Leaderboard

Popular Content

Showing content with the highest reputation on 03/06/20 in all areas

-

Here goes the next stage. Building the reinforced concrete ring beam. The plan is to build the steel cages off site in a shed due to awful weather, then deliver to the site. Lots of things arriving on site! The yellow plastic takes the place of traditional shuttering. Apparently this is faster and therefore cheaper. This will help pay for the huge amount of claymaster I need. It's still a little wet out here so digging might get interesting. We're armed with pumps and a couple of diggers so what could possibly go wrong? It took a couple of hours on Monday morning to measure out the site accurately, then the team got on with digging and cutting the piles to the right height. The cages started to arrive on Tuesday and installation was swift. The kitchen and family room cages nearly complete. The building inspector was happy with the progress on Wednesday so on with the show! With a bit of luck the concrete arrives on Friday. Then we can open the first of the four bottles of Cava allocated to the significant milestones.3 points

-

Can’t wait to get home from work today. The sun is shining. The roof should be dry. There’s a hole somewhere. I’m going to get home and get up on that roof with a hosepipe and find it. If it’s not in the roof surfacing then we’ll let the roof dry and hosepipe the roof light tomorrow. That’s my Friday night. Nothing I’d rather do ?3 points

-

I am hoping to start work on site in May, about two-months later than my original plan. Things may well slip further and I am fine if they do. Currently, the timber frame is being designed, by a specialist frame-designer based in Herefordshire that was recommended by (and contracted via) my chosen local timber-frame company. And the frame designer has just sent me the line-and-point loads (see below), so I have in turn just sent those on to my foundations designer in Ireland so that the insulated concrete-raft foundation can be designed in parallel with the frame. (To save on VAT, I also contracted the foundation designer via my frame company.) In parallel, with this, I am in the midst of arranging a fibre-optic data connection to my plot. I already have electricity connected. The fibre connection comes from a local fibre ISP who have been pleasingly helpful. The connection requires a new overhead wire from the end of the access road about 40-metres to the gable of my neighbours house and thence down to the ground and on to my plot. My neighbour is being most obliging, partly because he also gets a connection and can drop VirginMedia, who has been unreliable for him. To my astonishment, the whole installation will be free as I, it seems, am eligible for a voucher from the government that covers the cost. The voucher does not cover the VAT but the company kindly agreed to absorb that cost themselves (!) when I mentioned zero-rating. I am getting closer to choosing a groundworks team and finalising the details of the groundworks. I am pushing the boundaries of what is acceptable for what is supposed to be a "no-dig" build but it will all be done with expert tree-specialist oversight. I need clay heave protection which will be 220mm thick so digging down about 375mm was needed if my final floor level was not going to be high in the air. For my screw piles, I will probably go for a supply-only deal for the ground screws themselves and have the groundworkers install them with a mini digger (in my presence). I am told that installation is simple. For the installation of the insulated concrete raft, I still have not identified who will be the installer. I am tempted to speak to all the local concrete pourers to see if I can find someone who has experience of insulated rafts. The raft design is going to slightly unusual. Because the insulation is not load bearing and because I have a ridge height restriction and want tall ceilings, the insulation will be thinner PIR rather than the usual EPS. To my distress, the local water company has insisted I make a water connection all the way 40-metres back down in the access road to the 5" water main there rather than 2" main directly in front of my plot, citing "the impact of another service". Oh well at least the water pressure will be good! I need now to apply for my drains connection. I had been waiting on the tree matters to be resolved as it has an impact on the trench routes. For the protected trees around may plot, I have just finalised the Arboricultural Method Statement (AMS) with my tree advisers. This unlocks the chance for me discharge my nine planning conditions, all in one go. It took a surprising amount of time to work out how this is to be done, requiring a counterintuitive use of the planning portal to create a new planning application (!). I have paid deposits for my windows and front door (IdealCombi) and my roof lights (Roof Maker, their passive-house-certified product). Bauder, my chosen warm-roof and green/sedum-roof supplier, has been very helpful with advice on matters such as waterproofing when the rooflights are too close to the edge, and on standard roof-edge details for my architect. As soon as the frame-design is ready, I will be tendering among the local Bauder-approved installers. I have identified my brick-slips cladding I will use (Eurobrick P-Clad) and worked with my architect so the corners and window openings are properly proportioned for the brick counts. I have just booked myself on a slips training-day for 2nd April in Bristol. On my to-do list are signing up for building control, warranty company (reluctant purchase) and buying site insurance. I also need to arrange some bespoke aluminium copings and profiles. The intention is that the frame will go up, the roof will go on, and the windows and rooflights will go in, in quick succession followed in short order by brick-slips cladding. With all of these done and installed, I will have a weathertight shell ready for first fix to start, perhaps around mid-summer time. Hopefully. (I am already dreaming about @nod-style metal framing!) I have been continuing to visit other Buildhubbers, with visits to two people installing Fermacell, and one Buildhubber all the way at the end of second fix. As always, I learn so much from these visits and am gratified by everyone's immense generosity. They are truly inspirational. And thanks to everyone at BuildHub for all the advice I havre received (and will undoubtedly receive in the future). The journey is just beginning. Comments, observations, guidance, suggestions welcome, as always ?2 points

-

I have put this thread here, as it really belongs with the CDM role / Health and Safety. Has anyone considered this? Though the numbers are small, we do have people coming on and off site - and some of us sometimes have a number of different subbies over periods of time etc. I have been consulting an expert over the gym where I own a small stake, and where the activity is as vigorous as any building site, and the points made have been: - Washing hands is still the key. Traditional soap is as good as gels etc. Having hot water is not quite as important as I thought it was. - Regularly wipe down areas touched by a number of different people - especially door handles and light switches, but also taps, electric sockets, whiteboard pens, buttons on drinks machines, handles on doors or equipment if used by different people etc. - Corona Virus lasts up to 48 hours on a surface. - Laminated signs with instructions on doors where people enter, in the washing hands / bathroom area, and on noticeboards. - Make a summary note in any Health and Safety manual / file / procedure. - Encourage wearing of gloves where possible / appropriate. (Either a gym or a building site probably have some glove--wearing anyway). - Have a supply of robust disposable gloves available, in case you need to insist. The reasons for self-builders to pay a modicum of attention seem to me to be twofold: 1 - For its own sake, to keep things rolling / be on top of things in a safe working environment for staff, and any regulators etc who visit. 2 - To have a suitable set of reasonable measures in place in case there is any attempted comeback later from any source (though it is unlikely) - the famous arse cover. Does anyone have suggestions / comments? Ferdinand2 points

-

What your wholesaler has tried to explain to you is true but the GU10 will cause more grief over time and also suffers lumen loss. A domestic downlight will probably average about 300-500Lm - so say a reduction of 30% (L70 I'd suggest if after 50,000hrs) so 150Lm loss, at that you would be hard pushed to actually see a difference albeit yes it would be there. The fact your wholesaler seems to well versed in this suggests that the integrated products they are selling are not very good and thus this issue is rearing it's ugly head too soon. I was on a site that had been handed over to the client 2 weeks ago, reception staff complained their desk was too bright, we had run the calcs and inline with CIBSE guides had designed the reception to 300Lux Avg with uniformity greater than 0.6. So in we went one evening with a light meter (only way to measure light in rooms with natural daylight penetration) and took a reading, on the desk we got readings of 250-350lux - fine, CIBSE LG07 would recommend 300-500lux for office spaces depending on use, so even allowing for the peak area of 350lux it was still well within spec, what I suggested the problem really was was the high gloss white reception desk reflecting light into her eyes! We rolled out a piece of cardboard immediately the issue was gone! However, on the lead up to this I advised the electrician to go into the fitting, and turn down the drive current from 1050mA to 750mA - now I didn't have the current/lumen curve so I don't know what lumen reduction that would have resulted in but at a 300mA drop we couldn't "see" any light drop - we eventually dropped it to 500mA and we began to notice it if we looked, others still could not see a drop - the humen eye is actually not that good at these relatively small light changes. The issue I have with GU10 is the little "driver" it is often no more than a cap and a resistor and some other bits, prone to being inefficient, getting hot and potentially being a big of a weakspot as the "driver" circuit usually fails before the LED. Aurora, JCC, Enlite etc. are "popular" among contractors as they are cheap and cheerful, you will generally not find Aurora speced on a job unless it was D&B or contractor lead - do not get me wrong I think they do fine, but as I see it they are really only suitable for the domestic market and often the optics and distribution is a bit rough. So most LED products that we would spec would be L90 - 100,000 - very basically it means that the LED will output 90% of it's initial lumens for 100,000hrs. L90 industry standard was always 50,000 - so if someone quotes L90 with no figure after it then it is only 50,000. You will also get L80, L70... Now even at 50,000hrs that is 11.41 years at 12 hours a day! So if the wholesaler is telling you about 30% lumen loss, then just how soon are they expecting this drop that you would start to individually replace lights? If I got say 15 years out a set I would probably be happy to replace it with the 2035 version which is 0.5W for 500Lm! Something to bear in mind is that all light sources degrade with time, florescents were terrible for it, people just saw they lit up and assumed they were fine but in fact they were well beyond their service life and could be as low as 50% of original lamp lumens. The high quality range of LED downlights use an LED engine/module which can be changed out, the Aurora units are largely all glued up and sealed - once dead, you bin them. A nice option for dometic installs is to buy a nice GU10 downlight and then buy the likes of a Tridonic LED engine and driver. You end up with a cost effective product with the light output and quality of for example a Flos or Erco down light which can cost £200 each! Like this: Note it has a decent heat-sink on it and optic etc. all built in. You can get a nice downlight for about £12.00-£15.00 and the Tridonic module and driver is about £15.00-£20.00 depending on lumen output - also, try and stick to around 3000K unless you want a white commercial feel.2 points

-

The calculation isn't easy, given the wide variation in grid CO2 emissions from day to day and even hour to hour during the day. Probably the best way to look at it is to estimate your total household emissions and subtract the emissions saved by the PV generation, to get an idea of the true impact. I was asked to give a talk in our village hall a while ago, about our build (turned out to be surprisingly popular - standing room only). When putting together the presentation I tried hard to think of a way to enable people to visualise CO2 emissions. The best thing I could come up with was to convert emissions that were saved, both from designing a low energy house, and the saving from PV generation, into trees. A mature tree sequesters roughly 20 to 25 kg of CO2 a year, in the form of carbon locked up in the timber. The SAP calculations for our house give a CO2 "emissions" figure of -0.9 tonnes/year. This equates to the CO2 sequestration from about 40 mature trees. All those who knew our site could see that we couldn't possible fit 40 trees on it, so it was pretty clear that our house was, at least in terms of CO2 emissions, less harmful to the environment than if it was planted with mature trees.2 points

-

2 points

-

1 point

-

If the solicitor is doing a good job they will have contacted the utility companies to get maps and find out if any cables or pipes run across the property. They can take 4-8 weeks to respond. Perhaps ask for a copy of the maps as they could be useful later? or perhaps don't ask if you think she hasn't sent for them yet! PS: We once had someone knock on the door looking to buy our house which was on the market. Four weeks later we completed and moved out.1 point

-

1 point

-

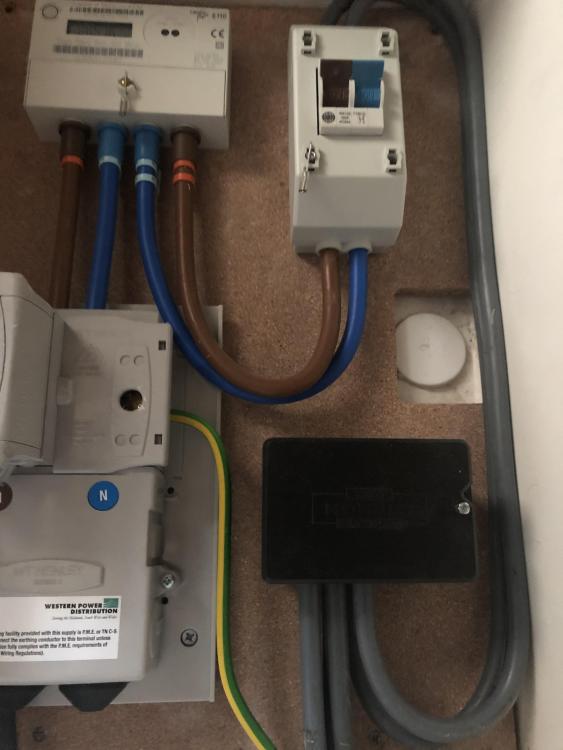

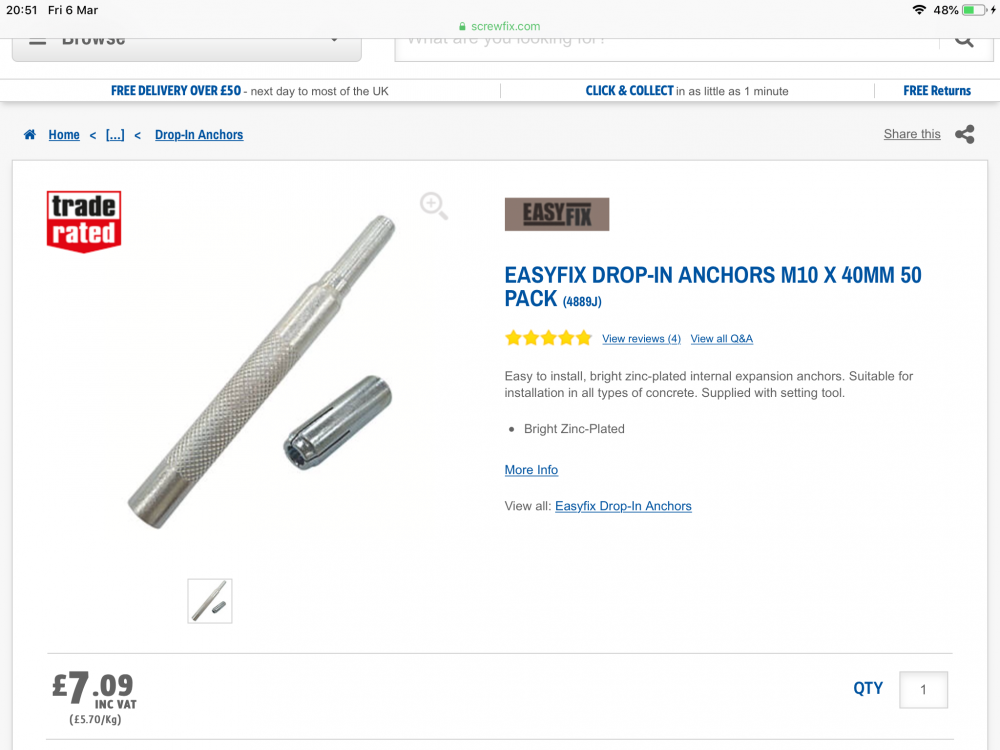

Do you know you don’t need to put that bit of timber up to fix those brackets to. You can get a little insert that you drill a hole in the block poke in insert and screw stud into it and insert expands in the block. I will shut up if you already know this.1 point

-

I think they’re all the same, they take their time to try and justify what they charge you!1 point

-

1 point

-

1 point

-

Well done on progress so far. It is certainly no fun doing this but I have seen a number of sites near me where the contractor has had to go back to remedy issues. The recent weather has brought lots of defects into focus. Once the soggy insulation is all stripped it should be easier to see what has gone wrong.1 point

-

I am one hoping to come in at a finished price of £1000 per square metre. Just to warn you, I am into year 5 of the build as I have been doing so much of it myself.1 point

-

We agreed a new improved frame and a bigger window size - so everything resolved. Thanks for your help everyone!1 point

-

There are a few here who have built for under £1,000/m², but they are very definitely the exception, rather then the rule. Some. like @Declan52 and @nod, are in the trade, and have done a lot of work themselves, and maybe they live in areas where stuff is cheaper. The flip side is that we also have members here whose builds have come in at closer to £3,000/m², maybe more, but again they are the exception, rather then the rule. If I had to guess at a reasonable figure to expect, then I'd say between £1,500 and £2,000/m² is around the right ballpark. Getting down below £1,500/m² requires a fair bit of DIY work, and also means shopping around a fair bit to get the best prices on stuff.1 point

-

Exactly! The issue however I think is the lack of official public announcements, even a simple ad campaign blasted out giving out fact, talk about the 10,000's of people who have recovered. If I was older or had existing morbidity yes I think I would be taking a lot more care and limiting my exposure but people have gone mad, I am sure they are expecting scenes from 28 Days Later. The media is to blame for a lot of this and ejits on social media with followers because they sang a song in 2004 and are now looked up to by the deluded.1 point

-

1 point

-

Went to the dentist yesterday, notice on the door “if you have visited any of these countries recently you are not allowed to enter” a list of about 8 countries followed. been there ,done that, conference calls are far greener than travelling by any means.1 point

-

I think there would be a trail of parts leading to the caravan thief if they tried with mine!1 point

-

We came in about at £820 m2 Doing most things ourself on a 285 m2 Three German bathrooms Very Large German Kitchen Over 200 mtrs of Italian porcelain So figures are very achievable Ok on here but I wouldn’t mention the hair salon elsewhere1 point

-

the air tight membrane will need to be reinstated. MBC advises yesterday that it can be patched with tape and a new bit of membrane. And then new insulation pump led in. So no issues there.1 point

-

? Happy to come over re the cabling. Probably worth a post on here for Ideas?1 point

-

Stay away from that circular reveal I remember the blog post! So do you have to repair your air tight membrane after or is a vcl different? How do you do it go mad with tape?1 point

-

Many GU10 housings, even fire rated ones, are completely open-back these days so should prevent heat build-up e.g. Integral's Evofire range: That said, perhaps integrated fittings might be better able to exploit the benefits of integrated heat sinks to improve cooling even further, as well as move the electronics further away from the LEDs.1 point

-

The build costs are entirely different for each build and it's very hard to say a budget will work for the size. However some have built for 800/m2 so it is achievable! However... my advice would be to spend a LOT of time reading and researching here and othe places to learn as much as you can and find the risks to your own individual project and finances. The more risk you can mitigate the smoother the build will go. My comments would be: 1. You seem to be doing a lot of the work yourself, if you work full time already...how will this fit in with life? Are you prepared for it to take 2-3 years to complete?. Most of us would love to build yourself and if you can do it great. But be realistic in the first instance.and plan plan plan. 2. Sizing - 200m2 seems small for the amount of things you want...these rooms are going to be very small if you dont compromise somewhere. I had planned 200 aswell and had less requirements than you...I am now at 250 not including my attached double garage... 3. To keep it cheap try ensuring the design is as simple as possible. A square box with straight walls will make it cheaper and easier here. 4. Good luck! Enjoy the process1 point

-

Evening all, Finally! A decent forum I can enjoy... Before the time of social media I was an avid forum goer, big on my underground electronic music. Rave scene jungliest movement forums were the only way I could network outside of the nightclubs. Photos from events would be posted up, pirate radios would hunt for talent and promoters would post up their flyers to try and gain momentum to get as many tickets sold before the night.... All seems a generational back in my day thing now but those were the best days, back then... Instagram, facebook and twitter changed the game and when we look back it was really only in the last decade that such trends have happened and what a change there has been! For the better.. imho no not really, negative feedback rather than positive criticism floats around freely... forums always felt more of a community to me, people sharing knowledge, wisdom and experiences to help learn and influence for the greater good, and from reading through the threads on the weekend it gave me a sense of those good old days before I had a career, before I had bills, kids & not enough time in the day! Gas engineer by trade (15 years), and now working as a supervisor for a housing association. I bought my first house when I was 20 and spent 8 years knocking it about thinking I would be a millionaire by the time It was done. It was pretty much done but we got bored of spending all our money at builder merchants so when the kids came along a few years back we bought a VW transporter, kitted it out and off we went, now we have Finley (1 and 3/4) & Penny (3 going on 30), an old dog named max, Lenny the tortoise. We just got married 2 weeks ago after being together for 14 years and now my new wife is telling me we need a bigger house.... She's right by the way! Great thing Is I've always wanted to build my own house I spent my childhood watching Grand Designs, bad thing is we may have to live in a caravan for awhile, lets hope the kids are buckled up because its going to be a bumpy ride but hey, what's life without a few challenges. And everybody who knows me knows I'm not the type to sit around watching Tv, always on the go like many of you are I sure. My brains constantly ticking over about the next 'big project' I'm working on, or at least working towards. To have our own self build we can all call home would be amazing and if we can make some memories building it well that's even better. Our plan is to snag the house we are living in and sell up by the end of the year, whilst this is happening we will be designing and obtaining planning for our plot, a bungalow that we bought last January for 170k at auction which is currently being rented out. It sits on some nice land about 1000 m2, a triangle shaped plot that is slightly sloping, its north facing with some potential views and is in prime close to centre of town position. It sits next to some green land giving a nice secluded feel about it and hop over the fence and you in some dense woodland. We hope to gain planning for a replacement dwelling by xmas and then move up their January ready to put a spade in the ground in April. Our hopes are to borrow £280k, that's £200k for the build, £40k to pay of the mortgage on the plot and £35k contingency. Ideally we want to build as big as possible but will be limited by budget. We need a 4 bed property with open plan living space, evening living room, multifunction room, bathroom, ensuite, d/s w.c, garage, workshop and a room to fit a small hair salon in. Using my skills I will be project managing, and carrying out as much as possible. I am seriously considering building in ICF with Nudura being the front runner, The fact I will be able to build the structure myself is a huge plus to me and potentially a great cost saver, the energy efficiency it will bring along with the soundproofing and sturdiness all sit well with us as a family. I am loving the way that the 1st fix and dry lineing can be installed and think it will make ease of a laborious job so I am looking forward to enrolling on a few courses in the next month of so, I also have a mate who started a concrete company last year and has the only pump and boom in the local area so I'm expecting some mates rates on the pour! Our wish list also includes a smart home using Loxone or Niko, high quality aluminium windows & some solar panels with an electrical battery pack system and a zinc looking roof or similar style, again it depends on cost but it would be great if it will all squeeze into 200k. One things for sure, I know we have our work cut out for 2 years but I know it will be worth every late evening, every cut and ache. Hopefully with some expert guidance from this forum we can make this dream come true and my kids can learn from their mum and dad how you build a future for your family. Thanks in advance Edd & Phillipa.1 point

-

Wow - your photo is almost identical to the mess we exposed today, condensation on the lower side of the OSB with soaked insulation. We have exposed even more of the area now. The middle section is the problem area. It has been a long day and we have just finished clearing up the mess (that pumped in insulation takes up alot more volume when it is pulled out!). We have looked back at all the build photos and the construction drawings for the upstands for the roof light. Its a bit of a puzzle but we are hypothesising that the water is leaking in through a mastic seal onto the frame of the rooflight (which sits under the glass). It is then leaking through a screw hole into the upstand (timber) (the frame was fixed into the upstand with vertical screws), travelling down to the bottom of the upstand where it joins the roof joists and then spreading both above and below the vapour membrane (the drips are coming from below the membrane, but the insulation within the membrane is soaked also. Of course there could be a leak in the roof material somewhere but that theory is not so obvious given where the water is being found and the lower roof deck being dry. Tomorrow and Saturday are supposed to be dry (no rain hopefully) so we plan to get some water up there and selectively test the various areas. I have messaged both companies inviting them to be present. I'll video the tests so we have some evidence because fixing this is going to cost someone some money. Thanks for all the advice, and supportive messages today. It is good to know you are all there.....1 point

-

Really sorry to hear this, let me know if I can help out in any way. I have to take my hat off to MBC here, they were equally helpful when I had the render issue - sending Brendan to site for half a day to work with the contractor to get to the root of the issue two plus years after the house was built.1 point

-

I would extend the pipe up above the WC and fit the AAV there. There is a risk of sucking the water out of the basin trap when you flush the WC.1 point

-

Exactly this. Took us nearly a year from start to finish. Two rooms were affected. In our case, it was due to poor sealing between the roofing membrane and the outlets through the parapet wall. Another one had started failing when inspected, so we insisted on all five being replaced. The roofer agreed to rectify, and fixed the membrane fairly promptly. Unfortunately, they then insisted on putting the rest through their insurer (even though the total costs were less than £2k from memory), which turned into a nightmare. Their attitude was so poor that if I hadn't had several million things on my plate I'd have sued them for every incidental cost possible, but in the end I decided the stress wasn't worth it and settled for the actual paid out costs. @Weebles, feel free to PM me if you want to talk about what happened and how we handled.1 point

-

I bought a £250 touring caravan (even came with an awning!) for exactly the purpose you describe. During the initial stages it's been really useful. I've been able to get out of the rain, make coffee, eat lunch etc. The awning has been useful for site meetings and the like because I put a large table in there so we can look at plans. I have a separate toilet that has a clean and empty contract on site now that there's a small team of professionals working on site, but they're using the caravan for making drinks and keeping out of the heavy rain. Once the team gets larger (during the SIPS erection) I will have to get a welfare pod for a couple of weeks simply to have sufficient space. All in all, it was £250 well spent even if I get none of it back. (and I expect to get a lot of it back even if I weigh in the aluminum from it, sell the fittings and build a trailer for taking my Lotus to the track from the chassis!)1 point

-

1 point

-

Anti-viral India Pale Ale! Not heard of that before or is it a contingency for when your GP confirms a Covid-19 diagnosis?0 points

-

If you want barking mad when it comes to employers and travel, then it's hard to beat the terms of my job when I was working in Scotland. The job spec was for me to be based in Scotland (West Freugh, near Stranraer) and work three days a week there and two days a week in London. The really daft thing is that my boss specified that the two days in London had to be Tuesday and Thursday, so I worked Monday in Scotland, drove up to Glasgow airport at ~05:00 Tuesday morning, got the shuttle to Heathrow, then a 45 min tube ride into central London. I did the reverse on Tuesday evening, getting back to Glasgow at ~08:30 and then driving home to Portpatrick (about an hour a half). Wednesday I'd be working at West Freugh all day, then back down to London on Thursday, etc I did this mad schedule for about 3 years until my boss in London was found naked in his office one Monday morning, having been locked in over the weekend. He was sectioned and diagnosed with some severe mental illness that meant he never came back to work. His replacement took one look at my travelling expenses (I'd managed to get a BA silver frequent flyer card, just on shuttle trips) and changed my work pattern so I worked in London on Thursdays and Fridays, with an overnight stay down there. Back then I was still eligible for overtime, and all the travelling time meant that I bought a new car every couple of years, just from expenses. Pretty knackering, though, all the same.0 points

-

Our builder provided a shed like building as a site van. Just a table in it and a porta loo round the back. No chairs, no heating etc When I commented that it wasn't very luxurious he said it was deliberate, didn't want people getting too comfortable in it or no work would get done when he's off site.0 points

This leaderboard is set to London/GMT+01:00

.jpg.c21f3ac78c9b7efd90cbdcb312744dc5.thumb.jpg.7adcad4c0e384f5ecd7d56b0618df6e5.jpg)