Leaderboard

Popular Content

Showing content with the highest reputation on 04/15/19 in all areas

-

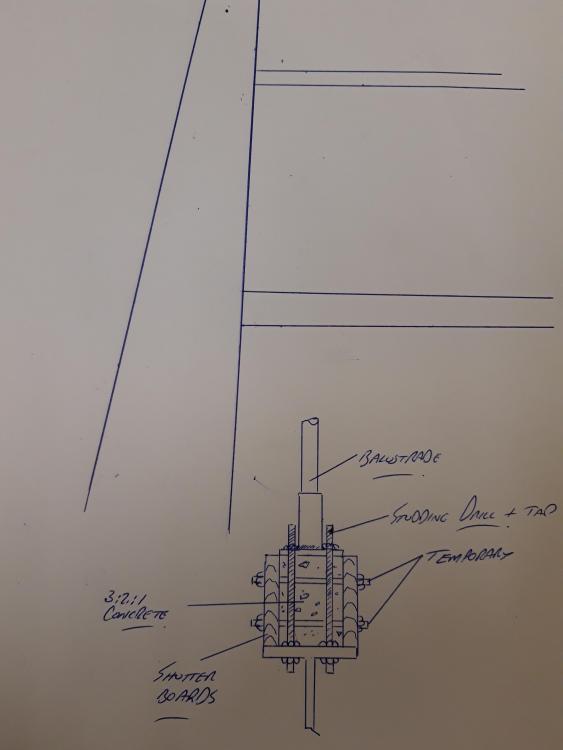

Well, it’s been a month since my last blog update. We've witnessed out first concrete pour and now have floor joists so we are all set to build the next floor. The bracing plan we have from JUB looks like we have the potential to pour the second floor and gables in a single pour. This is a decision I'm only too happy to leave to the builders who continue to impress us with their ability to get on with a job regardless. In my last blog we had got on really quickly and had the ground floor pretty much ready for a concrete pour. We needed to wait as there was no rebar on site for the cantilever lintels for the first floor. Our structural engineers had provided a revised structural plan toward the end of February, but it did not have a bar schedule. One was requested and sent through quickly. So far so good, we had the second lot of blocks scheduled for delivery on the 24th March. The original schedule allowed the pour and joists to be in place prior to the block delivery. At the same time as this was progressing the pricing for the next phase was finalised and we gave agreement to proceed. A hiccup with the joist delivery delayed work on site. On a small site the second block delivery pretty much took up all the available space. ICF blocks and a cramped working site are not good news. The ICF is pretty dense but it’s easily damaged when it gets in the way. We ended up playing shuffle the blocks to get the remaining work done and for the first pour. Our builders did a splendid job and just took it all in their stride they were careful with the blocks and didn't complain about the site restrictions once. We had been warned that pours are not for the feint hearted, thankfully in the end ours went pretty well. The only real surprise was the bottom courses of blocks on one side of the build started to move outward on the raft. Fortunately it was spotted and the pour was suspended while Mike and the other lads added some more shuttering. With the new shuttering in place the pour continued and was completed without incident. Apparently it's unusual for the bottom row of blocks to move, but given they are not keyed into the raft and are subject to the greatest concrete pressure it's not entirely surprising. The blocks on the second floor will be keyed into the existing blocks so they should not suffer. With the pour done it was time to get the ledger beams in place to take the first floor joists. Our structural plans had the ledger beams fixed by bolts at 500 centres with the joists at 400 centres. Sounds OK but in practice it’s not ideal as it means you get clashes of beams and bolts, so the plan was revised and the bolts put in at 400 centres so they would not clash with the joist. Ledger beams in place the joist went in pretty quickly, transforming the house. Once you get past the ground floor you need to get scaffold in place for an ICF, not to build from but to prevent possible accidents if someone were to fall through the blocks from the inside. Our builder wanted us to arrange the scaffold, not sure if this is the norm, I suspect it’s liability related. We have used a local firm ROM Scaffold. Their guys arrived on Wednesday and pretty much had completed their work on the Thursday. The scaffold will also allow for our window installation and rendering. Looking forward to getting the next floor up and starting work on the roof.6 points

-

I take all these per m2 figures with a pinch of salt. There are so many different ways of calculating the results I doubt whether anyone is comparing apples with apples. If it's a PH compared to a conventional house I would have thought using external floor area more sensible as a lot of the cost is in the floor and walls. Some people use all their costs, some cherry pick and leave out site works or paperwork or whatever. I can come up wildly varying per m2 costs depending on how I work it out. A house costs what it costs and if you've ended up with what you want, that's great. For most people it's the first, and for me the last, self build they will do so there is a steep learning curve and nobody gets it perfect the first time.4 points

-

Now being the proud owner of a sad old house on a great plot I have been wrestling with the fact I have zero usage of the electrics etc. From Feb when it became ours the meter reading has remained static as power has been turned off. EDF have three times now assumed usage based on the previous owner and billed as such. After many frustrating phone sessions with them today I have zeroed my account balance, this has actually happened last month but this time I found out something I wasn't aware of. I was expecting to pay three months standing charge and happy to do so, BUT what I didn't know was that if your usage is nill then the standing charge is waived too! Who knew that? I feel like this is a diamond in the rough of the self build experience so far. Anyone else heard this fact?3 points

-

So that went well, picked up the two gennie lifts at 8 am and beam in position at 12 ish not a job for the faint hearted this is how I work and have done for years do a risk assessment for everything not one on paper, in your head, look at what you want to do and work out your plan, then add in everything that could go wrong. Then work out the better way reducing the chance of a cock up. I decided to lift the beam and build the scaffold as it as it went up, lift beam build a bit more scaffolding3 points

-

The lovely man who sorted the mvhr has been back today to look at the ufh and service the boiler. Turns out that although I could see actuators up and bobbing red things on the other bits (forget what they are called) some of those zones were turned to a very low flow so hardly any water getting through hence cold floors and no matter what I turned room stat to I couldn't get the place warm. We did have some warm bits of floor and that is explained by areas where there are two loops and one turned up and one at min. The temp of water coming in was quite low too. All now reset and I can live with it for a week or so and if not right he will look again when he comes back to do another small job after Easter. Why couldn't the installer have either left it properly set up or told me where to look and what to do. No-one has ever explained to me how it all works until this man. Now I have some basic understanding after being at my wits end for the last 12 months trying to work it all out.2 points

-

I've just been doing some web searching about variations of oxygen proportion around the planet without much success. Only one said they were significantly lower in cities but that had some other aspects which seemed doubtful so I'm not sure about this. Still, if there really was a 2 or 3% decrease then you'd expect a 1% or so increase in CO₂ which would be remarkably high.2 points

-

2 points

-

But there isn't going to be a 2-3% difference in oxygen levels between places in the UK. It's more likely to do with machine calibration.2 points

-

Guys I think we have hijacked OP topic here. My observation that the construction type of build a lot of us have (not cheap as we have now established) may or may not be cost effective/heat efficient relative to to OP question of different type of slab/ufh install. My comments were as to style of build not a particular company.....there are others! Cost of build is a personal matter and we all build to our own pockets/parameters that influences the choices we make on which type of construction method to go for, in quoting my cost per sqm I am not complaining at price (I agreed it!) but commenting that it is not a cheap way to build. I think the cost benefits are longer term with this type of build and that was what I thought when we decided on it.....hope it works out that way:-) The self build calculator for June 2018 shows TF timber clad to be the most costly way to build......their averages are just that but it comes out more than insulated cavity brick and block which is at the lower end. I think everyone on this forum knows that my frame and slab were a c**k up and I still live with the consequences of a lop sided frame (no rectification possible) however I have put it to bed, the whole thing made me very ill and I have no wish to go back there. We have done what we can to mitigate the issues and thats it now. Time to move on. With the help I have had from all you lovely people I am slowly resolving the issues I still have with various things and now I have finally found someone to sort MVHR and UFH I hope we will be able to get the house functioning as it should. I am learning to love my house after a few years of sheer hell - and I know I am not alone there - I am looking forward to getting my garden sorted this year. Always a coffee available for anyone passing who would like to drop in.2 points

-

just as an aside to the problem you see the green stuff on the copper pipes --thats showing the plumber did not clean all the acid flux off after doing the joints In time that could cause corrosion of the copper pipe ,as you already have the tell tale signs probably will not rot pipes right through -- but cleaning all copper pipes very carefully after soldering is highly advised so no active acid flux left behind which is why i have already decided to have no joints anywhere that is boxed in by using a pexi pipe system and manifolds , junctions are in places you can get at them in the future2 points

-

I am thinking of a bath vaguely like this one, which a stand-alone but with an enclosed body rather than legs. https://victoriaplum.com/product/orchard-wharfe-freestanding-bath This is acrylic. Is there a better material? My gap it has to fit into is 800 wide. Thanks Ferdinand1 point

-

I like the forgefix torx head available at tool station. The klokow website mentioned is brilliant for Spax, all our cladding screws came from them.1 point

-

1 point

-

1 point

-

Had the same issue here as you know. Person after person compounded the issue when they arrived to 'fix' it and I ended up with a system that pretty much didn't work at all in the end. Luckily I had BuildHubbers to the rescue as I would still be sitting here freezing otherwise I imagine. There just don't seem to be any (many) people who understand how UFH is supposed to work here, probably because it's not that common and they can make money pretty easily using traditional methods.1 point

-

Yes it is a job to know if this was a deliberate taking advantage, or whether the guy really had no understanding and was as stumped as you, but too proud to admit he was stumped so he fed you BS and scarpered. I even have a plumber friend who has little understanding of how UFH works (but this is the same plumber that paid and MCS company a 5 figure sum to install his heat pump, so I suspect anything beyond an oil fired boiler and radiators is outside his comfort zone)1 point

-

I feel for you, @lizzie, as I'm afraid there are some people around who will take advantage of anyone that they think may not know much about something. Without in any way wishing to be sexist, I'm afraid that tradesmen taking advantage of women who they think may not know what they are talking about isn't that uncommon. My late mother was reasonably savvy when it came to practical stuff (she was a farmer) but even she got done by a plumber and a general builder, and both times I stepped in to sort things out.1 point

-

For some reason a lot of people just do not understand under floor heating. I have been to several to "make them work" and found basic things like the wrong thermostat connected to the wrong room. It is just a case of being methodical, and it is really simple. If your system was designed professionally, you will have been given a quoted flow rate for each loop. The only reason you might want different flow rates for different loops is to ensure an even heat up time, e.g a kitchen, which tends to have less heated floor area because you don't heat under the units, might want a higher flow rate than a living room where the entire floor area is heated.1 point

-

1 point

-

At the moment there is no payment at all for new PV instalations. Don't think PV on the roof will heat your house. At the time you need it most, in deepest winter, PV output is very low, it falls off a cliff in November. Assuming this is a new build, and reasonably well insulated, have you considered an air source heat pump? Each 1KW of electricity it uses creates between 3 and 4KW of heat, bringing electric heating costs down to comparable levels to gas. and if you then install solar PV it will help reduce your electricity costs, but it won't eliminate them. An ASHP should be eligible for the RHI payments.1 point

-

1 point

-

I would not bother trying to cast the channel into the concrete as if it is not spot on it will be difficult to remedy. Also the channel will get filled with all sorts of crud. We have put in some glazing where we used a recessed ali channel but formed the recess out of timber slightly over sized. We still needed to adjust some bits with a grinder and bolster. Ali trims all round. Ours slotted into the sides as well because it needed to act as a flood defence. Have you worked out floor levels with the insulation, waterproofing and fall required on the terrace v 1st floor floor?1 point

-

I just leave it overnight and drain it in the morning. No idea what temp it reaches but I'm sure most of the temperature difference is captured this way. Life's too short to think any harder about it than that!1 point

-

But if we weren’t then we could not afford things like massages, we would be spending it on heating bills instead, like most people do.1 point

-

I am very happy with my 2 × SunAmp PV, but reading this thread, then if I was having to start again with SunAmps, then I'd be tempted to stick with the UniQ 9 HW using a external Willis and circulating pump to heat it. That way I could have precise control of the heating strategy.1 point

-

Hi We loved this house and its location in east Cumbria, so bought it and moved in - a week before storm Desmond (2015) laid waste to much of northern England. Near the top of the watershed, we thankfully avoided being flooded by digging a relief ditch from the garden and bailing the patio through the night - what a great way to meet the neighbours! After a year of getting a feel for our new home (damp) we decided to embark on a refurbishment - which has slowly morphed into a full-scale renovation & remodelling project. Ever since buying my first house in Oxfordshire in the mid '80s I've always been renovating and whilst I feel confident in my designs which I know to work well, and being familiar with the concepts of sustainable homes and eco-building, I still feel like a 'newbie' in so many areas of the build process, plus physically no longer can I cope with day-after-day hard labour. So I'm really pleased to have local (younger) neighbours who are builders, and I hope to draw on the expertise I've already seen on this site. We decided to move out whilst the work is done and are lucky enough to be able to stay in my wife's parents' old house - leaving one of the cottages just 'liveable' for me to stay during the working week. It's an amalgamation of two 1850s farm cottages plus 4(!) extensions in a sheltered spot just below the top of a small hill protecting us from cold easterly winter winds but also preventing a view of the Pennines (you can't have everything!). The idea we now have is to demolish the oldest smaller SW extension (little more than a shed yet with '70s planning permission!) and the rear conservatory and build a highly insulated timber-frame extension with an outshut roof to lean-to against the back of the two cottages thereby making their cold rear walls internal. We're retaining the other end extension - just improving its insulation markedly. We're keen to get a mix of modern and traditional by using sustainable methods and materials in the newer parts of the project, whilst reverting to traditional materials in the renovation of the cottages. Whilst applying some of the practices, we don't feel able to attain the standards rquired of EnerPHit but we'll get as close as possible in terms of energy efficiency - insulation and standards of airtightedness. To give you an idea here's a photo from back in 2007 - showing the SW extension and cottage and half of the NE cottage - the Leylandii have all been felled ...1 point

-

TBH, I only know about it because it was drummed into my head when I initially did aeromedical training, and then again every two years for a bit over 20 years. The demonstration of the effect of Dalton's Law of Partial Pressures was by sticking me in a hypobaric chamber every two years and then being told to remove my oxygen mask at 25,000ft. Tends to ram home the message about hypoxia being very insidious...1 point

-

1 point

-

1 point

-

1 point

-

Re MVHR, you really need to spend some time in a house with it. The air in our house is always fresh. Never felt the need to open a window to "get fresh air" and kitchen smells don't linger and don't spread to other rooms, the mvhr extract vent not far from the hob deals with all of that. Contrary to what many think, it does not recirculate air around the house, it extracts stale air and injects fresh air, exchanging heat from one to the other in the process.1 point

-

Oxygen levels outside are more a function of altitude than country v city. Of course, cities have other components floating around that are less of an issue in the country (although those with certain allergies may disagree!) MVHR can absolutely make a difference to air quality, especially in relation to CO2 levels (which affect perceived air freshness far more than the O2 level). Re: per room temperatures, I don't zone our downstairs UFH. There's just one thermostat and that controls the whole house. However, you can set up the flow rates per room so that, say, the kitchen is cooler than the living room (or however you like it). Less flexible, sure, but has the big benefit of simplicity, with only a single thermostat and no need for per-loop controls. I haven't bothered, as I'm perfectly happy with it running with all loops wide open.1 point

-

1 point

-

the current trend to go full open plan will not make controlling temp through out the house easy and I Intend to have rooms and dif zones for temp control as I have now . why would i want kitchen same temp 24/7 as living area? -separate kitchen keeps smells where you want them . for that same reason I,m not convinced on MVHR ,as my wife will not stop opening windows to get in fresh air everyday ,how ever i build it Of course we do have fresh clean air up here last time i was in a garage with an mot gas analyser in glasgow and was similar in manchester the Oxygen content of the atmosphere was 18 .2 % here in the country side it is always 20-21% thats a large difference that no MVHR will make up for in your house1 point

-

No, not yet, but I've been sent a photo of the inside of it, so can see that they've changed the contactor for a larger relay.1 point

-

I'm also a fan of enamelled steel baths, and fitted one in our second bathroom. It would look to be pretty easy to bond one of those electric underfloor heating mats, or perhaps one of the silicon sealed mirror heating mats, to the underside of the bath, as a way of keeping it warm.1 point

-

1 point

-

1 point

-

I know exactly how you are feeling. I used a vibrating beam screed and I had it like a billiard table until the beam screed fell to bits and by the time I had sorted it the concrete was passed being workable. It is flat but far from how US self builders would like it!1 point

-

Planning works differently in every place, and on every different day in the same place ?. The name of the game is a design which is "acceptable in planning terms"; finding that balance is a dance you are dancing, and a game of poker you are playing. Here, I think you are being strung along in one or two aspects, and may have given more away than you needed in one or two (depending if the stuff was in anyway in order to give things away you don't need). But that depends on the case - such as whether she is recommending to the committee, or making her own decision. Enough waffle. Specifics. IMO it is time to call a halt. 1 - If the queries relate solely to her and her team, patently she does not need to consult with neighbours. That is probably a search for reassurance or wanting some cover. I would say no on that basis; she already knows what the neighbours think due to the opportunity to object. 2 - I think you could reasonably have expected her to know her own mind, so another cycle of reactions should not be necessary. If you have given them everything they wanted then you should have a reasonable expectation of immediate approval. 3 - I would also point out that they are required to make a decision within 8 weeks, and are now significantly over that deadline, or you can Appeal for non-determination (The exception is if you agreed to extra time), and would therefore like a decision now (bur a statement that strong is a judgement call in the context). Another 3 weeks is taking the P. And they will want a further 2 weeks to think about the answers. https://www.planningportal.co.uk/info/200126/applications/58/the_decision-making_process/8 4 - I would probably have offered half the height reduction requested, obscure glazing in the 2nd Flr window (which is as good as removal in planning terms and gives you light), and have kept the front balcony, or offered a Juliet (surveillance + more active street scene). I would have obscured the window with a stick-on film, which I might have been caught out on. But those are all contextual and there could be good reasons to be different. At this point, if you have offered everything they want, then I would expect an instant approval. Or I would perhaps be a little less generous on the concessions, and still request a decision. I would defenestrate the neighbour consultation request with prejudice. BUT ... I would always try and explore it all in a phone conversation first with the PO. eg "Why do you think you need to go back to neighbours, when you have already said the query came from within your team?". Resolution with a smile. But that is me shooting in the dark on a forum with an opinion, whilst this is your new house. Ferdinand1 point

-

I am the opposite to @Onoff We have a floor to ceiling height of about 2440mm. I just love the fact i have been able to board all the walls without cutting a silly little bit off the end of each board. The 40mm gap at the bottom will be covered by the skirting.1 point

-

The thing everyone here is missing is that a passive slab is a fair proportion of the build cost for a well-insulated, airtight, build, and that slab will often include the UFH (ours did) in the price. Comparing an all-inclusive insulated, and guaranteed airtightness, weather proof, house shell (it's far from being just the frame) and passive slab package, to any other build method, needs to be done on a like-for-like basis. For example, you can't reasonably compare the cost per m² for a single storey build on a passive slab, with a two or more storey build, of the same sort of total floor area, as the ground floor cost (which includes the passive slab, UFH etc) will always be a lot higher than the upper floor cost, so a single storey build will always look around 15% to 20% more costly, per m² total floor area, than a multi-storey build. The cost of having 300mm of insulation under the slab is always going to push the price up; it did for our build. We could have opted for conventional foundations and frame for maybe 20% to 30% less initial cost, but we'd have then had to add loads of insulation, install UFH, and screed the floor afterwards, so spending as much as we would have for a passive slab, and not getting an airtightness guarantee, either. We had no additional costs for the ground floor at all, as the UFH was in the slab, the surface was dead flat and I was able to lay flooring laid directly on it (and I'm aware that @lizzie's slab had problems that needed rectification, caused by the poor workmanship of a subcontractor).1 point

-

Going with a floor to ceiling height in excess of 2400mm. Started off at approx 2470. As I replaced the ceiling joists anyway I should have set them lower. Thought I had it covered by buying in 2700mm boards to save myself a join in the plaster board. What I didn't account for was the line of slim rips needed by the ceiling. Took forever to do. If I'd had thought about it some more I could have had pretty much full tiles all the way up, lost the rips at the window sill etc. Should have lowered the wall length shelf above the bath/basin to the height of the window sill. Wall mirror and shaver socket would have been better positioned for say someone shorter or in a wheelchair. Should have brought the 2G window further in rather than leaving it level with the outside face of the cavity wall. Should have bought one of these kits for doing the silicone years ago: Should have mitred this trim joint: Should have used grey solvent weld soil instead of the brown along the bottom of this wall. Could have saved all the worry and having to buy gap filling pvc cement: Overall though the quality of my wall tiling is my biggest downfall. It'll make it a pita to clean on some bits and keep snaggjng the cloth I'm sure. The shelf height thing above a close second though, the Feng Shui there is just wrong.1 point

-

This makes me smile every time I read it. It is what I do to fences, and @Onoff to gates. You are very fortunate that you did not end up with a Borders’ version of the Palace at Knossos, complete with Minotaur in the basement. You could recruit some toyboys and have a Scottish Seraglio. F1 point

-

Some assumptions that are unsafe and issues that can cost you a lot... The grass verge out front is part of the highway. The approved house will fit on the plot. The plot is the size implied by the site plan/title plan/planning drawings. There are services nearby so you must be able to connect to them easily. There are no services across the plot. It's a green field so no need to check for soil contamination. The access road is a bit narrow (but my van fits down it so should be ok). The seller says he will get planning permission for you. It's ok to start building your house the day after getting planning permission (At least two issues). Cutting down a nearby willow tree will stop you having to dig deep foundations. If you aren't allowed to put surface water into the main sewer you can always use soakaways. A self builder is always exempt from the CIL. A self builder can reclaim any VAT they are charged. Not using enough insulation. I'm sure there are plenty more.1 point

-

We have built a timber frame with timber clad house and used brick slips for the plinth. It will be interesting when we come to sell it whether they think the brick slips are real bricks.1 point

-

How about; a row of piles 120mm 'out' - (allowed tolerance 130mm) meaning our front wall needing some creative thinking later this year [surveyor error] ICF blocks laid - over a few meters - more than 20mm out of line causing significant expense and aggro extending the first floor joists walls built and left without concrete in them for 5 weeks, blowing down in a turbulent easterly gale in July ( cost several thousand ) wall blocks hammered into line (rather than being relaid) thus causing fractures in the ICF and a huge blow-out - ( cost a few thousand ) steels manufactured 300 ish out of line at one end, correct at the other, meaning several weeks delay and about £1500 of remedial work concrete slab laid to 25mm below FFL - GOK how to sort that - posts to follow Getting out of bed in the morning feeling cheerful. BIG mistake. (PS, apologies Ferdinand ...)1 point

-

it is clearly crying out for either an internal or external Helter-Skelter. Not as much as windmills do, but it needs one. ???1 point

-

AnonymousBosch I will do just that. I had to go into the council to read the objections as they are not made public on the portal. The one neighbour obviously does not want anything going there, from what she had said. The bad thing about it was that she bought the house off the person that I'm buying the land from. She was offered the plot, but declined and then said she had no problem with anything being built.0 points

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)