Leaderboard

Popular Content

Showing content with the highest reputation on 09/14/21 in all areas

-

3 points

-

Morning all, I have just started a self build and I'm excited and daunted at the same time. I currently clean windows for a living but in a previous life I was an electrical meter installations engineer working for United utilities. I also attended college during That time and completed an NVQ2 plumbing. I have for the last 2 years been an extremely keen hobby woodworker and have learnt much. We own a 2 bed semi detached home and have had the conservatory taken away and the ground is being taken up to make way for the footings for a 2 story side extension and a single story rear. We are aiming for 750 deep and 600 wide footings, the BC will be in tomorrow to see if that's adequate. We have our fingers crossed. We do live in a clay zone. We originally had 50k for the build which I think would have been tight. After some terrible news from a very expensive solicitor my wife's previous marriage resolution has left us with 30k. Needless to say we're devastated. We are hoping to be able to build the foundations, the walls and the roof with our budget. Or at least get as close as possible! Then we can chip away at the inside as we find more cash. I plan to do as much myself as possible. We have builders quotes but they're way out of budget and they also seem to be giving us a wide berth, ithink it's because we need things doing on a tight budget and therefore we would be probably more awkward than someone who can simply afford to get stuff done. We have an 8 year old boy who's had a bit of a tough time so far, he's been diagnosed with a genetic deletion. We also have a 15 year old daughter going into GCSE. Me and my wife have been sleeping in the front room for 8 years and it's been taking its toll on us. I work hard 6 days cleaning windows but I am preparing myself to undertake this build learning what I need to learn and working as hard as I possibly can. I know it's going to be hard, I anticipate mistakes and tears. I would very much appreciate somewhere to go for advice, I can work so much out myself but realise I'm no builder. I hope this introduction is well received. Many thanks Paul3 points

-

I've recently placed an order for various breather membranes, Intello, tapes, gaskets etc. I estimated around £2.2-2.3k's worth if purchased over here. Once it's arrived and I've paid our VAT, duty etc I'll try and pull a breakdown together and see how it all compares. Delivery time etc. Ben3 points

-

I've used loads of stainless in various widths and it is very malleable. If you wanted, ping me a pm with your address and I'll pop a few meters of offcuts, probably 75 or 100mm width, in the post for you to see how it works. If it's too wide you can actually cut it with scissors. I use Robinson wire cloth, better prices than the Amazon link. https://www.robinsonwirecloth.co.uk/online-shop/Soffit-insect-mesh-stainless-steel-30m-roll-p496120772 points

-

Talking ball park then to achieve similar tensile strength to a mild steel 8.8 you want to aim for A2-80 or A4-80 if using stainless. The 80 bring a higher strength that 70. A2 and A4 refers to the corrosion resistance properties. A4 basically the best, for marine and harsh chemical environments. Those fasteners I linked are 316 which is aka A4 so top flight corrosion resistance. They'll be good.2 points

-

During August we focussed on clearing the exterior of the site to allow for easier access for future work, such as laying drainage and installing electricity. This was the back passage when we started, at the end of the winter before all the weeds started growing. and this is after most of the roof is gone and the bank & retaining wall are cleared. In the south west yard where the electricity pylon is, this time in the middle of winter. This was what it looked like. during the clearance, lots of mess and now, getting ready for the electricity to come from the pylon. We need to do a trench to within 1m of the pole and still need to dig up the yard, but as that is thick concrete that's going to be quite a bit more effort with the breaker and digger. Aside from that we reduced the size of one of the openings in the barn to allow for the pantry, something I have now and can't do with out. After knocking out the half blocks, this also shows how the back bank looked before it was dug out, lots of bracken. and now reduced in size. What does Sept bring, well I don't know yet, block work to build up the internal walls I hope, but HID has a bad hip at the moment so moving and lifting blocks is a bit beyond him at the moment. So, we shall see. Have fun and 'see' you next month. Jill1 point

-

To most of you, losing a finger would be a bit of a pain, but if, like me, you've already lost two, then an additional lost digit might be seen as careless. Losing one finger almost always (according to my surgeon) means losing more than one tenth of your grip. That means I've already lost more than a fifth of my grip. An additional loss of an eighth of what's left would be really bad news. Angle grinders should be renamed finger removers . Its the variety in the way they remove fingers that gets me. Look at this. Exhibit1: Innocent little tool bag that I sling on my shoulder every morning as I whistle my way to work. Carole King helps.. '... You got to get up every morning with a smile on your face and show the world (except for plumbers) all the love in your heart then people gonna treat you better, you're gonna find - yes you will - that you're beautiful as you feel ...' Spot the little FingerMincer? Yes, its the mini angle grinder tucked into the corner of the tool bag. Bastard little thing. Reaching absent-mindedly in the bag for a WhatChaMaCall it, I nudge summat (no idea what) and that movement switches the grinder ON. I could not have removed my hand from the tool bag faster from a raging fire. So fast in fact that my arm hits the scaffolding and I now have a bruise that could have been inflicted by an angry Mike Tyson. Wanna a photo? Naaah, too much ugly detail Now the drill is: job done, battery out, pop the grinder in the bag. Brilliant grinder. Just the right size for someone with only four digits on each hand. Vorsprung Durch Fingerentfernung. (finger amputation)1 point

-

Standard cordless drill with two 5ah batteries and charger for £150... Considering that the batteries are £100 each, great value. https://www.screwfix.com/p/makita-dhp453ste-18v-5-0ah-li-ion-lxt-cordless-combi-drill/487kg#1 point

-

1 point

-

I was cheap and got plastic. It's terrible. Fragile, staples rip through it, rolls back up, and doesn't stuck too well to glue. Pay extra and get steel.1 point

-

1 point

-

You can def have both UFH and rads quite easily. I think UFH works well on the ground floor. In a new house the upper floors tend to need less heat, and if you have Velux or large glazing it may have a fair amount of solar gain so maybe just rads up there as they are simple to control. When selling, I have found there is no premium for UFH and some buyers can be a bit wary.1 point

-

You are not supposed to jack the door up with an air bag. Loosen the screws shown then turn (3) to raise / lower the door. Remember to loosen the screws on ALL the hinges and adjust (3) on all the hinges the same amount.1 point

-

1 point

-

1 point

-

Base 8? Yes @markc. Ya wanna see the grandchildren's reactions. There's much fun to be had moving from noticing that 2 (yes 2 missing grandma!), to disbelief, on to verification, confident comparison ( which is where they are now). Octal numbers next, I think: he's already enjoying programing his FloorBot. It's an ill wind that blows nobody any good innit?1 point

-

Fyi these are all galvanised fixings a few years old. The one on the left stamped 4.6 a lower tensile grade that the 8.8 on the right. Treat any unstamped bolt as the lowest grade unless proven otherwise. You can see some have a little rust on them. Periodic spannering may damage the galv coating on the head. Similarly you can see rust where a couple passed through other steel plates and moisture would have lodged. These are bright zinc plated bolts, much shinier, not as good as galv: You can also get a "yellow zinc" finish. Slightly better than bright zinc plated...but still w@nk for this! ?1 point

-

Haha, reminds me of a job a good few years ago, stainless steel conservatory for lord and lady Sainsbury … bloody nightmare job, part of snagging was that it made a big noise and shook when you slammed the sliding door open! .. we put a couple of rubber blocks in so the door bounced back …still shook the frame (approx 4 tons of it).1 point

-

Windows getting fitted this week then, many thanks for the assurances1 point

-

I think they're w@nk. For the few quid it'll cost I'd go stainless. https://www.orbitalfasteners.co.uk/products/m12x7075-sleeve-anchor-stst Then what do I know having worked on all forms of holding down units for man riding equipment, staircases and ladders etc for 40 years? ?1 point

-

We made the mistake of concentrating on insulating for winter rather than summer. Having a SSE facing rear has contributed to high levels of solar gain in the summer months. Our large hall and landing window is non-opening and can easily raise the inside temperature to 32deg. We have now finished installing an electric pergola for the kitchen and electric solar blind for the hall. These both operate from the Somfi app and coupled with the Velux have made things much more controllable.1 point

-

And I thought I was accident prone, it’s usually the stupid unforeseen things that get you.1 point

-

I would say they are BZP (zinc plated) decent drill, good clean hole and they will be fine1 point

-

Wow, that information is so useful. It looks as though it's another case of specifying suitability for the winter months, with no thought given for the extreme heat in the summer months. WE used an architectural technician last time and we followed his specification - however, the "retired" RIBA architect we are currently using has not offered any advice either. It may be a case of "you get what you pay for". I'm going to research the information you have given - many thanks for going to all that trouble - it's not something I would have considered and as can be seen from my post, I have been concentrating on the windows and shading.1 point

-

With the top lip I was getting at there don't appear to be any pre drilled holes for fixing to the lip. If you drill anything powder coated you'll break the skin and water will get underneath. I've seen it so many times, PPC just lifting in sheets and rusty steel underneath. If you do have to drill extra holes @pocster then you need to clean the steel where you've drilled and touch up the coating. They may have given you a touch up pot? Tbh I'd pack round the hole with grease and just wipe off when nutted up. For all other fixings I'd be smearing the threads with aluminium based anti seize paste and dropping the torque settings a tad.1 point

-

1 point

-

If you have the spreadsheet you can make "cooling load" appear by enabling "mechanical cooling" (N29). May not be suitable, but if i) you are building to PH standard ii) have PHPP with cooling load iii) having a heat pump, then worth considering.1 point

-

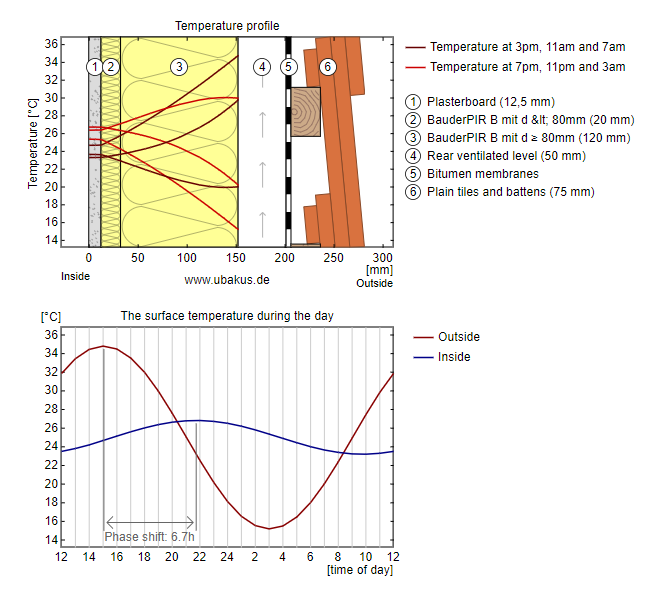

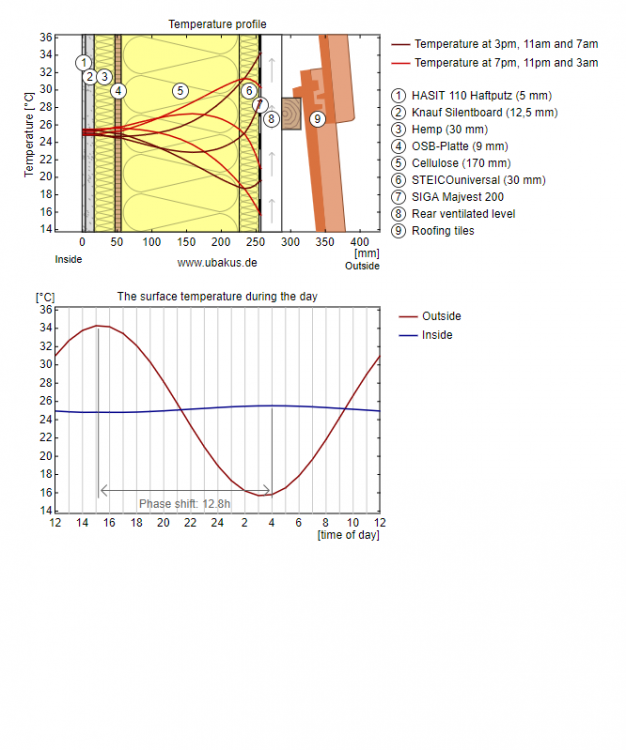

I guess your first buildup was something like this. I calculated a U value of 0.188 and a phase shift (decrement delay) of 6.7hrs. This isn't a great number and may have added to your overheating. A better option for heat protection. Similar U value but a phase shift of 12.8hrs. Notice the much less extreme swing for internal surface temperature in the summer. This makes overheating easier to control. On a cold winters day both roofs will perform the same against the cold. The website I used was. It's worth having a play. https://www.ubakus.com/en/r-value-calculator/? It includes this importance sentence in the blurb there too. "For a proper summer heat protection, materials with a high heat storage capacity should be used, ideally in combination with an outer insulation. In addition, the direct sun exposure through windows must be reduced to an acceptable level by shading means, e.g. outer blinds, roller shutters or sun sails"1 point

-

The water company will replace the lead connection for free - as long as all of the lead on your side is replaced first.1 point

-

I almost never give quotes. If I had to quote a fixed price for every job, I would have to take account of every difficulty that I might encounter and factor in the job taking that long, and the quote would be higher and I probably would not get the job. Usually I estimate jobs and most times things go well and the final bill is lower or no higher than the estimate.1 point

-

Thermal conduction is to do with temperature differences. Convection is to do with physically moving, in this case, air. Now a ground floor sitting on the foundation, and then the semi infinite heat sink of the earth, will conduct energy from the UFH to the ground, so that needs lots of insulation. Between floors is a different issue in reality. Convection dominates. Warm air rises and then gets trapped by the ceiling. This reduces the ∆T between the air temperature and the UFH system temperature. Between joists is also, generally, an air pocket, so has fairly decent thermal properties. What is important is reducing unwanted, or uncontrolled, air movement between the house and the exterior. This will, apart from being drafty, cause disproportionate energy losses. So while the place is stripped bare, make sure that area is airtight, it is easy and cheap to do when nothing, apart from the joists, is in the way. Consideration must be taken into account for condensation risks, but that is a different issue.1 point

-

Exactly the same for us : they / we (8 of us) all pitched in to disassemble the delivery trucks curtain sider load bed to get the window ( a 4m slider) out. The Polish driver was going to do it (disassemble the curtain-sider) on his own. As it was, he'd already started taking it to bits at 6.30 am. " I wan get beck hom tonight " " Where's that?" " Warshva" " Wot, Warsaw? You driving straight back?" "Iz no proplem" Fookin great big grin..... followed by "Yeah: Tacho fooked , izzz goood " Where there's a Pole, there's a way.0 points

-

According to @pocster, everyone in Cornwall starts with 12 fingers and toes, it is only the webbing that masks the extra ones.0 points

-

Direct from the roof. The flat roof is snug up against the bottom row of tiles. When it's proper heavy rain it's like the Orinoco up there. Sorry, couldn't resist0 points

-

0 points

-

If you loose a couple of fingers do you start counting in base 8? ?0 points

-

0 points

-

0 points

-

Yep, stainless steel everything or over time they'll all rust and blow the concrete aside from leaching rust down the staircase. He has been warned.0 points