Leaderboard

Popular Content

Showing content with the highest reputation on 12/11/18 in all areas

-

besides @ProDave, I became a professional Heating engineer inside about 10 posts earlier today, so this should be simple. Next week - @Big Neil runs workshops for DIY nuclear reactor building3 points

-

IMO -- and it is a personal one -- our MBC passive raft with embedded UFH worked out cheaper than the equivalent traditional foundations + beam+block + insulation + UFH and screed and was a lot less hassle, but the caveat here is that doing a passive raft well is a skilled job and you risk being let down badly if the build crew aren't good at what they are doing -- in that everything has do be right for the pour and once started the crew is working against the clock. OK we also have a twinwall, but our supplier also does single-wall solutions so it can be done. We also had a complication with our slab because of our external skin and a potential thermal bridge that the SE designing the slab missed. See this post: But the final result looks good (sorry for the cloudy day). The engineering brick plinth wraps the outer EPS 300 and the outer stone skin sits on a foamglass layer to complete the thermal isolation of the slab. The entire house is heated by a single immersion heater element in what is known as a Willis heater, but that's a separate discussion.3 points

-

Booom. That's a win for the day - small maybe but i'm counting it. Needed that. Thanks to everyone. @joe90 i'll be on to you the next time i need a diagram for something. If in return anyone wants to know anything about kebab shops in Salford, the Lotus Elise between 1995 and 2001 or the pitfalls of women from the Stoke region... I'm your Man!3 points

-

A SunAmp with PCM58 outputs water at 58ºC, ideal for showers, baths and space heating. But it needs an input water temperature of about 65º or so to charge it. ASHPs struggle to generate water at 65ºC*. If they do so they become much less efficient and have to work hard, which causes them wear out, and to freeze-and-defrost cycle when its cold, especially when the outside temperature is around the freezing point for reasons to do with humidity. Not good. Not recommended. There is a SunAmp being developed with PCM34 (one person on here already has one). This outputs water at 34ºC and needs an input of perhaps 45ºC, which is easily generated by an ASHP. Water at 34ºC is OK for space heating but not warm enough for a shower but it can be used as a pre-heat for input to a boiler or heated tank (or indeed a SunAmp with PCM58). Does that help? PCM = phase-change material ASHP = air-source heat pump * there are special multi-stage ASHPs that can generate higher temperatures, but they are mechanically more complex and more expensive.2 points

-

Talking of magnets on sticks, I have several pencils here with neodymium magnets glued on the ends. Buy some pencils with erasers on the end, pull out the eraser and glue in a neodymium magnet around 6mm in diameter in the end with a bit of epoxy adhesive (Araldite or similar). The pencils work as normal around the site for marking out, but will hold screws or nails for driving, without risk of hitting your hand, will retrieve dropped nails and screws, and as I recently found, will very accurately find buried plasterboard screws. On the same topic, but related to cleaning up the site, I glued and screwed a 50 x 50 batten to the bottom of a broom handle and screwed a row of countersunk neodymium disk magnets to it, the ones that are around 20mm in diameter and intended for door catches. I placed a heavy duty plastic bag over the end, with its neck tied to the handle, and had one of the young labourers drag it over the site for an hour or two. He collected a decent pile of discarded nails, which were easy to remove from the magnets just by pulling the plastic bag inside out and pulling them off into a bucket. This probably saved one or two tyre punctures I suspect.2 points

-

2 points

-

A varied, and educational, long weekend laying down laminate flooring (one of the Uniclic range from Quick-Step) to help an acquaintance improve his house in London. The task was to lay about 3 rooms-worth full of Uniclic Laminate (28 packs), and moving a lot of furniture around - the killer reason for needing two people. My protagonist in laying the laminate, and moving all the furniture, is a detail-of-finish man, and at one stage was whittling away with a multitool for 20 minutes at a piece of laminate to match the outline of a curly 1930s doorpost; a demented boy-scout aiming for "Floor Laying, Advanced". Inevitably the worst happened. As at Beauvais Cathedral in 1284, the integrity of the structure did not quite measure up to the aspiration of the designer, and there was a sharp crack followed by some of the most creative language expressed in 750 years. It worked second time around. Having bought a car with the dimensions of a small barge (aka my new Skoda Superb Estate), this was the first opportunity to really test the performance over a long run. An MPG of 59 on the way down to London on a Thursday afternoon / teatime, and 64 mpg on the way back on a clear run, measured on a tested-and-accurate car-computer, will do for a car that can fit in a couple of coffins, and tow 2 tonnes. It is about 10-20% more economical than my old non-turbocharged Citroen BX from the mid-1990s, and has twice the power. Whilst on waiting time, I was able to binge-watch on Netflix the documentary The 9 episode 11hr documentary mini-series The Civil War, by Ken Burns. I never studied this historical period at school, and time to reflect provoked a few new insights for me - a bit of an eye-opener. I had not absorbed just how contemporaneous is the American Civil War. We (or at least I) think of it is a long time ago, but the war was only 5 years before my own Great-Grandfather was born. The last Civil War widow - Maudie Hopkins - only died in 2008. Yes - she was a 19 year-old who married a pensioner during the depression, on what looks like a classic security-for-care type arrangement, but the point stands. Sobering.1 point

-

Winter is coming, the White Walkers are on the way and, in the meantime, grey snow arrived in my house on Friday. Allow me to explain. It seems that much of the artificial snow that you see on film sets is, in fact, made from blown cellulose, particularly to cover outdoor areas without damaging flora and fauna. I now know this after having some cellulose insulation inadvertently blown into the garage on Friday when the insulation found a gap in a board and made its way through. No big deal, it was spotted early on and most was re-used, but it struck me that, apart from the colour, it looked a lot like freshly fallen snow. As you can probably guess from all this, the cellulose is being blown into the house at the moment. Gordon and Keith arrived on Friday morning - a pair of very nice Welsh guys who do all the cellulose blowing for MBC and other passive type house builders, a job that keeps them busy as evidenced by the fact that they've been working on my place all over the weekend and will still be there on Monday morning. The cellulose delivery arrived ahead of Gordon and Keith as a palletised delivery. Not surprising, given that there were 570 12kg bags. That's a lot of cellulose. At this stage, Gordon can't say whether it will be too little, too much, or Goldilocks cellulose and just right, as it's ordered in by MBC on his behalf. Here's the delivery with the curtain sides just being opened on the lorry: One of the pallets toppled off the forklift so the driver and I hauled the bags into the house and stacked them inside and I got a couple of photos of the packaging detail for anyone who's interested. The process of putting the cellulose in is pretty straightforward. The bales of compacted cellulose are fed into a machine housed in Gordon's van that fluffs the stuff up. This then blows it along a tube terminating in the metal tube that goes into a hole that's been cut in the airtight board. As he goes along and the sections are filled, numbered cork bungs are put into the holes. The holes are only temporarily sealed with the bungs in case the cellulose settles or takes a little while to work into all the nooks and crannies, but once Gordon's happy that this has been done, the cut out disc of airtight board is put back in place and taped up with airtight tape. Because the cellulose is blown in under pressure, it will find any gaps or holes and do a good impression of fake snow. The leakage in the photo above came into the garage via a loose board right at the top, above the cassette of the twin wall, after it forced the gap open. It looked like loads - the entire floor was covered, there was a fair bit on the walls and a nice pile below the leaky board. it looks like more, but this is barely about 1 bagful. The guys have worked their way around the house, downstairs and up, getting the bulk of the cellulose in and leaving the fiddly bits over to Monday morning when they should be finishing up. One job that absolutely had to be done ahead of the cellulose going in was a bit of first fix work for the brise soleil. The brise soleil is a set of vertically arranged horizontal timber fins. The timber fins are fixed to a steel framework that, in turn, is fixed to the face of the building, around the opening for the window in front of the stairs. There are 6 fixing plates, 3 each side, and these need something behind the board of the frame for the coach screws to bit into and spread the load once they penetrate the frame. Reasonably straightforward, unless the cellulose has already filled those cavities. So come Friday morning, my all-round handyman and builder, Drew, was in cutting holes into the building to pack out the fixing points with some sturdy pieces of timber. Everything was taped back up again and ready for the cellulose and, in a couple of weeks, the steel frame for the brise soleil. Also in on Friday were the flat roof guys, finishing the final part of the garage roof. This is the last part of the flat roof work and I'm glad that it's all finished. I have to admit that I completely underestimated the amount of work involved on the flat roof side of things, not least the parapets that were fiddly. As a result, I've spent a lot more on getting this done than I had estimated before my quote came in and it also edged up with the amount of carpentry work that had to be put in ready to receive the membrane. However, I haven't busted my contingency on it and costs are still comfortable. Here's a photo of the finished garage roof. Skipping back to the beginning of the week, I had my garage door installed on Monday and I'm very pleased with it. I find it hard to get excited by a garage door, but in so far as it functions well and looks quite nice, I'm pleased. The door is made by Ryterna and I dealt with Joe at Dorset Garage Doors Ltd, just up the road from the house in the next village. He is a really nice guy to deal with and his team were very nice, too, so I'd be happy to recommend them. They also offer Hormann doors, but the Ryterna came in at about £1k cheaper, so that was the one for me! Joe reckons the major difference is that the mechanism on the Hormann door is slightly smoother. Personally, I'm not at all fussed if the mechanism on my door makes a little more noise for the sake of £1k. The door itself is a sectional one and the exterior is powder coated in the ubiquitous RAL 7016 to match the windows. We've had a bit of a tidy up on site this week, as well. It was badly in need of it and I knew that I'd need the space in front of the house for the cellulose coming in and, once that's done, all the other deliveries for the internal workings of the house. There's plenty more tidying to be done, but we'll wait for the rain to stop for that. Speaking of rain, it was awful weather here last week, as it was for much of the country, and the storms lashed Dorset. I'm still getting some water ingress via the windows, but it's not the fault of the windows. I understand water ingress much better now having gone through so many different forms of it during the build. The current one is because the south southwest face of the building gets the brunt of the weather and the cladding isn't on yet. As a result, the blue paper membrane is saturated and the water seeps in around the edge of the window frame and the window opening and comes into the building. It's not a vast amount and will dry out quickly enough and I'm not stressing over it as my upstairs slate cladding starts going on Monday. My only concern here is that I need some first fix done for the motorised external roller blind that I'm having on the upstairs south window (this is the one with the worst of the water ingress) and my supplier was caught out by this. I've been telling him for a couple of months that his stuff needed to go on as first fix and before the cladding, but he decided that this wasn't the case and put things off. When he finally came down to measure up, he agreed that it did need to be done as first fix, but I don't think he will have his order from the factory before that wall is ready to be clad. I may have to do a bit of juggling, but it's really annoying when people don't listen to what you're saying because they think they know better, without even having looked properly. So tomorrow sees the site getting really busy again. The (pitched) roofers are back in to do the vertical slate cladding. The slate is the same stuff that's on the roof and will be riveted in. The only part of the upper storey that doesn't have the slate is the surrounding of the brise soleil window, which will be the Tier cladding. Also in is Nick and team who will be working on first fix for all the systems going in. Drew will be helping out with boarding and general carpentry work that needs doing so that equipment can be properly position up in the loft space and elsewhere, and I daresay the alarm system guy may be along at some point, too. My groundworker, Keith, is due in at some point next week and we're aiming to get Paul's pond dug out. This will be an ideal test to see just how well that clay of ours holds water with the winter rains coming in and it will, hopefully, confirm our thoughts that we don't need to line it. Judging by the moat around the house right now, we're feeling reasonably confident. More to follow next week.1 point

-

1 point

-

1 point

-

Panorama is quieter. I have the Abajo myself and I can vouch for the Panorama. If you are looking for a hob with 4 zones on induction the Novy product is one of the best I have found.1 point

-

No it works. What you need is for the vent to come down into the plinth void where you connect it to the recirc box in the plinth space. We have installed it.1 point

-

As a tip that may or may not be useful, a 22mm pipe bending spring fits neatly inside 25mm MDPE. Dropping one down (tied to a bit of string) to where you want a sharper bend, then heating the pipe evenly and gently with a hot air gun, then persuading it into a tight bend, works very well. You just have to hold the bend whilst the pipe cools down, when it will retain the set bend near-perfectly.1 point

-

That fits with what I'm observing with the Qontroller behaviour. When powered off and then on again I'm guessing it forgets about looking for a temperature drop, assumes the unit needs a warm start (assuming the temperature is above the cold start threshold) and therefore closes the contactor to allow the unit to charge. This explains why our unit reliably goes into charge acceptance mode when turned off and then back on again. All we need now is a firmware mod that automatically emulates the reset from turning the power off then on again and we'll be sorted.1 point

-

Thanks both. I found a splendid local sawmill and they are sorting it out for me - delivery by the end of the week.1 point

-

We have an Isoquick PH insulated raft foundation. We have a single stud wall, but the 'stud' is a timber I-beam. The I-beam sole plate sits on the edge of the concrete and all the Icynene insulation is within the I-beams. There is 15mm OSB3 racking on the outside of the I-beams with external rockwool insulation on the racking board which joins with the EPS upstand.1 point

-

The insulated slab is Isoquick and they were the company who installed ours, which was the first in UK back in 2010.1 point

-

1 point

-

It will be an improvement, and only trying it will tell. I don't buy the "priority" thing. Anything else drawing cold water will use up some of the available flow.1 point

-

I fitted a 300 litre UVC. You need a larger one as you are storing the water a bit less hot, and you need one with the high capacity heat input coil. Mine was in the region of £850 They are quite tall, about 1.8 metres, so I doubt you will get a tank and a washing machine in that cupboard, which may be a good argument to swing it in favour of a sun amp for your application. But both the washer, and the sun amp are heavy, so whichever goes on top will need a substantial shelf to sit on.1 point

-

15x the diameter increasing to 25x in very cold weather.1 point

-

If you go for the simplest solution (like I have) ASHP driving UFH directly, and heating an UVC to 48 degrees for DHW: Assume a COP of 3 when heating the UFH so that's 2200KWh of electricity @15p per KWH that's £330 per year for space heating. Assume COP of 2 when heating DHW so that's 1150KWh of electricity @15p per KWh that's £172.50 per year for hot water. The real figures will be cheaper than that, as most of the time the COP figures should be better than that, and you will probably find a cheaper electricity tariff than we can get up here (extra 2p distribution surcharge) The fact you can halve (or better) the DHW costs by using a simple unvented cylinder is what swung me away from the Sun Amp solution. Yes the UVC will have a higher standing heat loss than the sun amp, but that heat loss is more than made up by the saving in heating cost. Plus for half the year that "loss" is just helping to heat the house. The sun amp solution makes sense if you have a lot of solar PV so are always looking to use up surplus PV generation, are short of space, or the particulars of the install mean the standing loss from a conventional tank becomes an overheating nuisance.1 point

-

Just to note for others that there is an option with UniFi for it to update firmware itself without intervention. But if I recall correctly that's not turned on by default (might be wrong).1 point

-

I did exactly that. I was more worried that the BT hub having wifi enabled might restrict /penalise AP access but guess not. Renamed 'do not use wifi' which means tenants will try of course. :-)))) Just gone around the house with my phone connected and seen it 'switch' as I roam - so happy!!!1 point

-

Sounds like BT have limited the options, probably to simplify their online support calls. The option you were looking for was to disable the WiFI network. The only disadvantage of having your BT modem transmitting an alternative WiFi network is that those that attache to it wont "roam" to the other APs. Some Wifi routers allow you to make the SSID "invisible", so people won't see it as an option. Look for that setting. Or alternatively name the Wifi network transmitted by your BT modem as "Do Not Use" or similar. Or simply just don't give them a password for it. So long as this other BT Wifi Network is set to to automatically choose its frequency it should not interfere with your Unifi WiFi network.1 point

-

Nick will help with generic questions on here I’m sure but system specification is part of his day job ?1 point

-

Perhaps go for simplicity. A PCM58 SunAmp charged by E10 electricity. Much less capital cost. Probably only slightly higher running costs. Fewer things to go wrong. Simpler all around. Less hassle. Small and compact too. You could ask @Nickfromwales to specify the system. He knows a lot.1 point

-

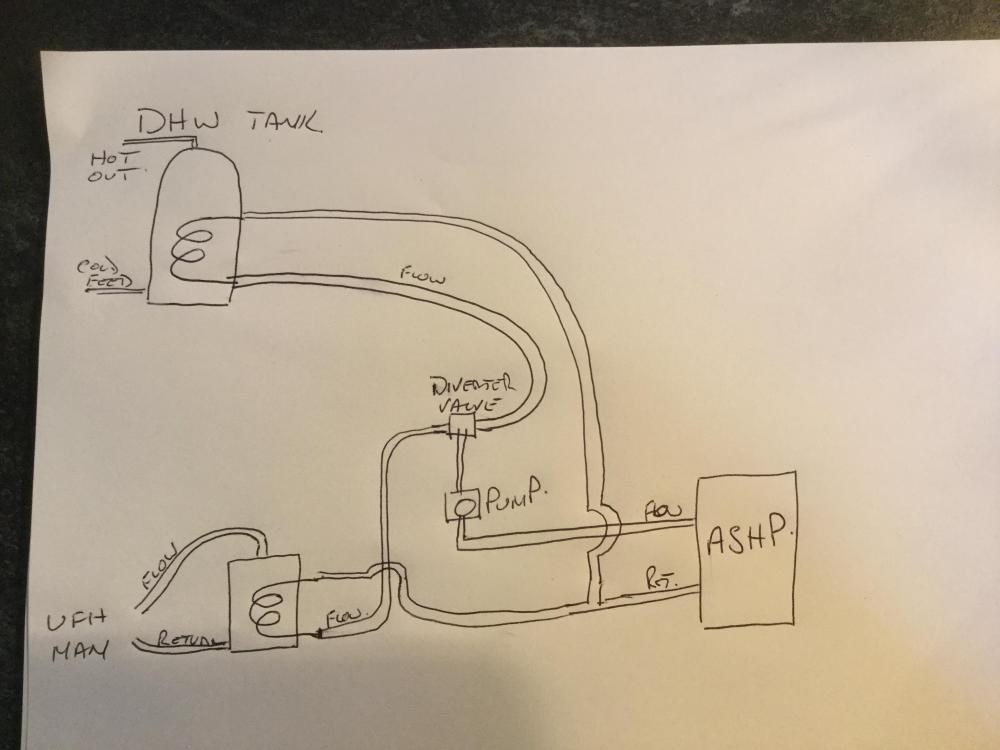

ahhh, so the coil looking thingey going into the DWH tank is a loop of pipe aswell.. good stuff. So You can supplement that with a heating element taking excess PV generation (or simply straight from the mains) if required to be hotter. So now i'm a fully qualified heating engineer who wants me to do their whole installation gratis??1 point

-

Yes, the things clearly work so obviously it doesn't. But it must take some cleverness in the design to make sure. I imagine that's at least part of what their secret sauce is about. Yes, the last bit of energy stored is as sensible heat warming up the liquid above the melting point. Yes, again. I imagine it goes over a fairly narrow range of temperatures but you'll need an extra few degrees (say an extra 7 °C → 65 °C) to get the heat flow in to work quickly enough to be useful. If left on its own it'll likely just sit at 58 °C. As heat is lost (slowly) through the insulating panels and pipework, a small amount of material will solidify releasing replacement heat to keep the temperature stable.1 point

-

So am I. I can confirm that the unit behaved the same this morning as yesterday. Turning the Qontroller off and then on again reset it and switched the contactor on, ready to receive any charge from excess PV that might be available (looks doubtful so far today - it's cloudy and the output isn't yet covering the house base load).1 point

-

1 point

-

No reason at all, ours is downstairs in the utility room and easy to access.1 point

-

I fitted a bit of OSB behind the plasterboard in the ceiling, complete with a cable run ready to hang and connect up a cooker hood above the hob. I can't see any need to actually buy and fit one, as the MVHR does a fantastic job of both removing cooking smells and preventing condensation in the kitchen. Makes me very thankful that I didn't spend a lot of money on buying and fitting an extractor hood, as the wasted cost of just putting in the bit of timber and terminated cable is negligible.1 point

-

It might be "correct" but I always tend to over engineer things and I just like the security of the hanger folded over the top of the wall plate and a few more nails to keep it there.1 point

-

No, none at all. The unit still delivers hot water in exactly the same way when powered off or on, as the Qontroller has no way of knowing that hot water is being drawn off, even when powered on, other than by monitoring three temperatures within the heat cell, near the bottom, centre and top of it.1 point

-

1 point

-

The PCM doesn't start to melt until 58oC or above. They accept 65oC as the chosen injection temp when using a wet external source for heat input. You can go as high as 70-75oC if its delivered in a stable flow, but the advice ( requirement ) is that it never gets near 85oC. An ASHP, for eg, chucking out 55oC is totally useless with a PCM58 unit as it will not melt it. Heat will be absorbed, but the PCM will not phase change until 58oC or above is achieved.1 point

-

No, I'd kept it powered up since it was installed, with the exception that I turned off briefly when I added the neon indicator to show when the charge acceptance relay is on or off.. It only occurred to me to turn it off and on again as an experiment this morning. I have a time switch sorted out now, so will turn it off for a minute and then back on gain every morning and see what sort of difference this makes to utilisation of PV.1 point

-

Slap your hampton on it when the red light's showing and report back!1 point

-

Many thanks @Square Feet you would be most welcome so if in the area make contact, the kettle(hot water tap) is always on?1 point

-

Just make sure before you nail them home you check and check and check again to make sure they are in the correct position. Them twist nails are easy to hammer in but a real pain in the arse to take out. And just nail every hole.1 point

-

0 points

-

maybe if they didn,t make the hangers out of old bean cans they wouldn,t need as many fixings0 points

This leaderboard is set to London/GMT+01:00