Leaderboard

Popular Content

Showing content with the highest reputation on 02/21/22 in all areas

-

@SuperJohnG don't overthink it bud, it's as easy as you say, tape and seal away to your hearts content. Need to make a hole, make a hole then seal the membrane to the pipe/cable etc with tape. I had loads of silicone left over from the SIP people so the missus went around and ran a bead along every panel to panel join - worked really well, (I did it all pretty much one man band), where the soleplate meets floor etc - every join. Not too difficult as the panels are big so not overly onerous. Seal the membrane to the floor slab - I ran a bead of orcan f first, pressed membrane to that then taped with the tescon. I did bottom sheet first and used the double sided tescon stuff to hold it in place, also chucked a bit of the tape on here and there. Lap top sheet over it then sealed top to bottom. Get the battens up in good order else things start sagging - a day or two is generally OK. The Double sided tape holds it all taught to the wall without having to staple the shit out of it. The battens trap it there. I did my 180mm mvhr ducts after the brick skin went up - stupid but the way it worked out generally because I wasn't sure exactly where stiff would go. I havent used any proprietary grommets etc to seal, just orcon f in places and tape. My air test was 0.24m3/hr/m2 - it's easy enough, just be reasonably diligent. I'm sure I have holes and bits I missed in the membrane easily done but I looked at this as a compound effect. SIP is good for airtightness anyway, silicone the joins = better, fit insulation and tape all joins so another layer, fit vcl and seal up - in my head, cumulatively it would give a good result and it did. I used 38mm battens and 47mm back boxes - useful if you have a lot of two way switching. I do, wanted most lights to be switchable from multiple locations and some of the back boxes are horrendously clogged up.2 points

-

I used 25mm battens almost everywhere. 25mm battens and 12mm plasterboard is a near perfect match for a 35mm back box. I even managed carefully to run 15mm copper pipe in a 25mm service void. I only used 45mm battens in the utility room where I had 22mm copper pipes to fit, and those, with fittings, simply would not fit a 25mm void.2 points

-

No reason for it to arise alarm bells. We found that windows are like kitchens people charge what they think the market can bear. After going to multiple companies we settled on two and it was in the six months haggling that reduced the bill. Norsken the other company we shortlisted got very close to Velfac's price, we went with Velfac as they give a six year warrantee if their windows are installed by one of their approved installers. We used Wescott Construction, not cheap but very much worth it. They were the most professional builder of the whole project.2 points

-

The stat on an oil boiler is like a limiter. The flame runs flat out until the flow temperature reaches the limit set by the boiler stat. With a small load the flow temperature can hit the limit very quickly causing cycling. The buffer tank is meant to stop this by acting as an extra load so the flow temperature stays below the boiler stat limit, or at least helps it stay below the limit for more of the time. For this to work a lot of things have to be right... The boiler stat must be set high enough or it gets in the way and causes cycling. The pump speed must also be fast enough to suck the heat out of the boiler and put it in the buffer. The buffer must also be big enough and the stats on the buffer must be set up to so that the capacity is used (having a big fuel tank on a car is a waste if you always fill it up when it drops below 90% full). It took me awhile to tune up our system. When first installed it cycled so much the average output was too low to heat the house when it was very cold outside. I ended up fitting a bigger pump and smaller jets in the boiler. That pretty much eliminated cycling.2 points

-

Tell the joiners to stop being lazy. CUT the battens and leave gaps at 450mm above FFL and 1150mm above FFL as you can see in my first picture. Those are socket height and switch height are where you are most likely / be allowed, to run cables horizontally. Cutting battens as you fit them and leaving that small gap gives space for cables, and no danger of damaging the VCL when drilling the battens. and if the gaps end up not being used then no harm is done. It also makes it easy to use all your battens with no waste.1 point

-

My No 1 tip, since you didn't mention it, is a service void. So as you line your entire house, with the air tight membrane, and all joints taped, you fix vertical battens at 600mm centres. This gives you a void to run cables and pipes without any of these penetrating your air tight layer. Only services that must exit the building penetrate the air tight membrane and are sealed where they do so. Some examples:1 point

-

That's the scary thing. Manufacturers/suppliers that take the utter **** and those customers that haven't received multiple quotes or are fairly happy with the product and pay the price they were supplied. They shouldn't have been in a position to knock £10K off to get your business. If they were comfortable with £15K in the first instance, then why did they "try" and fleece you for an extra £10K in the first place?1 point

-

@Temp No won't be rushing. Just keeping it as an option should the need arise. We've still got the downstairs UFH to go in at some point in the next couple of years so that may help in getting rid of the heat produced. Tbh at present I'll probably just leave the buffer set to turn off at 65°. We'll just monitor it to confirm all is working as it should.1 point

-

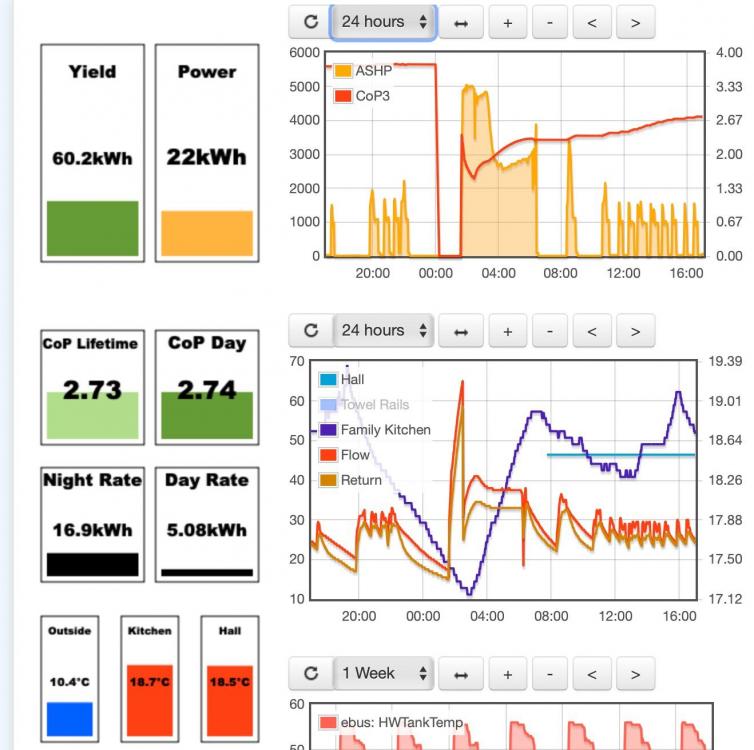

J1mbo .. interesting and thanks. I did wonder why the working figure was higher .. never occurred to me that the yield didn't include the power used. Every day a learning day!1 point

-

Have you thought of doing an air test before you go any further to try and find any poor areas. you can rig up your own if you are a bit handy.1 point

-

The COP is (Yield+Consumption)/Consumption roughly - more like 3.71 point

-

Yes, all circuits run at same temperature. The UFH is directly couple - no blend valve I've not tried Active , so can't comment vs Expanded I run ebusd on a pi using the ebus adapter (Wemos D1) WiFi , with a circuit I built myself from here (whilst I wait for ebus Adapter 3) . This is linked to emoncms which is where I do the graphing and trending. Using emon I can measure the power consumption from the ASHP and fuse this with the environmental yield from ebus to generate a rolling CoP. Because I run the ASHP harder overnight (when it's typically colder) , my CoP suffers .. but I'm paying 5.5p/kWh (for the time being ? )1 point

-

Nudura have just done two in Stroud, 3 storey bottom storey walk out, all cut into a shale bank. talk to Icf supplies in Essex. steve Burgess they supplied it. I went there to watch a pour being done.1 point

-

Hello @HelenS, and welcome. I can't help with the decentralised MVHR, but just taking a step back, are you renovating to a level where there is a benefit from Heat Recovery? ie. planning to get at least below 5m³/m².h @50Pa infiltration rate, and ideally below 3m³/m².h MVHR can be over-sold, and really only comes in to its own when you are sufficiently air tight that mechanical ventilation is required for good air quality.1 point

-

Contega tape is also fleece backed so if you expose it to water on one edge it will act as a capillary mat. And a horizontal gap between the edges of the cavity closer won’t allow any water across.1 point

-

As per @PeterW the door or window frame and sealant around them keep the water out. Cavity closer helps stop water and cold air tracking across.1 point

-

Cavity closer should never see water so it’s fine although what are you wanting to achieve..?1 point

-

1 point

-

I don’t think you need the visqueen and just buy decent aluminum tape to cover the joints. As it won’t be subject to movement or light/heat variations then it will not degrade. Ultratape Rhino is good and not expensive for what it is - available in 50/75/100mm widths on 50m reels. https://www.sealantsandtoolsdirect.co.uk/tapes-and-trims/aluminium-foil-and-heat-tape/ultratape-rhino-aluminium-silver-grey-foil-tape-75mm-x-46m1 point

-

I would advocate a seperate airtight layer with a good membrne and proper airtightnes tape. It will only amount to hundreds of pounds but will have the most dramatic effect on the comfort if you get it right. You will save a few £ on the tape with less joints too if you use a membrane. IIRC you're on a tightish budget so you may be able to use seconds PIR with imperfect facing then too to save a few quid. By the way are you planning to insulate the service void? It would seem a waste not to, espically as mineral wool is about the best bank for your buck when insulating.1 point

-

General comments, if you are really well insulated, 0.15. U value or better and airtight, your heating demands are very low, so the heat loss is slow. I have my heating set for 19 degs, 24/7, the boiler comes on once a day to keep that temperature. My average heat input by gas has been 2.2kW since September for 190m2 single storey. "If you can shut off the heat but can't call for it, is this just by using standard TRV's? What's the benefit to having electric towel rails over water heated." Answer, we have UFH in the bedrooms, but like cool bedrooms, when the house is warm in the winter, we can open the bedroom door and within an hour the room is the same temperature as the rest of the house. But with doors closed we can have the bedrooms a few degrees cooler. We just wanted to be able to switch the UFH of in the bedrooms sooner than the rest of the house. We are using a standard Salus head on the UFH manifold. We have electric towel rails for two reasons. First is for summer towel drying, so there is no requirement to use the CH. Second our house is super insulated and the UFH only needs to come once per day, the electrical towel rail allows flexibility for towel drying in winter also. "What are you referring to as linking to an area, do you mean don't extract from the ensuite, or do you mean to make sure the ensuite radiator is always linked to an area that will be calling for heat throughout the day?" Answer, I am talking about the heating not ventilation. Have the ensuite/bathroom radiators on their own zone for heating. One of the reasons for electric towel rails, so I heat these rooms even with the rest of the heating off. If I was doing it again I would have electric UFH instead of water, for complete flexibility.1 point

-

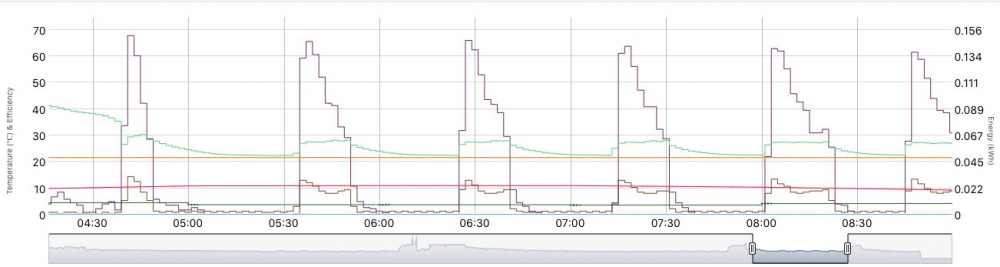

So i've been thinking about this too. I'm very interested in @TerryE's ideas, but am currenlty running things with the ASHP controller's weather compenastion to see how it behaves: This is what I've observed: - The Vaillant heat curve of 0.2 tells ASHP controller to use a flow temperature of 25C with the current external temperatur. - The power output by the UFH is a function of, not only the flow temperature, but also the pump speed though. Given the ASHP controller doesn't know anything about the pump speed, the heat curve required needs to be re-adjusted if the pump speed is changed. - Vaillant has various weather-compensation modes. The one I'm using considers internal temperature, but doesn't turn the heating off when a set-point is reached, but rather keeps running with a lower flow temperature. - In practice what happens is that the UFH pump runs continously with a mixer valve being adjusted by controller to maintain 25C UFH flow. The ASHP itself powers up every hour or so for 10-15mins and raises buffer temperature to around 28C, and then powers down. So whats the issues with this? Well, if you look at the supposed efficency of the ASHP for A7W35 it's 4.8. But, if I look at data from 6am to 6pm today, for example the actual COP is just 2.9. So it looks like leaving the system on all day and allow it to adjust temperature isn't particulalry efficient and, given UFH is in a passive slab, it would be more efficient to allow ASHP to run at a steady state for longer periods of time and then turn off the heating circuit. This requires either continuing to use weather compensation, but using the mode that turns off the heating when setpoint is reached, or moving to a differnt, probably externally controlled, heating strategy. EDIT: The energy figures on the right are kWh/2min. So ouput climbs to 4kW for 2-3min and then starts dropping off.1 point

-

Yes if they want it to perform well, 75mm is woefully poor for a floor with UFH. Many of us find it sad that people are still building like this, and the customer is probably not aware of the poor job they are getting and not been advised that more insulation = lower running costs and a warmer house.1 point

-

If you don't extract you would also end up with lots of damp issues also. Yes it would end up cool. So don't link to an are area that wouldn't be calling for heat. We have electric rads in ensuite and bathroom for that reason. You say you are well insulated per regs. Do you mean you have building regs insulation only?1 point

-

No, it's the opposite. Assumption 1: this question is in regards to heating season, when the outside air temperature is (much) lower than the internal temperature. Assumption 2: the building is to a high spec for insulation and airtightness An MVHR supply vent puts out air slightly colder air than the internal average air temperature. So in a steady state, and ignoring highly localised sources of heating, supply side rooms will be slightly colder than the average internal temperature, and thus extract rooms sightly warmer. Now most designs naturally arrange heating sources to compensate for this, focusing emitters in the living areas which tend to be supply side rooms. But also those rooms tend to have more glazing which further cools them. So we'd need all those details to give any sort of real estimate. Does that make sense? Hopefully that helps with the other questions1 point

-

Set the studs tight against the block Studs ceilings need skimming before the wet plaster Hessian stud and ceiling to block Or 100 mill fibre tape Not 50 mil tape1 point

-

If you are definitely considering woodcrete have a look at Isotex from https://insulhubuk.com/ Much better block than Durisol also use the search function on here as there are a couple of builds with pictures using woodcrete blocks1 point

-

A timber frame holds up the upper floors and plasterboard is ok to protect the timber.1 point

-

Why not put the first floor joists in, place a a row of acrow props under the floor as dummy support in the place of the stud walls. Then build up Nudura and fit roof. Remove acro props, don’t allow anybody upstairs, pour floor screed and replace one or two acro props to take any sag out of floor, then build stud walls removing props as you go.1 point

-

I used standard blocks and 200mm cavity full fill with rockwall batts. I also used stainless ties as difference In U value nit justified by the cost of basalt. I also had first coat plaster done in sand and cement (much cheaper) and final coat in plaster (very solid sounding walls and can hang anything). Make sure you parge coat between floors (between floor joists where plaster does not go.) simple to use silicone where cables go into back boxes to make airtight.1 point

-

Many people have benefited from this resource in the past, and I am sure will do so in the future. So I have pinned this post.1 point

-

Since you don't have any solar PV it would be wasted on you. I will look after it and "keep it warm" for you.0 points

-

I have 150mm pir + 25mm eps under my bathroom floor and the room is still bloody freezing... ?0 points

-

Peter, thanks for the prompt to this interesting discussion. My only quibble is with the verb "tried" ? I would say that the system has been working really well for over 4 years now. IIRC, you have a pretty energy-efficient house with decent internal thermal mass. This puts you well outside the operating domain of most standard controllers. A good indication is the 24hr heat-loss without heating (mine is just over 1°C per day). I use two straight-line functions to calculate total daily heat requirement: Planned demand in kWh as a function of Δt: (set-point - Met-office predicted temperature) A feedback adjustment as a function of Δt: (yesterday's average room temp - set-point temperature) When you schedule the on times isn't that critical. I do mine overnight so I get a ~1°C ripple over the day. Moving a chunk to an afternoon boost would drop this to nearer ½°C I am not sure that you really need some fancy (and expensive) controller. An RPi zero 2 controlling a relay or two would be perfectly adequate.0 points