. This was approved by the planners without further consultation. Note ours is just a recycling tank not a storm surge attenuation tank like it really should be.1 point

-

9 kWpis a relatively large installation. Roof mounted, especially roof integrated, used less area for the same output than ground mounted. In England, there is a limit of 9m2 for ground mount, bigger needs planning permission. You will have to look up the connection/installation rules in the ROI, they will be different. Theoretical there is no reason a competent person cannot fit then, they are basic panels, held in place with captive bolts on rails, that are bracketed to the roof joists. Your structural engineer can work out the extra loads imposed i.e. wind and snow. The main thing to remember with PV is to make sure there is no shading. Even a small amount of shading on part of single module can seriously reduce the performance.1 point

-

The drainage field for our previous house and at least 2 others in this road, is under the field behind us, which is Arable land growing usually wheat or barley. So there does not appear to be an issue growing "food" on the land. The drainage field is quite deep deliberately to be well below the depth a plough would turn the soil.1 point

-

Yes my Pi Music box seems to run for weeks on end without needing a re boot. What does still upset it is losing it's internet connection when streaming, if that happens too many times it just seems to lose the ability to re start streaming. But that is much better now we no longer use a lousy ADSL internet connection that was the best available when we got it, but frankly it was always a lousy unreliable service delivered over a copper cable network in such poor state is was a wonder it could actually handle a voice call.1 point

-

1 point

-

Simple. The stat in the immersion reaches the set point, and bingo, no more input goes to the immersion and export kicks back in at full wallop. Shut off the power to the immersion, whip the lid off, and post a pic of the settings on the stat head please.1 point

-

The ASHP and immersion will likely work separately from each other and it looks like your ASHP set point temp is 48 degrees and the thermostat in the immersion is set to around 55 degrees. If your ASHP heats the tank to 48 degrees the immersion will always try and heat to 55 degrees, if theres power available. If your priority has now changed to export rather than divert then you need to turn the immersion stat down to just under 48 degrees to stop divert into hot water, or bin the solic!1 point

-

The thing to consider also, a well insulated house on weather comp, a 7 to 10 degree day your flow temp are likely to be circa 25 degrees. Your floor temp is likely to be only one or so degrees higher than target room temp. Once rooms are above floor temp the UFH heating is no longer giving heat to the room. The closer the room temp gets to floor temp the lower the floor output. Floor heating is nothing like radiators and takes a bit of a mind set change. So although it sounds odd the floor looks after its self and will start to a small degree moving heat to areas on the north side of the building if you leave the water circulation on.1 point

-

we didn't put PIR inside studs. our studs are filled with 140mm glass wool (Isover 32) with 80mm/100mm PIR internal to the studs. What IS a PITA is cutting that internal PIR around the roof attic trusses. no issues when insulating internally on cut roofs as it's simply a large sheet screwed through to the rafters/studs. but, if the OP is going pumped cellulose in a 140mm TF then I would suggest they consider other companies that offer twin wall 300mm thick walls fully pumped with cellulose and get rid of the petroleum based insulation. Although, if the TF company is doing the PIR install work for you then it's not such a ball ache! I'm sure I've saved a load of money doing it myself but it is so very time consuming I do kind of regret it.1 point

-

I started our heating journey similar to you, lots of zones, but after 18 months have ended with a single zone. Your buffer size is defined by the smallest zone that can be in use, and the amount of water you need in the available system to give a suitable heat pump run time and allow defrosting. So the smaller the zone and bigger the heat pump, the bigger the buffer. Other thing to consider is flow temperature, to get best CoP it needs to be as low as possible, so coupled with UFH both require long run times, so forme the zones did nothing just got in the way of a simple system.1 point

-

I can grow a plant from seed for free. I can't grow a solar panel. The installation is nice and easy, you can plant a lot of trees very quickly. I can dig a hole but I can't wire or installed electric/solar panels. I can store energy more easily with a tree. I can't do that with just a solar panel. 100 years seems a long time for harvesting trees. Conifers can grow to a large size in thirty years. We harvested alder trees a few years ago and by coppicing, this could be done again in ten years. Trees capture carbon, solar panels do not. My limited understanding is that solar panels become less efficient over time. How would a thirty-year old panel or in hundred years perform? Where do old panels go, can they be recycled? My energy supply chain is easy to understand with trees. No idea where the panels have come from. Why have a resource come all the way from China or Korea, thousands of miles when I can control the energy I use, meters away from my house? Trees provide a place for wildlife to thrive. If I put down just panels nothing would benefit from this but me. You can buy significantly more land in some areas of the UK than in others. We have at least 100 times the space of an average garden. There are more resources than just firewood from trees, branches, and leaves provides a great resource to the garden. In my location, it is probably more efficient to have a few wind farms which would provide my electricity energy rather than having loads of land for domestic individual solar production. Just to say, I am not anti-solar panels and I would consider them in the future (assuming I can understand where they have come from and how they can be recycled). It was 2 celsius outside when I left the office at 7ish, the house was 18.5 celsius when I came in and I have burned this evening a single round of spruce and probably a single smallest branch from an alder tree. I have heated the house to 22 celsius with this. It's cost me nothing. A big external heat pump would probably have cost me a couple of quid at least to heat the house this evening.1 point

-

Heating exclusively with wood is working just fine for me. I finished our self-build in 2020. Solar panels are going to be more cost-effective in say Kent compared to my location in the Hebrides. Growing trees for biomass heating is going to be more cost-effective in the Highlands than in Kent. Building regulations should allow flexibility for buildings to be designed to suit the environment in which they are going to be located. Blanket bans are a terrible idea. I burn a small trug of logs in the winter evenings mostly from wind-blown trees or from coppicing. In the summer my south-facing glazing is my heating source. With the rebate of £400 and a further one of £200 expected from being off the grid from gas, I will have free energy for 8 or 9 months.1 point

-

Your logic on the smell is sound. Meanwhile, back in the real world. Ive NEVER been in a house with a wood burner that wasnt immediately obvious as soon as you entered the room. And over my lifetime, that quite a lot of houses. The blurb available suggests that 35% of those particulates are from burning wood. Im happy to admit, i dont know if those figures are correct, but its a high number for something that for most people is for effect rather than genuinely used as a heat source. In my village every single house has a central heating system. But they all have wood burners too. Im the only one without. Im not one for banning things, and as i said, poison themselves if fine, but not me as well.1 point

-

Are they highly inaccurate statements? Every single house ive ever been into with a wood burner, you can smell it. That means combustion products are in it. And that includes the sub 2.5 micron particulates. Frankly i dont care if you want to poison yourself, but i do care when those activities caause me to suffer. Visible smoke isnt the issue. Its those small particulates. You cant see those. I get there are circumstances in rural locations where its probably not a real problem for others, but for houses connected to the gas network? Really?1 point

-

Ok we will set up a factory then. OSB is made close enough to see the smoke from the factory...oh ..smoke!!!?? But they only use whole tree trunks. No recycling as far as I know ( and they would tell us). Seriously though, I was once dismantling a 1930s shed, made with lots of high quality pine trusses. First nobody wanted it reclaimed (despite the county council sponsoring a sheltered workshop to take it and sell back.) Just words. Secondly we couldn't get it taken to the waste incineration plant (20 miles away, but not what they take). Words. Thirdly , no waste company would take it other than as mixed waste. Fourthly, I contacted a government quango that was promoting reuse, re- etc. They had very nice representatives and beautiful brochures (Would I like a few?) I asked them for a sustainable solution. No idea. But it is what you are for, and only that. Nope. So we gave up and let a demo company take the lot. It probably went in a field. That was Kent. Offcuts in Highland? There is no incineration...all unrecycled goes to tip. We had perhaps a couple of barrowloads maximum. So I am still thinking that burning it is pragmatically appropriate.. Saves electricity. Doesn't rot underground. No transport. I should also emphasise that, being diy, the cutting is thought out and waste is a miniscule proportion, so fewer trees died than with your average builder.1 point

-

I am fed up with these terribly written articles in the papers and media every other day giving wood burning stoves (WBS) a bad name. I have written to many of the broadsheets "environmental editors" when they run inaccurate articles pointing out the mistakes. The one I love to debate is the often reported, yet highly inaccurate statements about the WBS smoke coming into the room in which it operates. I collect, pre-season, split, stack and season all my own firewood; softwoods and hardwoods. I reckon I am on about a 36month seasoning process with the firewood I have just now. I use pine kindling and some smaller softwood logs and a piece of hardwood or two to get the stove lit, I manage the start up in that I keep a close eye on it, lots of air, get the fire caught well, you want to get the flue warmed and get a nice draw, at this stage. Usually seen when outside getting an armful of logs, there is a gentle whisp of smoke from the chimney. Once the fire is going well, I close down the air supplies to normal running mode and let it go. I was outside most of yesterday with the stove on inside, I saw no smoke all day. The issue is idiots with stoves.1 point