Leaderboard

Popular Content

Showing content with the highest reputation on 02/22/19 in all areas

-

I think the problem is in the nomenclature. Should be "centres" this side of the Atlantic...3 points

-

Yes the regs say max height for switch 1200mm Room height is 2400mm. What idiot builder decides it is a good idea to put all the dwangs (noggins) half way up? Quite a few I had to knock out and move a little higher to get the switches where I wanted them.2 points

-

2 points

-

@lizzie and @JSHarris to be absolutely fair to Halcyan: Their marcomm uses a different definition of "soft" to Jeremy's. Whether or not you agree, that's presumably a position they think they can defend under UK law and regulatory practice. If you dig down far enough into their website, there's a white paper that clearly admits they don't know how it works. Hence, presumably, the pseudo-scientific arm-wavery. Now, neither of those points lets me forgive the company for spamming this group with pseudo-science. But I'm perfectly willing to believe that it does do a similar job as phosphate dosing (but somehow using metal discs instead dosing with phosphate). In other words, Liz says it seems to precipitate out the calcium in a way that doesn't stick, just like my Combimate does. And that's cool.2 points

-

It's simple. All the intermediate joints in the wall board sit on the centre of a stud. But the very first (and last) sit on the outside edge of the stud. So think of it as the first stud is offset by half it's thickness to account for this. Don't forget this fact when cutting your noggins. If the "end" is a corner, then you also have to decide which board will overlap over the end of the first, which gives you another correction for the thickness of the board to make.2 points

-

Best layout I had was the wc so you sat side on to the end of the bath. Came in well handy when I had food poisoning...2 points

-

1 point

-

Warm up time is easily managed by setback / advance of heating on / off sets points, so don't get hung up on those. The issue is with folk who are not conversant with these 'technologies' stating Chinese whispers and causing undue worry amongst folk who hang on those 'professional opinions', howsoever generalised ( or even flawed ). If you are building to a good standard ( our UK building regs are utter ? so please don't go by those ) then your home will never actually go 'cold' ergo your 'warm up time' is massively reduced because the heating has far less work to do to get you back to your perceived comfort temps. How far the house drops to between comfort events is easily managed by deciding how 'cold' you're willing to let the house drop to and setting the setback ( aka economy ) temp accordingly. Look at it as "how hot and when" as opposed to "when will the heating switch on or off" where you set comfort and economy temps to be maintained rather than times for the heating to come on / go off. This only needs to be strictly observed for ~4 months of the year in reality, so base your decisions on that If they use proper Pex-Al-Pex pipe then you'll only seriously damage it if you take a hammer to it. My screeders regularly run barrow-fulls of screed over the pipes and then one of them will up-end the barrow on partially visible pipes but still with no ill effect. The stones in the concrete are of absolutely zero concern I assure you ( and I've been here more than once over the last 23 years ). Adding the fibres would be a cheap assurance and will be of no detriment, but they're usually only used in a non-reinforced slab where the mesh isn't present, to avoid cracking. You'll be fine.1 point

-

Once a Replicator can make me a fully functioning Seven Of Nine I'll buy one!1 point

-

I doubt the Gault goes down that far, as I believe the deepest layer in the UK is only around 100m deep, and where you are it's probably around the same depth as here, about 40m or so. We have Gault under our house (we built on the top of the layer) and found that it's about 40m deep, with about 12m of Lower Greensand underneath it (where our water comes from) and the Wealden Group underneath that (we could tell when our driller hit that, as it's as hard as hell, and the drill pretty much stopped going anywhere).1 point

-

In the old place we had a corroded waste in a basin. It was a pedestal basin. I suspect that they put in the basin, connected up the fittings then put the pedestal in. Then we tiled around the base of the pedestal. I couldn't see any way to change the waste, so I just gave up and built a new house.1 point

-

We have one tap with exactly that type of fixing, and I can understand your frustration, as I've had to tighten it back up twice so far, and it's a complete PITA to get at, even with a deep socket and extension. Our kitchen tap, OTOH, has a brilliant fixing, a deep (around 150mm) hollow nut, around 30mm in diameter, that projects down far enough that you can see it. It was a doddle to install, and made me wonder why more tap manufacturers don't use something like this. Mind you, it was Dutch, so may be they like to make life easier for installers.1 point

-

Warm up time will mean that your slab will respond quicker if the pipes are in the top 1/3rd but also cool quicker. The deeper the pipes, longer the heat up but also a slower swing to cold due to the slab acting as a big storage heater. This is relevant if you want to use ASHP and off peak electricity as you heat up the slab overnight and the heat is lost to the building during the day. If the slab is going onto the foundation blocks then you may want to consider either changing the design slightly to just have the slab inside the blockwork and insulate at the perimeter and underneath as currently as designed you have a cold bridge into the foundation blockwork.1 point

-

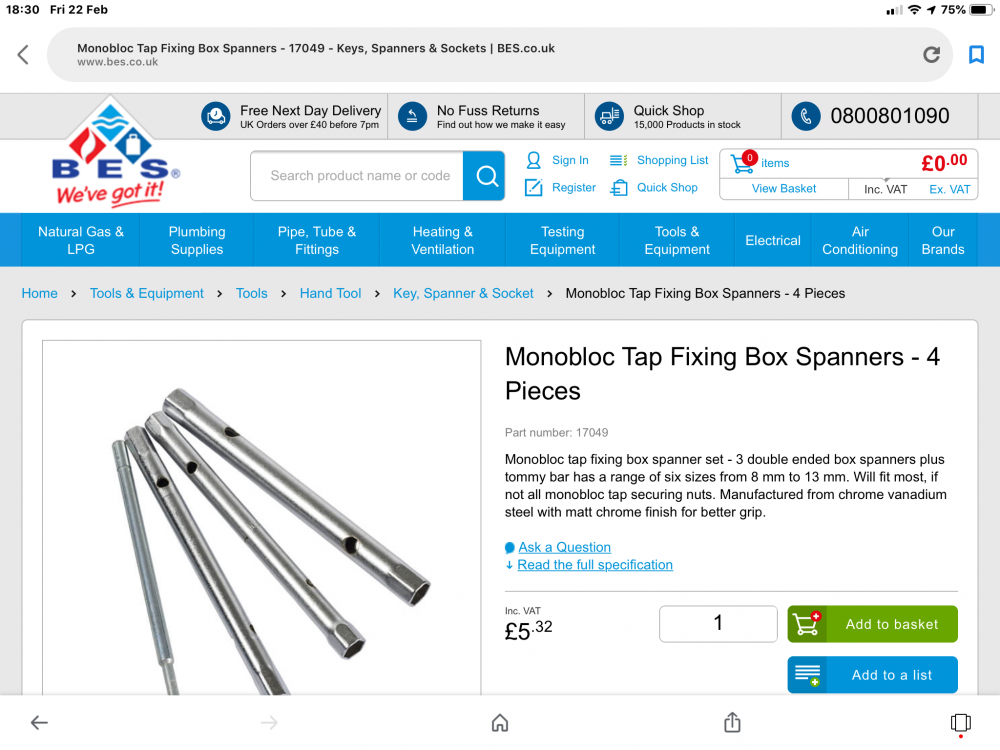

Guys thanks so much. Just found a utube on use of monobloc spanner. Think I can give that a go - a 2 person job but I have another (even less adept than me) body here so will make use of him. Off to screwies tomorrow!1 point

-

My fault, I thought when you said you didn't have spanners you meant you did have a socket set. Anyway, looks like @cherryfountain has the right idea if you can't tighten it by hand.1 point

-

1 point

-

The Scotsmans way is the "tool-less" way. Push the tap a little to the right of centre. Hold it there. Reach up with your other hand and tighten the brass bit as tight as you can by hand. Then holding the brass bit, turn the tap back to centre to tighten it the last bit. It sometimes works,. don't blame me if it does not. I much prefer the taps with a solid copper "tail" far less likely to work loose.1 point

-

A lot depends on how far up you can get your hands and how much purchase you can get. The angled spanners might work but it will be difficult to exert a lot of torque using one, a long socket would be better. As it is a one off use try and borrow one or find the cheapest piece you can find that does the job. These at £5.05 on Amazon would probably do the job assuming that you have the wrench that fits into them. https://www.amazon.co.uk/Amtech-I6400-Sockets-4-Inch-9-Piece/dp/B003XKIGR8/ref=sr_1_1?ie=UTF8&qid=1550860851&sr=8-1&keywords=deep+socket+sethttps://www.amazon.co.uk/Amtech-I6400-Sockets-4-Inch-9-Piece/dp/B003XKIGR8/ref=sr_1_1?ie=UTF8&qid=1550860851&sr=8-1&keywords=deep+socket+set1 point

-

Stand it on what ever you want when the house is signed off, stick it on e bay for the next poor bloke who has to deal with such a thing.1 point

-

Normally such a tank will be supplied with a pressure reducing valve set to 3 bar. Looking again at the photo I think that is the pressure reducing valve and over pressure relief all in one. It looks like it might have failed and needs replacing.1 point

-

The chip I used seems to be obsolete now, and finding a DIP version of a similar chip may not be easy (I've not looked for a few years now), but there may be some around. Pretty much all the electricity meter chips work in much the same way, and have similar interfaces, so it shouldn't be too hard to find one. An alternative might be to get an additional meter installed. The Elster A100C is a really good option (around £30) as it has an optical serial data port, that constantly outputs power, current, voltage etc. The data protocol is documented, so it's relatively easy to just stick an IR receiver on the meter port and get all the data you need. This link has details about doing this: http://openenergymonitor.blogspot.com/2012/08/reading-watt-hour-data-from-elster.html This link has a bit more on the protocol used: http://abatis.org.uk/projects/rdmeter.html Edited to add: I found the A100C datasheet, which has full details of the data transmitted etc: A100C_Operating_Instructions.pdf1 point

-

Unless you go for a wireless solution, you will need to decide where the immersion controller is going and then get a current measurement (probably from the consumer unit) to that point. In my case the incoming supply and thus easiest place to measure is out in the meter box. But I predicted that situation and I ran a spare length of 5 pair armoured telephone cable back to my comms / AV cupboard, and from there a CAT5 up to my plant room. That gives me 4 twisted pairs from the meter box to the plant room for my current transformers and a couple of spares. The one I already have connected seems to be working okay. The electricity meter chip is probably a better idea, that can still be hooked up to an arduino if that is what you are familiar with programming.1 point

-

Hard to say. The pack would probably have been in better condition, as it would only have been charged as a part of the hybrid mode, by the car, so the depth of charge and discharge would have been heavily limited. My last Prius Plug-in didn't seem to suffer any degradation at all over the five years I had it, though, after ~40,000 miles it was still delivering much the same EV range as it was when I bought it, despite having been charged twice a day every weekday, plus at least once every weekend. It seems that EV and PHEV battery packs seem to be remarkably reliable, as failures seem pretty rare, and degradation is lower than I would have expected it to be. One reason may be that EV battery packs don't get cycled as much as other stuff with lithium batteries. I find that I'm only charging the i3 once a week, if that, so it sees a fair bit less cycling than something like a modern mobile phone.1 point

-

I have seen these used by cable TV installs where the wire comes through the wall. Can you post a picture of the finished fitting if you go ahead with it? I really like the one in the first post but the circular ceiling recess looks like mission impossible.1 point

-

1 point

-

OK so the M-10 M-60 rainfall values are what you are interested in. If you assume that M-10 is 600 seconds, then you will have to store 0.35l/sec or 210 litres. If you took the exceptional M-60 rainfall (ie 3600 seconds) you need to store 1,260 litres. I would expect that you could use the M-10 to calculate the minimum and then suggest that using the M-10 +200% would be a reasonable factor, so you would need 630 litres. I can write this up properly, and based on your quote above will charge you an attractive £150.... This may help...1 point

-

The vents that BPC supply come with a few little plastic curve shaped things. They are designed to be inserted as baffles if one side of the vent ends up very close to a wall.1 point

-

1 point

-

How about these: https://www.creative-cables.co.uk/metal-ceiling-roses/7053-black-cylinder-rosette-kit-bracket-screws-and-cable-retainer-8057730181235.html1 point

-

That will be a (probably plastic) piece designed for and supplied with that particular light fitting. If you have a fitting like than and are missing one, contact the manufacturer. If a different application, be more specific what you are trying to achieve?1 point

-

@Big Neil for reference I've just checked an email I got this morning. Given most of the perk leases are around 10% of salary, this is from the £350-450 band from Nationwide (other lease companies are available...) Ford Mondeo Vignale Estate 2.0TDCi - £292 BMW X1 sDrive 1.8d - £293 Toyota Rav4 2.5VVTi Hybrid - £293 Mercedes C Class C200AMG - £294 BMW 4 Series Convertible 420i M-Sport - £294 Renault Zoe 80Kw Signature - £294 Alfa Romeo Giulia 2.0 TB Super - £295 BMW i3 125Kw Lodge - £295 Hyundai i30N 2.0T GDI - £299 BMW 520d M Sport - £300 Audi Q3 35 TFSI S Line - £303 Jaguar XF 2.0d R-Sport - £304 Renault Scenic 1.3 TCE 140 Play - £308 Range Rover Evoque 2.0D - £312 Nissan Leaf N-Connecta - £314 So if you look at that list and compare to a Ford Focus at £256 from the same list... you can see why there is little uptake on the Nissan Leaf when for £20 less your planning officer can have a BMW 420i M-Sport Convertible..!1 point

-

This piece in H&R acknowledges the concept of in-slab ufh, but does not give a howto, which may be what you really want. https://www.homebuilding.co.uk/underfloor-heating-guide/ There are various pages from Installers eg https://www.buildingservicesindex.co.uk/entry/44100/Warmafloor/Underfloor-heating-for-structural-concrete-floors/ F1 point

-

I think with the younger generation, thirty somethings, it’s all about status, IMO that’s why there are so many working mothers these days because they have to have the house, the car and the fancy holidays. I stayed at home with my children until they went to school and we had a council house, an old banger and holidayed in a caravan!1 point

-

A lot of the new cars are perk cars - the lease deals on them are ridiculous, we see regular offers on 5 series BMW for £259 pcm on a 24 month lease. This means you do see people with cars that seem “out of place” with roles - nothing more than good finance management ..!1 point

-

The lads that built mine all had posh cars - lived at home with Mum and Dad (or just mum) so have proportionately large disposable income.1 point

-

That is what I thought hence my surprise when a lady planning officer turned up in a vehicle I normally associate with argi business farmers of 3000 acres of wheat. Purhaps she is married to the brick salesman.1 point

-

1 point

-

Anyone can easily get a nice looking car on pcp or hp. And its all about appearances, nice car and a well dressed sales rep gives a good first impression.1 point

-

I may be wrong.....l. But is it not because if your using 1200mm sheeting or plasterboard it will start against the wall and you want the joint to land in the middle of the stud........1 point

-

We have a triple glazed roof window in our bathroom and I chose low (32%) solar transmission glazing. As a result we don't have a problem with overheating but it is slightly darker in there in the winter. The room faces ESE.1 point

-

Today we went to the free training day at Swindon NHBRC for the Isotex build system. The day was a very similar format to the Durisol training day but the whole day felt less formal and went really well. The actual hand's on part of the day, I thoroughly enjoyed, I felt we learnt much more about how to actually use this product, including how to fix something that we know is likely to happen (putting a block round the wrong way so that the insulation is on the inside and not the outside). The issue with this is the break it will make in the concrete honeycomb - the wall will have a weak spot so you have to fix it. We built over a window frame, cut some blocks, talked about door openings and left feeling quite confident about the product. So now I have seen the 2 products that are in contention in a training environment. My verdict comes down 100% on the side of Isotex, luckily Peter agrees and I didn't even have to tell him what his decision was! The reasons for this are really a confirmation of my thoughts prior to the training: Less webbing so that the concrete honeycomb is more complete Smoother so that they appear to "shed" less The pass block which keeps your "brick bond" does make life easier as there will be less cutting of blocks on site. The design of the block increases the air-tightness of the finished wall - Durisol has two woodcrete faces that butt together, Isotex has open ended blocks that fill with concrete, sealing the air gap. I felt that the support during a build would be better - that is purely a gut feeling of course, but there is no way of quantifying this without talking to lots of previous self builders. It was clear however, if we needed a visit, they said they would come out to us in addition to the visit that they actually schedule in to make sure you are getting on ok at the start of the build. The choice of build methond is one of the more fundamental of any self build and in addition to the quantifiable benefits that have helped us favour this product is the inevitable personal prejudices that we all have regardless of how much we may try to neutralise them. For me, having the saleperson talk positively about a foundation system that I have only heard good things about on this forum made me feel that they were on the right page with how builds should be today. Durisol were quite dismissive of insulated slabs. MVHR - again, Durisol were dismissive, let the house breath and you don't need an MVHR. Isotex understood the need for air-tightness and therefore an MVHR to give you the ventilation that is needed to keep the house healthy. Our next steps are to visit a site for both product on pour day. Hopefully we should be able to do this in March as they both have pours quite locally to us. The BBA certification is still rumbling along, however for me it not a particular concern. If we can get a mortgage and the 10 year warranty insurance, I really can't see an issue. That along with the fact that we will not be bulding until next year, when BBA certification (for what it's worth) should be in place means for us it is a minor item. So, for us, we have a product in a clear lead, it will come down to real world usage on a site with people like us and of course price. Finally, it was lovely to see @Tom's Barn again and to meet Karen who is hopefully a member of Build Hub in the very near future.1 point

-

TLC Electrical have a range of downlighters of different types https://www.tlc-direct.co.uk/Main_Index/Lighting_Menu_Index/Lighting_Downlights_Index/index.html The void depth is typically given somewhere on each page but I would also check the makers data in case of errors.1 point

-

Velux don't do unvented, Fakro do. Infuriatingly this drives the price up considerably. Beers Building Supplies have offered a decent discount off Fakro RRP, so perhaps try them. I'm afraid the lead-in time won't change though. They suggested 21 days for unvented as this is a special order product, whereas they have thousands of vented ones on the shelf, which can be dispatched immediately. For the u-value debate (if this is of any use to anyone) on 118x78cm rooflights we're looking at a u-value of 0.97w/m2k (centre pane value 0.5w/m2k) for triple glazed and 1.3w2K (glass u-value 1.0W.m2K) on double glazed, the latter of which is probably the option we'll end up with. I don't know what they're like, but have just come across YARDLITE unvented off the peg rooflights with delivery in 3-5 days and a next day option available. https://www.yarddirect.com/yardlite-aax-centre-pivot-unvented-white-pine-roof-window I wonder if anyone has used this brand before and can vouch for it?1 point

-

I would run the brickwork up to 25mm from the timber frame return. On the timber clad wall, form a corner from 2 pieces of larch ripped down to 75mm. Butt 1 side of this corner to the brickwork and the other fix to your timber batten having run some dpc vertically. Bring out the timber battens on this section to the same depth of your batten + corner. You may need to add an extra stud or 2 to the timber frame to support the corner.1 point

-

Concrete is heavy and expensive and that is a very deep makeup for residential. If it is deflection or sound insulation you are interested in, compare it with timber / engineered joist solutions. 15mm plasterboard is better than 12.5 as it is less likely to sag.1 point

-

Indeed. So if new homes won't be able to have gas, what will they use instead? Don't tell me those in charge still believe that wood pellet stoves are carbon neutral or environmentally friendly? If so heaven help us. And if Electricity is to be the new fuel, then what is going to happen over the next 7 years to improve the capacity? Turning more homes all electric, and the growth in electric car usage, is going to impose some massive changes to the network, with little sign of much of a plan to deal with that. Or is there another side to this, the fact that North Sea gas is in decline and it's a case of wanting to reduce our dependance on gas so we are not held ransom to imported gas?1 point

-

This thread (as great as it is) reminds me of my time spent with a religious community.... I was very intrigued by their way of life and was trying to see if I had any give in my very atheist tendencies...... one day I was standing on top off a hill with the leaders wife and there was a beautiful rainbow...... the lady asked if I knew how a rainbow was created, yes I said and started telling her how A rainbow is a meteorological phenomenon that is caused by reflection, refraction and dispersion of light in water droplets resulting in a spectrum of light appearing in the sky. It takes the form of a multicoloured circular arc.... she looked at me like I was daft....... no no no she said and proceeded to explain that God said to Noah and to his sons with him, “Behold, I establish my covenant with you and your offspring after you, and with every living creature that is with you, the birds, the livestock, and every beast of the earth with you, as many as came out of the ark; it is for every beast of the earth. I establish my covenant with you, that never again shall all flesh be cut off by the waters of the flood, and never again shall there be a flood to destroy the earth.” And God said, “This is the sign of the covenant that I make between me and you and every living creature that is with you, for all future generations: .... I looked at her like a stunned mullet. This is all in good faith or good humour ..... whatever ‘I enjoyed thread.1 point

-

I have a Combimate, where you have to change some magic marbles in once a year. The kettle does not fur up but there is still residue where cold water evaporates such as in the tray of the fridge water dispenser, in spite of the fridge also having a water filter.1 point

-

I have bora on induction. There are people on here who prefer other manufacturers but thats personal preference. I liked Bora best so thats what I had. I had always cooked on gas and insisted I was having gas in new build (domino was what I was going for) then I had experience of induction in rental house. Would not go back to gas if you paid me and that is astonishing coming from someone who was so committed to gas we paid 13k to get mains gas in!. My advice would be try to find some way of living with an induction for a few weeks and see how you like it.1 point

-

We use a small ozone generator to neutralise cooking odours. It certainly helps, especially if running whilst creating the odours. This is in addition to a recirc hood, and MVHR on boost. If more is required (e.g. when griddling steak) we'll open windows on opposite sides of the house and use the pressure differential to do quick air change.1 point