Leaderboard

Popular Content

Showing content with the highest reputation on 10/17/19 in all areas

-

No longer a muddy building site after nearly 3 1/2 years, Hooray. Landscaping just finished during the wettest 2 weeks of the year. Never mind, it is done. Used the plastic honeycomb gravel crates with the weed membrane on the back. Lawn & wild flower meadow to sow, fencing & planting to be done, so still a long way to go, but at least some progress.10 points

-

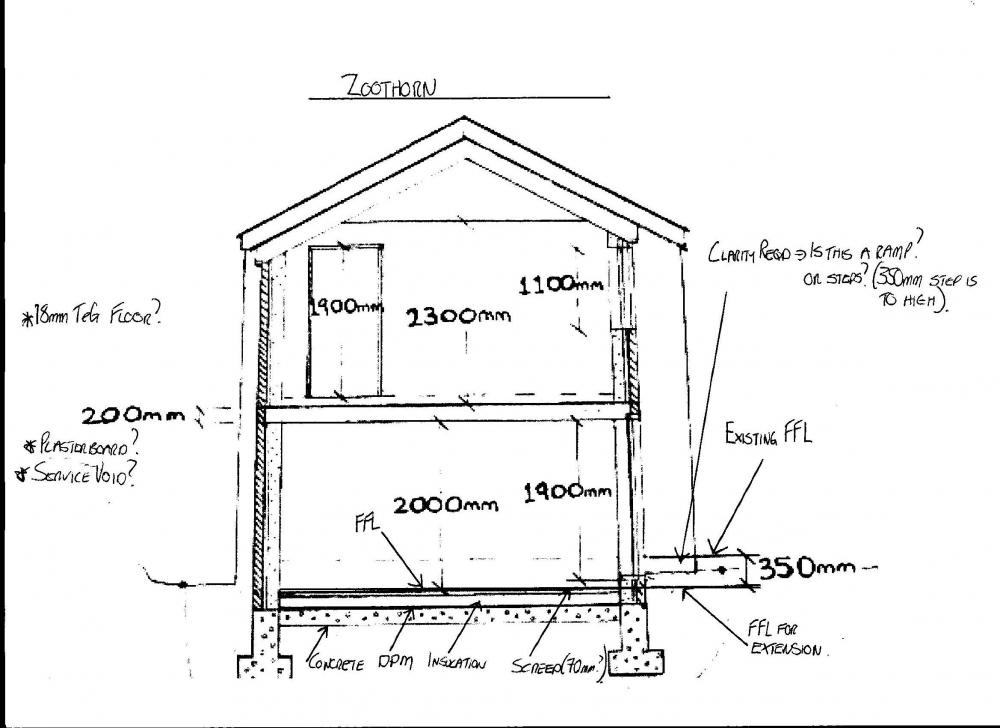

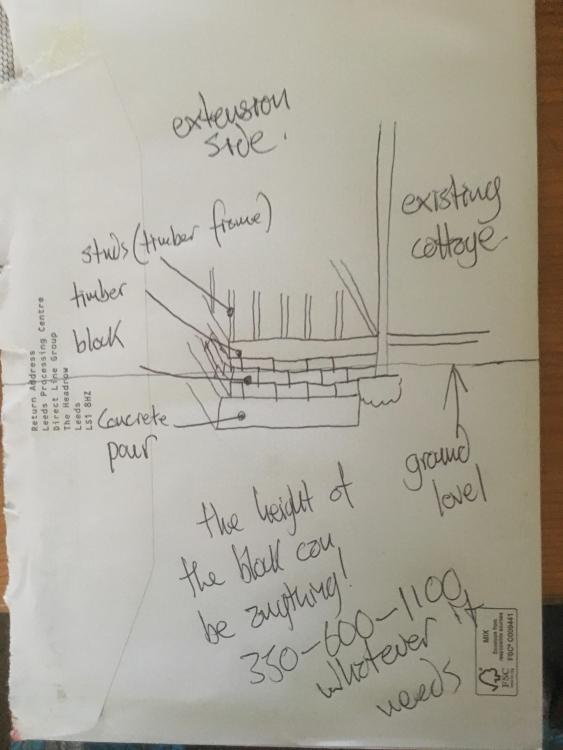

@zoothorn you are going in circles. First thing's first, you need to take a deep breath and a step back. Next, you need to work out how to move forward. Please try to read the following as an attempt to help, not an attack. We all understand you are on a build notice, not a full plans. The problem is, in normal circumstances - regardless of how you choose to deal with the council - you would have a drawing showing e.g. whether the insulation is above the slab or below, how thick it is, how it and the screed meets the external walls, all the questions you are asking us on here. You may not care about the u-value, but you must understand the insulation has a thickness. And therefore it will affect the depth of dig and, depending on position, the height of the slab surface, since it needs to sit somewhere between the ground and your finished floor. It is quite possible that the insulation is going on the slab, that this and other construction elements are going to add up to about 350mm and that your builder is bang on track to deliver the floor height you wanted. If so, it is also possible that your builder is finding you hard to work with, that reassurance and detail he's attempted to provide doesn't appear to be going in, and that he's doing his best to deliver your project through a flurry of continual panic attack, second-guessing and secret measuring. It is also quite possible he has it wrong, and plans to belligerently insist you accommodate or pay to fix his mistake. If you had a set of drawings, it would take you seconds to look at them and establish which of these possibilities is the case. It would then be easy to either relax, or to put your foot down and insist the builder puts things right before payment. You chose not to pay a professional to produce those drawings. You chose not to spend the time to research the detail of building construction and draw them yourself. I understand why @Onoff's "fag packet" comment upset you, but I can also see that - against advice given here - you have spent a lot of time producing a beautifully presented drawing that does not actually communicate any more information than a rough sketch would have. Further, one in which things that are critical to you - like the height from existing house floor level - are not explicitly labelled but rely on implied knowledge (there are lots of things a dashed line could represent). The builder may well be happy with it, but that does not change the fact it is not clear enough to give you certainty or confidence over what's being built. When you complain on here that builders have huge power, and that there is "nobody in the client's corner" : that is not normally the case. You have chosen to have nobody in your corner by choosing to run your project based on trust, informal communication, and the sparsest of details about what you want. Your builder didn't prevent you using an architect, and nor did we. It is important to take this on board, because if you do not get to grips with your role in the process you will continue to have the same problems whether you continue with this builder or (as some have advised) sack and replace him. So, moving forward you essentially have two options: * Convince yourself that your plan is perfect, that you have crossed every t, that only a "fkin idiot" could misunderstand it, and that you have the best builder in the western world. If so, trust them to do their job, stop asking questions, go on holiday, come back when they're done and enjoy the extension. * Accept that you have created a situation with a lot of room for error in which ongoing conversation is going to be crucial. Approach your builder with this tone - come from a place of "I'm worried I didn't make the floor level clear enough, and it looks low to me : can you talk me through what's going on top of the concrete and mark on my wall where the floor level will end up?" If that's not as expected, discuss the options for resolving it. Stop asking us to guess what your builder may or may have done or be going to do and ask him.6 points

-

@zoothorn. Switch your computer off right now. I realise that I'm asking you something that's really difficult . Have a well-deserved long weekend off SWITCH OFF AND WALK AWAY NOW .. See you next week, eh?4 points

-

I have taken time to read the full thread. Forums are just that, so I don't see any reason not to - it's your choice whether to take anything from this or not. I think there are two simple steps to be taken. 1 - Mark the Finished Floor Level on the wall of the existing structure. That means quiet literally that - the level that you want the final floor to be. And communicate that clearly to the builder. Nothing else matters here - the FFL is the concern, therefore mark where it's to be and that supercedes the drawings. It's been stated the builder knows what he's doing - leave them to it. 2 - You should step back entirely from this build after addressing the above and leave them to get on with it - you've said they are the best out there - so leave them to it. I get a real sense you are causing more problems than you are solving. Having read this thread from start to finish, the sense I get is that you are not really getting to grip effectively with the technical design. I say that respectfully and gathered from your own words. It is full of contradictions and all sorts of anomalies that others have pointed out. That's a fairly blunt response but there is no sugar coating this - you're out of your depth, but you have a competent builder, so leave them to do it. Your drawings are not clear in the slightest (I say that knowing you think the opposite) and therefore you have no right whatsoever to complain about things not being how you thoughts they would be. That's a decision you took - you can't have your cake and eat it - you can't provide the most basic level of drawings and then think you have a right to complain when the actual build isn't how you envisaged it - you should have done full drawings. This thread is, as others have said, going in circles. It's no problem being out of your depth - many here will admit to that, and that's what we're here for - but most will accept advice, filter through the various views, and act directly one way or another. Reading through this thread, there's been much good advice that it appears you ignore and provide excuses as to why - mostly blaming the builder who one minute is great and next will tell you to f*** off and walk off the site. That's whats' lead me to make this comment. ANd that's probably why someone suggested it's a wind up. I say this with the best will in the world - lots of people have given great advice and for the most part, you won't act on it - if you won't sack this builder, then you must let them get on with it and stop interfering. There is no middle way as you are unable to work productively with this builder. All the best with the build.4 points

-

+2 - this problem is utterly trivial, it really is. It's a tiny area and will be super easy to rectify and not cost much. Waz down some insulation and concrete, job a good'un. Looking at the picture, it'll barely need a cube of concrete.3 points

-

mark the wall, thicker insulation and its a job fixed with half a days work. even if you say 'yep its my fault ime a donkey and will pay' it will cost you less than going to court and for the stress it will save be worth it. or mark it up and tell him he's wrong and has to fix it. Or mark it up and let him tell you he was going to use thicker insulation and all is OK. Do something, but certainly mark up the wall to prompt the discussion. Don't try to second guess what comes next3 points

-

After getting some good advise on the forum (DON T DO IT!!! LEAVE IT TO THE PROS!!!) I decide to ignore that and buy some 2nd hand equipment on ebay. How hard can it be http://tintabernacle.blogspot.com/2019/10/setting-out.html?m=1 It wasn't. Just time consuming. At the end it always is a question of wether it is cheaper doing it yourself or if it actually would have saved £££ getting a pro in. My case for doing it myself (as much as possible) is the massive knowledge gain. Even if it turns out to be the same price than having someone doing it for you (which most of the time isn't the case), I wouldn't want to miss what I learned so far.2 points

-

You have 30 minutes to answer the following question. Do not copy what @JSHarris, @Onoff or @ProDave or that other really nice Scottish boffin write. @TerryE writes with disappearing ink so its OK to look at his answer. Write your name at the top of your paper and on each page that you submit Your invigilator will collect your online answers and collate them below. Q1: Isolators isolate. Switches switch. Discuss. A good answer will make reference to the ways in which switches and isolators are similar, and the ways in which they perform different functions. An excellent answer will give good, clearly expressed examples of when an isolator should be fitted instead of a simple switch. A good answer will show how switches are sometimes Double Poled, and sometimes not, and the reasons for the differences. Top marks will be given for those answers referring to how switched fused spurs and fused isolators are used, especially those made by Scolmore. Oh bugger it, lets cut to the chase. The examiner doesn't know when he should fit an isolator, and when a mere a switched fused spur will be adequate. Ta! Ian2 points

-

Another vote for the Irwin Quick Grip clamps. Really useful if you were born with only two arms, as they can be used with one hand, leaving the other free to hold whatever it is you're clamping in place.2 points

-

2 points

-

Just thought I’d share this with those that are looking for cheap Quick way of soundproofing Pictured is the standard gypliner with push fit brackets These simply screw to the side of the joists in a 400 x 1200 grid pattern Then clip the gypliner stud in place You can create a void from 25 mil to 1502 points

-

Imagine going to school at 5 years old in the UK speaking German only. I learned to fight hard very quickly. Entrenched-Minded locals exist in every country I have visited and worked. As I moved and worked round Europe, at first I found it really difficult. But then realised that I needed to give - be open - be generous with that difference. Relax with that difference. Shrug, grin, share a joke, but don't allow people to take the piddle - beyond the local average. I mean it's really hard not to take the piss out of @JSHarris, even harder not to take it out of @Declan52 and others. Judging how far to take the piss out of them is a learned art. And maybe it's some of those really subtle cues when talking to real people that you might have missed now and again. You - like me- might interpret some stuff a little too literally. Take stuff a bit too seriously - need exactitude . Because it's comforting. I've said it before @jamiehamy's advice above seems to me to be a good starting point. It'll take courage, I know.2 points

-

The sooner you augment the drawing and provide a copy to the builder, the better. The basic nature of the drawing genuinely is causing more issues here than it creates - and will continue to do so. What's happened in the past is irrelevant - the drawing serves no-one. To get over the immediate hurdle, augment your drawing - and provide it to the builder - if nothing else he'll say 'yes, that's what we're doing'. If not, he needs to alter to get the desired FFL. I don't want to dwell on it - but you MUST have this conversation with him. It's not optional. Everyone, not least you will feel better once the air is cleared on this. Moving forward further, I stand by my comment - leave him to it, or get properly stuck in and be constructive in working with the builder. And if the latter but he won't accept it, then sack him. There are many other details you'll soon come up against, many are evident when I look at this drawing in more detail. I'm puzzled by the 2000 ceiling - but that's your choice - however the drop down 350mm will need to be a good metre before the extension ffl of you'll bebumping your head - hence comment on whether this is stepped or a ramp down (sorry if I've missed)2 points

-

This is so easy to sort out, you are adamant that you are correct and your builder is at fault go out side and mark on the wall finished floor height, not a dot or a mark on the render, a bloody great straight line. Phone builder get builder on site and ask him how he believes he will get your floor up to this height Outcome 1. builder agrees to get floor to this height at his cost, bingo carry on outcome 2. He tells you it’s your fault and he won’t do anything, pay him for his time so far and move on, get another builder. You may find he is happy to walk away.2 points

-

1 point

-

Bear in mind there were over 400 posts on his "Basic cement / Ballast" post and over 1600 on his "Help with kitchen renovation / 1st house" post. I know he seems a bit spammy / troll-like, but I quite enjoy @zoothorn's topics, if not always his sometimes tiresome posts.1 point

-

See my post above. Irwins are great, its the cheapo copies that go bang on me. The ones I pictured were Lidl Powerfix I'm sure. Same concept as the Irwins but I guess plastic insides. I'll dig the broken ones out and post a pic.1 point

-

The first plot we looked at had already had a preliminary archaeological investigation, with some early industrial age stuff being found. When I tried to pin down the costs of the watching brief, and any consequential costs arising from anything uncovered, I found it was a bit like giving them an open cheque book, with all the blank cheques already signed... Because they didn't know what might be under the site, they couldn't give us a price for the archaeological work. The lowest estimate was for a few days spent looking at excavations and not finding anything to look more closely at, the highest estimate was open ended, as they wanted us to pay for what could turn out to be several weeks of detailed work, uncovering, recording and preserving whatever they found. Be interesting to hear how the big developers deal with risks like this, as they must have ways of being able to put some realistic bounds on the likely cost. I didn't pursue this further at the time, as a major boundary error, plus the unlawful relocation of a right of way, effectively put the kibosh on the purchase.1 point

-

Evening @zoothorn can you tell us honestly how much money you have paid the builder so far. Im not convinced that you haven’t paid him far too much, as I suggested you approach him for a discussion and if that discussion was unsuccessful then you part company. You seem very scared of upsetting him which leads me to the thoughts that you have stumped up a load of cash and are feeling scared you have made some bad choices. Now if this is true you need to say so, this way we can see how to rectify your height difference with the minimum amount of grief. If I have read this all wrong I apologise, and in which case you have nothing to loose. Fook him off, start again in the spring with a new builder and some better understanding of what you want to build and how to achieve it, because you need someone to talk you through each step so you are clearer when it is being done correctly and when it isn’t.1 point

-

1 point

-

1 point

-

https://uk.video.search.yahoo.com/search/video?fr=mcafee&p=oregon+power+sharp+system#id=2&vid=08f08ace01cb34a3fbc32b06473f655d&action=view any body any experience of these -- looks like a good thing1 point

-

I wholly agree with the idea of doing as much yourself as you can, for much the same reason, learning something new. I had a fair bit of worry over our setting out, despite having checked and double checked that the critical stuff was in the right place. Just as well I was so concerned about getting things in the right place, as we ended up with a foul drain stack coming up closer to the inside edge of a wall than I really wanted. My fault for thinking that having it within ~±30mm would be OK, it really needed to be within about ±10mm of where it needed to be.1 point

-

nobody said it was difficult --its just a very simple total solution you make your own choice just a suggestion ,which like most get slagged -just because1 point

-

would not argue you could do same from bits cheaper --but this also has the 220 litre tank + a pump --very neat unit . a nice self contained solution1 point

-

1 point

-

If the workpiece is large enough to hold, simply hand held would be ok but if your not confident then any kind of clamp that secures the piece and stops it moving about will be suffice I use these https://www.screwfix.com/p/irwin-quick-grip-6-mini-one-handed-bar-clamp/291391 point

-

Shouldn't be a problem. The diagonals are only out by 30cm , should be alright I think. ? But I can't wait until Digital setting out is finally available for cheap. Would make life so much easier.1 point

-

@gc100 try https://www.gov.uk/guidance/discharges-to-surface-water-and-groundwater-environmental-permits. Or. This is the company I bought my Vortex from and they gave useful information https://www.wte-ltd.co.uk/. Or Email enquiries@environment-agency.gov.uk. The Vortex can discharge to a ditch that’s dry for part of the year, which is what we have, no one checked to tell If I was telling the truth?1 point

-

Generally an isolator is for the isolation of an electrical circuit which is already open - i.e. they ought not to be used to kill loads or connect loads, they also should have a greater distance between the contacts to ensure isolation. Switches are designed to switch loads on and off. A fused spur often will only switch the live, much like an MCB doesn't actually fully isolate a circuit, whereas an isolator will isolate both poles - it sort of depends what you are wiring up. An isolator would be fitted to something that you would want to work on while still installed - plant should really be isolated - a fridge can go on a spur as your really not going to be working on the internals while it is still connected. So on a DB or the main cable-head the isolator disconnects down the whole system. Examples of where I would spec isolation: HVAC units. Compressors (i.e. permanently installed units). Pump systems. Example of where I would spec a spur: Fridge Heater Alarm panel However, as always there is always crossover.1 point

-

I’ve said that and you ignored me. I’ve said (as have others) that you need to mark FFL on the wall, and then ask him how to get to it. You could well be right, but until we know if the slab is FFL, or what is going on top of that slab, then you could well be wrong too1 point

-

If you have to ask for support about issues like that, walk away from the build. Right now. Give yourself a long weekend away from the build. Right now.1 point

-

@zoothorn, have you read @Russell griffiths post? Re-posted (reformatted) here [...] [...] mark on the wall finished floor height, not a dot or a mark on the render, a [...] straight line. get builder on site and ask him how he [...] will get your floor up to [the marked] height Outcome 1. builder agrees to get floor to [the marked] height at his cost, [...] Outcome 2. He tells you it’s your fault and he won’t do anything, [and then] pay him for his time so far [...], get another builder. [...] and then follow @jamiehamy's advice above.1 point

-

1 point

-

If you read that last post from @AnonymousBosch as an attack then you need to stop, walk away and get a coffee and come back in a while. That was him/us asking if you have anyone to talk to about this other than the forum and the builder. You are asking the opinion of 3,000 people, and giving no useful pictures, no guidance on what was originally agreed, and more importantly, not listening to the advice you’ve been given. If I wasn’t 150 miles away, I would come over and have a look, and try and give some advice but I can’t. So, you need to either take the advice given - such as call the builder and talk to him about it, or you need to just let him carry on, and when it’s done you can show us a picture of the end result.1 point

-

and yet still we don't know where and how much insulation will be (was?) fitted. Have you now decided that this poured slab is the finished floor? Why? So regardless of what bricks and blocks are currently in place, your FFL can be ANYWHERE between where it is now and maybe 400mm higher. We don't know. You don't know. Your builder does. Is he correct? You don't know, we don't know.1 point

-

Without a doubt, SketchUp. For the lay 'person' it is (IMHO) the best way to visualise what your future house will be like, all in glorious 3D. It takes a while (well, it did for me) to get to grips with it, but when you get the hang of it's incredible. CAD is beyond me, I've tried and failed, but what CAD can't do (can it?), is show those intricate details, just beyond that 'section' drawing. The joints and the corners, where the roof and gable end meet the wall (or can it?). For me it was probably most useful in designing our recessed blinds, how that all comes together, up in the corners and with the cladding etc etc would have been mighty difficult/expensive without me spending numerous late nights knobbing around with SketchUp and realising where gaps would be and it just wouldn't have worked based on the limited information contained in a sectional drawing. And it's free.1 point

-

1 point

-

There have been quite a few houses built like that in the Netherlands. Not that big a deal other than the need for the service connections to be flexible. Obviously, there are a lot of houseboats there plus fairly ordinary-style houses which float but also some which are normally ordinary land-based houses but are designed to float when flooding happens.1 point

-

Think that is called a barge. Bit like when Kevin McClod put his caravan in a whole, but more watertight. There was a bit in the climate press the other day about flood risk. The 1:100 events are now 1:20 while the 1:1000 are coming in at 1:100. That is globally I think, but the UK is not well places geographically. But having said that, after a month of daily rain, I have not seen any bad floods. A few years back we had some bad ones. What I have seen is a lot more ditch cleaning by farmers. So maybe lack of maintenance caused some of the problems down here. Who knows.1 point

-

we designed a round house a while back for a riverbank setting that had a 8ft diameter caisson in the bank and then a centre pin the house stood on. From that there were 4 angled arms, each with a section of screw thread connected to a central drive that in the event of flooding would pull the arms inward and allow the house to lift up by up to 4 feet ... Now that was barking mad ..!!1 point

-

Many of them now actually have eps cores to reduce the weight. As Peter says they are not structural.1 point

-

OK - did you take a standard build and just want to go with raised piles and use them as the free flow area ..? The issue is that piles create both a free flow area and an obstruction. They can trap debris in the gaps and cause bigger issues hence why you need hydrology to help. You can get away with reinforced banks and flood basins if managed carefully.1 point

-

They are not structural - they just have a core of concrete as its cheaper than using the mix they have for the outer.1 point

-

Maybe ... needs a watching brief. Mentioned on here from time to time. With a risk of having my head chopped off for sticking my neck out (said the giraffe), you could perhaps should be maintaining your relationship as you do your house; little and often with rituals that enforce regular attention on both sides. Suspect that most people do stuff anyway. As I understand it, one thing is not to drift off from knowing each other as well as you did before the build whilst you both change, and a regular whatever to stop the underpinning resilience of the relationship being drained away. So to speak to evolve together rather than in different directions which potentially creates a ‘gap’. F1 point

-

Keep up the moaning and dramas you will be ignored on here. All the best for the rest of the build.1 point

-

I'm sorry but I can't help thinking that this thread some sort of wind up?! @zoothorn it seems to me [and please forgive me for being direct but I agree with many others above that the flavour of this thread is somewhat disturbing - ] that you are quite liking this attention and regardless of the sound advice being offered, you are more than happy to just crack on with the worries / concerns. You need to be mindful that peoples sympathies will soon turn if such advice being offered is being met with continual indefensible comments. For the sake of everyone trying to assist, please do what @Carrerahillhas suggested and save us for all the dramas because I can't help thinking they are self inflicted and you are not interested in changing anything. As I said earlier, this build will just lurch from one drama to another and I for one will not be investing anymore of my time in it if you don't seem to be helping yourself.1 point

-

Because you are not mixing the rain in with the concrete the concrete will come in a truck, from the moment that truck leaves the yard that concrete will start to cure by the time it gets to your job it will be well on it’s way if it takes 30 minutes to unload the truck, and they get it all in by 10.30 you could lay bricks on it 24hours later that concrete will be bashed into shape with the end of a rake or at best a piece of wood, the finish will be rough at best and bloody atrocious at worst. you are not going to jump in the trench and mix the rain in, it will sit on top as the concrete cures the rain will just sit on top like oil sitting on top of water, the two will not combine if this was a finished floor it would be different.1 point