Leaderboard

Popular Content

Showing content with the highest reputation on 11/10/22 in all areas

-

Nope, sorry mate, mine is virtually silent (you have to listen hard to hear slight air movement noise unless on boost) +1, and I made my own manifold and lined it with acoustic foam to act as a silencer as well, also the flow adjusters are at the manifold not the outlet into the room (these can create noise as they are throttling the air in the room)2 points

-

2 points

-

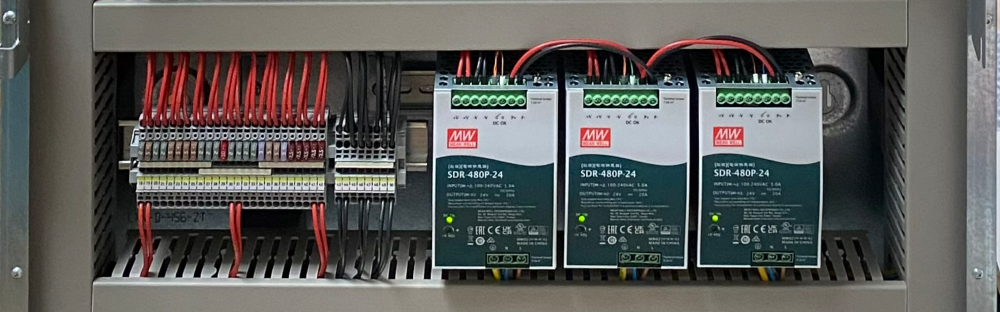

I have a preference for using larger power supplies connected in parallel and then seperately fusing each 24v circuit. This balances the load and provides some redundancy. Also means you don't have to define which circuits are fed from which power supply so much more flexible and if one dies (rare I know!) you can disconnect and swap it out without half your circuits not working or needing to rewire anything. This is how I generally do it..........2 points

-

A, there weren't many low energy homes. B, gas was cheap and no one knew any better. C, People that knew better installed a buffer, I assume as they are not new. May even start short cycling before that at very low flow temps. You either need a big capacity system or a buffer. Most heat pump manufacturers mandate you have a buffer, or a minimum volume, and have a min flow rate all the time. I can still get it with a gas boiler and 160L buffer at very low flow temps. Have just increased buffer temp to compensate. Think when all heat pumps were non modulating the issue was seen and installs had to have a buffer. With inverter drives, there is more modulation but not as much as a gas boiler. Both will short cycle at low flow temps and low heat loading, unless you design around it.1 point

-

Hi I have a Viessman 200-W system boiler installed with weather comp, no internal stats, building heatloss is 3.7kw and have MVHR installed. You are correct, even though the boiler modulates to 1900w, it does in fact, in the words of the Germans, micro start. We have UFH at 150mm centres, in 100mm concrete screed across approx 128m2. Plus a basement with UFH same spec but 33m2. We maintain 21deg internal temp. When first installed the boiler was firing circa 100 times a day!! I now time the heating periods, 7.30am-10.30am and then 2.30pm-9.30pm. I have had to adjust the set back temp to 4deg to prevent the bolier firing all night. Our floor just about coasts through the night. So with a fair bit of faffing we are down to about 20 fires in a 24hr period on the above heating times. HW is timed once a day for 1/2hr, we have 300lt UVC. I am toying with the idea of a buffer to try and smooth out the feed to the UFH. Today with outside temp at 12deg the flow temp into the UFh is 26deg. The UFH is one zone for the whole house, plus one zone for the basement, they are both mixed circuits controlled by the boiler. So we have no actuators and all circuits are run fully open. It is a great system, but does micro fire in the shoulder seasons. I had words with Viessman in the UK and Germany as they said what I am experiencing is normal and not a problem! the boilers heating rating has been turned down to 25%. Hope this helps.1 point

-

You will need one more 32A mcb as you presently have 6 30A fuses and that Cu conly comes with 5 32A mcb's.1 point

-

I haven't used this, but the details talk about RGBW so there must be a way to use it for RGBW. Yes, you can use each one of theese dimmers for 4 white LED strips (or for two tuneable white strips). So you would need 6 of these, 4 for your white LED's and another 2 for your RGBW strips. Yes, its still 8A/192W back to the driver. Each 5m LED would be 4A/96W each.1 point

-

1 point

-

I ended up taking a day off doing some of the cladding. In about 6.5 hours I did about 68 linear metres and a window trim. Working solidily, treating cut ends and laser leveling every couple of lifts, so not rushing it too much. On my own experience £3 may be a tad rich1 point

-

1 point

-

1 point

-

No. Any mcb's you find for that will be old / second hand, if you do find any new ones they will silly money. And an rcbo for that is like hens teeth. Spend the money on a new up to date consumer unit.1 point

-

I agree it's a good solution, especially with limited panel depth. One of the better products to come out but a little pricey. You can get a couple of decent 20A power supplies for around £300, so it'll come down to whether the additional functionality of the PSUB (!) is worth the extra £350. If you balance it against the higher cost of a deeper enclosure then it starts to look a bit more affordable too. My home setup has a standard depth panel and needs 40A so I might be tempted at some point to get one.1 point

-

You may remember back in August my husband a brilliant idea of how to use my big non-induction pan on our induction hob. Our new, very expensive Bora hob! It worked really, really well … until it didn’t, and the pan which was the conductor overheated and bowed 😩 This caused the disc on the bottom to protrude, and as I was stirring the mahoosive pan full of whatever it was I was batch cooking, the conductor pan turned and made circular scratches in the black ceramic glass. The other day I got a quote to replace the glass as I was so upset about how it looked, but when I talked to the engineer he said he would try buffing the scratches out first with Barkeepers Friend. As I happened to have some I gave it a go. Would you believe it, it worked really well! Not all the scratches are gone, but I’ll keep at it gently buffing and try to remove all the scratches. Saved us over £921.60!!! Top photo was the damage. Below photo is after first attempt to buff out the scratches. In time it may well be like new again 🤞🏻1 point

-

Ours is rigid, and we don't have that problem, but doing it again would use radial, as it seems easier to install.1 point

-

Yes, it's an LXN6-D panel. It will power a dozen or so 24v circuits with LED strips using RGBW compact dimmers and also has 5 RGBW tree dimmers in the panel powering quite a few WW Loxone spots using seperate channels. Regarding lighting power usage, Loxone's project planner says it assumes a load factor of 30% for lighting when calculating power requirements. I think that's way too low but is probably part of their assessment as to how big the new power supply and backup product was designed. I always sit on the "over engineered" side of the fence and wouldn't like to see power supplies at max capacity. Loxone installers will just design and install and not worry about future requirements whereas I think it's always good practice to have a bit of spare capacity.1 point

-

That looks neat. Is this in Loxone panel, or you have a seperate panel for lighting? Do these drive Loxone RGBW tree dimmers? Looks like that setup is around 500 My initial plan was to centralize everything and use DIN-mounted power supplies for LED's (potentially in a seperate/deeper cabinet), but had to give up on that idea when I realised that our electrcian had used 0.5mm2 flex for all LED locations, even those 20m away. Instead, we've now ended up with 3-4 locations throughout the the house (some in the loft, one on top of kitchen fridge etc.) that have a 5-core 230v+DALI feed from the plant room and then have fairly local HLG-series meanwell power supplies which supply 1 or more EldoLed drivers and in LED's. Not centalized and not going to look as good, but will do the job. I think I'm leaning this way tbh. more research is required. Its an attractive option if you loads is <960W, even though it's almost twice the price of a couple of 4080W power supplies, given the additional capabilities it has. In your case though, where you are up at 1.3kW, I wonder if you can assume average usage <960W and/or maybe have Loxone automatically DIM lights when total power consumption gets high. That would be interesting!1 point

-

Amen to that. I've got around 60m2 of "workshop" space that gets intermittent use. When I say "workshop" it's carpeted and furnished so high levels of comfort are expected when we're "working" in there, on demand. A couple of mini splits now do the climate control and I still can't get over how little power they sip while doing an incredible job at heating the space. Yesterday I was struggling to paint some shelving units out in the unheated garage - with the water based paint refusing to dry properly even after six hours. So brought them in to the workshop and cranked the A/C up to 23oC. It got from 18 to 23 in around 20 minutes and kept it there all evening. The energy to do that was something less than 2.1kWh (the total for the full day). Unlike IR heating, it's all-round warmth. Prior to the A/C being installed we were using ceramic panel heaters and while they were quick to heat you up when sat within a couple of meters of them, the contrast with everything else in the space being cold, was decidedly unpleasant. All that for a totally unaffordable electricity bill at today's prices. No thanks!1 point

-

Radial will get you as close to silent as possible. Series creates cross talk, and requires huge ducting at the start of the system in comparison. I use Brink and have reports of “complete inaudibility” with attenuators at the unit and airflow managed by design, to compliment. On 2 installs currently using the Brink Flair + main units, plus Brink Air Comfort units for post heating and cooling Fantastic results on my previous passive ( airtight ) projects, all using Brink, and that’s all I use these days tbh. Prices for your install should be a bit above the midrange of what you’ve been quoted, but spec / design will dictate the final price.1 point

-

Could just be a bit of solder that’s found it’s way into the impeller housing of the pump. Best to open the pump up and visually inspect the impeller housing and impeller blades, before continuing on with any further processes of elimination. A bit of solder / other debris will result in a quiet pump then becoming sporadically noisy. That situation occurs when the pump stops and the debris drops out of the housing, with gravity, then it eventually gets sucked back up into the pump and around you go. It’s that, or a failed / failing pump. Air is not the culprit, I very much doubt that, unless it’s so bad that the pump is running bone dry. If it was, you’d have no flow registering on the manifold flow gauges.1 point

-

Thanks for the suggestion. My house I had before was a refurbishment someone who had lived in it 20 years and never done anything to it, including vacuum... It had green gunk electrical cables, no central heating, old everything. I had basically stripped that bare and then hired trades people and did some laboring to help with them. But very basic laboring. I didn't trust myself with finish work or cutting ect and I just paid for that. I really should improve on my DIY though. I was pleased with what I achieved but it was a fairly basic finish except the kitchen was decent and one of the last things I had done to be fair. Thanks so much for introducing me to the open day1 point

-

Use Illbruck FM330 foam. It's airtight and remains flexible, Brilliant stuff.1 point

-

We have the alitherm 600,and managed to get the overall average u down to 1.4 with laminate, low e class and some filling. Nit great, but better then the 1.6 we were looking at. Were due to this, 3 week delay due to laminated now.1 point

-

Thanks everyone, Our carpenter wrote a letter confirming he had worked on the house until the date of completion. We've had a letter from HMRC today explaining they now have all the info they need and they will now process our claim within the 6 week timescale, once processed it will take 20 days to pay us. Does this mean we are now back down to the bottom of the pile and it's going to take another 10 months to get paid 😭 It's really annoying how they only gave us a few weeks to reply to their correspondence or our claim would be cancelled but they can work with indefinite timescales.1 point

-

The work needs to commence before the permission expires. Once commenced it can take as long as you like. Get the planners or building control to confirm that the work you have done constitutes commencement. Often doing the foundations is required. The garage consent has expired. A driveway would not normally be considered commencement. I think you may need to bring the wall in so that neither it nor the eaves clash with the corbelled parapet wall. Do it on ground and first floor and lose the step. Does your LA use the edge of the neighbouring window for the 45 degree rule? Some use the centre I think so you could maybe have the same size, just shifted along.1 point

-

Assuming the place is watertight and it is now just a case drying out, then a tiny bit of basic physics may help. Relative humidity is not the amount of actual H2O in a mass of air, rather it is a ratio of the amount of H2O that is in the air to the total amount it could potentially contain. This is why it varies with temperature. Think of it as a sponge that can hold 100g of water, but is only holding 75g of water, still feels wet. There are three main ways to get rid of liquid H2O, physically remove it i.e. find something to mop it up. Heat it until it evaporates i.e. blow hot air on it. Change the ratio of dry air to wet solids i.e. dispersion/diffusion. Usually we do the latter two in one cycle, so we heat which lowers the RH, then we disperse it into heated air, that is at an even lower RH. Now if you cannot easily run a fan off electricity, some sort of natural ventilation will be needed, careful design can increase this. One way to increase the input of outside air is to have a hole in the wall downstairs, and another hole in the wall upstairs, then add heat near the hole downstairs. This will reduce the RH of the air in the building, which improves the evaporation rate: evaporation takes place at all temperatures, not just above 0°C. By allowing the hot air to rise though the building, while being replaced with air from outside (which will almost certainly have a lower amount of H2O in it), drying will slowly take place. This is why forced ventilation is used, because if you are only taking out a few grams of H2O every hour with natural ventilation, it will take a very long time. If you are on site, or the site is very secure, you could use a portable generator and a gas heater to heat and force the wetter air out. If the structure of the building is very wet, then it will take a long time, and a lot of energy. You may be better off making up some clear windows on the sunny side, and let the sun help (wait till March). Also removing all plaster and getting back to the minimum structure will reduce the amount of trapped H2O that has to be removed. If it is a single skin brick building, make sure the wall 'facing the weather' usually the SW side, has good pointing and maybe a waterproof treatment. Purely as an experiment, it would be interesting to put a sheet of clear acrylic over the outside sunny wall to act as a greenhouse. This could help heat the wall from the outside, while also keeping it dry. Small vent holes at the top would be necessary.1 point

-

Went through it in detail. They are off ok some big ticket items and hadn’t included some other big cost items. All the other stuff is where I expected it to be.1 point

-

1 point

-

Ah, a posh version of my system in Dorset. Except I’ve got a stainless back boiler in a mk1 Rayburn. And no central heating 😉 The only thing I would add: please fit a laddomat to that 355. The back boilers are weak, and complicated/expensive to replace. The 355 doesn’t like being taken apart to have it changed. Not the finest Rayburn, but certainly the most capable.1 point

-

Really down to how you feel your relationship is with him, I bet your roof is costing you £12-15 grand at least so £150 extra to you is peanuts. It could be a good Will thing on your behalf so he thinks your a good lad so goes the extra mile to do a good job, or he thinks your a tosser who should have a forklift and cannot wait to get off your job i think there is a saying would you rather be right or happy. Or if you think he has priced it well just walk straight up to him and say you expected him to have one, the other companies that quoted the job all said they would bring one, shrug your shoulders and walk away.1 point

-

Old MEM board, sticky fuse, wiggle it about, plastic breaks up and you get a good crack from it. …. Not that I would know 😉0 points

-

No, and now I have finished the house my wife announced she wanted a divorce, lovely judge decided she gets a big chunk despite me funding nearly all of it , and neither of us can live here 🤯 (sorry fir the rant but I am very pi##ed off), oh, and thanks fir the offer 👍0 points

-

0 points