Leaderboard

Popular Content

Showing content with the highest reputation on 09/15/23 in all areas

-

Row of gabion baskets. Dig trench, bit of stone, run the wacker up and down, face up with the stone you were going to use. Natural looking, flexible so no cracking if you get any movement. Fast, and not a lot of skill needed. Sounds perfect.3 points

-

You need to get this checked by an engineer. Ceiling joists tie the rafters together and prevent roof spread. There are ways round this (the purlins may be sufficient) but potentially as sketched this is not a suitable arrangement. .... ruddy architects.2 points

-

Yes I would stick with 32 in the stud wall but try to make the slope greater so less chance of gunk sticking2 points

-

Wall hung frames put most of the load into the floor, keeping a low pan and high frame attachment points onto the wall also reduces the lateral load imposed. On your wall, if you sit down heavily you may/will see some wall deflection but if is doable. Add a couple of stiff timbers top to bottom where the mountings are and the wall will be fine2 points

-

... will be available from December and is claimed will be installed for free (after BUS) if you do not need new rads or a cylinder upgrade. Presumably since it is made in NI it is a spinout of the RED acquisition. Their own web site has not been updated yet but there is this and more or less identical coverage in many other publications.1 point

-

Always off the hard mains normally, but down to preference (and understanding why the choice is made) tbh.1 point

-

Which is why advice provided during pre-app is caveated that it’s the informal opinion of the officer and does not represent the decision of the Council. I’ve never liked it.1 point

-

Drill closer to the front of the stud and clad with 15mm OSB for fixings stuff if a problem, but if you want to run 32 from basin to stack 1m away then 32 will be fine, just if you set the same two basins alongside each other and put 40 to one you can actually see the difference. Don’t ask me why, but I think soap suds killing the air break plays a big part. I mostly apply the ‘one up’ rule regardless, but you can have a day off and fit 32 if it s actually that close to the stack.1 point

-

Holes in the centre of timber has much less damaging effect than off one side, as I said I would go with 32 with a greater slope (if possible).1 point

-

You should have all the ‘white goods’ etc straight off the mains, then a NRV and then the accumulator > bathing. The outside taps should be off the mains before it enters the building.1 point

-

@SimonD I started in the same place - wife demanding, we be able to run 3 showers at once, because it would be required. The system I installed could just do that. Only time 3 showers have run at once is when I did the test. Since then only one shower at time, used, irrespective of how many people are in the house.1 point

-

1 point

-

I would humbly suggest that you employ a water engineer that sits you down to have a proper think about the real world water demands and whether all the outlets are actually going to be used at once 😉 I know it's not what many want to hear on BH but the reality is that when you sit down to work out the real patterns in a house the concurrent demands are less than most people think. You've also got the pesky building regs and resultant design guidelines suggesting less water use per person. I know I've said this before but when I designed my system I started off in the same trap. I thought I needed to supply 3 bathrooms concurrently blah blah.However, instead of looking at upgrading the mains supply and accumulator, hot water recirculation and so forth, I looked instead and reducing overall flow rates while retaining pressure so even with less than 30l/min peak flow I can supply all bathrooms and whatever outlets without anyone complaining - although my only complaint is that I feel the kitchen tap (which comes restricted to 6l/min as standard) doesn't fill my pots quite quickly enough when I'm in a hurry. Our current main drench shower is regulated to 6l/min and it works really well. This approach was in part inspired by comments made by @markocosic to a thread I started a while ago about a similar question. Just fundamentally changed how I looked at the problem. You can also use 10mm pipe for toilets, basins, dishwasher, washing machine which also reduces impact on flow.1 point

-

1 point

-

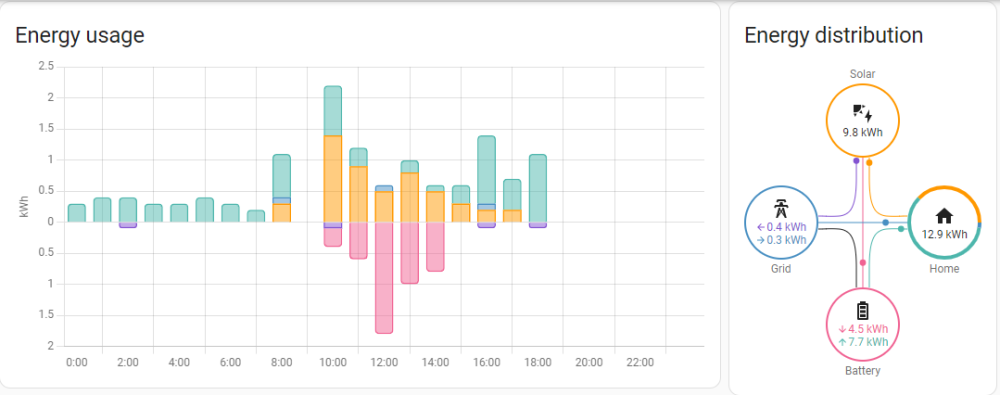

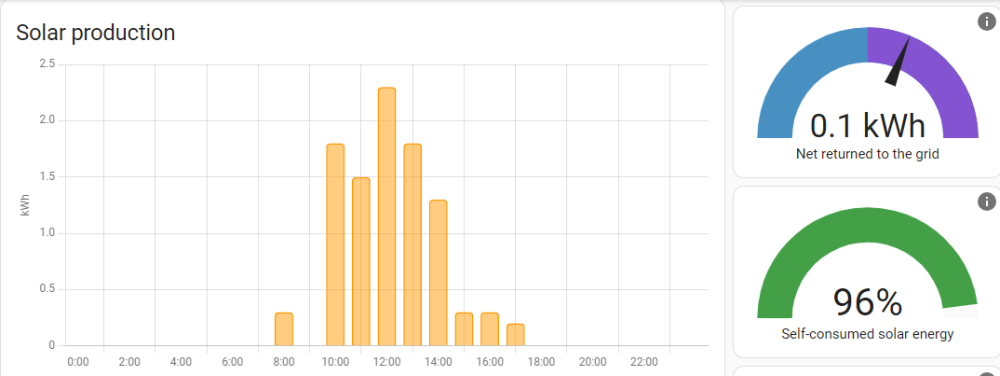

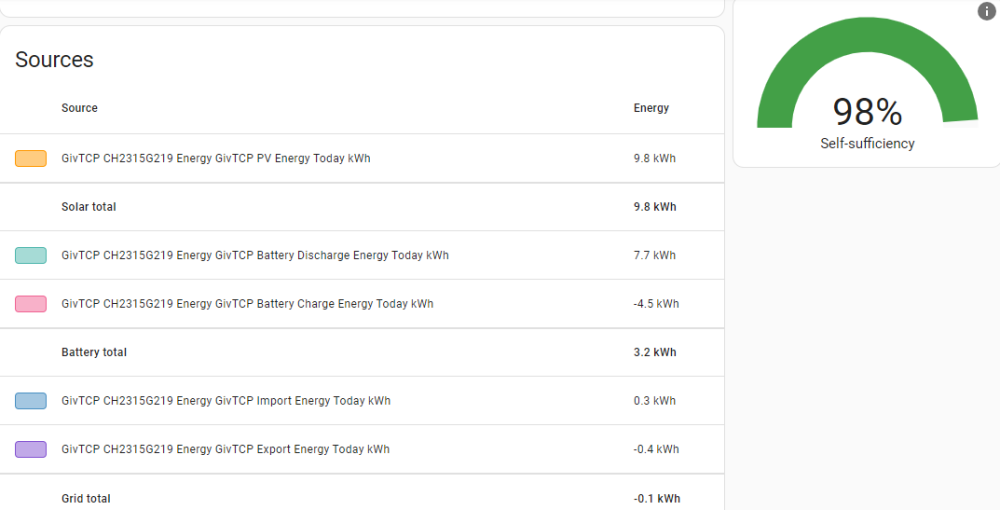

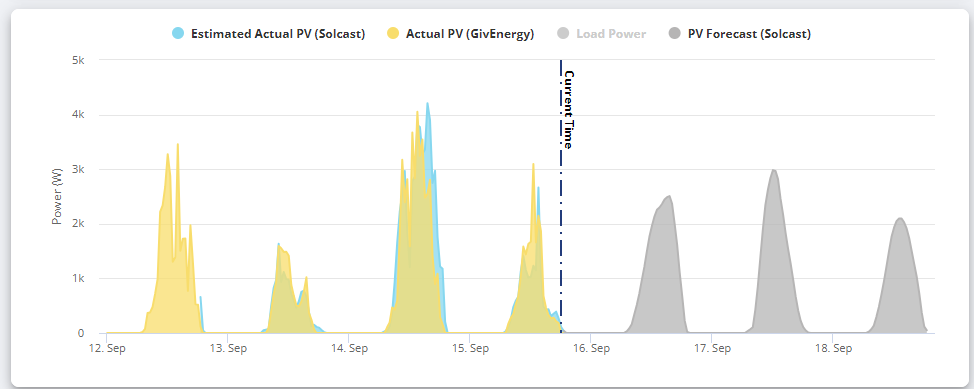

So a small update and stats Have now added the battery inverter to home assistant. The main reason that I got home assistant was to automate the charging on cheap rate, but only charge by the amount required, based on how much PV generation is likely the next day. GivTCP is the app running on Home Assistant, this connects to GivEnergy Inverter via an API, it also looks up the solar forecast from Solcast - another API. Dont get E7 for a couple of weeks, so running generated solar only. Have updated the Home assistant energy page, which looks like this, this is todays stats On the GivEnergy Cloud, there is the same data, but the forecast data is also represented. Fine tuning the Solcast page for my array you make small changes to angle and direction to fine tune the forecast compared to actual, but its not too bad from the looks of it.1 point

-

1 point

-

1 point

-

Simple fix a 2 port buffer of around 25 to 50 L capacity (closer to 50L is better), across the flow and return loop to the boiler or across the flow and return from the UFH, where ever is easiest to install. No need for low loss headers or 4 port buffers and additional pump (s). Parts list Two Tee pieces, A buffer or volumiser https://www.theplumbshop.co.uk/products/expansion-vessels-intermediate-buffer, these are cheap enough, you need to insulate yourself. Two isolation valves1 point

-

Absolutely Very little weight on the top We did four on our last on metal studs and five this time Worth putting a door timber in the studs for metal1 point

-

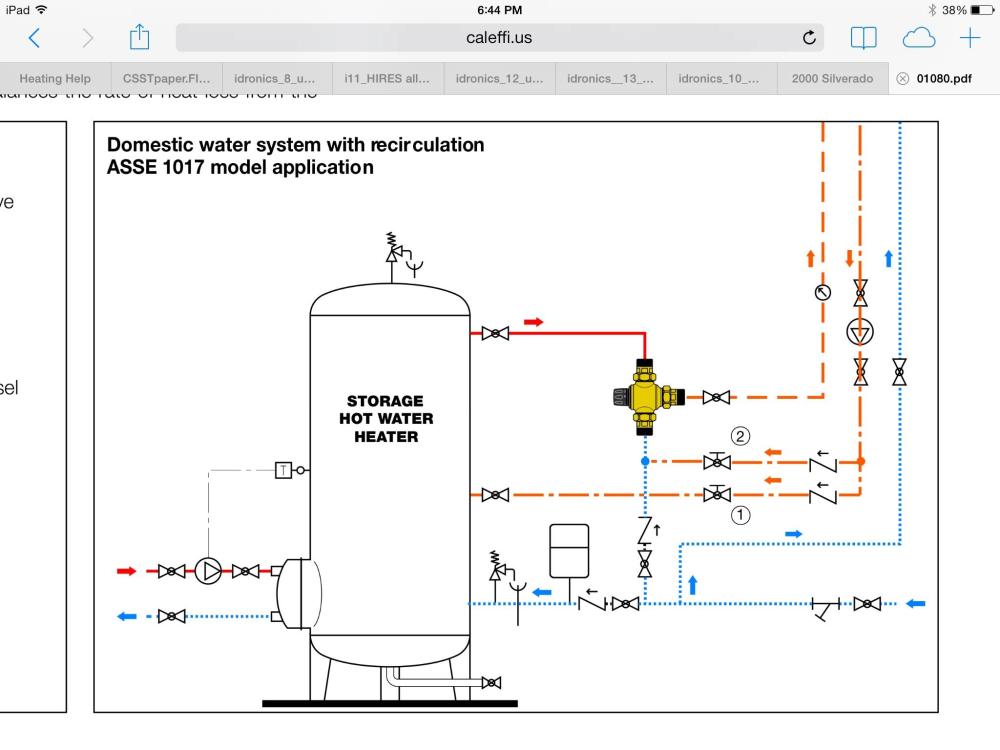

Every day a learning day. So had a dig round the internet to find a drawing of the layout in fig. 4 more applicable to a UK cylinder with a dedicated recirculation loop taping point. See below. The bypass and return valve would be a globe valve or similar to allow accurate and repeated flow control. This setup should allow a continuous flow of water through the cold port of the mixing valve1 point

-

There is a rather complicated plumbing arrangement you can use to fix this (see figure 4 https://www.hpacmag.com/features/recirculating-domestic-hot-water-system/ . In the North America you can buy this as a single integrated unit but they're not available here for any reasonable price.1 point

-

I also had a full landscape plan with loads of trees etc, no one even looked or cared at time of building sign off. Tick in the box stuff at the planning stage. Something to hang you by, if someone complains later I suppose1 point

-

At the risk of repeating myself BC arnt interested in planning matters Just that what you have done complies with building regs On our previous build I build a disabled access ramp out of ply and mineral felt and the 400 m2 of drive was hardcore BC simply added a foot note Disabled acces temporary but adequate Landscaping incomplete1 point

-

Thanks very much for that. Very useful to know. Thanks be to God for people who know their stuff. I was fishing for a reply from you @George Pragmatic, sensible, cheap. It's the '...not a lot of skill...' bit I like best ============== If anyone ever wonders why BuildHub attracts such a wide audience among self-builders, this thread is more than adequate demonstration. I've gone from - How the Hell do I do this, to - why I should do this, but not that AND why I should or shouldn't. Saving money time and effort. For people new to BH Quick cautionary note 🙂 the responses given above are not professional opinions - they are merely the advice of interested online colleagues . It's up to me to evaluate their answers and take the final decision. ==============1 point

-

I'm going for moisture resistant caber floor and tanking around wet areas (bathroom and shower area)1 point

-

Ours was signed off Subject to the correct paperwork being sent across , air test ,electrical and gas safety certificates and sap as built with the outside still completely unfinished no garden no drive no fences. Really wasn't bothered at all about it just said now your in you can take your time to get it done.1 point

-

1 point

-

Yeah my plumber went away thinking it was working perfectly too. It was only after a couple of days of occasionally having to run off a shedload of cold water when I opened a hot tap, that I worked out what was up. Fundamentally putting a TMV inside a secondary return circuit is bad design, as you're trying to mix in additional water with no where for it to go to. Regardless how far it is from the UVC, when sufficiently hot water hits the TMV it will shut off the hot supply and block the pump until the TMV cools again. Possibly resulting in the user having to draw a slug of cold through it to achieve that. So It will perform erratically for the user but very hard for them to recreate the issue for anyone to diagnose, so very possible that the designer/installer would ever know what they did wrong. (The MIs on my TMV also say it should be located as near the appliance as possible, but that's more that anti-legionnaire police wanting DHW distro at >60° than anything to do with correct function)1 point

-

1 point

-

its almost as if whoever designed this had it in for you with that terrible insulation design. 100mm of cavity batts would have been 1\4 of the price, be fitted easier and give you a better result. If you paid a 'professional' for this design I'd be instructing solicitors.1 point

-

I always found grand designs to be lacking in actual detail regarding their builds, focussing more on what goes wrong (to make good TV.)1 point

-

Not sure why a mixing valve would not work at the top if a cylinder. It is supposed to be first thing hot water goes through. https://forum.buildhub.org.uk/topic/21490-thermostatic-basin-mixer-taps/ Are you sure the issue wasn't the plumber not installing the check valve on the secondary return. As then if the secondary return pump is off the easiest route for the hot to go would be to reverse flow through the secondary loop to the hot water outlet.1 point

-

OK, fair enough. Perhaps that explains why you can't find/buy them. Thanks for the heads up and for explaining.1 point

-

Even if your airtight test shows you have a leakage rate of that, that isn't the figure you would used in a heat loss calculation. The 50Pa used during the test is the equivalent of extremely high winds, on all sides of the house - so you have to have the lowest temp and extremely high winds from all directions at the same time, which is rare or impossible. You would be fine using 0.5. It's only really going to be that if you have mechanical ventilation running 24/7. Otherwise the infiltration would less than 0.2. If you have a SAP report the infiltration rate will be in there.1 point

-

The air changes per hour will make a huge difference and you should be nowhere near 3 in a new build. Try 1 as a conservative starting point.1 point

-

I second that, my only comment was an architect is not always required, I designed my build because I knew exactly what I wanted, been in the building game years and when finished it did exactly what I wanted BUT I am in the minority, most people need guidance on what is achievable and that is where an architect is valuable (as long as you get a good one 🤷♂️).1 point

-

Here’s an article that discusses it. https://professional-electrician.com/technical/thermal-insulation-and-its-effect-on-flat-twin-earth-cables-niceic/1 point

-

Sadly have too much to do! Need to build a stud wall to block this work in so it can be boarded and plastered next week. No rest for the self-builder!1 point

-

Then by intuition you should get a bit of velocity behind the flow to clear the short 600mm run. Crack open the beers and have a long lie tomorrow.1 point

-

0 points

-

0 points

-

0 points

-

I agree I like the one where a plumber demonstrates how to bend a copper pipe and you can clearly see his finger trying to cover a kink0 points

-

"British designed, British manufactured [and] optimised for British homes". Opps, that's not very inclusive wording if meant to include NI.0 points

-

0 points

-

Shows I can bull shit with the best of them still. I was thinking that it may be worthwhile knocking up a very simple spreadsheet that does a sanity check. Or if there is a clever person on here, a web based one.0 points

-

0 points