Leaderboard

Popular Content

Showing content with the highest reputation on 03/13/24 in all areas

-

Right, so I was able to test to 6 bar using the pump I had. I now have two sealed manifolds ready. I guess the next test will be when I connect them up to the mains in a few months time. Thank you to everyone for your input. PS, I am a convert to the liquid sealant which worked first time on the joint I was having problems with. (High-Tech 35 S 77 PTFE Sealant for Gas and Liquid WRA compliant from my local (non-chain) plumbers merchant)3 points

-

Where in Devon are you? I am in Devon and just done a build with ufh, ASHP, and cylinder and can provide some input. I looked at mvhr but decided against it. Maybe post some drawings up and we can all look at the best way to fit it in. Also I have some ufh pipe and a manifold cabinet I am looking to get rid of if you need some2 points

-

Yes, 2 x 6mm glass panes and lamination 1.5mm (easiest way to explain), 13.5mm overall - that glass unit is laminated.2 points

-

we created all the penetrations from the plant room before the first air test. A 100mm duct for power (in and out plus PV) and 50mm duct for data/control wires (BT fibre in, CAT6 out (plus spare), ASHP control). These go into an external kiosk. Which has an external distribution board and a POE network switch. What this means is that all external wiring and external data requirements are wired with no additional penetrations plus if we forget any we can add them at a later date. Air tight grommets used to seal ducts. And they will be filled with air tight foam once second fix is complete. They were temp sealed for our first air test (0.42 ACH)1 point

-

The best strategy is to try and design the penetrations out as far as possible. I ducted as much as I could under the slab into the plant room so all my electrical/data cables and water into the building is through ducts. I included a couple of extra ducts to both ends of the house to make adding something else easy although I was mostly using up some leftover ducting. Where I had to come through a wall I also used ducting suitable for the size of the cable then sealed up both ends with Pro Clima Roflex duct seals and tape. I used an intumescent foam to seal the ducts. Pro Clima also do a butyl seal tape that I found to be a great product for harder areas as you can form it to shape. I also sealed all the ducts using Filoseal. https://insulationmerchant.com/collections/pro-clima https://www.filoform.co.uk/filoseal-re-enterable-duct-sealing-system1 point

-

Look in to the details. For example, my economy 7 night rate is basically the same as my PV export rate (15p ISH). I used to run a diverter to heat water, but it doesn't make economic sense. I instead run the heat pump off peak, with a COP of 2, it's twice as cost effective as a heating with solar diverter. And in the summer, from 7am-9am, I could be generating 1kW or more from my PV, making it even cheaper. Also, there's a limit to what you can store, and use. Yes, you could put a massive tank in and heat it to 70c. In the summer that just means additional overheating woes. Finally, I don't see he point in two immersion heaters (just lower) and a legionella cycle is NOT needed. ,1 point

-

You can make your own. I would not like to guarantee they would be quite as good as the proprietary ones, but I have had some success. Basically EPDM, as many holes as you need, and air-tightness tape around the perimeter.1 point

-

I too use a dehumidifier rather than a tumble drier in a small bathroom and it works well.1 point

-

There is also “farmers lung” breathing in mold from hay etc leading to fibrosis and is not curable.1 point

-

1 point

-

Not much info there. About all I did glean from that is is is a split unit. No idea of power, price etc.1 point

-

Maybe because we have very poor quality control in the building industry. It is also populated with arseholes.1 point

-

I agree on the solar panels mainly because I know of two house fires caused by them one of which was a new house. They are also ugly imo. Flat roofs are fine if done correctly using modern materials and then maintained. It wasn’t done ‘in the old days’ so much because the lack of suitable roofing materials. Materials science has come a long way over the last few decades. What that house is starting to show is everything I don’t like about wood cladding.1 point

-

Also called bypass mode. You switch off the network routing capability of the Starlink router so all it’s doing is powering the dish. You can then use a third party router of your choice for the extra functionality you might need. In my case it was to use my mesh networking system.1 point

-

I use a dehumidifier to dry washing in a small utility with no window. Normally I don't have the extractor on. The cable through the wall plugged into a socket the other side is fine, especially if you don't need the dehumidifier elsewhere.1 point

-

In a closed space , the discarded air needs to be replaced through an open door or under it if there is enough gap. But a corrugated duct and restrictions such as bends and a small outlet are likeliest. Has it ever worked properly? Original question.. Yes you can plug it in the adjacent room.1 point

-

First check the fan is extracting (enough suck to hold a sheet of paper up to the ceiling when on) If not it is usually the poorly installed cheap nasty flexible ducting that is full of condensation and hence blocked.1 point

-

If your fans not doing to the job and you need to dehumidifier. Your fan is rubbish and needs to be replaced. Cheap ones are cheap for a reason...our last house the builder installed cheap no brand intermittent extract fan and after the first year it would not hold a piece toilet roll in place running at full speed. My first port of call would be the extract fan. Greenwood CV2GIP are ace through wall or ducted.1 point

-

The dehumidifier you use also uses electricity - and doesn't recover any heat. I'm wincing when I write this..... have you tried leaving the door open after ablution? Keep the heat (for a bit) and costs you nowt.1 point

-

You can get heat recovery extractors. Failing that you could put a fused spur in the bathroom as long as it's outside of zones and protected by RCD - I'm not a spark, so you would need to check exact regs1 point

-

Ordered the kit, worth a punt and I can return if not happy after X amount of days, not got too much to lose, will report back.1 point

-

For the renovation yes, or extension. Doing UFH correctly on a renovation so you get really low temps isn't easy and if you do the rest of the system flows at a different temp, so it a fudge, your heat source efficiency doesn't gain. Fan coils, set your flow temp at 35, your heating is sorted, set a heat pump at 12 to 15 and the cooling is sorted also. UFH will always include an additional chunk of downwards heat loss, that you don't get with radiators or fan coils. Example I have a floor U value of 0.09, so pretty good and the floor sits at around 23 to 24 during the heating season, with a room temp of 20, my downward heat loss automatically increases by 15 to 20% because of it.1 point

-

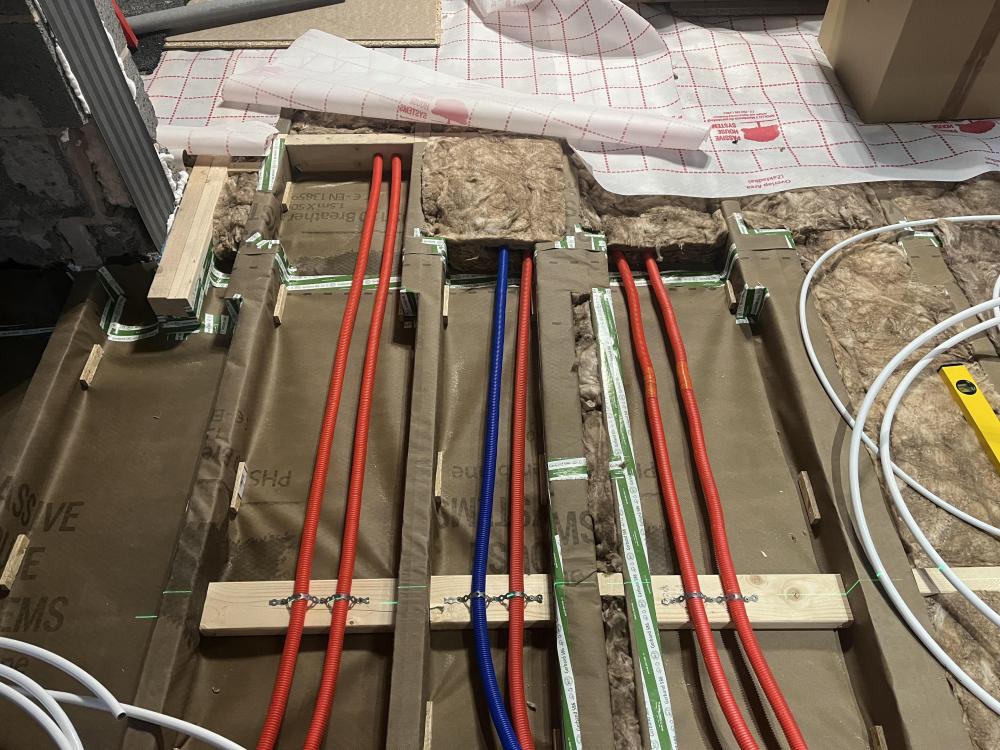

Everyone has different ideas, I just refuse to go under walls (for any reason), where a mad joiner can drill holes straight into a pipe by not being careful. Also hate small loops as this ends up driving a buffer, bigger manifold for a needless loop, manifold actuators etc.. Trial copy of loopcad will tell you if you are likely to overheat any areas, so any remedial actions can be completed before you install.1 point

-

i respectfully disagree 😉. The pipes won't need to go through the WC and its doorway, if they are coming up out of the screed into a timber stud wall / recessed cabinet, they can go 'south' into the kitchen (maybe 3 circuits) and spread out, with one circuit going 'north' into WC. This way the heat requirement of the WC is separate to the main living areas and it won't over heat in the WC.1 point

-

I would choose option 1. IMO better to have access to the manifold in the plant room than having to scrabble around in a void. Easier to isolate just one pipe (assuming you have isolators on the manifold).1 point

-

From my finger in the air calcs, if UFH pipe spacing is 150mm in the screed (usual for an ASHP), you are looking about 6.7 linear metres of pipe per m2. 56m2 will be 372 linear metre of pipe at least. So you are looking at 4 circuits (being <100m), maybe 5 depending on zoning. As @SteamyTea noted all these circuits can be in one zone and controlled by one thermostat, which may be apt as its open plan on the ground floor, but i would probably go for a separate zone and circuit in the WC / Utility.1 point

-

1 point

-

However with plastic, long flowing bends (where possible) and fittings only at the end)much less friction than copper with many 90’ bends and t junctions. I once replaced a tortuous route in copper to a customers shower that was pathetic with a plan to include a pump, when the pipe was replaced the pump was not required as the pressure/flow was miles better (and hep2o inserts are slim stainless not chunky plastic).1 point

-

1 point

-

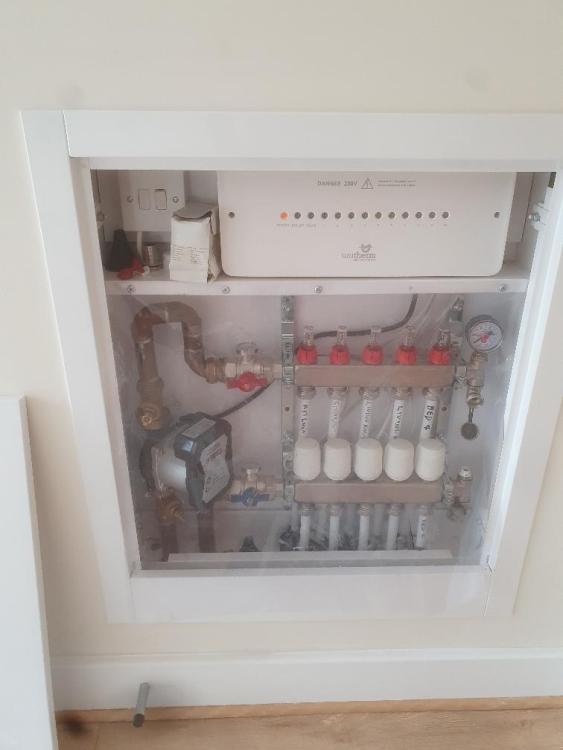

I fitted the UFH manifold in my bathroom into a 100mm space. I had to turn the pump in it's side and remove the knob from the blending valve. You can usually borrow 50mm space behind the kitchen cabinets as well.1 point

-

i would stay you best bet is to out the UFH stuff in a recessed cabinet between the WC and kitchen about here, opening into the WC. However this timber stud work wall has to be thicker to accommodate it so you will loose some floor area https://www.wundatrade.co.uk/shop/home/underfloor-heating-manifolds-and-pump-sets/underfloor-heating-manifolds/medium-recessed-waterproof-manifold-cabinet/1 point

-

MLCP is a good compromise, holds it's shape and doesn't rely so much on the outer layer to form the connection. I think if I was to go again then I'd go MLCP rather than HEP tbh. Keeping hep scratch free over the duration of 'My' build has been hard work.1 point

-

1 point

-

This may need a bit of clarification. There are Zones and Circuits. 1 circuit can have many zones. Basically the zones are connected together in parallel and act as 1. Different pipe spacing can change the amount of power that is delivered to different rooms. That is a good point, if not built yet then it is the time to review the thermal losses.1 point

-

My day rate electricity is currently 37p/kWh (and getting cheaper by the quarter). So £8500 / 0.37p/kWh = ~23 MWh That is about double my area. I use around 3.3 MWh/year, and I have no technology at all, just insulation and airtightness. So if you use double that, and if you fit an ASHP you will use a lot less, that is 3.5 years worth of electricity, and nearly £500 a year on lost interest. PV on its own is probably worth while, as long as you do not get a silly price to install it and 3.5 kWp is a usable amount. You can probably use 2/3rd of that, which amounts to 2.3 MWh/year. Leave the batteries until a later date. A 5 kW monoblock ASHP will probably do you, as will a 200 litre cylinder. All you need, keep it simple.1 point

-

Are you at planning stage or have you got build regs drawings done yet? Layouts would really help I presume you are only having ufh on ground floor and rads on first? You need more than one zone on ground floor and you are limited that ufh circuits should be less that 100m long. Sounds like you will have 3-4 pipe circuits and need to find space for 4 circuit manifold, pump, and control unit. This can be placed in a timber stud wall in a recessed cabinet if space is a premium. This is what we did. As for cylinder you can get combined cylinder and buffer tank in one unit. We used world heat pre plumbed. Have a look at a 200-250 ltr tank for indicative size.1 point

-

Try https://www.neutralenergysolutions.co.uk/ Also there is these guys around for solar / storage. https://www.365energyltd.com/ Also unitherm have a base in Exeter and can provide LG kit and parts easily. https://www.unitherm.co.uk/1 point

-

Some things, DHW, Space Heating and MVHR are in reality, separate, so should be treated as such. DHW can be dealt with in 2 ways. Heated and stored for later usage, instantaneously heated when needed. MVHR is just ventilation, it saves you opening the windows. The confusion starts when the heat source for DHW and the space heating are the same unit. We have got used to that with combi gas boilers, but they work in the same way as a heat pump, but just at a different power level. The word power is important there, it is not temperature or energy. Basically, you put water in one side, hotter water comes out the other which you then use to heat the house or a cylinder for your hot water (or use directly). So the only controls you need is a diverter valve to push the water into either the heating system or the DHW system. The problem comes because you want the heating system at a lower temperature (generally) than the DHW temperature. That is set up by the boiler/heatpump control system. It may seem complicated when people start talking about different temperatures and flow rates, weather compensation or load compensation, but all that really means is that the maximum power point is not always the same as the maximum efficiency point (like a car, too low in the rev band and it will still die, too high up the rev band and it will use a lot of fuel). Batteries and PV are a bit more complicated as they are more to do with your usage pattern and the amount of generation on the day in question. There is a lot being made of how great batteries are, but they are still an expensive form of getting electricity to power something. Just because the energy used charge them may be cheap, or seemingly free if from your own PV, there is still a cost because they do not last forever, and if you don't use most of your stored energy, then the next charging opportunity is missed. Sometimes this energy can be diverted to the DHW, but if that is already 'full' then it gets exported. Initially I would treat each part individually and monitor what is happening (well worth spending £100 on a decent logger), then after a year or two, start to tweak the systems, which may involve buying some extra kit, usually more sophisticated controllers. Where you are near Exmouth has a similar climate to where I am, warm, lots of rain, burst of powerful sunshine, and always windy. You cannot control those elements. So. Set up MVHR and let it do what it is designed to do, change the air and recover some of the energy in it. Set up the heating system to deliver at the lowest temperature and flows possible i.e. weather compensation. Set up a diverter on the PV system to charge batteries first, then divert to the DHW cylinder. You can try running heavier loads like a washing machine around noon, but these days washing machines are very energy efficient, I think mine uses about 300 Wh for a load, 10p worth of the most expensive day rate electricity that EDF can supply me. Make sure you don't have parasitic loads draining your system, I used to use an old desktop PC to monitor my energy usage, it drew 300 W of power constantly. I now use a Raspberry Pi that uses so little that it is basically unmeasurable. Buy the lowest power/highest efficiency fridges and freezer you can get, they really do make a difference. @Radian (not seen him around for a bit) bought a new fridge that uses less energy than my much smaller one, and mine only uses 5W. If you really want to save energy, get a more economical car. My current car uses 700 Wh/mile (65 MPG) but an EV can easily halve that. And monitor and analysis your usage.1 point

-

1 point

-

I’m currently using a combination of 12mm and 16mm MLCP in a retrofit scenario. 16mm to cold outlets (from manifold) 16mm for rad flow/return (manifold) 12mm for DHW & DRC so far seems robust and does indeed have little ‘memory’ so holds a shape. HOWEVER I mistakenly thought it would pull through conduit. More than one sharp 90 and no chance. I’ve actually kinked it twice trying to thread a big loop so give yourself lots of working space to ‘lay it’. I’ve spent about £150 in fittings which covers approx: 10x 12mm to 3/4 euro ones 10x 12mm to 15mm copper adaptor 30x(ish) 16mm to 3/4 eurocones 40x(ish) 16mm to 15mm copper adaptor 100m of 16mm and 80m of 12mm cost <£100. A steal compared to JG or Hep. Though despite measuring and thinking I’ll do the whole house with 100m, three rads have eaten the whole reel. can see me using another 200m on top easy!1 point

-

Because 32 is absolutely rubbish, it does not allow for a flow of water and bubbles or air, a larger bore pipe allows water to sit at the bottom and air to pass over the top. 32 really needs doing away with.1 point

-

Just as a tip, don't wrap the thread with ptfe, you don't need it and it might make you think you've tightened the compression fitting enough when you haven't. You only need to wrap the olive. Personally I hardly ever use PTFE tape any more preferring to use a jointing compound.1 point

-

Someone screwed the pooch on this one. Company have gone back to the glass manufacturer and told them to redo the glass to the correct specifications. I think someone is in trouble as that’s not going to be cheap. i’m so glad I noticed as that could’ve been a massive safety issue. lesson learnt to never trust the manufacturer sticker!!1 point

-

Welcome, I am probably one of the few people with a similar sized house on the forum. I think this is quite a general discussion and if you want advice on anything specific such as ICF then it is probably best to create a specific post referencing that. This kind of intro post is likely to become quite rambling. To some extent you are really building three houses which makes things more manageable, but I would not underestimate the costs and time require to maintain such a large building. I would maybe try and decide this within the family before going ahead. There is always something breaking, not working as expected, needing replaced etc. it takes up a lot of time and money. Think of the maintenance on 10 standard three bed houses. How will it be owned, costs apportioned etc. My house is around 1000sq metres including the integral garage. It cost around £2m to build 8-6 years ago. We just finished a smaller house for my parents last year and it cost around twice as much per square metre. I would be quite concerned that your budget is low and already seems tight. In my experience I got constant questions from the architect and builder over the course of construction. The questions always went along the lines of we can do A that costs X or B that costs 2X. 9/10 B was the right decision. It would get very stressful if the budget was tight.1 point

-

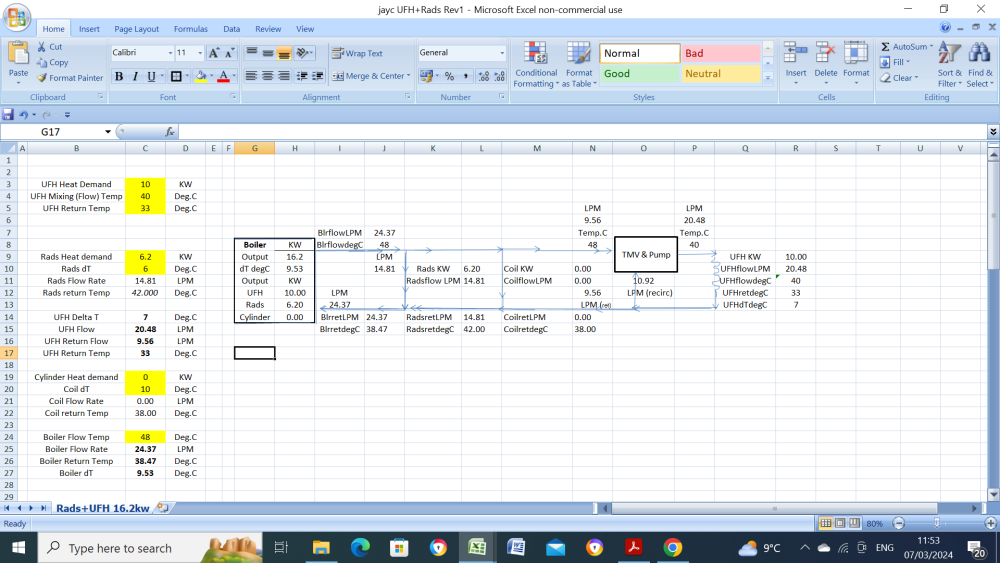

This may (or may not) be of some help of seeing the "total" picture, I configured this when my daughter was installing UFH and just tailored it to your UFH + rad heating demands, I'm not sure when you say spec'd for DT25 if you mean rads designed as "T25" rads?, if so they will give a rad output of 40.6% of T50 sized rads and would require a oversizing factor of X2.46. say 2.5. I'm also assuming that the required boiler flow temperature required is 48C and the UFH required manifold temp is 40C. I didn't include cylinder heating.1 point

-

Hi, Hoping someone can help us out here with some advice/expertise! We are at such a loss of what needs to be done to fix this problem, we've been told by some people that we need to remove the beads and replace them and then replaster over and paint the whole house and some have told us the whole house needs the render removed and restarted (obviously very expensive!). Our house is about eight years old (small developer, no NHBC certificate, just an architects certificate that doesn't help us) but we have significant damage to the render. The builders are refusing to help and have told us it isn't their issue. We obviously have the rust issue but also the paintwork is damaged as well. Is anyone able to offer any advice about what needs to be done? When we bought the house four years ago the damage has been painted over so this wasn't an expense we were expecting to have to pay out for! We'd be extremely grateful, thank you so much for reading.0 points

-

0 points

-

0 points

-

0 points