Leaderboard

Popular Content

Showing content with the highest reputation on 12/31/19 in all areas

-

I run a plastering and tiling - framing business I brought a gang of Brickies in at the beginning and the rest my wife and myself have done and come in at 830m2 due to the small amount we have paid on labour Other than my son spending 4 days on the 350 m2 of rendering I’ve had no help from our business It would have sort of defeated the point Plastering is something I would advise all to stay away from A short courses are ok if you are going up an old cottage You dont want to be looking at a terrible finish Aims isn’t ideal for houses but isn’t easy to get right Tiling can look really good if you take your time We did most of the wiring and plumbing but had an Eletrician terminate and test same with plumbing We hadn’t done slating before but found it easy to do 300 plus m2 I pay loaders £1.50 a board to load in Myself and my wife loaded six packs So when you get your plastering quote that’s what you can nock off Even things like attaching a membrane to the high load dpc Then laying the king-span My wife did all that 155m2 £3.50 You can save a small fortune All while working full time people have said why don’t you get a couple of guys that work for to do some of the work They still would cost me a couple of hundred per day Soon adds up We are in the process of rendering 3 self builds The three couples have no building experience But are lugging bags of render up Doing all the masking for us and frost sheeting at night They are saving themselves two wages each day that we are there2 points

-

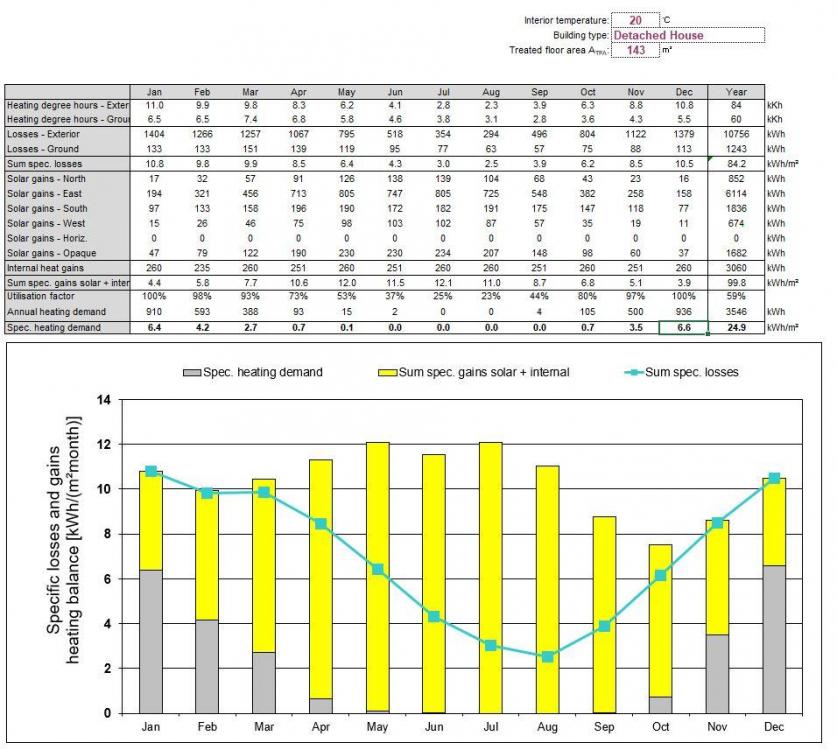

Hi all I'm struggling to match the PHPP data in the screen shot below with the sizing requirements for an ASHP. If I have a peak heating load of 6.6kWh/m2 for December for a floor area of 142m2 = 937.2kWh, how do I marry that with working out the ASHP requirements (with an appropriate overheard added just in case)? I am quite sure I'm missing something blindingly obvious here but any education (as ever!) gratefully received ?1 point

-

Yep ! But it works . Stuff like your link is certainly worth a punt . Not sure I want your Cctv watching me in the bathroom ... that would shock even the strongest of hearts .1 point

-

Here’s an idea there’s s house in Cirencester that has loads of odd jobs that need doing, you could come and practice on it. No college fees. Free tea and biscuits staff a bit grumpy1 point

-

That is the main reason, apart from shading, I would choose them. I would think that not many installers that fitted them are still around, and how long will the service be supported by the manufacturer.1 point

-

A few bottles usually helps negotiations, also if mention that the facing brickwork will be much better finish than if built inside out it will soon make sense. Offer to take a walk round each day and keep their side tidy, perhaps even have in mind to sheet the scaffold on the side of their house if necessary to prevent dust and mortar getting on their property.1 point

-

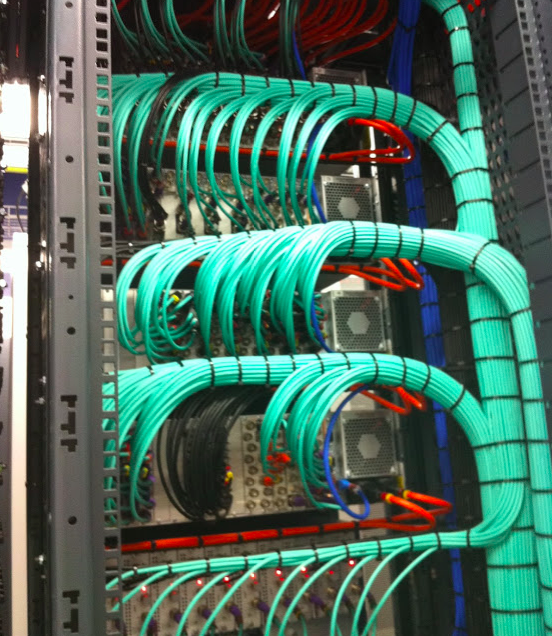

Posted this before I think but it's worth having a flick through the CEDIA guidelines on home wiring - http://www.cedia.org/files/file/smart-home-recommended-wiring-guidelines-eng-press.pdf - Even if it just gives you a little inspiration its worth a quick read. Re: cabling types - for 99% of residential installs I expect cat5e is really more than enough but if I was doing it today i'd look towards cat6a, 10Gbit/s* over 100m should do most people!! (Incidentally to achieve the full 'spec' of cat6a (and above) it has to be terminated properly and matched with the same category patch leads etc. It's not just a case of crimping on a RJ45 connector this time) Heres some cable p*rn from installs I've worked on to inspire -1 point

-

My mother does this. Gallons of hot water straight down the drain. I don’t have a washing up bowl. The only time I would use one would be if camping. I am a dishwasher fan. For everything. I have a pair of stainless steel under mounted sinks in the kitchen. Seem to be ok. I have a ceramic Belfast type sink in the utility. That’s ok too. Both are easy enough to keep clean. I have had resin and composite sinks in the past. Both nightmares.1 point

-

When I looked into this I couldn’t make the maths stack up. If you take a standard ASHP with a 50c output and you want a 300 litre tank at 70c, then you’ll use a little over 1000kWh in a year. At direct electric prices on E7, that is about £70/yr. At a CoP of 2 - which is reasonably optimistic at 70c, this reduces to £35. A HT ASHP with a lifetime of 20 years would need to cost less than £700 more than a standard ASHP to make financial sense over using a standard 3Kw immersion to do the top up. Most I’ve seen are north of £12-1500 more so it’s a no brainer.1 point

-

Had to google that, PHE = plate heat exchanger, which can be used to transfer heat into the hot water tank (especially with a low temperature heat pump), versus using a traditional coiled pipe running though the bottom of the tank (with a high temperature heat pump)? Getting this back to the original topic, ASHP sizing, I'm looking at replacing our mains gas combi boiler which provides domestic hot water (DHW) and under floor heating (UFH) to our three bedroom two story approx 125m2 mid terrance house, built about 2005 with reasonable insulation (EPC rating C). We have 5kW of solar PV and a time of use electricity tariff. I'm still chasing local installers to get multiple quotes, but the first one back suggests (before doing an on site visit) a 12kW monoblock HT heat pump (space will be tight so the monoblock makes sense), no thermal store for the UFH, and a 250 litre slimline cylinder or SunAmp for the hot water. I'm wondering if a 12kW ASHP is too about right or too big, and what the trade offs are. Too small a heat pump: Have to leave it running more hours a day (problematic with time of use electricity tariffs), or in extreme cases would need supplementary heating. Too large a heat pump: Wasted capital cost. Would only be on in bursts, making it less efficient (short cycling issues)? Would this strengthen the case for a thermal store for the heating side (again higher capital costs)? In terms of data, I have about a year's worth of hourly gas usage via a Loop Energy Saver (since replaced with a smart meter). Looking at peak daily usage, and peak hourly usage, and counting on the morning and evening hot water demand spikes to be spread out with the storage, I think a 12kW heatpump should be more than up to the demands - perhaps even overkill.1 point

-

Nope. On or off, isolators NOT attenuators Flow restriction always at the outlet.1 point

-

1 point

-

Option 3) put down electric mats under the tiles. We have wet UFH on ground floor (suspended timber, alu spreader plates) but went with electric mats on a timer in the bathrooms. Works fine and was relatively low cost.1 point

-

We have micro inverters installed below each solar panel, a long DC cable from there to our plant room where the main inverter is. AC run from inverter to electric panel is very short. Works fine. I had our solar installer try to convince me we need to mount the inverter next to the PV panels as the DC cable had to be as short as possible to reduce losses. His suggestion was to mount in the warm roof or bedroom (we have no loft space). I found a solar calculator that assesses losses including cable diameter and length, it showed the opposite of what the installer claimed. He said no more and just installed it as I wanted after that. Yes the inverter is warm, I see it as a positive in the winter, though the plant room does get a few degrees warmer in the summer due to all the plant and DHW cylinder.1 point

-

Hello. I'm planning on using a company to provide my entire system, for the purpose of my confidence that it will all fit together well and work efficiently without causing me disappointment. I don't feel confident to go it alone as such. Obviously a lot of ££ at stake here, and I'm not one for blindly believing the sales blurb, so I'm hoping clever people on here can cast an eye over my quote and let me know if anything stands out as seeming problematic. My build is a barn conversion, single storey, long and narrow. Nominally 3 bedroom, but currently just me and partner (no kids on horizon). This quote is from NuHeat. ASHP = Your system price - What's included? Qty Item Description 1 NIBE F2040-8 (typically capable of heating a property with 7kW heat loss at design operating conditions, in compliance with MCS standards) air source heat pump kit, charge pump, and associated fittings. 1 Docking assembly for air source heat pump with Nu-Heat hot water cylinder, buffer tank and supplementary electric heating 1 EnergyPro® 300 litre unvented stainless steel HP cylinder for use with NIBE ASHP, including fittings and G3 kit. (Please note that the cylinder warranty does not cover private water supplies, e.g. boreholes. Please speak to your Account Manager if this required.) 1 100 litre (stackable type C) buffer tank assembly with four tappings and one immersion tapping, with immersion heater 1 Electric metering kit for one single phase heat pump and two additional immersion heaters 1 Includes delivery of heat pump and tank by carrier to UK mainland only Support Option SUPPAK N1(R)HP Heat pump system design and supply (which must be invoiced to the Homeowner), with a comprehensive Nu-heat MCS Customer Handover Pack, free Technical Support and one on-site commissioning visit by a Nu-Heat Engineer. The visit will include the system handover, MCS administration and certification, and warranty activation. Following successful commissioning, Nu-Heat will provide MCS documentation to support eligible customers in obtaining relevant Government funding through DECC. The heat pump installation shall be managed by a formal Subcontract Agreement with the customer's own plumber and electrician for their respective works. Installers of the system shall sign and return Nu-Heat's Sub-Contract Agreement before any installation work commences, and adhere to the MCS and RECC standards. MCS Certification will be produced by Nu-Heat. Item Description Domestic hot water loop for use with Nu-Heat's EnergyPro HP cylinders and NIBE F2040 heat pump. 15m Pre-insulated, flexible, flow and return pipe (DN25) for installation underground with heat pump connectors UFH = Your system price - What's included? Qty Item Description 1 Wilo Para RS25/6 pump (EuP compliant) with valves 2 Isolator pack for Optiflo manifolds 1 System expansion vessel 1 8-port Optiflo manifold module with zone valves, flow meters, isolating valves, temperature gauges, pressure gauge and wiring centre - view details 1 7-port Optiflo manifold module with zone valves, flow meters, isolating valves, temperature gauges, pressure gauge and wiring centre - view details 8 Dial thermostat - view details 1 Dial thermostat and remote sensor for wet rooms 1068 Metres of 14mm Fastflo® heating tube with oxygen diffusion barrier - view details 30 14x2 Eurofitting nut, tail & olive and pipe bend support 135 m² SM14 floor components - 14mm Fastflo® tube tie, screed expansion edge strip and pipe staples 1 Commissioning accessories pack 1 Design specification, manuals and documentation - view details 1 Delivery to UK mainland only following receipt of full payment and acceptance of CAD drawings. Your input / feedback would be welcome. Thank you.1 point

-

For the sake of putting it in and the minimal cost compared to trying to retrofit something, I would include UFH in both floors, even if you don''t use it initially. You can at a later date set up the slab cooling for both floors. I have piped in both floors >400m2, the house is passive standard (un-certified) and you cant tell if the heating is on or not as it is so gentle (UFH flow temp of 26oC) however last summer when it was extremely hot (house just finished) the slab cooling did come on for a few days, usually in late afternoon and of you touched the floor near the manifolds you could just about tell it was cooling, but it had the desired effect in keeping the house livable.1 point

-

I'd also suggest that lagging cold pipes inside the heated envelope is wise. I didn't bother to lag the cold water pipes in our services room (which is inside the house) and had problems with condensation dripping from them in the summer. They are all now insulated with armaflex. Armaflex isn't cheap, but I've found that it's both easier to use and more effective than the rigid plastic foam stuff.1 point

-

1 point

-

Somehow I have told the boss we'll be in for Christmas....? Most likely 2019 though, but I did not mention that.... But ideally would like to have the downstairs livable with at least 1 bathroom, kitchen and UFH in operation, which means I need to get my skates on. For my retro-extension I will have 2 bathrooms (1 upstairs, above bedroom 3), utility with WC and Kitchen. I have 2x 12kw Sunamp units that will provide DHW and also my UFH (real life testing will prove whether I need to go for an ASHP/off-grid PV panels next year, but that will be another topic...). Looking to getting my plumbing sorted and have decided to go for plastic over copper using a manifold setup for most rooms. Pipe runs are fairly short, with the longest being to the kitchen (18m) - can't avoid that. Water flow (42L/minute) and pressure (6bar iirc) are all good. Sunamp units will be located in the cloakroom ("CLKS") so a short distance to the manifolds next door (1.5m ish) in the utility room UFH manifold is located next to Sunamp units The upstairs bathroom will be located above bedroom 3 with a piperun of approx 10m max to the furthest outlet My plan was to use: 15mm pipe for all runs/ to all outlets. I believe CJARD on ebuild had that approach as did @JSHarris so I can't be too far off. Instant hot water tap in kitchen so hot water pipe would be pretty much redundant (unless i use it for mega washing up session) so I don't think there is a need for HRC. Only potential 'hot water wait' outlet will be upstairs for shower/bath but that will only be 9m run. I was going to use 10mm for some outlets such as toilets and basins ("to reduce water velocity and stop the WC from over monopolising water pressure" as per @Nickfromwales) but will obviously need reducers which brings extra cost and another potential leaky join - though hep20 is pretty fool proof I read!), so if I can stick to 15mm all round, then I can just get two rolls of 100m. So hopefully can do without 10mm?plumbing plan.pdf Any flaws in my thinking? I'll have more questions with the finer details no doubt (PRVs, NRVs etc) later on! Attached is a rough plan. Pipe runs are indicative only at this stage but show their relative locations. NB: Kitchen run has to go the route as indicated due to cathedral ceilings. Cold water pipe runs not shown but will be roughly in same routes as hot. Upstairs not shown seperately but located above bedroom 3. plumbing plan.pdf1 point

-

You need to have long flexible pipes between the ASHP and the house wall, if it's going to be located fairly close to the house, but those flexible pipes need to bend around in a loop so they don't transmit vibration into the house structure (I found this out the hard way and had to replace mine). This means you have some leeway when it comes to positioning pipes, and you could always run short length of insulated rigid pipe along the outside of the wall to get the terminations for the long flexible pipes in the right place. There's a bit in our blog about the need for long flexible pipes for the ASHP, part way down this entry: http://www.mayfly.eu/2014/07/part-thirty-one-its-slow-going-on-your-own/1 point

-

Well we've spent the weekend fitting the ASHP pipe according to @JSHarrisrecommendation (thanks Jeremy, great help as always). Bought the pre insulated pipe that @Barney12 recommended. Stripped off the outer corrugated protection for the part that enters the access pipe. Luckily there was a double layer of insulation and we only needed to remove the first layer. Then connected the 1.5m flexis. Wrapped them in insulation and then wrapped the stripped back section and the insulated flexis in polythene and duck tape. The pipe fed in pretty easily once we got some rope tied around the corrugated section about two meters back and used it to give us a grip on the pipe and enable us to push it in. We can now just get the paving guys to bury the pre insulated pipe to the approximate position for the ASHP.1 point

-

As above, I used 50mm polypropylene drain pipe. I then ran 28mm Hep2O pipe for the actual ASHP connections. If you use plastic, you must be sure to use the type with an oxygen-proof barrier. This approach was relatively easy for us, because our runs were completely straight (except where they come out of the slab in the plant room), and ran within the EPS under our slab, so didn't need separate insulating. Where is yours running? Underground?1 point

-

I suspect that we're going to do this as two passes, the first is some heavy and at times geekish discussions. Hopefully the outcome is something that one of us can summarise There's no point in trying to go through the theory and practicalities of the flow calcs, because a guy called John Heartfield has done a good job of this on his articles: Part 1 -- The Theory, and Part 2 -- Real Systems. However, it would be good to have a structured discussion on the pros and cons / ins and outs of pipework sizing and radial vs loop or branching designs. I've been doing the calculations on my system and there is little clear benefit in going to 28mm, as 22mm will carry the heaviest flow rates and as manifold, supply and all central pipework are within a 2.4 × 0.65 × 1.4 m cuboid service area, all of my copper runs are really short. In our system the 2 × SunAmp PVs are the main limiting constraint as these will bottle out at @14 ltrs / sec at 3 bar so 2 in parallel mixing 2:1 with a cool stream will be unlikely to deliver more than 35 ltr/min in practice, but that's enough to have a shower and fill the bath at the same time. Two things that Hearfield doesn't discuss are: Dead carrying capacity. This only applies to DHW connected appliances, but it an efficiency issue. Small is good. Noise. Flow against a pressure gradient is doing work. This is shed as temperature rise or as noise, and goes up on a square law. And if you get the design wrong then pipe (and appliance) noise can be a real pain. An example of the latter is the header tank cold fill in my current house. This runs up a stud wall between our ensuite and the family bathroom in our current house. Our washing machine is an indirect feed cold-fill job and we usually run a washing cycle overnight kicking off at ~4am to take advantage of E7 plus be ready for the morning and every night from 4:00, the ballcock fill on the indirect tank sets up a pssshhhhttt on the fill riser. So laminar flow in pipes is also good = don't use devices which create a lot of noise or tight elbows etc. which cause a lot of energetic turbulent flow at high pipe velocities. So we have got our service area inthe new house on the ground floor, well away from bedrooms, and the pipe runs are short, etc. The room has acoustic insulation on all internal sides. Any other comments / views / advice that we should consider / reflect in an overview? PS. John Harvey does go into a lot of detail on noise issues, manly in Part 1 so I did him an injustice.1 point

-

I was working today on a new build that was having the "professionally" designed and installed heating system commissioned,so I took some time to have a look and talk to the guys. It was a Mitsubishi ASHP coupled to a "pre plumbed" Mitsubishi cylinder and controls. The nuggets of information I gleaned, in no particular order were: The tank was an unvented cylinder for hot water only. Heated to 45 degrees by the heat pump. Once every 3 weeks, on a day of the week of your choosing, it automatically uses the immersion heater to raise the tank to 60 degrees for an hour as an anti legionella measure. Because of the low grade heat input, they said it would require too large a heat input coil, so it used a plate heat exchanger to heat the tank. The UFH runs directly from the heat pump. No buffer tank. It either runs DHW or heating, never both together. When in heating mode, the heat pump runs at a low temperature which you can set. They say this obviates the need for UFH mainifolds with temperature control, instead you can use a dumb manifold (cheaper) and just dial up the flow temperature you want for the UFH in the heat pump controller. The outside unit ran very quietly, and I didn't see it icing up or needing to defrost, it was about 3 degrees today. I was particularly interested in the no buffer tank, and direct operation of the UFH with a dumb manifold. Certainly something to think about.1 point

-

@le-cerveau, that's precisely correct: you may as well control from a single aggregate temperature. However, you also need to trim the manifold valves so that the flow-rate through each loop is roughly proportional to the area covered by that loop. This is a one-off calibration / setting issue. One simple way to achieve this is to balance the loop lengths within 10% say and use the same loop density on all floors, then you can just fully open all manifold valves. The other way if you are using separate temperatures is to use the temperature curves on the 3 loops to determine if one is out of balance.1 point

-

There was quite a discussion on ebuild about how running a slab at +1c of the desired air temperature would allow a near perfect control scenario however the bigger question is how much warmer does the water need to be to keep X CuM of concrete at YdegC when the losses from the room are whatever. The logic would be that if you ran the water at 25c then the floor and consequently the room can never be heated to above that by the floor (notwithstanding solar gain etc) The issue being that most UFH manifold mixers don't seem to be able to run this low so your only choice would be to connect the ASHP direct to the floor but that then either loses the ability for you to constantly circulate the floor circuits to even out hot/cold spots and may cause short cycling of the ASHP as the heat load of the room varies and triggers the heat cycle unless you directly link the manifold to the ASHP and risk the potential cooling of the slab as the ASHP initially starts the water heating cycle. One for more thought - and potentially a separate thread ..?1 point

-

Ok - the only way to damage a pipe in this way is to cause the damage during installation - PEX is good to 10 bar, UFH is 1-2 at most and to get PEX to expand more than 0.5mm needs around 4 bar. Pumps are circulation pumps not pressure pumps so there is no way for a pulse to be created unless there is a fast actuating manifold valve and even then, that would be a sub second pulse only when it closes. Whilst I respect he's been doing it a while, I would hazard a guess that the recalls are due to pipe damage on install that manifests as a leak later. If you pressurise PEX to 3 bar during a pour, it will need a significant force to deform it hence why they always suggest to pressurise as you're effectively walking on a very rigid tube. Without water in it, you stand the risk of deforming something that is inherently unstable due to its shape i.e. a thin tube. I don't know of a single supplier that would warrant their product if it hadn't been pressurised at pour - who's providing the pipe ..?1 point

-

I have done a bit more digging into 7, 9 & 12kW ASHP performance (I am looking at the Panasonic range). WHSDC07H3E5 Water Out (oC) 35 40 Outdoor Air (oC) Capicity (W) Input Power (W) CoP Capicity (W) Input Power (W) CoP -15 4600 1980 2.32 4600 2190 2.10 -7 5150 1920 2.68 5076 2140 2.37 2 6550 1960 3.34 6575 2290 2.87 7 7000 1570 4.46 7000 1835 3.81 25 7000 970 7.22 6740 1140 5.91 WHSDC09H3E5 Water Out (oC) 35 40 Outdoor Air (oC) Capicity (W) Input Power (W) CoP Capicity (W) Input Power (W) CoP -15 5900 2660 2.22 5650 2820 2.00 -7 5900 2340 2.52 5850 2610 2.24 2 6700 2140 3.13 6650 2380 2.79 7 9000 2180 4.13 9000 2485 3.62 25 9000 1260 7.14 8660 1475 5.87 WHSDC12F6E5 Water Out (oC) 35 40 Outdoor Air (oC) Capicity (W) Input Power (W) CoP Capicity (W) Input Power (W) CoP -15 8900 3620 2.46 8500 3790 2.24 -7 10000 3660 2.73 9600 3950 2.43 2 11400 3310 3.44 11000 3530 3.12 7 12000 2530 4.74 12000 2960 4.05 25 12000 1660 7.23 11800 1940 6.08 These figures are taken from the service manual + the CoP calculation. Assuming I take the water at 35oC with my house load (max) of 4401W this gives me a comparison of: Option % required CoP 7kW @ -7 85.46% 2.68 9kW @ -7 74.59% 2.52 12kW @ -7 44.01% 2.73 7kW @ 2 67.19% 3.34 9kW @ 2 65.69% 3.13 12kW @ 2 38.61% 3.44 7kW @ 7 62.87% 4.46 9kW @ 7 48.90% 4.13 12kW @ 7 36.68% 4.74 This would suggest I discount the 9kW model due to poor performance at 2oC and lower CoP, so then it is down to 7kW or 12kW. The 7kW machine is running at 63-85% capacity from 7oC to -7oC, whilst the 12kW machine is at 36-44% capacity with a better CoP. So in theory the12kW machine can modulate down (30%) quite happily though at 7oC the load will start dropping. All this is ignoring less that ideal build (higher heat load) and DHW preheat. So is a 7kW machine working reasonably hard a better bet than the 12kW machine that is idling but with a greater DHW reserve? The pain continues.1 point

-

We have a 5kW Panasonic Aquarea for our close-to-Passive-House-standard 289m2 house. As I've mentioned elsewhere, we have quite a bit of shading and nothing like Jeremy's warm microclimate, so the ASHP spent a lot of winter ticking over gently keeping the insulated slab at around 21-22 degrees. As for DHW, over winter we have the ASHP heat the tank to 55 degrees between 4 and 6 o'clock each morning. Looking at the temperature plots, that seemed to be about the maximum time it took to get the whole 250L tank up to temperature (and it did get to pretty-well bang on 55 degrees, despite the ASHP being located 9 or 10m away from the tank). The top 30% of the tank is then heated to 85 degrees by the upper immersion heater that switches on at 6am. I don't believe we've ever run out of water with our family of four. Also, we have 8.5kW of PV. It occurred to me the other day that the ASHP probably hasn't had cause to turn on for several months due to the amount of energy being pumped into the tank every day. I wonder whether not being used in this way could negatively impact longevity?1 point

-

I was told that an inverter ASHP can only modulate down to 30% of capacity (unlike a gas boiler which can go down much lower). So when the heat load is lower (e.g. mild spring day) it might end up cycling more often if lowest modulation is still too much heat input. And to amplify this effect, ASHP COP will be higher so your 30% is worth more than the 30% on a really cold day. In my case we had space heating demand of 3kW but went for a 7-8kW ASHP (the calculator said oversized by 263%) so as to improve DHW recovery times - household of 6 did not want to risk running out and having to wait forever to heat.1 point

-

You'll need several loops, but you don't really zone this sort of system (in the sense of setting different operating times and flow temperatures for each zone). That actually makes things a lot easier. I personally just turned the temp right down on the manifold mixing valve and left it to the the ASHP to supply 25 deg C water to the slab as required (I put in a small heating curve so that was a bit higher when it was very cold, but not sure if that really made much difference). My issues were with upstairs heating, specifically in bathrooms. I thought we could do without, but we found it just a little too chilly getting out of the shower over winter. The tiles, in particular, are surprisingly chilly underfoot, as much because they are conductive as due to their actual temperature.1 point

-

Hey, we are an open-minded forum, please do not judge people's proclivities for cablep*rn.0 points

-

That's the weirdest bit of perving I have ever heard of. Bet they kind of liked it though.0 points

-

0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)