Leaderboard

Popular Content

Showing content with the highest reputation on 10/31/21 in all areas

-

Here is a comment from the article, sums it up. Fresh Air , Bristol, United Kingdom, 3 hours ago Clearly their system was poorly designed. If heat pump technology is as bad as they say it simply wouldn't exist. Using heat pumps we can reduce our heating energy demand by 75%. I've worked on 100's of successful installs. We need more qualified engineers in the country. End of. They work.4 points

-

I use may own charcoal. I don't believe for a moment that the cheap commercial charcoal in bags comes form sustainable sources. Anyway if it is from 'abroad' then it has travelled a long way. Start the barbecue with any old bits of stick from the garden with some hardwood cuttings (fruit tree prunings) on as the next layer, along with 'harvested home-made charcoal. At this flamy stage put food on in frying pans/planchas to make use of the heat. As the fire becomes glowing and controllable, it can be used as a conventional bbq grill. Meanwhile, all around the fire is lined with oak logs, which burn smokily along with the starter fire and then char for the next time. After cooking, extinguish the fire asap. The amount of water shows just how much heat and fuel is still in there. Next day set aside the recognisable charred logs and charcoal for the next time. Then collect all the ash in a bucket and hose and stir. 5% ash at the bottom, and 95% reclaimed charcoal (very fine) floating above it. The oak is local and it takes 3 logs per session. No parrots died.3 points

-

To reflect on that. Much has been, and is being achieved. The fringe people such as Insulate Britain (on whom I've been forthright before), the E/W Green Party, and Greta, spend their rime shouting that nothing has been achieved unless we XYZ impossibilism this week, such as ripping out all gas boilers by 2025 and so on, have made themselves irrelevant to the practical debate, as well as being entirely fictional. To have a position of "more ! more !! more !!!" with no useful comment is both misleading and stupid. One of the current pernicious ones is IB's claim that nothing has been done about insulation, which is and remains untrue. We'd all like more, but we're starting from here - which is part of the way on then journey. If I'm being persnickety, is not Scotland's electricity now around zero-net carbon? I believe Scot Gov claimed 97% green for last year. Plus it's November in the fair city of Glasgae, so it is probably making a carbon-profit from all the howling gales. As opposed to the Howling Gaels celebrating their large rugby win yesterday. This is a comment from Dave Keating, a writer at the Politico.eu who basically functions as an amateur PR Man for the European Commission, and who spends his time scraping barrels to find anti-UK narratives to put into the ether, or the anti-UK aspects of any story as a mirror of an obsessively pro-EU Commission stance. These days he's trying to explain why Poland must be punished for breaking EU law, when none of the others who broke it (Germany, France etc) were. (If anyone doubts that, go and follow DK's twitter feed for a month.) This one is a fair observation: My view on where the UK needs to be is that we are making very rapid progress, as we all know - due to hit the improved -55% EU target if they've agreed it yet by around 2024 Q1/2, and that we should refocus our overseas aid budget to helping stable developing countries (eg Ghana not Libya) move towards low carbon development by helping in those areas where we have practical expertise, and helping them develop their own green economies to build low-carbon-intensive wealth. Wealth is necessary for fertility to plummet, and self-dependence is necessary for real development. I think the UK is unusual (some Scandis are the same) in not having used aid as a tool for creating dependence. Ferdinand2 points

-

So - nothing about me being aggressive, right? I thought so. But you are incensed, offended that my opinion doesn't conform? Grow up. People have the right to have opinions that you dislike. I understand it's difficult but this is the only way. Repeating BS about the biggest problem humanity has ever faced - FCOL, I grew up being afraid of the nuclear war, climate change is really nothing in comparison. And the self-righteousness, oh, you know, selfishness, all that. You know nothing about me. You have no idea how much stuff I buy, how often I fly etc. You may be greener than I am or not - I could not care less. I buy stuff with the money I earn, I don't steal. Until such time it is illegal to do so I will continue doing what I believe is best for my family and myself - like most normal people do in reality. Humility, you really need to learn what that is.2 points

-

1 point

-

I did that to a barrow. I was filling it with my digger, and it started to fall over, so I tried to stop it falling with the digger bucket. Digger 1, Barrow 0.1 point

-

The test method for thermal conductivity accounts for thermal drift and worsening of lambda over time often found with PUR, Phenolic and XPS foams. Declared values should reflect long term lambda (20-30 years)1 point

-

Be here somewhere. https://revisionscience.com/gcse-revision/physics/physics-gcse-past-papers/aqa-gcse-physics-past-papers1 point

-

A couple of probing questions if you don't mind. 1. How do you plan to install the breather membrane while maintaining the ventilation cavity? 2. How do you maintain that PIR is twice as good as mineral wool? I get a U value of 0.304 for PIR and 0.398 for full fill rockwool (lambda = 0.035w/mk) with 100x45 studs @400cc. 3. How do you plan to deal with the shrinkage and expansion of the studs with varying humidity and temperature? Won't the boards loosen and you'll get thermal looping? Legend has it that PIR off gasses and degrades in R value over time as well as shrinking like most other foams. I've been searching for over an hour to find a non biased long term study on this but can't. The below is a screen shot of one manufacturers declaration of dimensional stability. 4. Maybe someone more qualified can explain what this means. There is some anecdotal whisperings of this. http://www.greenbuildingforum.co.uk/newforum/comments.php?DiscussionID=16490 By creating a clear ventilated cavity you'll completely negate any insulative benefits of the current stone+ rubble wall.1 point

-

Mine (LG therma V) will turn on the circulating pump at about 5 degrees. It does not run the ASHP, it just runs the water circulating pump for a minute or 2 to draw it bit of heat from the house, or at least move the slug of cold water into the house and replace it with some house temperature water. The instructions for the ASHP say to use antfreeze, but it appears to be programmed to assume you have not done that so it tries to keep the fluid temperature above 0. This function is not documented and cannot be turned off.1 point

-

Warm up water, or bricks. You get extra energy from the fusion phase, a lot more energy for no change in temperature.1 point

-

You are tackling this from the wrong angle. Rather than work out how to use the "spare heat" i would be looking at how to eliminate or reduce the spare heat creation. 400W projector? do they not yet make LED ones? If not I bet they will soon. 1000W for an IT cupboard. You need to re think from first principles exactly what you are trying to achieve there? Something that consumes 1000W for long periods of time has no place in a modern low energy house (unless it happens to be the heating system)1 point

-

Well I guess it's the 'something useful' part, right? I'm sure that I can pull hot air from somewhere relatively easily, but now do I use it? I'm not quite seeing how a humidifier helps? Well, since the house is near-passivhaus-level I'm not sure that excess heat is not going to be a problem? Even in my current 'standard 70s' home, just my PC running a game very clearly increases the heat in the room. If we can spread it around the house, maybe that would suffice? Frankly the math here is too alien for me for now, not sure where to start digging in to how (e.g.) a 8kW ASHP can handle 1KW of actual heat generated? Obviously it sounds like it would easily work but I'm sure reality is different?1 point

-

Flat roofs on the front of properties are not attractive at the best of times, let alone one that is raised against one at its standard height. I do think a lean-to pitched roof is a lot more likely to be favoured. No harm in trying? Can’t find an example of a pitched roof next to a flat roof at the mo but food for thought… before and after. The latter being a lot more appealing.1 point

-

In real life, I dispute that dry lined walls in old stone buildings are better. They might be if detailed properly. But almost without exception my findings are the cavity created with the dry lining is open to the loft space and just allows cold air into that cavity, bypassing most of the insulation properties of the wall. This shows itself in winter when you remove a switch or a socket and an icy blast of cold air comes out of the vacated hole.1 point

-

Did for me. Here is a 2017 paper. Covers just about everything you need. AQA-PH1FP-QP-JUN17_(1).pdf1 point

-

1 point

-

Why the need for antifreeze? Are you winter prepping? Just dry test with air if you’re just needing to prove the pipes before install. If you’re just looking to treat the system at the point of commissioning then you just do that via the upper manifold vent / drain point with a 3/4” or 1/2” flexible hose and a funnel. Make sure the lower manifold air vent / drain are completely removed otherwise it’ll be ridiculously slow going.1 point

-

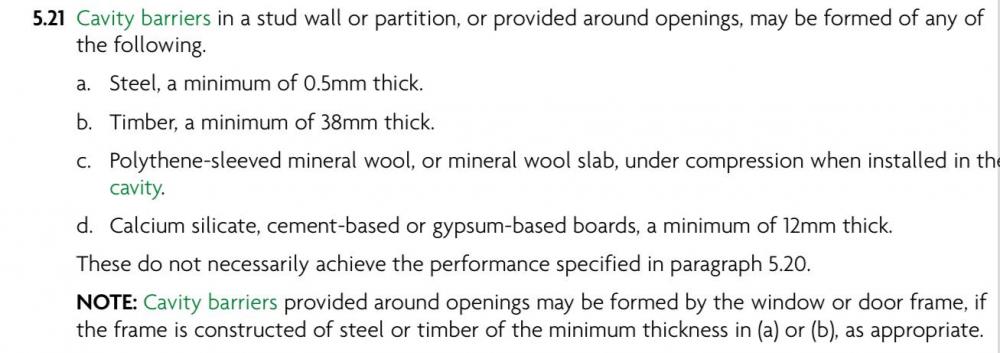

Thanks for the link to AD B. I did say AD B is not my usual source of advice, and humble apologies for not using the latest amended version, however the essence of fire safety advice rarely changes, only how it is presented. This Diagram 5.3 is commonly misquoted as it was in the previous ADs and the NI TB E. The diagram only related to 5.18c where some cavity barriers may be omitted where cavities are closed as per the diagram. It does not mean that all cavity barriers need not have FR obviously, only a lower standard (than 30/15 FR) ie 38mm timber or 0.5mm steel is a lower standard but can be accepted in ADB 5.21. The presentation of this is quite confusing and should be improved in AD B hence our debate. I have indeed read both BS 9999 and BS 9991. Again humble apologies for quoting BS 9999 instead of BS 9991 but they both concur. Both BS 9999 paragraph 34.2.1 and BS 9991 paragraph 19.1.1 are identical and offer more clear guidance than AD B on this subject and confirms my stance that cavity barriers are required and PVC Frames are not suitable alone. I did not imply the subject matter entertained you. I said I would entertain your argument. Very different things. It is obvious you have decided that you wish to exploit perceived loop holes in the wording of ADB for a lower standards of fire safety, which is a shame but I would advise against promoting this view to others. cavity barriers around window opening was one of the big failures in Glenfell tower disaster. Where PVC and spray foam and such inappropriate materials were used around pvc windows and services. That failure in the flat where the fire started was the catalyst for what ensued.1 point

-

Lots of naysayers will jump on these stories for reasons I don't really understand. I think others on BH have pointed out that the grant value often disappears in the extra costs of an 'approved installer' who has more costs than the local specialist. ie the grant does not benefit the end user. I know of many failures of ground source systems, and it was down to being inappropriate and badly installed. What chance that this 'story' could be resolved by some expert attention?1 point

-

Welcome I am no expert, but take an interest in all things ASHP. Sounds to me that there may not be much volume in the pipework, so the heat pump quickly heats fluid in there, compares flow and return temperatures, sees little difference and shuts down. So our initial diagnostic seems correct. How large is the buffer tank, if there is one? I am assuming it heats the DHW no problem.1 point

-

NHBC isn’t the best standard by far ..!! And yes I agree but you design in access ..! There are loads of ways of sorting that, and for example the OP has a property that is raised above ground level so there are options on the vertical legs etc. I’d hazard a guess that BCO hasn’t been near site to see what they are suggesting - they are overstretched and using COVID as a reason in a lot of places but anything that isn’t a square box to min regs they are basically trying to ignore.1 point

-

The fitting that the 21.5mm pipe goes into just doesn't look right - its hard to tell from the photos but it doesn't look like a solvent weld fitting, also the 21.5mm pipe also appears to be at quite an angle to the fitting which will cause problems - what is the 21.5mm from? a boiler condensate? Can the 21.5mm pipe be pulled square?1 point

-

The climate conference …. Let’s burn thousands of tons of fuel to meet up, live it up and discuss getting others to burn less fuel. ?1 point

-

Yes they can. Ask them where in the building regulations it states that …? Regularly spec a single run with a 45 degree branch and rest bend coming up through the slab.1 point

-

1 point

-

Once plaster starts to crumble and come away from the wall easily it’s time to remove it. ppl get them skimmed over but they sound hollow if bumped and often fall off anyway.1 point

-

I'm glad I am no longer a Mod. I'd have shut this thread down long ago. Whats the matter with some of you ... ? Expletives and childish insults all over the place.1 point

-

This smacks of doing something because "thats what people do" rather than considering 'why' am I doing this and 'what does it achieve'. The pipes come pre pressurised, the minute you cut it you will 'know' that the pipe hasn't been damaged during laying. After laying its child play to walk around the slab without deliberately standing on the pipe. During our you ain't doing anything about it. People will stand where they will. This is just a load of good old fashioned tosh! Yeah the maths works out, in practical terms it is over engineering at its finest. The pipe is solid, I could jump up and down all day long on a piece sat on mesh and the odds of me piercing it are low. If you want to do it then do it, it doesn't cost anything other than a few quid and some time. I would question what is the point. I did all of my slab except the concrete pour, was walking all over the pipe for weeks before concrete went in, didn't waste my time pressurising and no drama. That pipe is solid, you ain't gonna puncture it unless trying to. The thing to worry about is kinking it rather than puncturing it.1 point

-

I used coach screws for the side fixings, into the stud work. The sort you do up with a ratchet and socket. I had to unclip the cistern and lean it back to get to those. Mine fixed to what was a blocked up doorway so was quite deep, I made up extensions for the top. Resin anchored the studs in: Bottom into concrete: I lined the recess with sound absorption panels: I glued 9mm ply to the front of my frame as I had to bring the wall out by that much: Test fit the Aqua Panel to go over the front: A bit of Sikaflex over the ply:1 point

-

We have bought small straw bales over the last few years, and have never had problems sourcing them. Though for these, we never had a spec to try and meet. They can be wheat or barley for construction, it makes little difference. What is important is that they are as dry as possible, and are baled at the maximum compression possible. We have built up lots of farming contacts locally over the years, and a neighbour has offered for us to use his straw. This grows 100m from where we hope to site the house. It may be a bit of a faff for him in terms of the exact spec we are looking to achieve with the bales, but even if we paid double the market rate for the finished bales, it would add less than a grand to the build cost. We've not even applied for planning yet, and I'm well aware that the odds are stacked against us. But we'll fight as hard as we can to get it, and have a lot of support locally. Including all the local residents. We can but try.1 point

-

I've recently placed an order for various breather membranes, Intello, tapes, gaskets etc. I estimated around £2.2-2.3k's worth if purchased over here. Once it's arrived and I've paid our VAT, duty etc I'll try and pull a breakdown together and see how it all compares. Delivery time etc. Ben1 point

-

Question I'd ask yourself is whether the bi-folds are more likely to be open or shut. In all your renders above, they are open - which creates a lovely uninterrupted view. In reality they are likely to be partially open or closed so you have the vertical bar effect - nothing wrong with this if it's the aesthetic you're looking for. We have 4.5m sliders so can have a 2m ish opening if we want but rarely want to tbh. Obviously if the weather is inclement, they stay closed but on hot summer days we keep them closed to keep cool air (night time purge) in the house and also to keep noise out. Other issue with a wide open garden facing aperture is you can get a lot of stuff blown in (leaves, tree dander & pollen etc).1 point

-

After some digging the answer for those interested is that they are the same product.1 point

-

0 points

-

0 points