Chablais

Members-

Posts

51 -

Joined

-

Last visited

Personal Information

-

About Me

Self employed for last 25 yrs, in cycle retail. Recently sold the business and now starting major renovation and extension of our house. On a very fast learning curve!

-

Location

Cumbria

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Chablais's Achievements

Member (3/5)

14

Reputation

-

MVHR Valves in vaulted ceiling help

Chablais replied to richo106's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I fitted studding across the apex to create a void for the ducting and a flat surface for the valve to fit to. Very simple. I used 90mm dia semi rigid ducts so needed the appropriate space to install them. -

I used the same 90mm dia semi rigid ducting, it will bend to 90 deg if you have the space, otherwise i would use a 90deg connector. Smooth, large radius curves are always preferable, as all changes in direction will disturb the airflow and affect the pressure drop. Be careful if going through pre made joists, put pads were the ducting touches any of the metal braces, and ensure they are secured well. A smear of silicone grease on the connector seals also helps installation. Remember to label all the ducts as they land at the distribution box, and cap all the ducts if construction is ongoing to prevent dust ingress

-

Gas boiler vs ASHP & short cycling in low heat loss property

Chablais replied to ruggers's topic in Other Heating Systems

Hi I have a Viessman 200-W system boiler installed with weather comp, no internal stats, building heatloss is 3.7kw and have MVHR installed. You are correct, even though the boiler modulates to 1900w, it does in fact, in the words of the Germans, micro start. We have UFH at 150mm centres, in 100mm concrete screed across approx 128m2. Plus a basement with UFH same spec but 33m2. We maintain 21deg internal temp. When first installed the boiler was firing circa 100 times a day!! I now time the heating periods, 7.30am-10.30am and then 2.30pm-9.30pm. I have had to adjust the set back temp to 4deg to prevent the bolier firing all night. Our floor just about coasts through the night. So with a fair bit of faffing we are down to about 20 fires in a 24hr period on the above heating times. HW is timed once a day for 1/2hr, we have 300lt UVC. I am toying with the idea of a buffer to try and smooth out the feed to the UFH. Today with outside temp at 12deg the flow temp into the UFh is 26deg. The UFH is one zone for the whole house, plus one zone for the basement, they are both mixed circuits controlled by the boiler. So we have no actuators and all circuits are run fully open. It is a great system, but does micro fire in the shoulder seasons. I had words with Viessman in the UK and Germany as they said what I am experiencing is normal and not a problem! the boilers heating rating has been turned down to 25%. Hope this helps. -

you can adjust the springs, we have similar set up to you, and needed to adjust the pre load on the springs to enable the window to stay open at all. There are videos and pics online of how to do it. Best done at install time as some of the covers on the outside need to be off to access the springs and adjusters

-

Storage combi or UVC choices for new build

Chablais replied to ruggers's topic in Boilers & Hot Water Tanks

Defo not HWRC for us, purposely designed NOT to need it, tbh couldnt see the point of making thehouse super efficient and then running HW around the pipe syetem just so you can have instant HW. If you are super insulated and more importantly, airtight, then a log burner will almost certainly over heat your house in next to no time. We chose not to have one mainly due to pollution issues, but also because the times we could actually light it and remain comfortable would be extremely limited, even here in the Lake District. -

Storage combi or UVC choices for new build

Chablais replied to ruggers's topic in Boilers & Hot Water Tanks

we used 10mm Hep20 to all basins and sinks, some pipe runs will be 15-19m, as Peter W says, flow rate at 3 bar will be fine, people staying at ours comment how quick the hot comes through. Although I have to say, most people are happy to wash their hands in cold water. We used 15mm to utility sink and all showers, 22 to the bath. Hope that helps -

Storage combi or UVC choices for new build

Chablais replied to ruggers's topic in Boilers & Hot Water Tanks

Hi Ruggers Weather comp is not new tech, used in Europe for at least the last 25 years. I was in your mindset before we started our build, to the point we installed enough back boxes for a Heatmiser thermmostat in every room and bathroom. However, once you build to Passiv level insulation and airtightness, you will find that the house, as a whole keeps the heat in. Trying to seperate rooms as zones is very difficult to near impossible, in fact, over heating the first floor is probably a bigger concern, as is any room with South facing windows. If I did it all again I would fit air conditioning units and use them to heat in winter anc cool in Summer, powered by PV. as much as possbile. I ended up with a UVC because we wanted the ability to run three showers at the same time. in reality it rarely happens, and a 222 would almost certainly have done the job, without the stadning losses of a cylinder. Yes, we are on PDHW with a solar cylinder, so has two coils, both connected to the boiler, so our re heat time is approx 12-15 mins. As others have said, the other reason we ended up with a cylinder was to have somewhere to divert excess solar PV to. We dont use any gas to heat water from about April - November, and we are in the Lake District. I did look at using a cylinder from ACV that is in effect a cyliner in a cylinder, and the 'jacket' water is used to heat the domestic water, so that would mean we couldhave used PV to heat both the heating water and shower water, but I struggled to find any plumbers/heating engineers with nay experience of using them. It would seem we ware about 20-30 years behind Europe in our approach to heating houses. We fitted a Belgian MVHR system, and it is normal fot it to integrate with the heating and colling system and also the window bilnds etc. to control shading/heating/cooling of the building as a whole. Not that we have, but we should have!! -

Rega Vent MVHR Reviews

Chablais replied to bob the builder 2's topic in Mechanical Ventilation with Heat Recovery (MVHR)

I used Renson, Enduro 380 used 90mm semi flexi ducts, it is very uiet and auto senses humidity and Co2 and any other pollution that causes airborne particles and boosts until the levels 'normalise'. So no boost switches etc. Can be operated via an App on a phone. Even on boost setting we can barely hear it. Using larger dia ducts helped I feel as reduces airflow speeds. -

it will make sure you are air tight if you tape the joints and tape it to the ceiling air tight layer, ever fixed a puncture in a bike inner tube, the tiniest almost not visible hole and the tube deflates. So think how many of those size holes are in the PIR joints and gaps. Also prevents moisture laden air reaches cold parts of the wall construction and potentially condensating. It is fiddly but I would say well worth the time and effort if done neatly. Energy costs are only going to go one way, worth spending time and effort now to reduce long term costs.

-

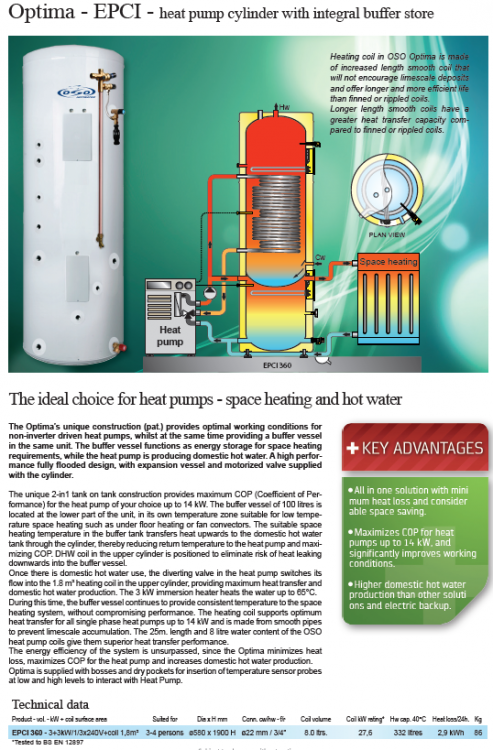

Hi Joth Thanks for the advice, I am also tempted by the A rated Delta Geocoil cylinders, as there are still a few on E bay at 395.00. I am a little put off by the heating coils being a smaller surface area than many other makes, which I guess only matters if a fast reheat time is needed. Also the Optima makes piping up easier and takes less space in our utility. I don't anticipate the buffer tank becoming hot in the summer months, as no heating demand. My challenge is piping it all up correctly.

-

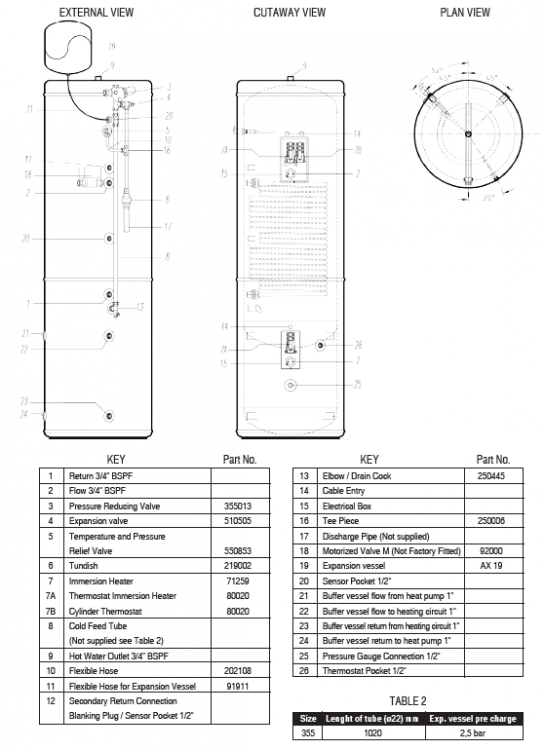

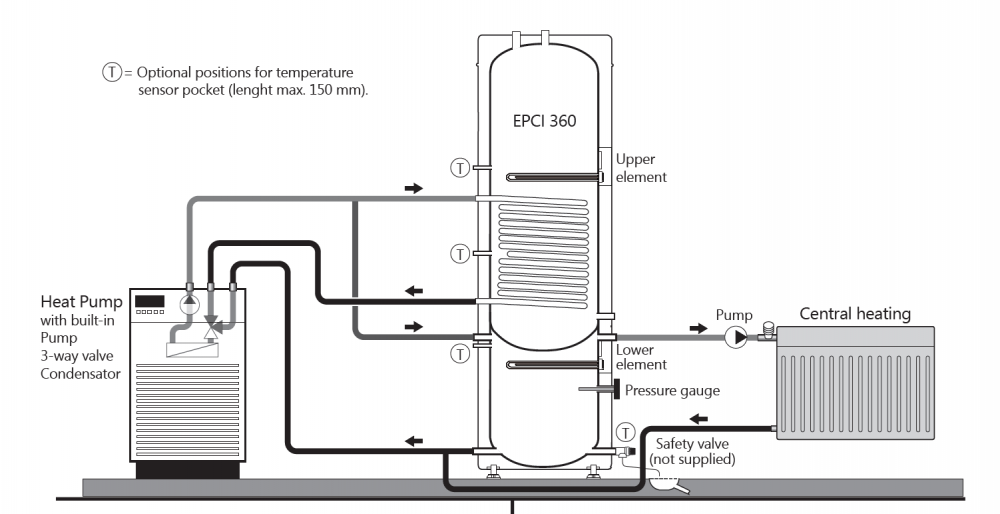

Hi Everyone, Can anyone offer any advice as to if the cylinder I showed is going to be suitable to use with a system boiler and UFH and three small rads. It is attractive as it keeps the two tanks in a single unit, and also has an immersion in each section. Is the fact that it is designed for a heat pump an issue?

-

Hi Nick Thanks for the reply, very helpful. The tank i am thinking of using is this https://www.ebay.co.uk/itm/OSO-Optima-ECPI-Heat-pump-cylinder-c-w-internal-buffer-store/113741035093?hash=item1a7b7e7655:g:70sAAOSwYkRc0rwF What do you think? I need to buy a new gas system boiler to power it. Was thinking the upper coil would give a faster re heat time, and both tanks have immersion elements in as back up and as somewhere for me to dump the 4Kw of PV to. I am struggling to 'design' the pipework to make it all work, not sure what needs to go where. So presume the boiler pump will supply to both upper and lower tanks, so a zone valve on each feed? Boiler controlled by stats in each tank Will I need a pump to pump to the UFh and Rads manifold( rads manifold on first floor) or will the pump on the manfold pull the water from the buffer, so a manifold pump on the rads manifold as well. Presume this one will not need a mixing valve. Going to duel fuel the towel rads, so electric in summer, or could divert PV to buffer immersion? Do I need some sort of bypass or non return valves in the system I have piped up all the potable stuff on a Hep20 manifold, and pressure tested with mains supply and it all works, so far so good. So now about to start piping for the towel rads and rads in 10mm Hep20 Do you have any recommendation for towel rails, was going to use stainless steel, seen these https://www.towelradiator.co.uk/stainless-steel-towel-rails Sorry for all the =uestions, trying to push on but wary of making errors in spec Found the forum to be very useful and insightful

-

Hi we just re roofed our entire house, converted to a warm roof, used 120mm PIR on top of the rafters, then 125mm mineral wool between, at the eaves we joined the cavity insulation to the rafter infill. Our airtight layer is on the inside of the rafters, we used Tyvek Airguard, taped to the inside walls. Most of rooms are up to the roof slope. It was fiddly in places but hopefully worthwhile. You need to invest in the correct tapes. If using a warm roof design, then think about windproofing it by sealing the roof membrane at all laps, and also tape it to the eaves protectors. Loads of good info on the Tyvek website

-

Trying to get my head around what I need to install UFH and four towel radiators and three small aluminium panel radiators. Been in touch with Wunda, asked about Wilo pumps and they said no longer supply, asked about a lower temp range blending valve and they said 35 is the min. So I started looking around at other suppliers. Came across Emmetti, and they do a mixed rail manifold M3V that has a hot side for rads and a cool side for UFH. Or is this just overcomplicating matters. Has anyone used their weather comp controls? They have a modulating blending valve connected to their weather comp, as I am feeding all the heating from a buffer tank, I presume I cannot weather comp the boiler, as it only gets a call for heat from the buffer stat, or the DHW stat in the main tank. My UFH is sitting in 55mm Cemfloor screed, sat on top of a concrete beam and block floor, with 300mm sprayed insulation on the underside, so it will be slow to respond. I was originally looking at Heatmiser Neo stats and multiple zones, but now thinking that due to the slow response, that the whole ground floor, circa 100m2 will eventually even out temp wise, and may be better controlled via weather comp and the modulating mixer valve. Has anyone any real life experience of this set up? It's a big learning curve for us, our project has gone from an estimate of six months to over 18 months in now, and we are keen to get the floor screeds in and heating going before winter. thanks Andy

-

Hi just trying to decide if I should use 10mm Hep20 or 15mm Hep20 pipe to feed three radiators and four towel rails via a manifold. 10mm is much easier to run and turn etc. but when you look at the inside dia. compared to the 15mm especially with the insert in, the difference looks huge. Will it create too much resistance or be prone to noise and clogging. The runs will be circa 5-8 metres between manifold and rads. Would it be possible to mix the pipe dia on the same manifold. Have used 10mm pipe to the basins and 15mm to the kitchen sink on the potable runs. Finding the plumbing a little more confusing than anticipated!